Cleco mPro400GCD-P Guide

For additional product information visit our website at http://www.ClecoTools.com

Hardware description

P2300HW-EN

2018-01

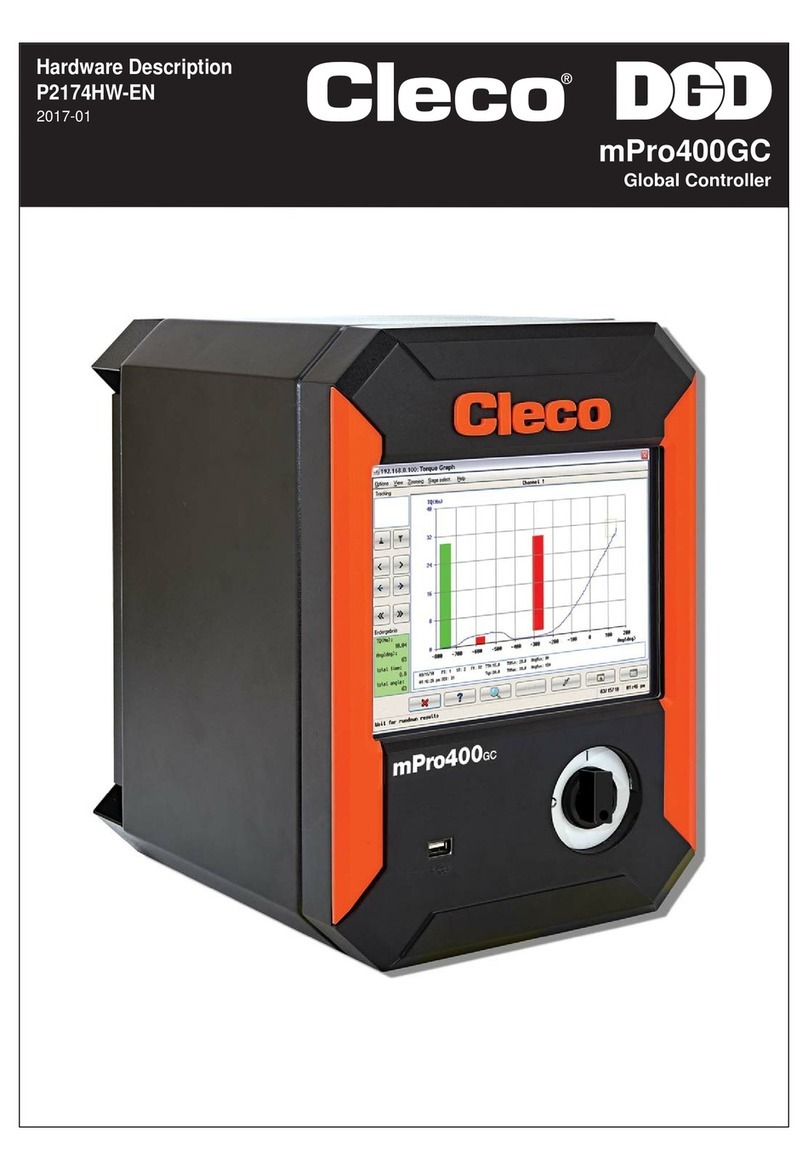

mPro400GCD-P

Global Nutrunner Controller Primary

2

P2300HW-EN

2018-01

Copyright © Apex Tool Group, 2017

No part of this document may be reproduced in any way or in any form, in whole or in part, or in a natural or

machine-readable language, or transmitted on electronic, mechanical, optical, or other media, without the

express permission of the Apex Tool Group.

Disclaimer

Apex Tool Group reserves the right to modify, supplement, or improve this document or the product without

prior notice.

Trademark

Cleco is a trademark of the Apex Tool Group Division.

