Cleco mPro300GCD-STO User manual

For additional product information visit our website at www.ClecoTools.com

Hardware Description

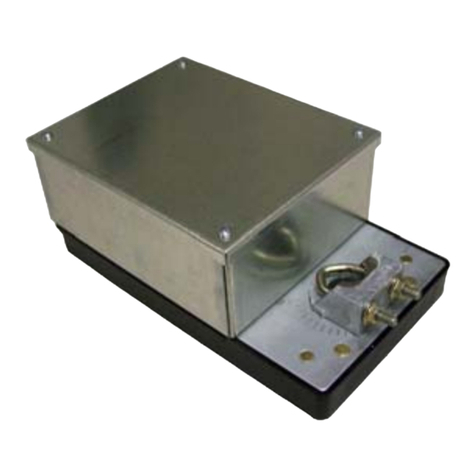

P2552HW

2021-04

mPro300GCD-STO

Global Controller Safe Torque Off

P2552HW |

2021-04 Apex Tool Group

Copyright © Apex Tool Group, 2021

No part of this document may be reproduced in any way or in any form, in whole or in part, or in a

natural or machine-readable language, or transmitted on electronic, mechanical, optical, or other

media, without the express permission of the Apex Tool Group.

Disclaimer

Apex Tool Group reserves the right to modify, supplement, or improve this document or the pro-

duct without prior notice.

Trademark

Cleco is a registered trademark of Apex Brands, Inc.

Apex Tool Group

670 Industrial Drive

Lexington, SC 29072

USA

Manufacturer

Apex Tool Group GmbH

Industriestraße 1

73463 Westhausen

Germany

Apex Tool Group P2552HW | 2021-04 3

INT

Content

EN

1 Notes on this Description ................................................................................ 6

2 Safety .............................................................................................................. 6

3 Product description........................................................................................ 10

4 Technical Specifications ................................................................................ 10

5 Pin Assignment.............................................................................................. 12

6 SD Card......................................................................................................... 14

7 Items Delivered ............................................................................................. 14

8 Accessories, optional .................................................................................... 15

9 STO safety function....................................................................................... 16

10 Operation and use......................................................................................... 20

DE

1 Zu dieser Beschreibung ................................................................................ 21

2 Sicherheit ...................................................................................................... 21

3 Produktbeschreibung .................................................................................... 25

4 Technische Daten.......................................................................................... 25

5 Steckerbelegung ........................................................................................... 27

6 SD Karte........................................................................................................ 29

7 Lieferumfang ................................................................................................. 29

8 Zubehör, optional........................................................................................... 30

9 Sicherheitsfunktion STO................................................................................ 31

10 Bedienung und Betrieb.................................................................................. 35

ES

1 Acerca de esta descripción ........................................................................... 36

2 Seguridad...................................................................................................... 36

3 Descripción del producto............................................................................... 40

4 Datos técnicos............................................................................................... 40

4 P2552HW | 2021-04 Apex Tool Group

INT 5 Asignación de enchufes ................................................................................ 42

6 Tarjeta SD...................................................................................................... 44

7 Volumen de suministro .................................................................................. 44

8 Accesorios, opcionales.................................................................................. 45

9 Función de seguridad STO............................................................................ 46

10 Manejo y funcionamiento............................................................................... 51

FR

1 À propos de cette description ........................................................................ 53

2 Sécurité ......................................................................................................... 53

3 Description du produit.................................................................................... 57

4 Caractéristiques techniques .......................................................................... 57

5 Disposition des connecteurs.......................................................................... 59

6 Carte SD........................................................................................................ 61

7 Étendue de la livraison .................................................................................. 61

8 Accessoires, en option .................................................................................. 62

9 Fonction de sécurité STO.............................................................................. 63

10 Commande et fonctionnement ...................................................................... 68

ZH

1␂ℝ㦻㙞承㠖ↅ

2⸘⏷㊶

3ℶ❐㙞承

4㔏㦾㟿㗽

5㙡⯃⒕揜

66'◰

7∪徶喒⦃

8棓ↅ᧨♾折

9672⸘⏷┮厌

10 㝜⇫扟嫛

Apex Tool Group P2552HW | 2021-04 5

INT

PL

1 Informacje dotyczące tego opisu................................................................... 84

2 Bezpieczeństwo ............................................................................................ 84

3 Opis produktu................................................................................................ 88

4 Dane techniczne............................................................................................ 88

5 Rozkład wyprowadzeń.................................................................................. 90

6 Karta SD........................................................................................................ 92

7 Zakres dostawy ............................................................................................. 92

8 Akcesoria, opcjonalne ................................................................................... 93

9 Funkcja bezpieczeństwa STO....................................................................... 94

10 Obsługa i eksploatacja .................................................................................. 98

PT

1 Com relação a esta descrição....................................................................... 99

2 Segurança..................................................................................................... 99

3 AtençãoDescrição do produto..................................................................... 103

4 Dados técnicos............................................................................................ 103

5 Atribuição dos conectores........................................................................... 105

6 Cartão SD.................................................................................................... 107

7 Escopo de fornecimento.............................................................................. 107

8 Acessório, opcional ..................................................................................... 108

9 Função de segurança STO ......................................................................... 109

10 Manuseio e operação.................................................................................. 113

11 System ......................................................................................................... 114

12 Connections, Cable Length.......................................................................... 115

13 Dimensions.................................................................................................. 116

6 P2552HW | 2021-04 Apex Tool Group

1

EN 1Notes on this Description

The information contained within this document is intended

for all individuals responsible for connecting and installing

the controller.

mPro300GCD-STO

Software instructions are provided in separate program-

ming manuals based upon the version installed.

The original language of this document is German.

