Cleveland

™

Project ________________________________

Item __________________________________

Quantity _______________________________

FCSI Section ____________________________

Approval _______________________________

Date __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

PRESSURE/CONVECT ON STEAMERS

MODEL: 36-PCGM-300

Cle eland Standard Features

I

I

Cooking Capacity for up to eight 12" x 20" x 2

1

⁄

2

˝ deep

Cafeteria Pans per compartment, or four 18˝ x 26˝ Buns

Pans.

II

Each compartment can operate independently as a pressure

steamer, or as a convection steamer, user selectable.

IIIn the Convection Mode; Pressureless cooking with

convection steam, permitting doors to be opened while

cooking continues.

IIIn the Pressure Mode; door is locked and sealed,

compartment operates at 5 0707 steam pressure

II

Solid State Controls operate water level and safety functions.

II

Each compartment is equipped with a 60 minute mechanical

timer, separate bypass switch for constant steaming

(Convection only).

IIDurable 10 Gauge Stainless Steel Construction:

For Compartment Door and Steam Cooking Cavity.

IISeparate Main Power Switch for “On/Off”

IIExclusive Steam Cooking Distribution System: The

Exclusive Convection Jets produce a high velocity

convection steam without fans. Coved Corner design in

cooking compartment distributes heat evenly and is easy to

keep clean. Creased bottom enhances drainage. Cold

Water Condenser for each compartment maintains a dry

steam. Fully insulated cooking compartment for thermal

efficiency. Removable Stainless Steel Slide Racks for easy

cleaning.

IIHeavy duty, one piece, solid compartment door design

with replaceable door gasket

IILeft Hand Door Hinging: Compartment Doors hinged left,

controls on the right.

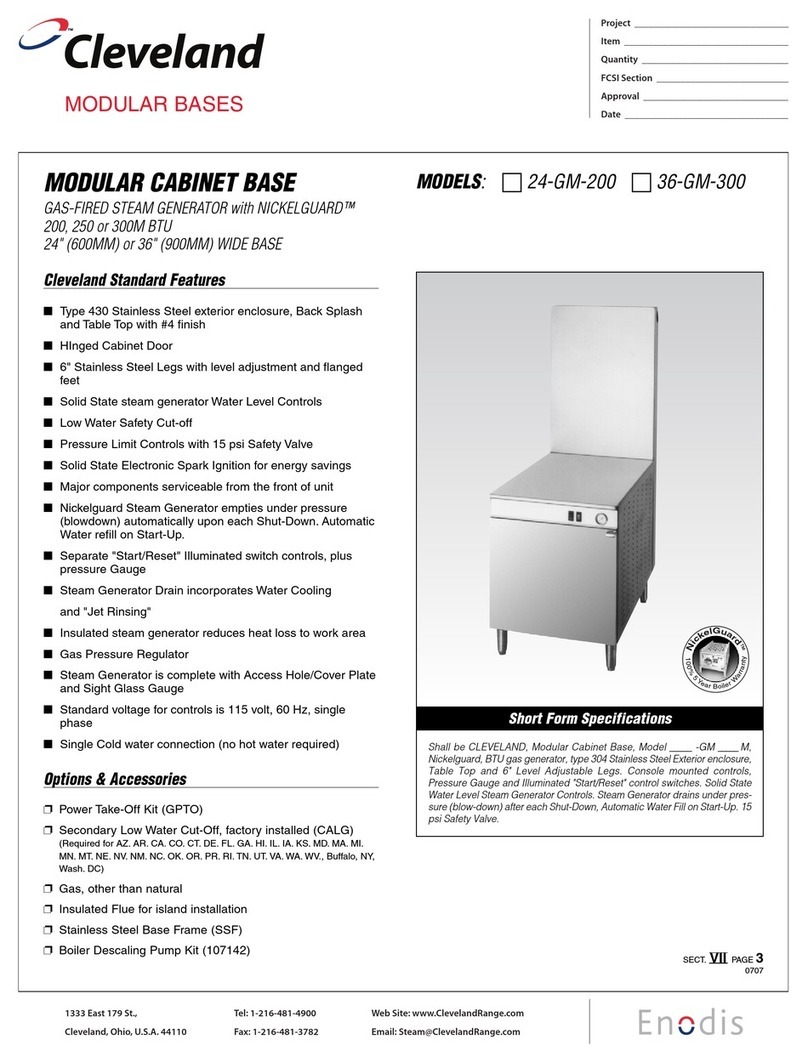

IIHeavy duty Stainless Steel Base Frame: 36˝ modular

cabinet

IIHigh Efficiency Gas Steam Generator with NickelGard,

Electronic Spark gnition and Automatic Water Fill on start up.

IIAutomatic Generator Drain at shutdown: Contains a

“Water Jet” Spray Rinse Cleaning Cycle to keep drain clear.

