Cleantecs SOLA-TECS W BJ 2010 Series User manual

SOLA-TECS W

Operating Instructions

BJ 2010 …

SN 0300 …

W800 | W1000 | W800 PRO | W1000 PRO

BA 0304029 R00 2021-01

Operating instructions for the

Sola-Tecs W cleaning system.

enW800 | W1000 | W800 PRO | W1000 PRO

2BA 0304031 R00 2021-01

Basics 7

Safety information 8

Information about tools required 8

Explanatory information 9

Overview of the cleaner components 10

Included with the cleaner 11

Types of Sola-Tecs W 12

Accessories required for operation 14

Your tool bag 14

Tool 15

How does the Sola-Tecs W work? 16

How does the Sola-Tecs W Pro work? 17

Components and their function 18

Intended use 23

Requirements of the photovoltaic surfaces to be cleaned 23

Requirements of the system user 23

Space requirement 23

Performance data in normal operation 23

Working width and weight 23

Performance limits in operation 24

Water quality for operation 24

Requirements of the high-pressure cleaner 24

EC Declaration of Conformity 25

Safety principles 26

For your safety 27

Working safely 29

Working safely 30

Selecting a safe starting point 30

Awareness of hazards in the working area 30

Checking the safety of the modules to be cleaned 30

Safety when cleaning 30

Checking and preparing high-pressure equipment 30

Table of contents

3

BA 0304031 R00 2021-01

Commissioning 32

Preparing to connect the cleaner 33

Unpacking out of the shipping box 33

Checking cleaner for defects 34

Checking the high-pressure lter in the connection pin of the

cleaner and pendulum tube 35

Transporting the cleaner to the place of use 36

Assembling the guide rollers 36

Assembling the pendulum lance 37

Assembling the high-pressure hose 38

Assembling the guying system 39

Connecting the high-pressure hose to the high-pressure cleaner 43

Setting the pressure on the high-pressure cleaner 43

Switching high water pressure on/off 44

Working 45

Working with the Sola-Tecs W 46

Setting the direction of rotation on the Sola-Tecs W Pro 46

Positioning the cleaner at the starting point 47

Starting the cleaner 47

The cleaning process 48

Switching off the cleaner 51

Parking the cleaner for pressure adjustments and breaks 51

Additional option to prevent the cleaner from falling 53

Taking out of operation 55

Disassembling the guying system 56

Disassembling the high-pressure hose 57

Disassembling the pendulum tube 59

Pushing guide rollers into the park position 60

Taking the cleaner off the roof 61

Table of contents

4BA 0304031 R00 2021-01

Table of contents

Transport and storage 62

Transporting and storing the cleaner 63

Checking the high-pressure lter in the connection pin of the

cleaner and pendulum tube 63

Allow water to run out of the cleaner 64

Checking components 64

Maintaining the cleaner 64

Preserving the cleaner 65

Lubricating components 65

How to stow the cleaner correctly in the transport box 66

Stowing the pendulum tube 66

Closing the transport lock 67

How to seal the box 68

Winterising the cleaner 68

Disposal 70

What happens with the waste? 71

Packaging 71

Resin for ultra-pure water production 71

Gearbox housing, gearbox parts, plastic parts, guying system

and brush roller 71

Prole tube, splash guard, pendulum tube and connection nipple 71

5

BA 0304031 R00 2021-01

Notes

Notes

5

5

6BA 0304031 R00 2021-01

It is IMPORTANT that you read these operating instructions

CAREFULLY BEFORE USE and

RETAIN THEM FOR FUTURE REFERENCE.

Visit our homepage at regular intervals and check for the latest

version of the operating instructions.

The operating instructions are intended for...

the Sola-Tecs W manufactured from 2010, serial number 0300.

The revision version of the operating instructions is R00.

