FLAT-TRAK®RECOVERY FLOOR Page 3

© 2017 CLEMCO INDUSTRIES CORP. www.clemcoindustries.com Manual No. 07763, Rev M

1.4 Tools Requirement

Open/box end wrenches, 7/16" - 3/4"

Socket wrench w/ 7/16" - 3/4" sockets

Screw drivers

Hex keys

Hand drill with bit assortment

Hammer

Drift pin

Welder

Measuring tape, long enough to measure the

floor area diagonally

Chalk line

2.0 INSTALLATION

2.1 Installation Notes

2.1.1 These instructions are general guidelines for all

sizes of Flat-Trak®floors. The assembly illustrations shown

throughout the manual are for a typical arrangement.

Layout drawings for specific jobs are provided with the job

manual. All floor drive sections are 98-1/2-inches long. If

floor extensions are used, they will be 30-inches, 60-

inches, or 120-inches long. All cross conveyor base

segments are 9-feet long, with a 40-13/16-inch long drive

section. If cross conveyor extensions are used, they will be

24-inches, 36-inches, and/or 72-inches long.

2.1.2 When both short and long conveyor extensions

are used, the shorter extensions should be located

between two longer extensions. See the example shown in

Figure 1. The 30-inch and 60-inch extensions are placed

between the longer drive section and 120-inch extension.

2.1.3 Extensions can be placed in any order; however,

the same sequence must be used on all floor sections.

See Note 1 in Figure 1.

2.1.4 Conveyor section widths are measured from

center to center. Since the beams are 3-inches wide, an

additional 1-1/2 inches is needed on each side of the floor

layout. For example: If a floor is four sections wide, the

total outside dimension of the floor width will be 147 inches

(four 36-inch sections plus 3 inches [1-1/2 inches on each

side]). Be sure to allow for the extra 1-1/2 Inches when

laying out the floor perimeter.

2.1.5 If the Flat-Trak®Floor is recessed in a pit or in an

existing room, it is necessary to have 3 inches between

the outside perimeters of the floor and pit or room wall.

The 3-inch space is needed to replace rollers.

2.1.6 Track beams are labeled "This side up" and "This

end toward drive cylinder". When laying out the tracks,

make sure the side labeled "up" is facing up, and the end

marked toward drive cylinder, is facing the drive cylinder.

Splice holes in the beams are positioned so they are on

the lower side when the tracks are right side up. If the

splice holes of two adjoining tracks do not lineup one of

the tracks may be upside down.

2.1.7 The Flat-Trak®floor is installed on a single level. If

the Flat-Trak®replaces an existing multi-level floor, a

single level floor capable of sustaining the gross weight of

the recovery floor, abrasive, grate, parts to be blasted, and

operator, will have to be constructed.

2.1.8 The electro/pneumatic cylinder control panel(s)

must be accessible to an air supply line and electrical

source, and located to enable installation of poly tubing air

lines to run from the panel to each air cylinder. One

cylinder is used on each floor conveyor section, and cross

conveyor section. The panel must be located within a

distance to require no more than 15 feet of tubing to the

cross conveyor cylinder. See note # 2 and the typical

arrangement in Figure 1.

2.1.9 Cylinder timing control panels come with four, five,

or six stations. One station operates one conveyor section

(one cylinder for each section). If the system has more

than six conveyor sections, more than one panel is

required. For example, if the floor has nine conveyor

sections, a four-station and five-station panel is used. If the

floor has seven-sections, two four-station panels are used.

The unused station(s) must be looped with a short piece of

5/16 inch poly tubing, and the flow control valve (used to

time the cylinder cycles) must be closed.

2.1.10 Control panels do not need to be mounted

together. It is best to separate the panels on large

systems, and mount each one as close as possible to the

cylinders they control. See Paragraph 2.1.8.

2.1.11 The Flat-Trak®is designed to connect to a Clemco

elevator, and recovery components. If other brand

recovery components are used, transitions must be made

to adapt to them.