Minimum Software Requirements

Additional Document References

Important Symbols

2 Safety

2.1 General Requirements

Only operate the controller after reading and fully

understanding this document. Failure to follow the

directions and safety instructions could result in elec-

tric shocks, burns and/or serious injuries.

Keep this document in a safe place for future refer-

ence! These safety instructions must be accessible all

personnel programming, operating or repairing the

controller.

2.2 Intended Use

The controller is a part of the Cleco Production Tools Tight-

ening System and is intended exclusively for industrial use

in fastening processes. Only use the controller under the

following conditions:

• In accordance with the components listed in the EC

Declaration of Conformity.

• Identified environmental conditions; see relevant docu-

mentation.

• Appropriate supply voltage; reference respective docu-

mentation.

• In EMC Limit Class A (electromagnetic immunity for

industrial areas). For the currently observed EMC

standards, see the EC Declaration of Conformity.

2.3 Foreseeable incorrect usage

Bridging safety devices is not permissible.

Do not use the controller:

• in potentially explosive areas

• in damp locations or outdoors

• in combination with cutting tools (drills, milling cutters,

grinders…)

• in non-industrial applications (eg residential area).

• For fastening applications not mentioned in the decla-

ration of conformity

• as climbing aid.

2.4 Operator Training

The tightening system may only be put into operation,

adjusted and tested by qualified and trained personnel.

Personnel must be instructed by qualified employees of

Apex Tool Group.

The controller has been preset by Apex Tool Group.

Adjustmenty of the controller to accommodate special

requirements may only be carried out by a qualified per-

son1).

Additional information are available in the Programming

Manual.

No. Description

S168300 Controller Software, Standard

S168677 mProRemote – Interface software between an

external computer and controller

No. Document type

P1730PM Reference Handbook

Fastening Sequences

P2279SB Systemhandbook NeoTek

P2461JH Quick Installation Guide mPro300GCD

P2486PM Programming Manual

mPro300GCD Standard Software

P3364C EC Declaration of Conformity

mPro300GCD-STO

Italic Identifies menu options), input fields, control

boxes, options fields or dropdown menus.

> Denotes the selection of a menu option from

a menu, e.g. File > Print

<…> Denotes switches, pushbuttons or keys of an

external keyboard, e.g. <F5>

Courier Denotes filenames and paths, e.g.

setup.exe

• Denotes lists, level 1

- Denotes lists, level 2

a)

b)

Denotes options

→Denotes results

1. (…)

2. (…)

Denotes action steps in sequence

Denotes a single action step

Sales &

Service

Centers

Cleco Production Tools – Sales & Service

Centers, see last page.

1 Due to their training, knowledge, experience and understand-

ing of the circumstances involved in this kind of work, suitably qual-

ified personnel are able to identify potential hazards and to initiate

appropriate safety measures. Qualified personnel are obliged to

comply with regulations.

Apex Tool Group P2552HW | 2021-04 7

1

EN

2.5 Personal Protective Equipment

(PPE)

When working with rotating parts, it is not permitted to

wear gloves.

Recommendation: Freely rotating u-GUARD pro-

tected fastening tools are available from APEX.

Wear close-fitting clothing.

Wear safety shoes.

If necessary, wear a hairnet.

Wear protective goggles, if there is a risk of flying

debris or parts being elected.

2.6 Warnings and Notes

Warning notes are identified by a signal word and picto-

gram:

• Signal word: describes the severity and the probability

of the impending danger.

• Pictogram: describes the type of danger.

2.7 Symbols on the Product

Be sure to understand the meaning of each symbol below

prior to installation, operation or maintenance service.

2.8 Standards

2.8.1 FCC and IC compliance

This product complies with Part 15 of the FCC Rules. Any

changes or modifications not expressly approved by the

manufacturer could void the user's authority to operate this

product. Operation is subject to the following two condi-

tions:

• this product may not cause harmful interference, and

• this product must accept any interference received,

including interference that may cause undesired oper-

ation.

FCC Responsible party

Name: William Cain

Position: Director, R&D

Address: 670 Industrial Drive

Lexington, SC 29072

United States

Phone: +1 803 951 7558

Email: William.Cain@ClecoTools.com

This product has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide rea-

sonable protection against harmful interference when the

product is operated in a commercial environment. This pro-

duct generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to

radio communications.

Operation of this product in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

2.9 System Relevant Safety

Instructions

Follow national, state and local safety and connection stan-

dards during installation. The standards take precedence

over the information in this section.

Danger

Symbol combined with the word Danger in-

dicates a hazard with a high level of risk

which, if not avoided, will result in death or

serious injury.

Warning

Symbol combined with the word Warning

indicates a hazard with a medium level of

risk which, if not avoided, could result in

death or serious injury.

Caution

Symbol combined with the word Caution in-

dicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injuries or environmental dam-

age.

Note

An symbol combined with the word Note in-

dicates a potentially harmful situation which,

if not avoided, could result in damage to

property or the environment.

General notes

includes application tips and useful infor-

mation, but no hazard warnings.

Electrical voltage

CE compliant

The product corresponds to the prescribed

technical requirements in Europe.

Read all instructions.

8 P2552HW | 2021-04 Apex Tool Group

1

EN Do not make any modifications to the controller, pro-

tective devices, or accessories without prior written

authorization from Apex Tool Group.

Do not attempt to open the controller or components of

the controller for troubleshooting or other work on the

device. In the event of a fault, any intervention can

result in serious injury from electric shock.

Operation with the device open may also cause the fol-

lowing:

- An increased amount of emissions: may produce

interference with other devices.

- Reduced immunity from interference: may produce

faulty results.

- Loss of remaining warranty period.

Risk Of Injury Due To Electric Shock

The controller and tool can conduct current in the event of

a fault. An electric shock can lead to cardiac arrest, cessa-

tion of breathing, burns, and serious or fatal injuries.