Apex Tool Group GmbH

Industriestraße 1

73463 Westhausen

Germany

Phone: +49 (0) 73 63 81 0

Fax: +49 (0) 73 63 81 222

Contents

P2300HW-EN

2018-01

3

1 Notes on this Hardware-Description 4

2 Safety 4

2.1 General requirements.................................................................................................. 4

2.2 Warnings and notes..................................................................................................... 5

2.3 System-relevant safety instructions............................................................................. 6

3 Technical specifications 8

4 Pin assignment 9

5 Storage access 12

6 Items delivered 12

7 Installation 13

7.1 Location considerations............................................................................................. 13

7.2 Mounting.................................................................................................................... 13

8 Prior to initial operation 14

8.1 Series 30/50EAN....................................................................................................... 14

8.2 Series 18/48EAE ....................................................................................................... 15

8.3 Connecting the controller to the power source.......................................................... 16

9 System 17

10 Connections 18

11 Dimensions 19

4

P2300HW-EN

2018-01

1Notes on this

Hardware-Description

The original language of this description is German.

This description is intended for all persons who connect

and install the controller. The software that is used is not

the subject of this description.

You can find further documents

Symbols in the text

2 Safety

2.1 General requirements

Only operate the controller after you have read this and

fully understood this document. Failure to follow the

directions and safety instructions could result in electric

shocks, burns and/or serious injuries.

Keep this document in a safe place for future use!

These safety instructions must be accessible to the

operator at all times. They must be presented and

made accessible to all persons using or repairing the

device.

Intended use

The product is a part of the Cleco Production Tools tighten-

ing system and is intended exclusively for industrial use in

fastening processes. Only use the nutrunner controller

under the following conditions:

• in conjunction with the components listed in the EC

Declaration of Conformity P3268C.

• under the prescribed environmental conditions; see the

relevant documentation

• with the permissible supply voltage

• within the power range, which is specified in the techni-

cal data

• in EMC Limit Class A (electromagnetic immunity for

industrial areas). For the currently observed EMC stan-

dards, see the EC Declaration of Conformity.

Do not use the nutrunner controller:

• in potentially explosive areas

• in damp spaces/outdoors

• in connection with cutting tools (drills, milling cutters,

grinders…)

No. Document type

P2279SB System handbook

Italic Denotes menu options, e.g.,Diagnostics

> Denotes the selection of a menu option from

a menu, e.g., File > Print

<…> Denotes switches, pushbuttons or the keys

of an external keyboard, e.g., <F5>

Courier Denotes input fields, check boxes, radio but-

tons or dropdown menus.

Denotes filenames and paths, e.g.,

setup.exe

/ Acts as a separator for the subdirectories in

a file path, e.g., File/Print (operating

system OS9)

• Denotes lists

Denotes instructions that must be followed

5

P2300HW-EN

Operator training

The tightening system may only be put into operation,

adjusted and tested by qualified and trained personnel.

The personnel must be instructed by qualified employees1)

of Apex Tool Group.

The nutrunner controller has been preset by

Apex Tool Group. The adjustment of the nutrunner control-

ler to special requirements may only be carried out by a

qualified person1).

Additional information can be found in the Programming

Manual.

Personal protective equipment (PPE)

Risk of injury by being wound up in and caught by machin-

ery

When working with rotating parts, it is not permitted to

wear gloves.

Recommendation: Freely rotating u-GUARD protected

fastening tools from APEX.

Wear close-fitting clothing.

Wear safety shoes.

If necessary, wear a hairnet.

Risk of injury due to parts being ejected.

Wear protective goggles.

2.2 Warnings and notes

Warning notes are identified by a signal word and a picto-

gram:

• The signal word describes the severity and the proba-

bility of the impending danger.

• The pictogram describes the type of danger.

Symbols on the product

Be sure that you understand their meaning

before operation

1. Due to their vocational training, knowledge, expe-

rience and understanding of the circumstances

involved in this kind of work, suitably qualified per-

sonnel are able to identify potential hazards and to

initiate appropriate safety measures. Qualified per-

sonnel are obliged to comply with regulations.

CAUTION! A symbol combined with the word CAU-

TION indicates a hazard with a low level of

risk which, if not avoided, could result in

minor or moderate injuries or environmental

damage.

DANGER! A symbol combined with the word DAN-

GER indicates a hazard with a high level of

risk which, if not avoided, will result in death

or serious injury.

WARNING!

A symbol combined with the word WARN-

ING indicates a hazard with a medium

level of risk which, if not avoided, could

result in death or serious injury.

This sign warns of a possibly damaging sit-

uation.

Failure to observe this note may cause the

product or parts thereof to be damaged.