7

BA 0304031 R00 2021-01

Basics

Components and functions

of the Sola-Tecs W

and W Pro

Here you will find information about:

Components of the system, tools for maintenance

8BA 0304031 R00 2021-01

Explanation of notices

Basics

Please note: …

Danger to life due to thunderstorms

A Avoid using the machine during thunderstorms.

This protects you from injury caused by lightning and from

hypothermia.

DANGER

Risk of injury from falling

A Use a fall-arrest system.

This will protect you from injuries from falling off the roof.

WARNUNG

Illness and hypothermia caused by bad weather

A In bad weather, wear suitable protective clothing.

This will protect you from illness caused by hypothermia.

CAUTION

Failure to comply will lead to serious injury or death.

Failure to comply may lead to serious injury or death.

Failure to comply may lead to injuries.

Failure to comply may lead to material damage and

impair the function of the product.

Additional information about product operation.

Information about tool

Reference to additional

information.

Risk of damage due to frost

A Prevent the machine from freezing up. Otherwise this could

cause damage to the components.

This will protect the machine from frost damage.

NOTICE

Safety notices

The notices are for your safety. The notices can be found in the general safety sec-

tion and are always accompanied by an action that requires specific attention.

Information about tools required

You will always find this information box in the header of the page. The box speci-

fies the tool required in relation to the adjoining text.

Info box The following

Tool is required.

Info box We recommend ours as

accessories Transport cabinet

made of aluminum.

9

BA 0304031 R00 2021-01

Basics

bottom

The title of the image indicates the

text to which the figure belongs.

Here we specify the Sola-Tecs W type

to which this explanation relates.

The detailed view highlights areas that

are important.

The numbers on the figures are associ-

ated with the steps in the explanatory

text. They always start again from [1] on

each double page.

The red arrows always indicate a move-

ment.

The blue double arrow refers to the

position on the illustration.

Image title

[3]

Explanatory information

This information can be found in the grey shaded illustration area. It helps you to

find the right illustration for the heading in the text, to understand the details bet-

ter, follow steps, complete movements and identify the position in the room.

