5

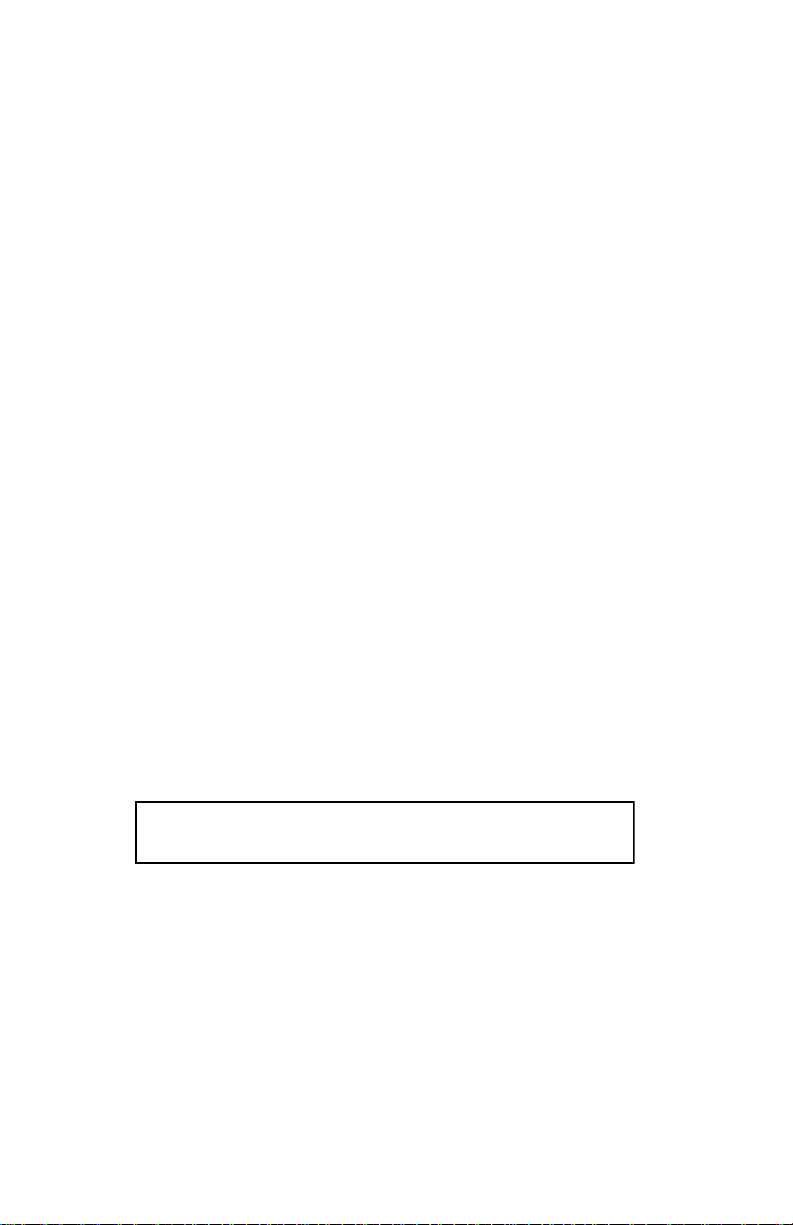

Sound waves are carried through the

solution in the tank and create a unique

vibrational pattern causing alternating

high and low pressures in the liquid.

During the low pressure stage, millions

of tiny bubbles form. This process is

called CAVTATION, meaning the

formation of cavities.

During the high pressure stage, the

bubbles collapse or implode, releasing

enormous amounts of energy. Working

in all directions, the bubbles attack

every surface and invade all recesses

and crevices, pulling debris off the

object being cleaned.

SweepZone Technology® enhances

the ultrasonic activity by automatically

changing frequencies, thus creating a

cleaning grid which literally sweeps

through the tank. A more uniform

cleaning pattern and significantly shorter

cleaning times result when “hot spots”

present in traditional ultrasonics are

eliminated.

Equally important to efficient cleaning is selecting a proper solution

for the cleaning task. See page 18 of this manual for cleaning

applications and solutions.

Congratulations on your purchase of an L&R Ultrasonic Cleaning

System. Your machine is part of a complete cleaning process which

is thoroughly described in this owner/operator manual.

What is Ultrasonic Cleaning?

Ultrasonic cleaning is created by sound waves that are transmitted

at frequencies beyond the range of human hearing. A generator

located within your system develops the high frequency power

which causes a transducer to radiate and produce the sound waves.