Page 8

dle to avoid damage to the air line.

5 Air Supply

The air supply to the blast helmet is a critical element of operator safety and is not included in the

scope of delivery. Please read this section with particular care. Poor air quality may result in ill-

ness or death of the operator (see 2.2).

5.1 Air quality

The air supply must comply with EN 12021.

A supply pressure of 6 - 8 bar must be ensured. This can be achieved using our CPF 20 air filter with

integrated pressure regulator (Art. no. 03580D) so that the right air flow is available (see also 5.2).

The quality of the air supply is critical and very important for ensuring the safety and wellbeing of the

operator. Particular attention must be paid to ensuring that the apparatus is not accidentally connected to

other gas supplies, e.g. oxygen, acetylene or nitrogen.

Never connect the breathing air line to an air source that has not been tested for gas or particu-

late contamination.

Do not use a piston compressor (oil bath) to generate the breathing air as there is a strong risk it

may produce high carbon monoxide concentrations.

The presence of excessive carbon monoxide concentrations may result in the operator’s death.

The breathing air must meet the following requirements:

-The air supply must comply with EN 12021.

-Before using the helmet, please read the owner’s manual, all instructions and labels, and all warnings

concerning the compressed air source. Please observe the compressor manufacturer’s state-

ments/warnings concerning the use of the compressor.

Warning:

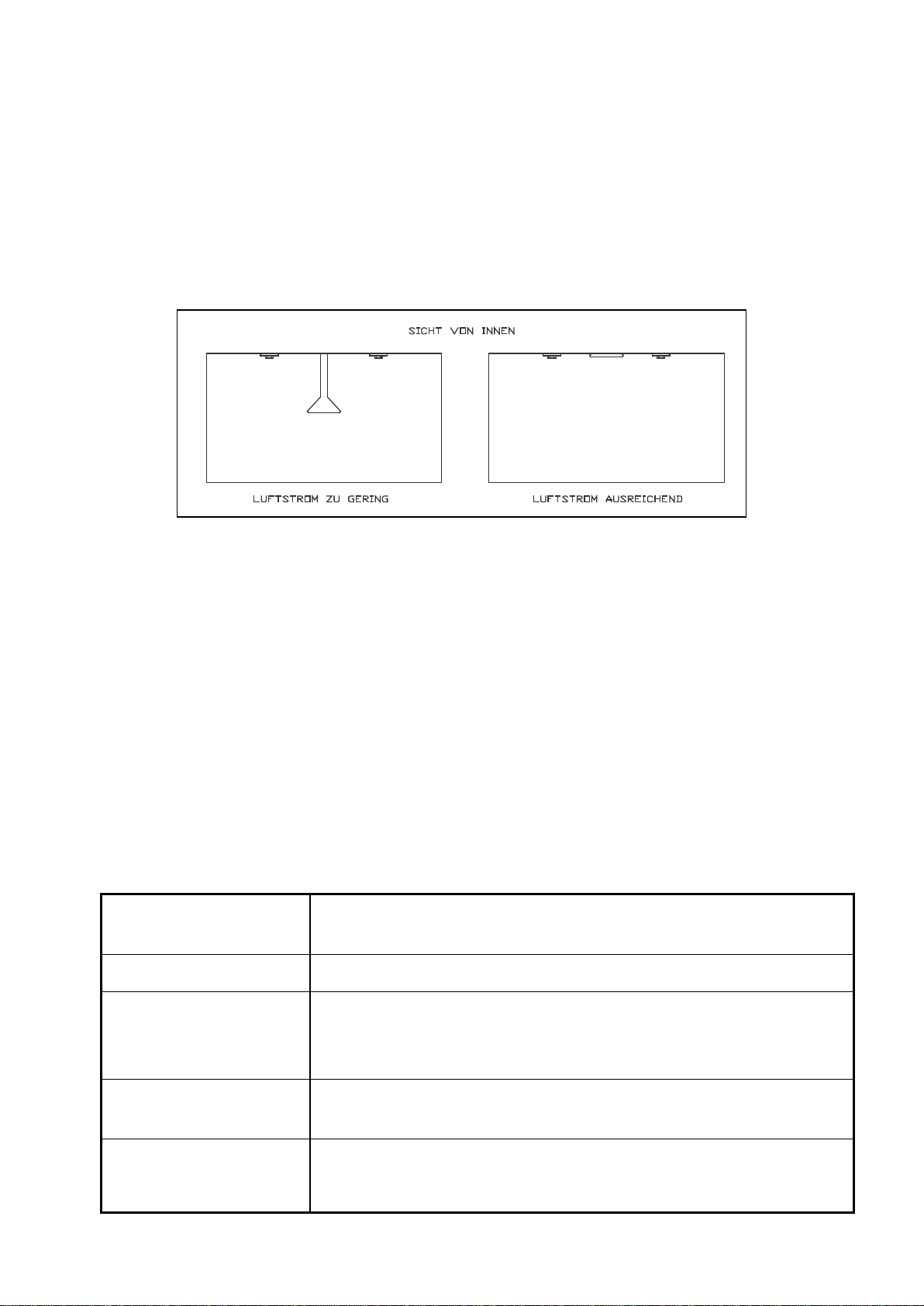

During intense use, respiration may produce negative pressure in the helmet.

-During intense use therefore, the air control valve needs to be opened wider to prevent the ingress of

dust into the helmet.

-If using an oil-lubricated compressor for the air supply, a high temperature monitor and/or a carbon

monoxide alarm should be fitted. If only a high temperature monitor is fitted, the air must be regularly

tested for the presence of carbon monoxide. The user is responsible for testing the breathing air, the

compressor, the carbon monoxide alarm, the air filter and the wearing parts. An overheated or poorly

maintained compressor may produce carbon monoxide or an unpleasant smell. It is also possible to use

systems to remove or convert carbon monoxide in order to ensure good breathing air quality.

-When using a compressor, the air intake must be positioned to prevent the intake of contaminants, e.g.

carbon monoxide and oil components found in exhaust gases. This applies especially when using porta-

ble compressors. For this reason, no vehicles or motor-powered equipment should be operated in the

vicinity of the compressor.

An appropriate filter (e.g. CPF 20, Art. no. 03580 D) must be fitted and regularly serviced to remove un-

pleasant smells, oil mist, condensation, rust from pipes and other constituents.