Page 7

The other end of the air supply hose attach to the Air Filter CPF - 20

respective CPF - 80 (more than one blaster).

Use moulded-in handle to carry the respirator. Never hold, carry or

hang the respirator by the breathing hose!

Mishandling the respirator in this manner may damage the hose!

5 Air Supply

Air supply to this respirator system is a critical component for the safety of the user and is not

included in this delivery. Read this section carefully. Poor quality air will cause serious respiratory

injury or death to the user (see 2.2).

5.1 Air Quality

The compressed breath air has to be conform to EN 12021.

A supply pressure between 6-8 bars has to be assured. The supply pressure can be regulated over our

CPF 20 filter with integrated pressure regulator (p/n 03580D) so that the blaster is provided with the right

air quantity.

The quality of air supplied to the respirator is extremely critical to the safety of the user. Special care must

also be taken to avoid accidental connection to any other gas lines, such as oxygen, acetylene or nitrogen.

Never connect a breathing air line to an air source that has not been tested for gas and particulate

contamination.

Do not use piston type (oil bath) compressors for breathing air. These compressors may produce

dangerous levels of carbon monoxide.

The presence of unacceptable levels of carbon monoxide (CO) or other gases in the breathing air

can cause death to the user.

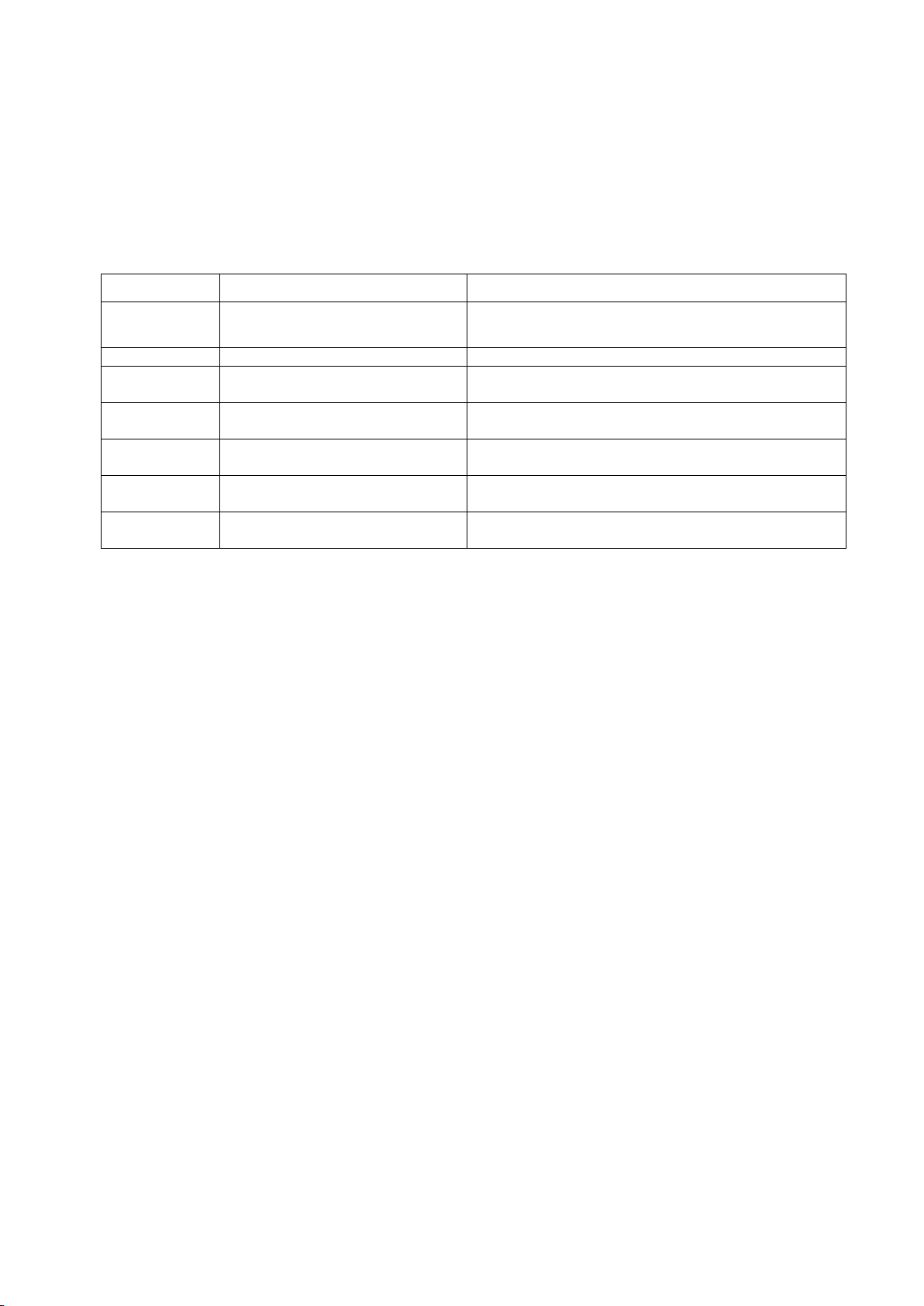

Breathing air must be only used in following conditions:

Prior to using the respirator, read the owner’s manual and all instructions, labels, and warnings related

to the compressed air source. Take special care about all the statements and warnings from the com-

pressor producer.

Warning: There could appear a negative pressure in the blast hood during inhala-

tion caused by a high intensity of labour.

That is why the air control valve should be opened wider while a high intensity of labour in order

to avoid the infiltration of dust in the blast hood.

We recommend our carbon monoxide monitor, CMS-3 for controlling the concentration of carbon monox-

ide.

Regardless to the air compressor type, precautions must be taken to prevent contaminants from

entering through the compressor intake. The compressor inlet must be located away from all sources

of toxic contaminants including carbon monoxide which is found in engine exhaust and in any form

of combustion. No vehicles should be allowed near the compressor intake.