Always turn off the controller before connecting power

and tool cables, cleaning or removal from operation.

Do not operate the tightening system if the housing,

cable or tool are damaged.

Installation

Use an approved hoist to raise controller to desired

installation location.

Ensure the controller is rigidly mounted and

secured(see Quick Installation Guide).

Organize cables and lines to avoid damage and trip-

ping hazards.

Observe the permitted cable bending radius.

In the event of a fault, high leakage currents may occur and

cause injuries by electric shock.

Use an approved power cable, with suitable ratings.

Prior To Initial Operation

Only operate on a grounded power supply with a neu-

tral conductor (TN system). Operation without a neu-

tral conductoron (IT system) is not permitted.

Ensure a standard-compliant PE connection is in

place.

A ground fault circuit interrupter (GFCI) type A is rec-

ommended to protect the supply line.

Prior to initial operation, carry out the protective con-

ductor measurement in accordance with the local reg-

ulations (in Germany, DGUV Regulation 3).

Do not switch on the controller until all connections

have been made correctly.

Operation

Protect the controller from moisture.

Immediately power off the controller in the event of

unusual noise, heating or vibration from the tool.

Disconnect the power cord and have the tightening

system checked by qualified personnel and repaired if

necessary.

Never pull the power cord to remove from an outlet.

Protect all cables from heat, oil, sharp edges and mov-

ing parts.

Replace damaged cables immediately.

Ensure tool and plug connections between the

controller and tool are clean.

Ensure the workstation and surrounding area are

clean.

Ensure the workstation provides adequate space for

the operation being completed.

When working with a nutrunner, remain alert at all

times. Do not use a nutrunner if you are tired or under

the influence of drugs, alcohol or medication. A

moment of carelessness when working with a nutrun-

ner may contribute to a life threatening situation.

Danger Due To Incorrect Torque Measurement

An undetected NOK tightening may contribute to a life-

threatening situation.

Recalibration (or capability analysis) is essential fol-

lowing incorrect use (crash, mechanical overload…).

For Category A Tightenings (VDI 2862) which are criti-

cal for safety, activate a redundancy measurement

(e.g., current redundancy).

Introduce regular monitoring of measuring equipment

for associated manufacturing equipment.

Only conduct tightening operations with a properly

functioning system. If in doubt, contact Sales & Service

Centers.

Danger Due To Unexpected Start Of The Motor Or An

Expected But Missing Stop

Despite redundant controller parts and monitoring func-

tions, an unexpected start of the machine can occur in very

rare cases. Possible reasons may include, but are not lim-

ited to: Remote control of diagnostic functions, bit dump in

the memory of the controller.

Mechanical hazards such as jars/jolts due to counter

torques; risk of injury due to winding up and seizing can

result from the tool.

Use the tool at the designated grip points.

Use the recommended reaction devices. For torques,

reference appropriate tool instruction manual.

After powering the controller on, wait until the boot

cycle is completed, approximately 60 seconds, before

powering it down again.

Use of Secondary controllers

Up to 15 Secondary Controllers can be added to a Primary

Controller. Upon shutting off or in case of a Secondary

Controller failure, the TSNet bus communication is inter-

rupted. The communication loss to the Primary Controller

has consequences for a Secondary Controller:

→No results are returned to the Primary Controller.

→Additional rundowns are not initiated.

→An in-process rundown is reported with the error

message SA (abort by removing the start signal) if

the TSNet connection is interrupted during tighten-

ing.

→A shut-off signal is no longer received and so a

shut-off is only possible

- via the start button of the tool

- after reaching the shut-off criterion

- via a safety shut-off after two seconds

WARNING!

Apex Tool Group P2552HW | 2021-04 9

1

EN

During remote-start operation (multiple tool setup) an inter-

ruption of TSNet bus leads to a delayed stop of the spindle/

tool. This delay is 2 seconds.

Maintenance

The controller is generally maintenance-free.

Consider local regulations for maintenance and servic-

ing for all operating phases of the tightening system.

Cleaning

Only clean the exterior of the tool using a dry or slightly

damp cloth.

Do not immerse the controller or tools in any liquids.

Do not use a high pressure or abrasive cleaner.

Disinfection of surfaces with alcohol-based disinfectant

is permitted.

Repair

Repairs to the equipment are not permitted.

Send the controller to a Authorized

Cleco Production Tools Sales & Service Centers.

Disposal

Components of the tightening system may present poten-

tial risks the environment. The tightening system contains

components that can be recycled, as well as components

that have specific disposal requirements.

Follow local applicable regulations.

First separate, then dispose of components.

Collect auxiliary materials (oils, greases) and dispose

properly.

Separate the components of the packaging and dis-

pose of them according to local regulations.

Return defective equipment to an approved collection

point or return it to the Sales & Service Centers.

Observe local regulations for disposal of

electronics and batteries. (In Germany,

the Electrical and Electronic Equipment

Act (ElektroG) and the Battery Act

(BattG)):

Used up batteries must be disposed

of properly. Return depleted or defec-

tive batteries to an approved collec-

tion facility or to Sales & Service

Centers for recycling.

10 P2552HW | 2021-04 Apex Tool Group

1

EN 3 Product description

Controller for use in safety-critical tightening.

The controller is primarily used as a control and monitoring

unit for one or more tools at a workstation. Depending on

the peripheral devices that are procured, the controller can

also be installed outside of the work environment.

Software is already installed on the controller. The tighten-

ing settings must be carried out by a qualified person using

the controller or remote PC software (mProRemote) in

order to start fastening work. For further information

regarding software operation, please reference the Pro-

gramming Manual.

