05ClearView Welding PAPR - User instruction manual

At very high work rates the pressure in the

device may become negative at peak inhalation

flow. PA700 systems are for use only by

competent, trained personnel.

Filters should not be modified to fit different

blower units.

ATTENTION

If any of these conditions is not kept or

followed, the warranty is automatically invalid

The user is advised to leave the

contaminated area immediately if:

The Manufacturer's Minimum Design Flow

(MMDF) warning Alarm sounds.

Breathing becomes difficult.

Dizziness or distress occurs.

Any part of the system becomes damaged.

Airflow into the Head-Unit decreases or stops.

Contaminant can be smelt or tasted inside the

Head-Unit

Materials that may come into contact with

the users skin are not known to cause allergic

reactions to the majority of individuals but in the

unlikely event of a reaction, the user should

immediately leave the contaminated area,

remove the unit and seek medical advice.

The PA700 unit is a belt mounted powered

respirator with a replaceable, disposable high

efficiency particle filter system. The system is

certified with the helmet OHE410 and the

helmet covers head sizes from 535 to 600mm

circumference.

The unit must not be used:

In an atmosphere that is immediately

hazardous to user hygiene or health and or

has oxygen content of less than 19.5% or

contains unknown substances.

In confined spaces or unventilated areas such

as tanks, pipes, canals etc.

Near to flames or sparks

In areas with danger of explosion

In an area where there are high winds.

If the blower unit stops working due to any

reason, the user must leave the contaminated

aread immediately.

It is also essential that:

Nothing is allowed to touch the moving parts

There is no attempt to modify or alter the unit

or filter in any way.

Water or other liquids DO NOT enter the unit

in any way - in particular the motor and fan,

the filter or the battery.

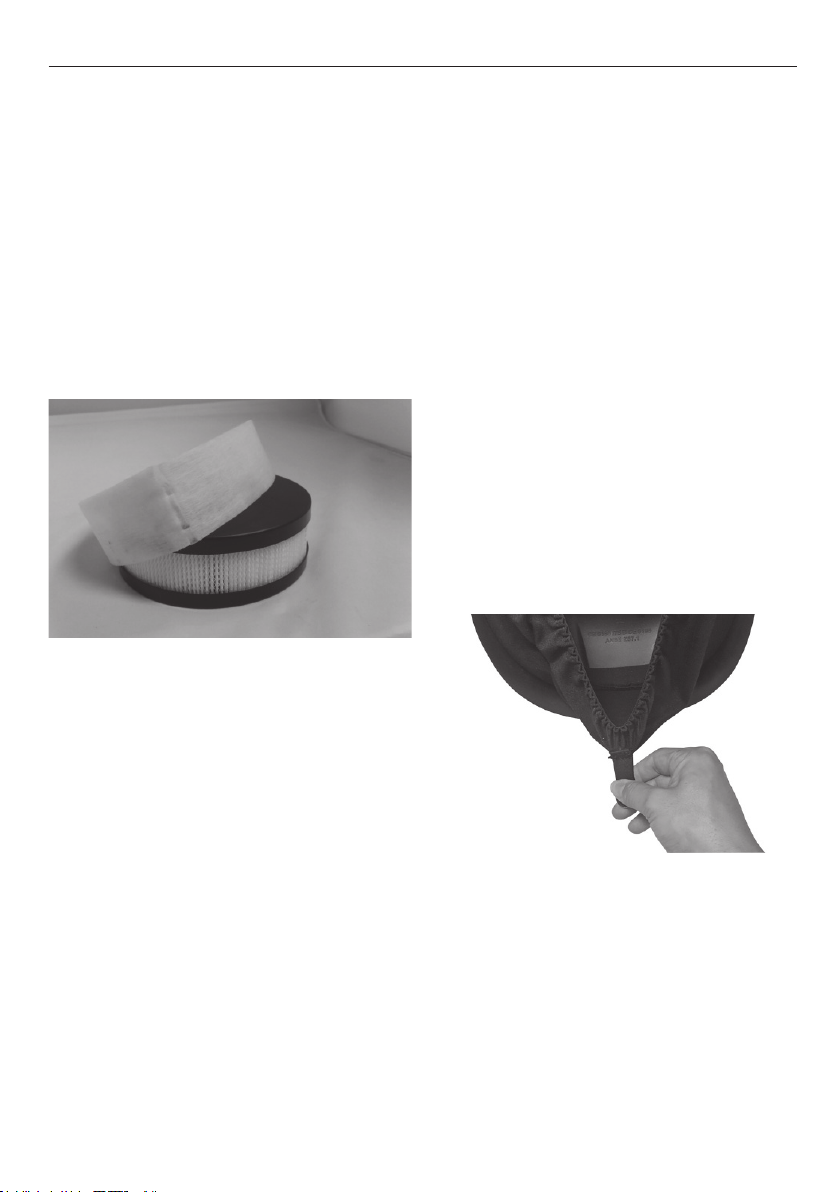

Make sure that the headpiece fits the user's

face perfectly. Only then the efficiency of the

system is sufficient. The protective factor of the

complete system is reduced if the seal of the

headpiece is not fitted properly, for eg. Due to

beards or long hair intervening into the seal line.

There is a possibility that the hose to the head

unit may become caught up in use. The blower

unit should be positioned on the person in such

a way as to reduce this possibility.

Filters cannot be fitted directly to the head units

and should not be adapted to do so. Correct

respiratory protection will not be provided if any

parts of the equipment are modified.