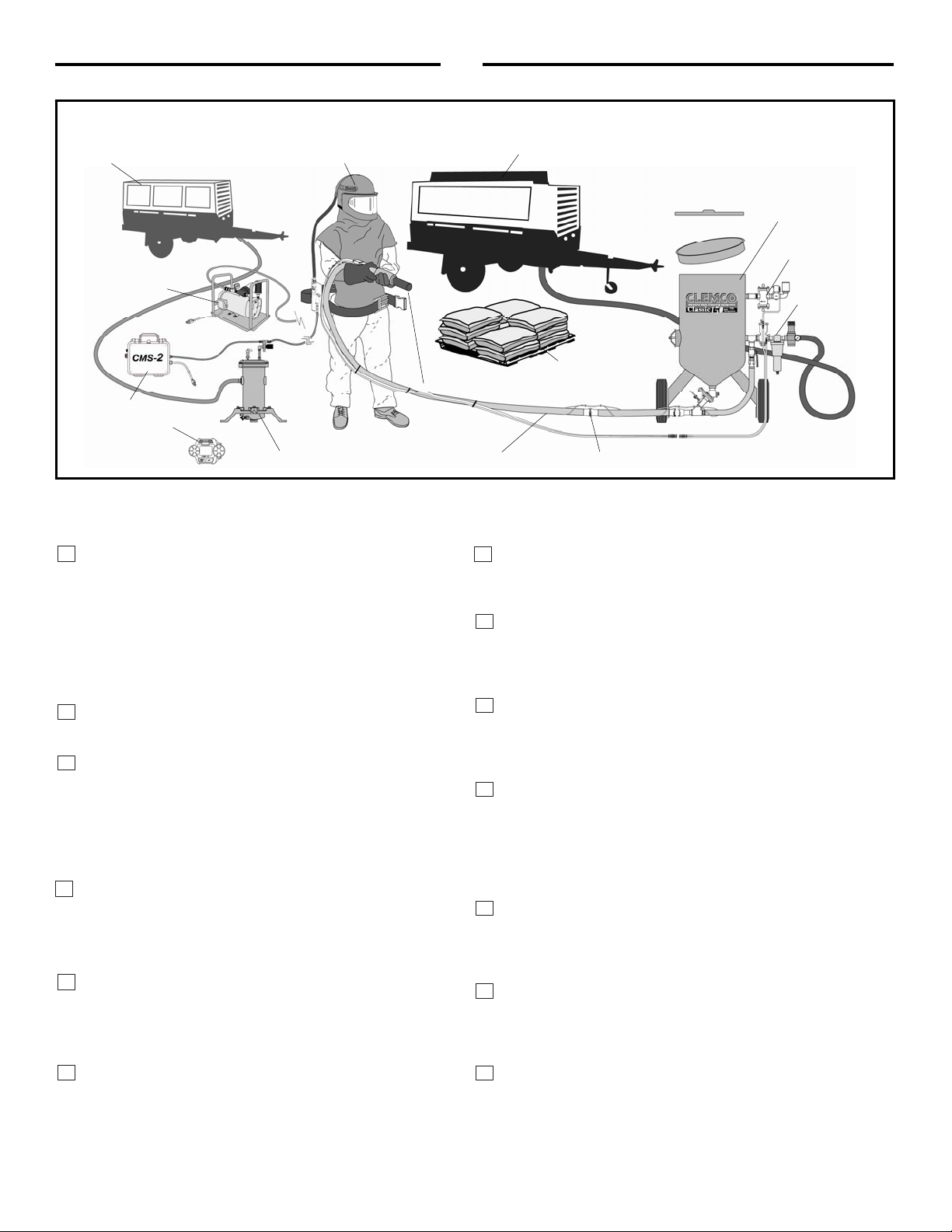

2.2 Uncrating

2.2.1 Uncrate and identify all parts. Use the checklist

shipped with the equipment, and the illustrations in Figures

2, 3, 4, and 5 to identify the parts. To help keep the

assembly area organized, and to avoid loss, leave small

parts in marked boxes until they are required.

2.2.2 Sort all parts into groups. The first parts to be

used will be the track beams. Identify and sort them as

shown in Figure 2.

2.2.3 Identify and sort hardware shown in Figure 3,

carriages shown in Figure 4, and cylinder equipment

shown in Figure 5. Make sure the carriages are flat.

Straighten any that may have bent during shipment. It is

important that the carriage frames lay flat on the floor.