top

W / W Pro

Sola-Tecs W…

10 BA 0304031 R00 2021-01

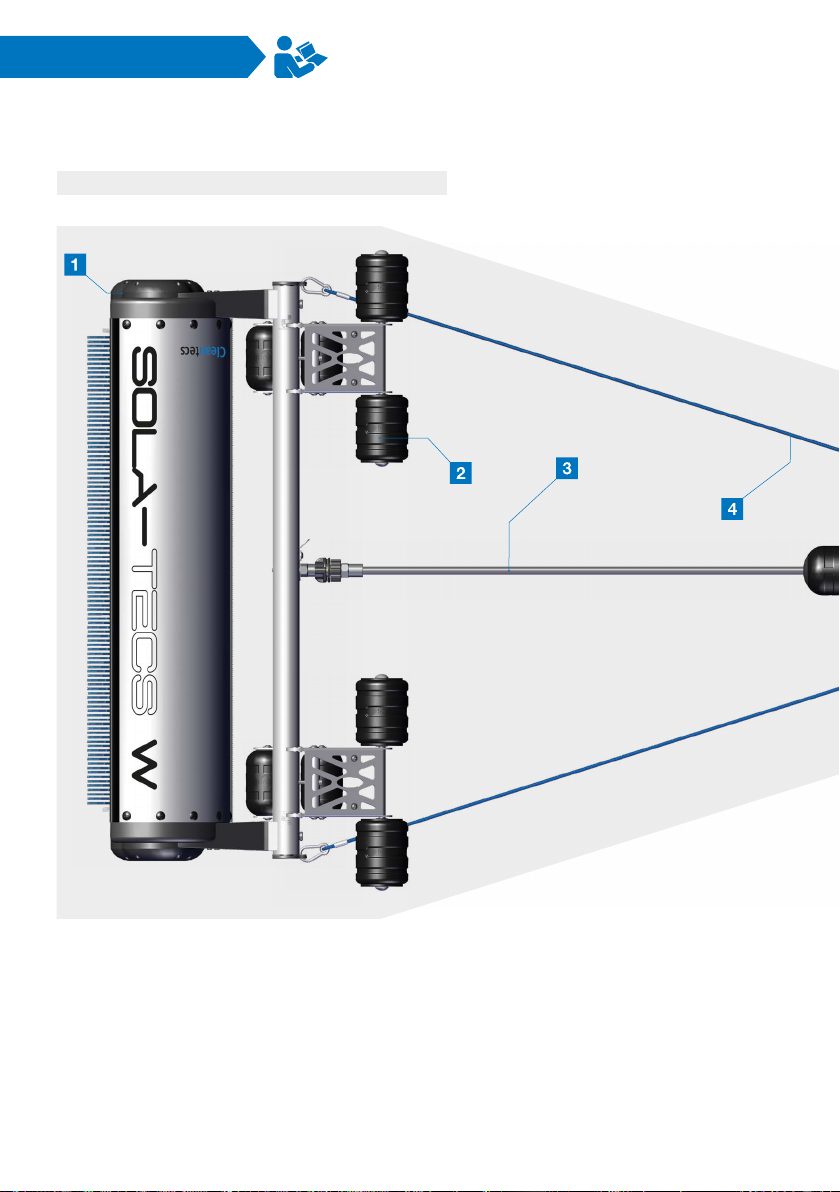

Overview of the cleaner components

Basics

11

BA 0304031 R00 2021-01

Basics

Included with the cleaner

1Sola-Tecs W basic device

2 Guide rollers

3Pendulum tube

4Guying system

5 Protective screw cap

12 BA 0304031 R00 2021-01

Basics

Types of Sola-Tecs W

1Sola-Tecs W800

2 Sola-Tecs W1000

13

BA 0304031 R00 2021-01

Basics

3Sola-Tecs W800 Pro

4Sola-Tecs W1000 Pro

14 BA 0304031 R00 2021-01

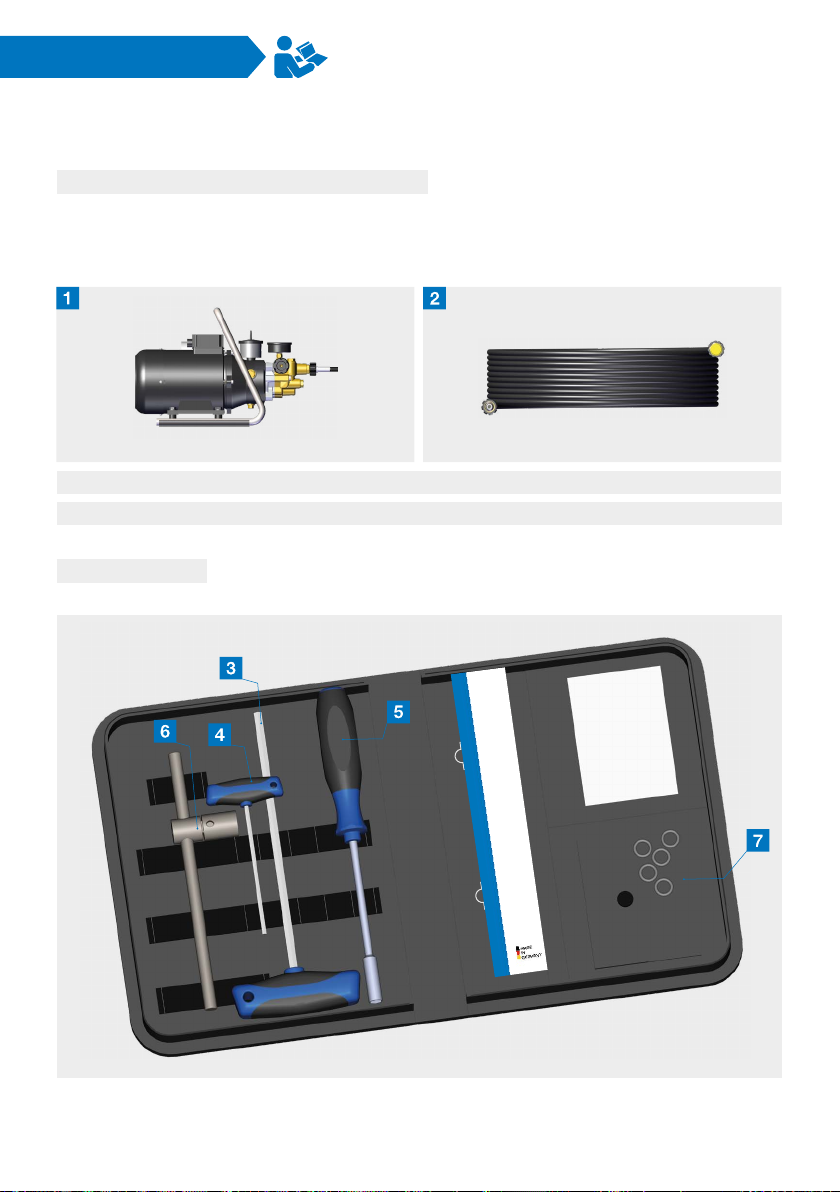

Accessories required for operation

The Sola-Tecs W belongs to a cleaning system. The accessories listed here are

required for operation.

Basics

1High-pressure cleaner

2High-pressure hose NW8

Your tool bag

15

BA 0304031 R00 2021-01

* The socket wrench set is needed for repairs, e.g. for loosening the clamping nut

on the nozzle needle. The repair work is described with the delivery of the spare

parts.

Basics

Tool

Hex key size 6

Hex key size 4

Socket wrench size 8

Socket wrench set*

O-rings

16 BA 0304031 R00 2021-01

Basics

How does the

Sola-Tecs W work?

The Sola-Tecs W system consists of a

brush roller with a gearbox housing on

the right and left, a water turbine drive,

a pendulum tube that reduces vibra-

tions from the cleaner to the operator,

and a guying system which, together

with the guide rollers, enables safe

and precise control of the cleaner. The

Sola-Tecs W is available in cleaning

widths of 800 millimetres and 1,000

millimetres.

A high-pressure hose with a nominal di-

ameter of 8 is absolutely necessary for