General notes

include application tips and useful informa-

tion but no hazard warnings.

Electrical voltage

WARNING Disconnect mains before opening.

CE compliant

The product corresponds to the prescribed

technical requirements in Europe.

Read all instructions.

ATTENTION!

6

2.3 System-relevant safety

instructions

We do not claim that these safety instructions are com-

plete. It is obligatory to follow national, state and local

safety and connection standards during the installation.

These standards take precedence over the information in

this section.

Do not make any modifications to the nutrunner control-

ler, protective devices, or accessories without prior writ-

ten authorization from Apex Tool Group.

Do not attempt to open the nutrunner controller or com-

ponents of the controller. Neither for troubleshooting,

nor for other work on the device. In the event of a fault,

any intervention can result in serious injury from electric

shock.

Operation with the device open also causes the follow-

ing:

- An increased amount of emissions: this can cause

interference with other devices.

- Reduced immunity from interference: the nutrunner

controller can produce faulty results.

- The loss of existing warranty claims.

During the installation

Risk of crushing. The nutrunner controller can fall and

crush parts of the body.

Use a suitable hoist.

Ensure that the nutrunner controller is fastened suffi-

ciently (see hardware description).

Lay cables and lines so that they are not damaged and

so that no one can trip over them.

In the event of a fault, high leakage currents can occur and

cause injuries by electric shock.

Use the included power cable. Use an appropriate

power cable when making changes.

For 115 VAC cables with a larger cross-section, use

Order No. 541683-01.

Prior to initial operation

Only operate on a grounded power supply (TN system).

Operation on the IT system is not permitted.

Ensure a standard-compliant PE connection.

Prior to initial operation, carry out the protective con-

ductor measurement in accordance with the local regu-

lations (in Germany, DGUV Regulation 3).

Do not switch on the nutrunner controller until all the

connections have been made correctly (see hardware

description).

Danger due to incorrect Torque measurement.

An undetected NOK tightening could have life-threatening

consequences.

Recalibration (or capability analysis) is essential follow-

ing incorrect use (crash, mechanical overload…).

For category A tightenings (VDI 2862) which are critical

for safety, activate a redundancy measurement (e.g.,

current redundancy).

Introduce regular monitoring of measuring equipment

on the machines.

Work only with a perfectly functioning tightening sys-

tem. If in doubt, contact APEX Sales & Service Center.

During operation

Immediately switch off the nutrunner controller in case

of unusual noise, unusual heating and vibration from

the nutrunner. Pull out the power plug and have the

tightening system checked by qualified personnel; have

it repaired if necessary.

Never pull the plug on the cable from the outlet.

Protect the cables from heat, oil, sharp edges or mov-

ing parts.

Replace damaged cables immediately.

Keep the tool and plug connections clean.

Keep the workstation clean.

Ensure that there is enough space at the workstation.

When working with a nutrunner, stay alert, pay attention

to your actions and act sensibly. Do not use the nutrun-

ner if you are tired or under the influence of drugs, alco-

hol or medication. A moment of carelessness when

working with the nutrunner can lead to serious personal

injuries.

Danger due to unexpected start of the motor or due to an

expected but missing stop.

Despite redundant controller parts and monitoring func-

tions, an unexpected start of the machine can occur in very

WARNING! Risk of injury due to electric shock. Contact

with line voltage or 380 VDC.

The nutrunner controller and nutrunner can

conduct current in the event of a fault. An

electric shock can lead to cardiac arrest,

cessation of breathing, burns, and serious or

fatal injuries.

Before connecting power and tool cables,

during changeover, cleaning and taking

out of operation, turn off the nutrunner

controller.

Do not operate the tightening system if

the housing, cable or nutrunner is dam-

aged.

7

rare cases. Possible reasons: Remote control of diagnostic

functions, bit dump in the memory of the controller.

Mechanical hazards such as jars/jolts due to counter

torques; risk of injury due to winding up and seizing can

result from the nutrunner.

Use the tool at the designated grip points.

Use prescribed counter torque absorbers. For torques,

see Instruction manual tool.

After switching on the nutrunner controller, wait until the

boot cycle is completed. This usually takes about

60 sec. Only then switch off / on again.