Nutrunner controllers with the suffix STO in the type name

are equipped with the STO safety function, see Chapter 9

STO safety function, Page 16.

4 Technical Specifications

Ambient Conditions

Power Supply

Safety Technology

Normative references

For product-relevant EC Directives, as well as the stan-

dards complied with, see the EC Declaration of Conformity.

Features Data

Operation Site Indoors

Ambient Temperature 0...45 °C1

1 Note the derating. See System Handbook NeoTek™

Storage Temperature -20...70 °C

Type of Cooling Convection (self-cooling)

Relative Humidity 10...90 %

No Condensation

Working Height Up to 3000 m

Above Sea Level1

Protection Class

DIN EN 60529

IP42

Protection Class

DIN EN61140

(VDE 0140-1)

I

Degree of Contamination

EN 61010

2

Transient Overvoltage

EN 61010

CAT

Maximum Shock

DIN EN 60068-2-27

15 G

Maximum Vibration

DIN EN 60068-2-5

59.6–160 Hz: 2 G

Features Data

Supply Voltage,

Single Phase

100–240 VAC ± 10%1

1 When operating outside the allowable voltage limits,

the integrated power supply enters a protection mode

and switches off. This protection mode can be reset

by restarting the nutrunner controller.

Rated Supply Current 2–1 A

Frequency 50/60 Hz

Peak Current 16 A

Rated Power 1600 VA max.

Idling 40 VA

Safety indices

Safety

function

STO Safe start lockout (STO, Safe

Torque Off) in accordance with

EN 61800-5-2, with SIL 2

Safe start lockout (STO, Safe

Torque Off) in accordance with

EN ISO 13849-1, Category 3 and

PL d

SIL SIL 2 Safety level (Safety Integrity

Level) in accordance with EN

61800-5-2

Category 3 Classification in the category is in

accordance with EN ISO 13849-1

PL PL d Performance Level is in accor-

dance with EN ISO 13849-1

DCavg 60% Low, average diagnostic cover-

age (Average Diagnostic Cover-

age)

HFT 1 Hardware Failure Tolerance

SFF > 60% Safe Failure Fraction

PFH 9.1 E-10 1/h < 0.1% of SIL 2, Probability of

dangerous Failure per Hour

PFDav

(T = 20 a)

7.9 E-05 0.8% of SIL 2, Probability of dan-

gerous Failure on Demand

TPTI

[months]

12 Proof Test Interval service life in

accordance with EN ISO 13849-1

MTTFd > 2.000 a HIGH, Mean time to dangerous

failure

Apex Tool Group P2552HW | 2021-04 11

1

EN

NRTL Certification

Electrical specifications

System Data

Weight

Issuing agency TÜV SÜD

North America

Certificate No. U8V 078313 0010 Rev. 00

Tested in accordance with • UL 61010-1:2012/

R:2018-11

• CAN/CSA–C22.2

No.61010-1:2012/

A1:2018-11

International

Certificate No. DE 3 - 31485

Tested in accordance with • IEC 61010-1:2010

• IEC 61010-1:2010/

AMD1:2016

Control signals STO-A and STO-B at [X41] and [X42]

Nominal voltage [VDC] 24 (based on GND_STO)

Voltage range [VDC] 0 … 28.8

Allowed residual ripple [%] 2 (based on nominal voltage;

leaving the voltage range is

not allowed)

Input current [mA] 4 (typical for 24 V)

Switching threshold On

[VDC]

> 17

Switching threshold Off

[VDC]

< 4.5

Switching time On [ms] < 1

Switching time Off [ms] < 1

Feedback contact FB1, FB2 [X41]

Max. voltage [VDC] < 30

Nominal current [A] 0.5

Resistance [Ω] < 1 (switched on)

Residual current [μA] < 2 (switched off)

Auxiliary supply 24 V [X41]

Nominal voltage [VDC] 24

Nominal current [mA] 100 (short circuit proof)

Features Data

System Functions Battery Buffered Real Time Clock,

Buffer Time: 10 Years (at 20 °C)

Display LC Display With Touchscreen,

7" TFT Liquid Crystal Display,

Resolution 480 x 800, Connection To

Panel & Touch Possible

Operating System Linux, Bootable Without Mechanically

Moving Drives, No UPS Required

HMI

(Human Machine

Interface)

Virtual Keyboard for Alphanumeric

Inputs

Model Weight

Ib kg

MPRO300GCD-STOEMEA

MPRO300GCD-STONA

MPRO300GCD-STOAPAC

11,9 26,2

including mounting plate 13 28,7

Features Data

12 P2552HW | 2021-04 Apex Tool Group

1

EN 5 Pin Assignment

This chapter describes the Cleco Production Tools specific

connectors. Standard plugs are not considered. All connec-

tions are short-circuit proof.

X5 – Serial port for additional devices

• All outputs provide RS232 conforming signals.

• The inputs allow voltages in the range from -15 V to

+15 V.

- Voltages < 0.8 V correspond to a zero.

- Voltages > 2.4 V are interpreted as a one.

- Open inputs are preset to zero using a pulldown

resistor.

• The power supply pins are connected directly to the

main board power supply

.

X7 – Anybus Compact Com

X21 – TSnet System Bus Out

Interface port for TSnet cable.

X22 – TSnet System Bus In

X23 – Supply

X24 – Tool Connector Digital

for 30/50/70/BD Series

Note

Do not connect or disconnect any device

during operation. Doing so may result in a

system reset.

Pin RS232-1 9 Pin D-Sub Male

with Screw Lock

1 –

2 RxD

3 TxD

4 –

5 GND

6 –

7 RTS

8 CTS

9 –

Module Order no.

