15

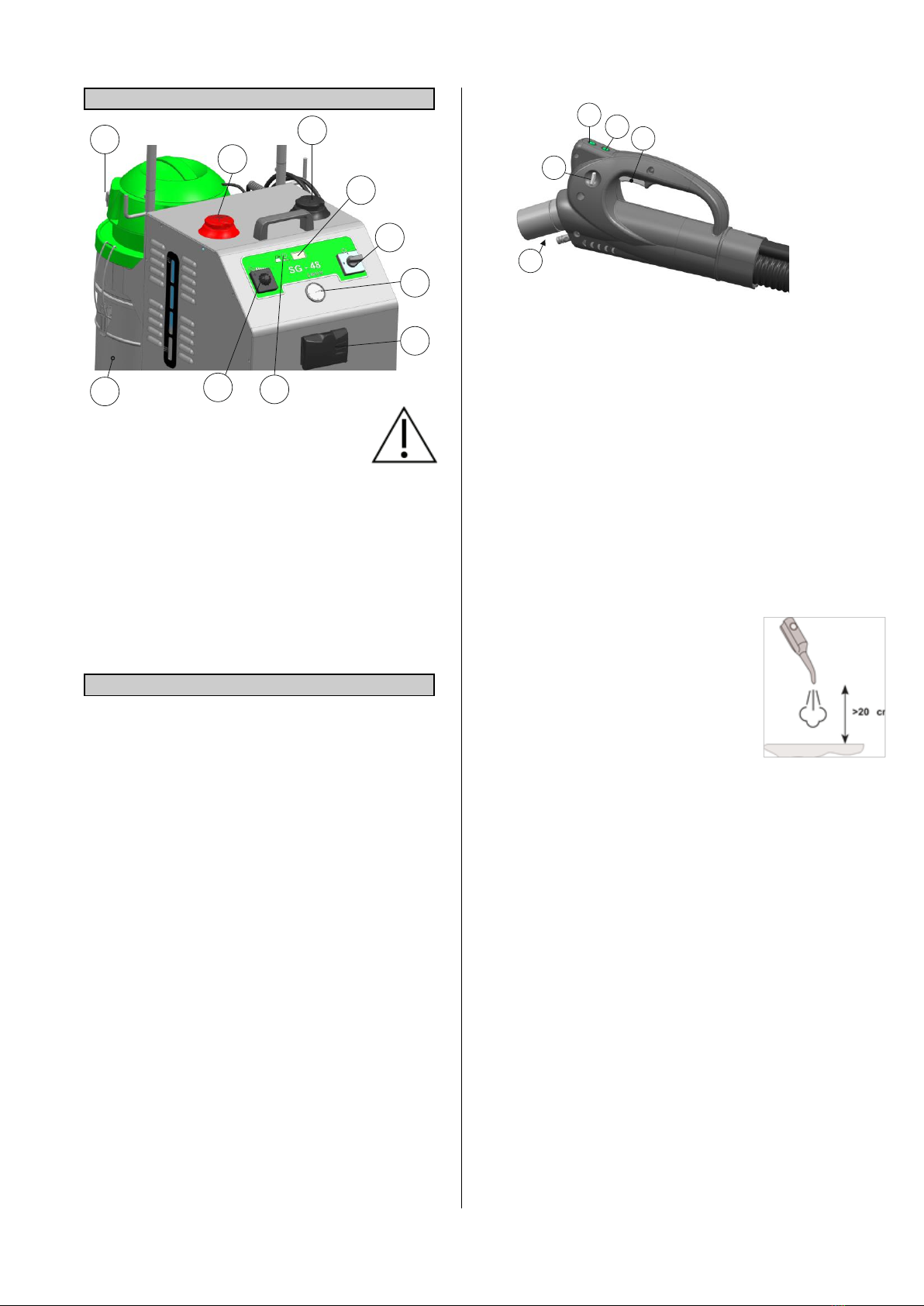

TANK-SUCTION ACCESSORY

Accessory to be connected

to the flexible hose to

vacuum and clean the

tanks.