operation. This high-pressure hose is

used to lower the Sola-Tecs W from the

roof ridge and pull it back up again.

The energy is supplied by high-pressure

water generated by a high-pressure

cleaner. The high-pressure water is

sprayed onto the turbine wheel on the

right and left via a ceramic nozzle in

the gearbox housing. This converts the

impact energy into mechanical work.

After the drive work, the water is used

to moisten and wash off the surface to

be cleaned. The water used to operate

the cleaner must be ultra-pure. This wa-

ter must be largely free of any minerals.

The quality of the water can be deter-

mined using a TDS meter. The maxi-

mum conductivity of the water must not

exceed 30 μS/cm (20 ppm).

This is important in order not to create

deposits on the cleaned surface and

to avoid damage to the water turbine

drive due to grinding effects.

17

BA 0304031 R00 2021-01

Basics

How does the

Sola-Tecs W Pro work?

The Sola-Tecs W Pro system consists

of a brush roller with a gearbox housing

with left and right switchable direction

of rotation, a water turbine drive, a

pendulum tube that reduces vibrations

from the cleaner to the operator, and a

guying system that, together with the

guide rollers, enables safe and precise

control of the cleaner. The Sola-Tecs W

is available in cleaning widths of 800

millimetres and 1,000 millimetres.

A high-pressure hose with a nominal di-

ameter of 8 is absolutely necessary for

operation. This high-pressure hose is

used to lower the Sola-Tecs W from the

roof ridge and pull it back up again.