PROFINET M40 RJ45 544357PT

PROFIBUS M40 M12 962291PT

PROFIBUS M40 DB9 962292PT

DeviceNet M40 962293PT

PROFINET M40 M12 962294PT

Ethernet/IP M40 RJ45 2 port 962297PT

Modbus/TCP M40 RJ45 2 port 962299PT

Note

Do not combine Anybus Compact Com M40

modules with Anybus CC M30 modules.

Pin Signal 8 Pin M12 Socket

Circular Connector X-Coded

1 Tx +

2 Tx -

3 Rx +

4 RX -

5 0 VDC

6 0 VDC

7 +24 VDC

8 +24 VDC

Pin Signal 8 Pin M12 Male

Circular Connector X-Coded

1 Tx +

2 Tx -

3 Rx +

4 RX -

5 0 VDC

6 0 VDC

7 +24 VDC

8 +24 VDC

Description IEC Conncetor

C14

Connector with Fuse Holder

2-Pin, 5 × 20 mm,

16 A Slow-Blow

Fuse, Schurter type 0034.3129,

5 × 20 mm, 16 AT, 250 VAC,

Interrupting Current, 100 A

Note

Use plug locking mechanism.

See Quick Installation Guide.

Pin Signal M23 Circular Connector

1-3 Power

4 PE

(functional

ground)

5 Tool bus

54

3

2

18

7

6

45

6

7

81

2

3

1

2

3

4

5

Apex Tool Group P2552HW | 2021-04 13

1

EN

X41, X42 – E-Stop

Signal assignment see 9.2.2 Interface overview, Page 17.

X9, X10 – Input/Output

Digital I/O Interface

The required signal circuits are connected to these input/

output connectors. The signal groups are connected to the

power supply.

• 8 inputs/8 outputs, optically isolated for 24 V level

• Output current: 500 mA per output, 1000 mA total

Connectors – Internal power supply

Example:

Inputs

• Internal 24 V power supply for the controller.

• Pin 11 and 23 (common GND) serve as a "return line"

for the outputs.

• Pin 11 and 23 must be connected to Pin 12 or 24 with

jumpers.

Outputs

• Internal 24 V power supply for the controller

• Pin 2 and 14 (common output) are the voltage source

for the inputs.

• Pin 2 and 14 must be connected to Pin 1 or 13

STO Function 8 Pin M12 Circular

Connector

X42 OUT Pin

X41 IN

Socket

Note

A single device must not require a current of

more than 500 mA. The current monitor

switches off the output in the event of an

overcurrent.

Phoenix Mini Combicon MCD 1,5/12-G1F-3,81

X9 X10

Signal X9 Signal X10

Pin I/O Name Pin I/O Name

12 Supply GND Int. 24 Supply GND Int.

11 Supply GND I/O 23 Supply GND I/O

10 Output O3 22 Output O7

9 Output O2 21 Output O6

8 Output O1 20 Output O5

7 Output O0 19 Output O4

6 Input I3 18 Input I7

5 Input I2 17 Input I6

4 Input I1 16 Input I5

3 Input I0 15 Input I4

2 Supply +24 V O 14 Supply +24 V O

1 Supply +24 V Int. 13 Supply +24 V Int.

14 P2552HW | 2021-04 Apex Tool Group

1

EN Connectors – external power supply

Example:

Inputs

• The external 24 V power supply for the controller must

be SELV (Safety Extra Low Voltage) or PELV (Protec-

tive Extra Low Voltage).

• Pin 11 and 23 (common GND) serve as a "return line"

for the outputs.

• The GND for the external 24 V power supply must be

used as the return line for Pin 11 and 23.

Outputs

• The external 24 V power supply for the controller must

be SELV (Safety Extra Low Voltage) or PELV (Protec-

tive Extra Low Voltage).

• Pin 2 and 14 (common output) are the voltage source

for the inputs.

• Pin 2 and 14 must be connected to the external 24 V

power supply.

6 SD Card

Required for the operation of the controller, the archiving of

data and configurations. Not included with the controller. 7 Items Delivered

Check delivery for transit damage and ensure that all items

have been supplied:

• Controller

• EC Declaration of Conformity

• This Hardware Description

• Quick Installation Guide

• Warranty

• Order no. SWB-S168300 – SD card plus Software

• Order no. S981211 – Mating Connector X9/X10 (2×)

• Order no. 962405PT – STO plug, bridged

Power Cord V Lock, varies by model:

Signal X9 Signal X10

Pin I/O Name Pin I/O Name

12 Supply GND Int. 24 Supply GND Int.

11 Supply GND I/O 23 Supply GND I/O

10 Output O3 22 Output O3

9 Output O2 21 Output O2

8 Output O1 20 Output O1

7 Output O0 (linking OK), e.g. 19 Output O0 (linking OK), e.g.

6 Input I3 (tool start), e.g. 18 Input I3 (tool start), e.g.

5 Input I2 17 Input I2

4 Input I1 16 Input I1

3 Input I0 15 Input I0

2 Supply +24 V O 14 Supply +24 V O

1 Supply +24 V Int. 13 Supply +24 V Int.

+-

Note

Only remove or plug in the SD card when

the supply voltage is switched off. Other-

wise, serious system errors and data loss

will result.

• Order no. 962276PT mPro300GCD-STO-EMEA

• Order no. 962278PT mPro300GCD-STONA 115 VAC

•–

(see Accessories)

mPro300GCD-STOAPC

Apex Tool Group P2552HW | 2021-04 15

1

EN

8 Accessories, optional

• Order no. 962037-(…) – Cable TSNet

• Order no. 961924-(…) – Cable STO

• Order no. 962199PT – Housing for connector X9/X10

• Order no. 961893PT – Termination plug

Power Cord V Lock:

Power Cord

• Order no. 962277PT 230 VAC UK

• Order no. 962311PT 230 VAC APAC

• Order no. 541863-02 230 VAC NA

16 P2552HW | 2021-04 Apex Tool Group

1

EN 9 STO safety function

9.1 Definition

The STO safety function enables the controller mPro300GCD-STO to provide a reliable solution for switching off the

energy supply at the output of the built-in nutrunner.