During maintenance

Consider local regulations for maintenance and servic-

ing for all operating phases of the tightening system.

The nutrunner control is generally maintenance-free.

When cleaning

Only clean the tool and the nutrunner controller from

the outside with a damp cloth.

Do not immerse the tool and nutrunner controller in

water or cleaning agents.

Do not use a high pressure cleaner.

At the repair

Send the complete nutrunner controller for repair to

your Sales & Service Center.

At disposal

Components of the tightening system present risks to

health and the environment. The tightening system con-

tains components that can be recycled, as well as compo-

nents that have to be disposed of specifically.

Follow the locally applicable regulations.

Separate the components and dispose of them by seg-

regating them clearly.

Collect auxiliary materials (oils, greases) when draining

and dispose of them properly.

Separate the components of the packaging and dis-

pose of them unmixed.

Hand in the nutrunner and the defective nutrunner con-

troller at your company collection point or return to the

Sales & Service Center.

Observe generally valid disposal guidelines

such as, in Germany, the Electrical and Elec-

tronic Equipment Act (ElektroG) and the Bat-

tery Act (BattG):

Used up batteries must be disposed of.

Hand in the batteries at your company

collection point or return to the Sales &

Service Center.

8

P2300HW-EN

2018-01

3 Technical specifications

Ambient conditions

Power supply

System data

Weight

Features Data

Operation site Indoors

Ambient temperature 0...45 °C1)

Storage temperature -20...70 °C

Type of cooling Convection (self-cooling)

Relative humidity 10 – 90%, no condensation

Working height Up to 2000 m (6,561.7 ft) above sea level1)

1) Note the derating. See system handbook

Protection Class DIN EN 60529 IP42

Degree of contamination EN 61010 2

Transient overvoltage EN 61010 CAT

Shock max. DIN EN 60068-2-27 15 G

Vibration max. DIN EN 60068-2-5 59.6–160 Hz: 2 G

Features Data

Supply voltage, single-phase 100–240 VAC ±10%

Rated supply current 1–2 A

Frequency 50/60 Hz

Peak current 16 A

Rated power 1600 VA max.

Idling 160 VA

Features Data

System functions Battery buffered RealTimeClock, buffer time: 20 years (at 20 °C)

Display LC display with touchscreen, 10.4" TFT liquid crystal display,

resolution 800 x 600, connection to Panel & Touch possible

Operating system OS-9000, real-time operating system, bootable without mechanically

moving drives, no UPS required

HMI (Human-Machine Interface) Virtual keyboard for alphanumeric inputs

Model Weight

lb kg

mPro400GC-P 30.2 13.7

9

P2300HW-EN

2018-01

4 Pin assignment

All connections are short-circuit proof.

X5, X6 – Serial port for additional devices

• All outputs provide RS232 conforming signals.

• The inputs allow voltages in the range from -15 V to

+15 V.

- Voltages < 0.8 V correspond to a zero.

- Voltages > 2.4 V are interpreted as a one.

- Open inputs are preset to zero using a pulldown

resistor.

• The power supply pins are connected directly to the

main board power supply.

X7, X8 – Anybus CC

Optional slots for Anybus CC modules,

X21 – TSnet system bus

Interface port for TSnet cable.

X22 – ARCNET system bus

The station controller has an integrated bus termination;

therefore, no external termination is necessary.

X23 – Supply

X24 – Tool cable 30/50EAN Series

X25 – Tool cable 18/48EAE Series

Do not connect or disconnect any

device during operation. Doing so

may result in a system reset.

Pin RS232-1

X5

RS23-2

X6

9 pin D-Sub male

with screw lock

1 – –

2 RxD RxD

3 TxD TxD

4 – –

5 GND GND

6 – –

7 RTS RTS

8 CTS CTS

9 – –

Pin Signal 8 pin M12 circular connector

X-coded

1 Tx +

2 Tx -

3 Rx +

4 RX -

5 0 VDC

6 0 VDC

7 +24 VDC

8 +24 VDC

ATTENTION!

5

6

7

8

1

2

3

4

Pin Signal 8 pin M12 circular connector

A-coded

1 N.C.

2 DATA-B

3 GND

4 +5 VDC

5 DATA-A

6 N.C.

7 0 VDC

8 +24 VDC

Description IEC connector C14

Connector with fuse holder

2-pin, 5 × 20 mm, 16 A slow-

blow

Use plug locking mechanism.