BRUSHES

MICROFIBER CLOTH

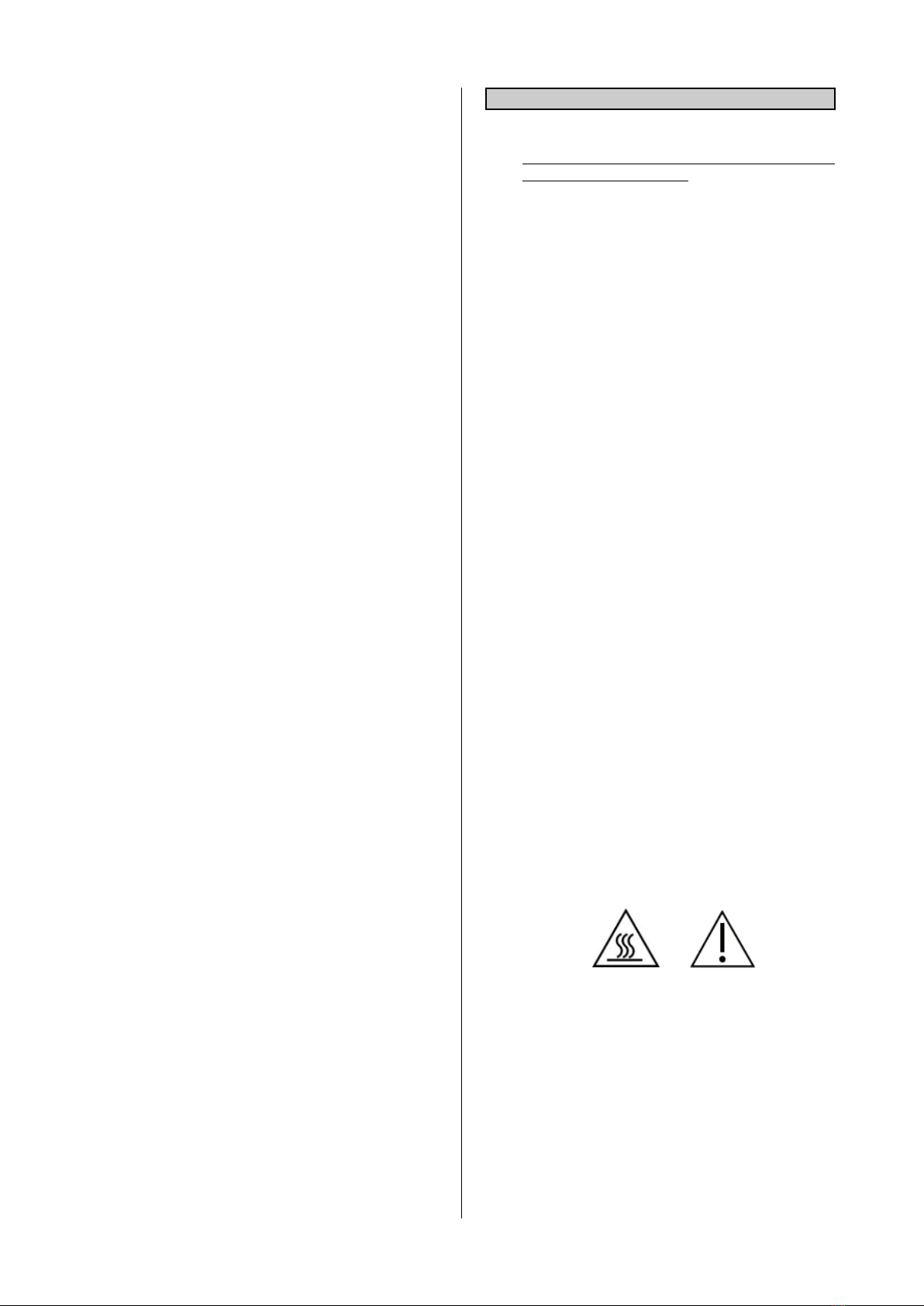

MANTAINANCE (End user)

*Always remove the plug before

cleaning or carrying out operations

on the machine. * End user must

not open or dismantle the

machine.