If several mPro300GCD-STO units are wired in series with STO connector cables, the STO function is guaranteed for the

complete group.

STO = Safe Torque Off. For the currently observed standards, please refer to 4Technical Specifications.

9.2 Performance features

• Reaching the STO safety function

• Potential-free feedback contact for the operating status.

Warning

Risk of electric shock

The STO safety function only provides protection against dangerous movements, not against electric

shock.

Always comply with the stipulations of the documentation, in particular 2 Safety, Page 6.

Comply with the documentation for the other components.

Ensure protection against the built-in nutrunner automatically restarting according to the required safe-

ty category of emergency stop applications, e.g. via an external safety relay.

STMD-H

672 $

672 %

9'&

9'&

,&

,&

,&

,&

w&

5(/

5(/

50 672$ 21

50 672% 21

24V 0V

1Pin 2 4 5 6 8 7 3 4Pin 5 6 8 7 3

Connection to the previous controller

or to a safety relay STO cable to the next

controller

Termination connector

STO connection flange

X41 IN

Connection

XS4

Auxiliary power

supply

24 V

Galvanic

separation

Power supply

Gate driver

OS + US

Activation of the

level converter for

gate signals

STO connection flange

X42 OUT

or

Apex Tool Group P2552HW | 2021-04 17

1

EN

When the STO safety function is active, the power supply

is safely interrupted by two separate shutdown paths to the

motor in the tool. The motor can not produce any torque

and therefore no dangerous movements. There is no moni-

toring of the standstill position. This is relevant, for exam-

ple, for torques generated by loads, such as suspended

loads, or by preloaded spring drives. In such cases, addi-

tional measures for shutdown must be provided that pre-

vent these reactions - these must be ensured and brought

about in a safety-related manner.

9.2.1 Diagnostic Coverage (DC)

The Diagnostic Coverage depends on the inclusion of the

integrated safety function for the controller into the

controller chain, as well as the implemented measures for

the diagnostics.

If a fault is detected during the diagnostics, suitable mea-

sures must be provided to maintain the safety level.

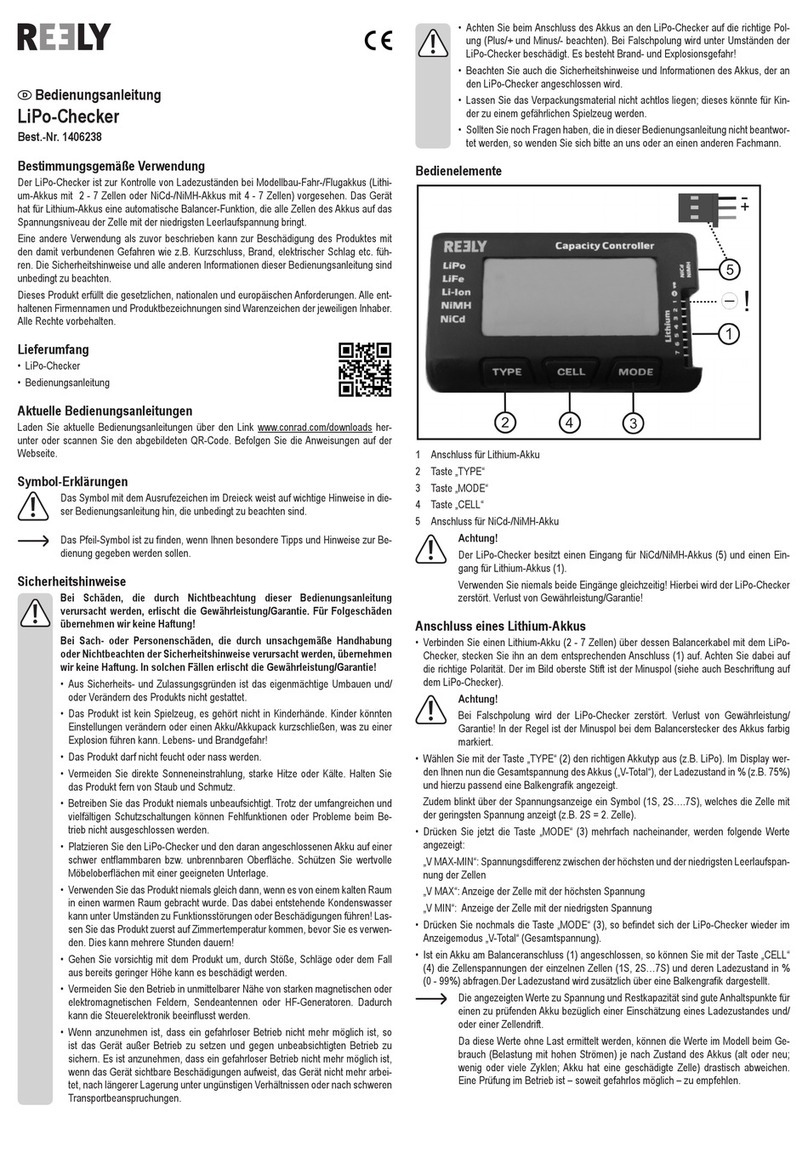

9.2.2 Interface overview

The STO safety function for the controller is controlled via

the digital I/O interfaces X41, X42. The interfaces for all

controllers with the STO function are designated the same,

color-coded and functionally identical with the same speci-

fications, see 5 Pin Assignment, Page 12.