See 6.3, "Connecting the controller to the

power source", Page 29.

Pin Signal M23 circular connector

1-3 Power

4 PE (functional ground)

5 Tool bus

Pin Signal ECTA circular connector

Push-pull

1-3 Power

4PE

5 Signals

Output (Sockel)

6

7

8

2

3

45

1

ATTEN-

TION!

1

2

3

4

5

5

1

2

3

4

10

P2300HW-EN

2018-01

X9, X10 – Input/Output

The required signal circuits are connected to these input/output connectors. The signal groups are not gal-

vanically connected to the power supply; galvanic isolation is required.

• 16 digital inputs/outputs, optically isolated for 24 V level/0.5 A

• 8 inputs/8 outputs/2 +24 VDC/2 GND

• Output current: 500 mA per output, 2000 mA total

Connectors that use an internal 24 V power supply

(Primary, Master)

Inputs

• Internal 24 V power supply for the controller.

• Pin 11 and 23 (common GND) serve as a "return line" for the outputs.

• Pin 11 and 23 must be connected to Pin 12 or 24 with jumpers.

Outputs

• Internal 24 V power supply for the controller

• Pin 2 and 14 (common output) are the voltage source for the inputs.

• Pin 2 and 14 must be connected to Pin 1 or 13.

A single device must not require a current of more than 500 mA. The current monitor switches off the

output in the event of an overcurrent.

Pin Signal X9 Pin Signal X10 2x12 pin Phoenix MCD 0.5/24-G1-2.5

Order No. S981211

12 GND-int 24 GND-int

11 GND I/O0–3 23 GND I/O4–7

10 Output O3 22 Output O7

9 Output O2 21 Output O6

8 Output O1 20 Output O5

7 Output O0 19 Output O4

6 Input I3 18 Input I7

5 Input I2 17 Input I6

4 Input I1 16 Input I5

3 Input I0 15 Input I4

2 +24 VDC A0–A3 14 +24 VDC A4–A7

1 +24 VDC-int 13 +24 VDC-int

Mating connector

Phoenix FK-MC 0.5/12-STZ3-2.5

Order No. S981211

ATTEN-

TION!

X9 X10

11

P2300HW-EN

2018-01

Connectors that use an external 24 V

power supply

(Primary, Master)

Inputs

• External 24 V power supply for the con-

troller.

• Pin 11 and 23 (common GND) serve as a

"return line" for the outputs.

• The GND for the external 24 V power

supply must be used as the return line for

Pin 11 and 23.

Outputs

• External 24 V power supply for the con-

troller.

• Pin 2 and 14 (common output) are the

voltage source for the inputs.

• Pin 2 and 14 must be connected to the

external 24 V power supply.

Signal X9 Signal X10

Pin I/O Name Pin I/O Name

12 Off GND2 24 Off GND2

11 On Common GND 23 On Common GND

10 Output O3 22 Output O7

9 Output O2 21 Output O6

8 Output O1 20 Output O5

7 Output O0 (linking OK), e.g. 19 Output O4

6 Input I3 (tool start), e.g. 18 Input I7

5 Input I2 17 Input I6

4 Input I1 16 Input I5

3 Input I0 15 Input I4

2 On Output O0-O3 common 14 On Output O4-O7 common

1 Off +24 V2 13 Off +24 V2

Signal X9 Signal X10

Pin I/O Name Pin I/O Name

12 Off GND2 24 Off GND2

11 On Common GND 23 On Common GND

10 Output O3 22 Output O7

9 Output O2 21 Output O6

8 Output O1 20 Output O5

7 Output O0 (linking OK), e.g. 19 Output O4

6 Input I3 (tool start), e.g. 18 Input I7

5 Input I2 17 Input I6

4 Input I1 16 Input I5

3 Input I0 15 Input I4

2 On Output O0-O3 common 14 On Output O4-O7 common

1 Off +24 V2 13 Off +24 V2

+-

12

P2300HW-EN

2018-01

5 Storage access

Abb. 5-1: Connection positions

6 Items delivered

Check delivery for transit damage and ensure that all items have been supplied:

• Global Nutrunner Controller mPro400GCD-P

• EC Declaration of Conformity

• Hardware description

• SP-1500

• Warranty

Pos. Name Function

1CF card

(Compact Flash)

Necessary for the operating system, archive files and applications. Included

in the delivery

2SD card, optional Function is software-dependent: software update, save/load parameters,

data archive files...