For the safety of the operator and to always ensure a

perfect performance, we recommend the following

checks and maintenance:

AFTER EVERY USE:

For a correct cleaning, it is advice to clean the machine

and its accessories with a clean cloth moistened only

with a few drops of water. Do not use alcohol or other

solvents, they may damage the plastics and

components.

To maintain efficient and easy to couple the

accessories, check the o-ring seal (steam sealing

gaskets) and possibly wet them with a little silicone

grease.

VACUUM FUNCTION: when you finish to vacuum, it is

advisable to vacuum some water to clean the conducts

and the filter. Afterwards, dry the bucket or do not totally

close it so that it will dry itself.

PERIODICALLY:

Periodically check that the power cord does not show

signs of wear or aging. If it is damaged, it is absolutely

necessary to get it replaced by specialized personnel

before being able to re-use the appliance again.

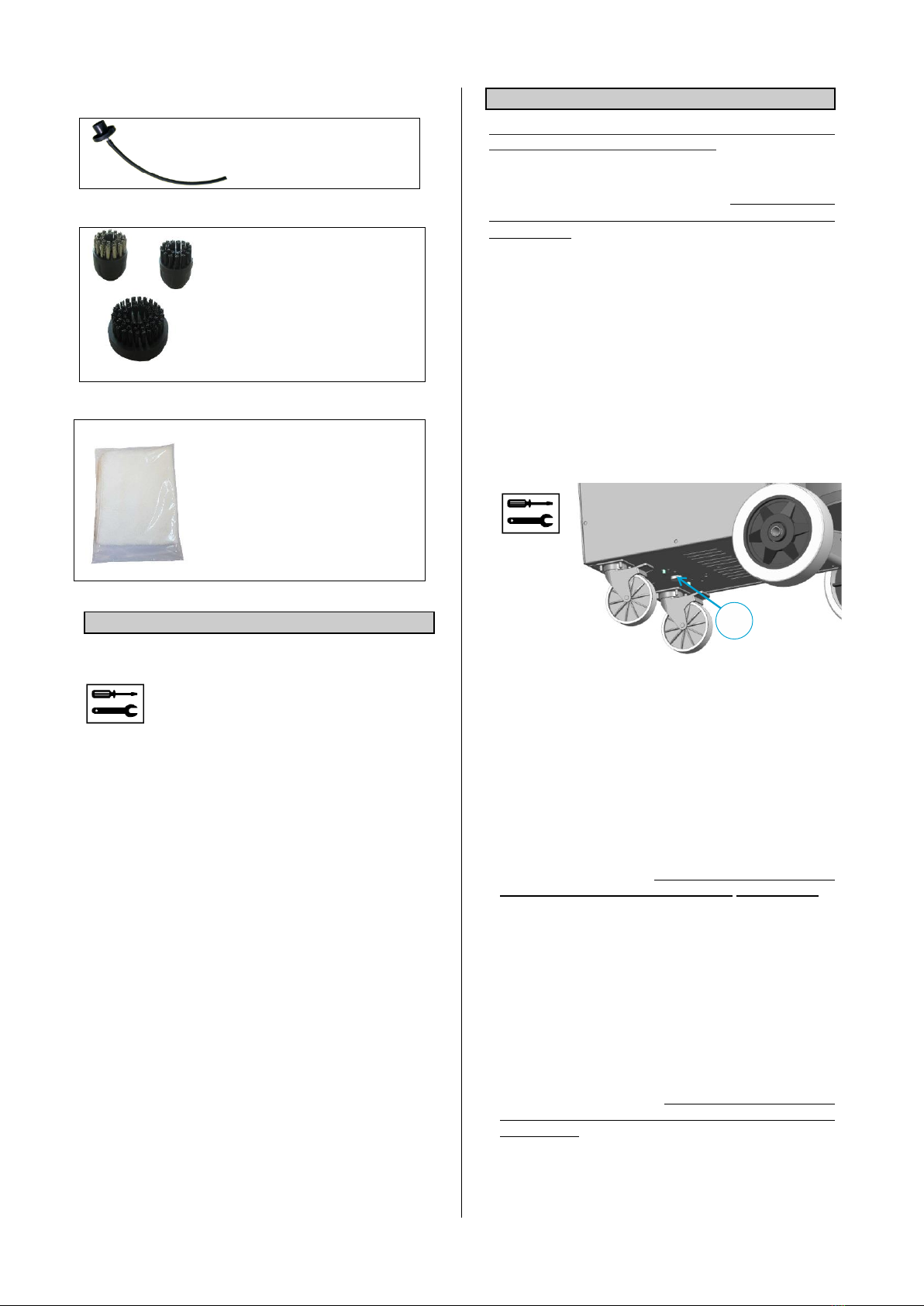

BOILER CLEANING (End user)

Once a year a check and boiler cleaning must be

carried out in our authorized centers.

RINSE: It’s recommended at least every 50 hours of

operation or 2 months.

a) DISCHARGE: The machine must be cold or definitely

discharged from the steam pressure and the plug

disconnected. With the help of a wrench CH 21

unscrew the cap (15) placed under the machine in

correspondence of the boiler (see image). After having

taken off the cap, shake slightly the machine to let the

water and the dissolved limestone out.

When the boiler is empty, clean and close carefully the

cap tightening it with the wrench.

b) FILLING: Fill the water tank (7), turn the machine on

and make it start again, waiting for the boiler to be re-

charged again.

(att: it may be that during the first charge cycle, the

“end of water” light turns on and you need to shut

down/restart the machine to complete the load)

BOILER AND TANK CLEANING:

The boiler cleaning is recommended at least every