The STO safety function is requested exclusively via the

two digital control inputs STO-A and STO-B. Another con-

nection of the signals, e.g,. feedback or auxiliary voltage, is

not absolutely required.

The state of the STO safety function is reported back via a

potential-free feedback contact (closer). This information is

linked in a successive circuit of several controllers with the

STO function.

Interface port X41 – IN

Depending on the position of the currently considered con-

trol in the STO line (see 11 System, Page 114), the inter-

face port X41 is the connection to the previous controller or

to the external safety relay.

By providing an auxiliary power supply of 24 VDC in con-

nector X41, it is possible to supply the voltage to safety

relays for normally open contacts, or similar.

Interface port X42 – OUT

Depending on whether the currently considered controller

is the last in an STO line, or whether another controller fol-

lows, the interface X42 is the connection to the next

controller or can be left without connecting further. If the

feedback contact is evaluated, a termination on the last

controller in a line is necessary.

Caution

There is a risk of the motor starting up when

there multiple errors in the controller.

If the final stage of the nutrunner module

in the controller fails during the STO state

(simultaneous short circuit of 2 power

semiconductors in different phases),

there may be a limited locking movement

of the rotor in the motor. The angle of ro-

tation corresponds to a pole pitch, which

acts on the output drive with the gear re-

duction. The angle of rotation for electric

hand tools from Cleco Production Tools is

always ≤15°.

Note

Cross-connection detection of the input cir-

cuit is not performed by the controller.

All system components allow the short cir-

cuit fault exclusion.

Pin Signal Description

1 24 VDC Output auxiliary power supply 24

VDC, for passive control of STO

Reference potential is GND_STO

2 24 VDC

3 FB-1-In Potential-free Feedback Contact 1

(informative) for the STO state

• Feedback contact open: STO not

active

• Feedback contact closed: STO

active

4 STO-A Input for control signal A for con-

trolling the STO safety function

Reference potential is GND_STO

• STO request at low level simulta-

neously with low level at STO-B

5 GND_STO Reference potential for all voltages at

X41

6STO-B Input for control signal B for con-

trolling the STO safety function

Reference potential is GND_STO

• STO request at low level simulta-

neously with low level at STO-A

7FB -2 Potential-free Feedback Contact 2;

for a description, see FB-1

8GND_STO Reference potential for all voltages at

X41

18 P2552HW | 2021-04 Apex Tool Group

1

EN

9.3 Control signals STO-A and STO-B

With the two control inputs STO-A and STO-B, the STO

safety function is requested by two channels. They allow

the direct connection of safe semiconductor outputs (elec-

tronic safety relays, active safety sensors) and of switching

contacts (safety relays with relay outputs, passive safety

sensors, such as positively driven position switches),

see9.6 Assembly and installation, Page 19.

To request the STO safety function, the 24 V control volt-

age at both control inputs STO-A and STO-B is switched

off (0 V). If both control signals are switched off simultane-

ously or within a specified discrepancy time, then the STO

safety function is active.

Tolerance ranges are defined for the input voltage range of

the control inputs STO-A and STO-B. The amount of

energy stored in the components of the STO circuit (e.g.,

capacitors) depends on the magnitude of the input voltage.

During switching operations, these amounts of energy

must be charged or discharged. As a result, the dependent

values for the switch-off time for the transition to the safe

state (STO) come about from the input voltage.

The requirements for the time response result from the

technical specifications in Chapter 4 Technical Specifica-

tions, Page 10.The time response itself is described in

Chapter9.5 Time response, Page 19.

Discrepancy time

The transition between a safe and an unsafe state is initi-

ated by level changes at the control inputs STO-A and

STO-B. According to the specifications for the safety func-

tion, both levels must be identical; otherwise an error mes-

sage will be generated. A state machine in the controller

monitors both signals over time. Due to component toler-

ances or bouncing contacts, the level changes never occur

at exactly the same time. This is tolerated by the so-called

discrepancy time as long as the level changes occur within

this time. If the levels of the control signals STO-A and

STO-B are different for longer than this time, a transition is

made to an error state that can not be reset. The discrep-

ancy time Δt is 100 ms. This can not be parameterized.

Test pulses

Test pulses from safety controllers are not tolerated and

must be deactivated for system availability. The exclusive

use of Cleco Production Tools accessories allows the short

circuit fault exclusion.

Feedback contact FB

The feedback contact indicates the safe state. If the STO

safety function is not active, then the feedback contact is

open. This is also the case, for example, when the 24 V

logic supply voltage is switched off due to a defect or a fail-

ure of the supply voltage. When the STO safety function is

active, the relay contact is closed.

The following table shows the state of the feedback con-

tact, depending on the input signals and the time. A pre-

condition is always the error-free state (Row 1 or 4). The

time Δt is the discrepancy time 100 ms.

The technical specifications for the feedback contact are

given in Chapter 4 Technical Specifications, Page 10.

Pin Signal Description

1NC

2

3FB-1-Out Potential-free Feedback Contact 1

4STO-A Output for control signal A for con-

trolling the STO safety function of the

next controller, bridged with X41.4

5GND_STO Reference potential for all voltages at

X42

6STO-B Output for control signal B for con-

trolling the STO safety function of the

next controller, bridged with X41.6

7FB -2 Potential-free Feedback Contact 2,

bridged with X41.7

8GND_STO Reference potential for all voltages at

X42

Chapter 4 Technical Specifications,

Page 10 describes the technical specifica-

tions for the controller inputs in the speci-

fied operating range of logic voltages.

The signals STO-A and STO-B should be

switched simultaneously if possible.

Note

The feedback contact has a single-chan-

nel design and may be used for diagnos-

tic purposes, but not in the safety circuit.

When switching on, the feedback contact

may briefly deviate from the input signals

until the nutrunner control is ready for op-

eration.