The energy is supplied by high-pressure

water generated by a high-pressure

cleaner. The high-pressure water is

sprayed onto the turbine wheel on the

right and left via a ceramic nozzle in

the gearbox housing. This converts the

impact energy into mechanical work.

After the drive work, the water is used

to moisten and wash off the surface to

be cleaned. The water used to operate

the cleaner must be ultra-pure. This wa-

ter must be largely free of any minerals.

The quality of the water can be deter-

mined using a TDS meter. The maxi-

mum conductivity of the water must not

exceed 30 μS/cm (20 ppm).

This is important in order not to create

deposits on the cleaned surface and

to avoid damage to the water turbine

drive due to grinding effects.

18 BA 0304031 R00 2021-01

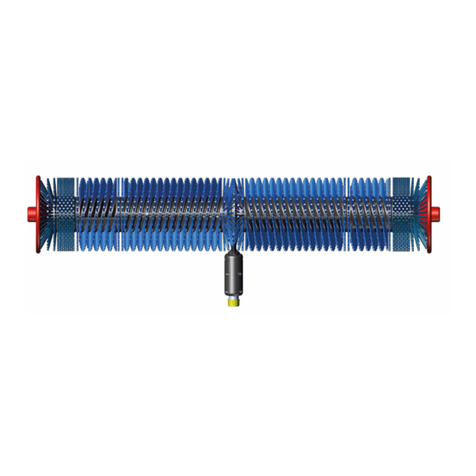

Components and their function

W / W Pro

The gearbox housing is the drive unit

of the cleaner. All components neces-

sary for the drive of the brush rollers are

installed here. The drive force is trans-

mitted from the gearbox housing to the

brush roller via a drive gear wheel.

W / W Pro

The brush roller is the component of

the cleaner that carries out the mechan-

ical cleaning work. The rubbing of the

brushes loosens dirt particles from the

modules.

W / W Pro

The profile tube is the cleaner’s chas-

sis. It holds the cleaner together and

is the connection through which the

high-pressure water is fed into the gear-

box housing.

W / W Pro

The splash guard protects the user

from splashing water. It reduces water

loss from spray water and increases the

wash-off effect.

W / W Pro

The guide rollers stabilise the cleaner’s

direction of travel as it is lowered and

raised. They ensure controllability even

when the cleaner is lowered at a slight

angle. The retraction aid makes it easier

to pull up again after passing over the

lower edge of the module.

Brush roller

Guide roller

Splash guard

Profile tube

Gearbox housing right and left

Basics

19

BA 0304031 R00 2021-01

Pendulum tube

Anti-twist protection

Guying system

Basics

W / W Pro

The pendulum tube reduces the trans-

mission of vibrations and movements

from the cleaner to the high-pressure

hose, thereby reducing work fatigue.

W / W Pro

The guying system reinforces the con-

nection between the high-pressure hose

and the cleaner. This allows the cleaner

to be controlled more precisely.

W / W Pro

The anti-twist protection fixes

the union nut of the high-pressure

quick-action screw connection with a

spring-loaded locking pin so that it can-

not come loose easily during work.

20 BA 0304031 R00 2021-01

W Pro

The switch button changes the point

of impact of the high-pressure water on

the turbine wheel, thereby enabling the

direction of rotation of the brush roller

to be changed. In this way, the cleaner

is pushed away from the operator or

back towards him.

W / W Pro

The brush on the splash guard is a

flexible barrier for the splash water. It

holds back the water and adapts to

possible obstacles.

W / W Pro

The edge protector allows the clean-

er to be placed on the splash guard

in order to protect the bristles during

breaks. This will prevent the modules

from being scratched.

W / W Pro

The body screws fix the splash guard

to the gearbox housings. Together with

the edge protector, they also ensure

that the modules are not scratched

during breaks.

Switch button

Basics

Brush on the splash guard

Edge protector

Body screw

This manual suits for next models

5

Table of contents

Other Cleantecs Cleaning Equipment manuals