200 hours of operation or 6 months.

1- Cleaning with suction of the plastic tank (7): Check

that the water level in the plastic water tank (7) is at

least halfway up, shake/move the machine to shake

the water and any possible deposit.

Connect the flexible hose to the connector block (5) of

the machine, and hook the “TANK SUCTION”

accessory into the handle, insert the accessory tube

into the tank (7) and completely suck the water in it.

(Operation also possible in the tank (8))

2- The machine must be cold or definitely discharged

from the steam pressure and the plug disconnected.

Exhaust the contents of the boiler, carefully following

what described in the previous point "BOILER

DISCHARGE".

Prepare 2 liters of water and vinegar, in proportions

of about 60% vinegar 40% water.

Insert the prepared liquid in the refill tank of the

machine (7).

3- Turn on the machine and wait for the pump to finish

filling the boiler. (Att: it may be that during the first

charge cycle, the “end of water” light turns on and you

need to shut down/restart the machine to complete

the load). When fully charged, the machine will start

the heating cycle (Heat): do not wait for the heating

but immediately turn off the main switch turn off the

main switch, unplug the power plug and let the

machine to rest for 6-7 hours.

(Att: do not let inside the solution over the indicated

time period).

4- With the machine cold and the plug disconnected,

shake it well and then open the cap under the boiler

These brushes must be

connected to the STEAM

LANCE. They are used to

remove resistant dirt and for

deep cleaning, even in the

corners or small spaces. Choose

the nylon or brass type according

to the surface to be treated.

Cloth to be used hooked with the

multi-purpose brush to clean

delicate surfaces, such as

wooden floors, furniture, etc. It

offers a great absorption power,

reduces the power of the steam

dispensed and reduces the

friction of the brush during the

treatment.