Row STO-A STO-B FB

closed

Leads to

diagnostic

error

after Δt

10 0 1 0

20 1 0 0→Δt →1

31 0

0 →Δt →1 0 →Δt →1

41 1 0 0

Apex Tool Group P2552HW | 2021-04 19

1

EN

9.4 Diagnostics

The STO safety function is monitored in the controller for

plausibility and operability.

9.4.1 STO status signal to control

Within the software, the status of the STO safety function

(1=OK, 0=STO triggered) is available at Input 15 on the I/O

level under device PM_DIDO.

If this status information is present in the application, this

must be assigned accordingly by the operator.

It is advisable to use the software input Emergency Stop.

Assignment is not necessary for safety reasons.

9.4.2 Fail-Safe state

If a fault in the safety technology is detected, e.g., if, for

example, control signals STO-A and STO-B have unequal

levels or there is a circuit defect, then a fault is triggered

internally. This fault can not be reset or can only be reset

by a restart, i.e., further start attempts no longer lead to the

turning on of the output drive.

It is assumed that there is an external fault and the

controller must be switched off. If the fault persists after

checking the external controller, then there is a defect in

the controller and it must therefore be replaced.

9.5 Time response

The control signals STO-A and STO-B are equivalent in

regards to their use, although the signals operate different

shutdown paths. They are described in terms of the time

response as a single, exchangeable STO signal.

The time from the shutdown of an STO signal to the activity

in the final stage of the controller is determined by the

external circuitry (see also9.3 Control signals STO-A and

STO-B, Page 18), including controllers connected in paral-

lel. The values given here refer to the Passive version (see

9.6.1 Passive circuit X41, Page 19) with a nutrunner con-

trol and the maximum cable length. The time response is

different for each layout and must be checked at startup to

see if it meets the minimum requirements.

9.6 Assembly and installation

When installing and wiring the signals, the requirements of

EN 60204-1 must be met. In this case, particular attention

must be paid to measures for short circuit fault exclusion.

For the STO cables 961924-xxx, the STO signals are indi-

vidually protected by a ground connection. The connection

to the first controller, and from controller to controller, must

not be longer than 60 m; in total in the system, a total

length of up to 1000 m is permitted for all of the STO con-

nections.

The following circuit examples show the intended wiring of

the STO interfaces. An analogous other use or connection

is not permitted.

9.6.1 Passive circuit X41

Fig. 9-1:

The STO safety function can be requested by various devices. The switch S1 can be, for example, an Emergency Stop

switch, a safety door switch, a light curtain or a safety relay. The safety requirement is 2-channel via the switch S1and

leads to the 2-channel shutdown of the final stage - therefore, this structure is for Category 3. The auxiliary power supply

24 V for signal generation is provided on the interface.

9.6.2 Active circuit X41

Fig. 9-2:

20 P2552HW | 2021-04 Apex Tool Group

1

EN The STO safety function can also be requested through active, fail-safe outputs of a PLC or with contacts as in Chap-

ter9.6.1 Passive circuit X41, Page 19, but with an external power supply. For an external power supply, only PELV power

circuits and PELV power sources may be used. The voltage source must provide a nominal voltage of 24 VDC (an abso-

lute minimum output voltage of 22 VDC) with at least 0.5 A.

9.6.3 Shut down of STO safety function X41

Fig. 9-3:

If the STO safety function is not required in a controller, the function can also be deactivated by means of jumpers in a

connector as shown in the circuit diagram Fig. 9-3:.

9.6.4 Connection X42

Fig. 9-4:

The connection to X42 at the last controller in a system is only required if the feedback contact FB is evaluated. Otherwise,

the X42 interface can also remain open. For termination - which means closing the feedback path - use termination con-

nector 961893PT.

10 Operation and use

10.1 Obligation of the operator

Check the functioning of the safety device at defined time

intervals. It is the responsibility of the operator to choose

the type of test and the time intervals during the required

time period. The test shall be carried out in such a way that

the proper functioning of the safety device is demonstrated

in the interaction with all the associated components. The

maximum interval between two tests may not exceed a

duration of TPTI, see 4 Technical Specifications, Page 10.

10.2 Overvoltage and polarity reversal

protection

The control inputs STO-A and STO-B are protected against

overvoltages and against the polarity reversal of the control

voltage, see also Chapter4 Technical Specifications,

Page 10.

The 24 VDC auxiliary voltage supplied at X41 is short-cir-

cuit proof. However, a short circuit or overload leads to the

failure of alll the internal logic voltages and thus to the fail-

ure of the primary function.

Caution

Never temporarily use the connections shown here for another system whose risk assessment re-

quires an STO safety function.

The risk of forgetting is given.

Table of contents

Languages:

Other Cleco Controllers manuals

Cleco

Cleco mPro400GCD-P Guide

Cleco

Cleco TME-100 Owner's manual

Cleco

Cleco DGD mPro400GC User manual

Cleco

Cleco mPro400GCD-M User manual

Cleco

Cleco DGD mPro400GC Guide

Cleco

Cleco CellCore 200 Series Guide

Cleco

Cleco mPro400GCD-P Guide

Cleco

Cleco DGD mPro400GC User manual

Cleco

Cleco mPro400GCD-S User manual

Cleco

Cleco DGD mPro400GC Owner's manual

Popular Controllers manuals by other brands

UCS

UCS T-RACK user manual

Sanhua

Sanhua SEC60 Series Manual and installation instructions

Fuji Electric

Fuji Electric MICREX-F Series manual

ZIEHL-ABEGG

ZIEHL-ABEGG Acontrol PSET6 operating instructions

dynarex

dynarex Oxygen Regulator CGA 870 Style user manual

Neptronic

Neptronic LT060X11 Specification & installation instructions