Only pull out or plug in the CF card when the supply voltage is switched off. Otherwise, serious system

errors and data loss will result.

Power cable

EU 230 VAC

Order no. 541683-03

Power cable

USA 115 VAC

Order no. 541683-01

Plug locking mechanism

Order no. 1× 544004-1

Power cable

USA 230 VAC

Order no. 541683-02

2

1

4× S909344

M3×5 DIN912

ATTEN-

TION!

13

P2300HW-EN

2018-01

7 Installation

Software is already installed on the controller. The minimum settings for your bolt connections must be car-

ried out by a qualified person with the controller or a PC in order to start fastening work.

7.1 Location considerations

Each controller is mainly used as a control and monitoring unit for one or more tools at a workstation.

Depending on the peripheral devices that are procured, the controller can also be installed outside of the

work environment. Ensure the following:

• The main switch must be easily accessible.

The main switch is the disconnecting device in case of danger!

• The ambient conditions are met.

• The ambient air can circulate around the housing unhindered.

• The display, the keypad and the connectors are easily accessible to the configuration.

When connecting accessories and tools, consider the following points:

• The assignment tool – controller should be unique and easily recognizable.

• Connection of a data acquisition unit

• Connection of remote displays, socket trays or remote parameter selection

• Connection of the controller to a network or to a computer

• Comfortable/safe use

7.2 Mounting

The controller can be mounted either on a wall, on a carrier or on a rack.

1. Loosen the central long fastening bolt on the bottom of the controller and disconnect the retaining

plate from the controller.

2. Fasten the retaining plate with M6×4 bolts. See 10 Connections, Page 18 of the 10 possible mounting

holes.

3. Use the 4 protruding bolts on the back of the controller to attach the controller to the holder.

4. Secure the controller on the bottom using the fastening bolt removed in Step 1.

WARNING! Risk of injury

You can be injured by the falling down of the controller, by vibrations or as a result of an unfavorable

arrangement.

Always choose a stable, load-bearing base.

The mounting fixture or wall must be able to bear a load that is at least 4 times that of the controller to

be mounted.

Recommendation: Controller suspension, e.g., Order No. MA-S395290

WARNING! Risk of injury

You can be injured by tripping or falling over loose cables on the ground.

Arrange and fasten all the cables that are connected to the controller so that they can not injure the

operator or other persons.

14

P2300HW-EN

2018-01

8 Prior to initial operation

The power is supplied to the tool via the networking with the controller.

8.1 Series 30/50EAN

Cable connection with the tool

Cable connection with the controller

5. Connect the power cable to the controller and a current source: alternating voltage of 100 VAC or

240 VAC.

6. Switch on the controller with the power switch (ON/OFF) on the front panel.

It is not possible to operate the Series 30/50EAN tools on connector X24 and the Series 18/48EAE tools on

connector X25.

1. Make sure that the green marking on the tool

cable is visible. If necessary, twist the sleeve

counterclockwise.

2. Insert the tool cable into the nutrunner handle.

3. Align the arrow mark on the tool cable with the

mark on the tool handle.

4. Hand tighten the sleeve ¼ turn.

1. Turn the tool cable so that Open is on top of

the ring.

2. Insert the tool cable into the X24 connector of

the controller.

3. Align the Open mark on the tool cable with the

arrow on the connector.

4. Hand tighten the ring ¼ turn.

Green mark

X24

X24

15

P2300HW-EN

2018-01

8.2 Series 18/48EAE

Cable connection with the tool

Cable connection with the controller

1. Align the groove on the tool cable with the start

switch on the tool handle.

2. Insert the tool cable into the handle of the nut-

runner and tighten by turning clockwise by

hand.

1. Make sure that the sleeve on the X25 connec-

tor is pressed back. A red ring is visible.

2. Align the groove on the tool cable with the

groove on the connector.

3. Insert the tool cable into the X25 connector.

4. Pull the sleeve forward to secure the cable

connector.

5. To secure the connector against extreme

forces, such as vibrations, shocks or rotary

motions, install the nutrunner cable securing

clip (Order No. S800556) as a spacer. Opening

of the locking mechanism is prevented.

Start switch

Groove

X25

X25

16

P2300HW-EN

2018-01

8.3 Connecting the controller to the power source

1. Ensure alternating voltage of 100 VAC or

240 VAC.

2. Connect the power cable to the X23 connector.

3. To secure the connector, install the plug lock-

ing mechanism (Order No. 544004-1) from the

bottom on the cable.

4. Insert both tabs into the grooves.

5. Slide the movable part forward.

6. Switch on the controller with the power switch

(ON/OFF) on the front panel.

X23

X23

17

P2300HW-EN

2018-01

EN

9 System

1

2

Pos. Product Possible connections

1 Serie 30EAN…/50EAN… 1×

2 Serie 18EAE…/48EAE… 1×

3 Serie 17BP…/47BA… 15×

4 Serie 18EAE…/48EAE… + mPro400GC-S 15×

5 Serie 30EAN…/50EAN…+ mPro400GCD-S 15×

6 Access Point

7 ArcNet-Kabel

8 TSNet-Kabel

3

mPro400GCD-P

6

CF-card

Main switch

5

4

7

8

18

P2300HW-EN

2018-01

EN

10 Connections

Abb. 10-1: Connection positions

No. Designation No. Designation

X1 Ethernet RJ45 10/100 BASE-T Connector #1 X9 I/O Connector

X2 Ethernet RJ45 10/100 BASE-T Connector #2 X10 I/O Connector

X3 USB V2.0 Port #1 X21 System Bus Connector TSnet

X4 USB V2.0 Port #2 X22 System Bus Connector ArcNet

X5 Serial RS232-1 Connector #1 X23 Power supply connection

X6 Serial RS232-2 Connector #2 X24 Tool Connector Serie 30/50EAN

X7 Anybus CC – Fieldbus X25 Tool Connector Serie 18/48EAE

X8 Anybus CC – Fieldbus

mPro400GCD-P_unten.png

X21

X1

X2

X3

X4

X7

X5

X6

X9

X10

X8

X24 X25

X23

X22

19

P2300HW-EN

2018-01

EN

11 Dimensions

266,7 mm

(10,500" )

327,66 mm

(12,900" )

276,23 mm

(10.875" )

381,0 mm

(15.000" )

336,30 mm

(13.240" )

288,04 mm

(11.340")

20

P2300HW-EN

2018-01

EN

Mounting plate

Possible receiving points for fixing the mounting plate of the wall

232 mm

(9.134")

197 mm

(7.756")

90 mm

(3.543")

10× 6,8 mm

(0.268")

378 mm

14.882")

341,8 mm

(13.457")

23,8 mm

(0.937" )

71 mm

2.795")

17,5 mm

(0.689")

2300_mz.png

10× 14,4 mm

(0.567")

10× 8 mm

(0.315")

332,5 mm

(13.091")

232,5 mm

(9.154")

32,5 mm

(1.28" )

Other manuals for mPro400GCD-P

1

Table of contents

Other Cleco Controllers manuals

Cleco

Cleco DGD mPro400GC Owner's manual

Cleco

Cleco CellCore 200 Series Guide

Cleco

Cleco mPro400GCD-M User manual

Cleco

Cleco DGD mPro400GC Guide

Cleco

Cleco mPro300GCD-STO User manual

Cleco

Cleco mPro400GCD-S User manual

Cleco

Cleco DGD mPro400GC User manual

Cleco

Cleco mPro400GCD-P Guide

Cleco

Cleco DGD mPro400GC User manual

Cleco

Cleco TME-100 Owner's manual

Popular Controllers manuals by other brands

Oldham

Oldham MX 43 user manual

Copley Controls

Copley Controls Xenus XSL-230-36 Regeneration Guide

Newport Electronics

Newport Electronics i Series Operator's manual

Dometic

Dometic Go Power! 30 AMP RVC MPPT user manual

Pontec

Pontec PondoSolar 250 Control operating instructions

Parker

Parker 6K8 installation guide