IIAutomatic Water Level Control System with Low Water

Power Cut-off Circuit.

IISteam generator equipped with High Limit Pressure Safety

Switch, 15 psi Safety Valve, and Steam Pressure Gauge.

IINSF Certified 6˝ Stainless Steel Legs with adjustable

flanged feet for a one inch level adjustment.

IIGas Pressure Regulator and Control Valve.

IIStandard Voltage for Control: 115 volts, 60 Hz, single

phase.

IIAll Controls are serviceable from the front.

IICompartment Door Steam Shut Off Switch.

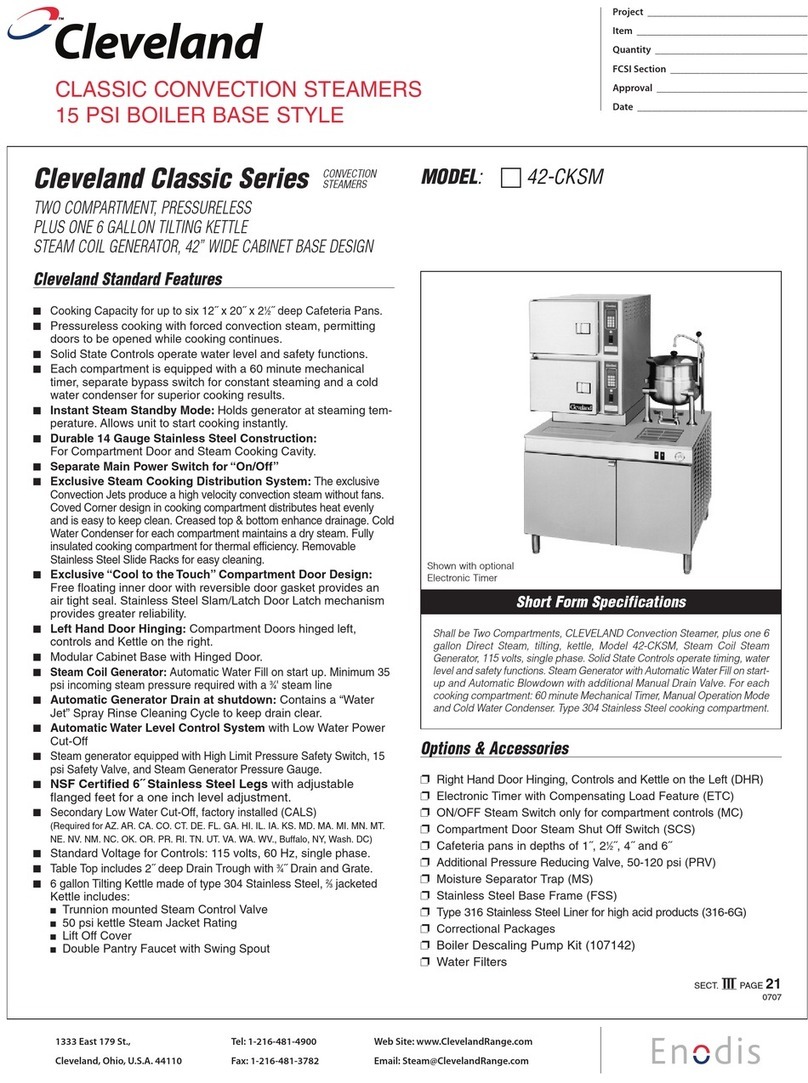

Sha be Two Compartments, CLEVELAND Pressure/Convection Steamer,

Gas-fired Steam Generator, Mode 36-PCGM-300, Nicke Gard, 300M gas,

115 vo ts, 60 Hz, sing e phase. Pressure/Convection Modes to be se ectab e

at user’s option with no restrictions as to any combination of modes. Type 304

Stain ess Stee cooking compartment. Insu ated cooking compartments. One

60 minute Mechanica Timer with Touch Contro per compartment. Audib e

and Visua Signa s for cyc e comp etion and steam shut-off. Separate visua

indication for each operationa mode.

Options & Accessories

ËElectronic Timer with Compensating Load Feature. (ETC)

ËCafeteria pans in depths of 1˝, 21⁄2˝, 4˝ and 6˝

Ë18˝ x 26˝ Bun Pans

ËStainless Steel nsulated Flue Cover (SSF)

ËQuick Disconnect for gas line (QDC)

ËCorrectional Packages

ËSecondary Low Water Cut-Off, factory installed (CALG)

(Required for AZ. AR. CA. CO. CT. DE. FL. GA. H . L. A. KS. MD. MA. M . MN. MT.

NE. NV. NM. NC. OK. OR. PR. R . TN. UT. VA. WA. WV., Buffalo, NY, Wash. DC)

ËBoiler Descaling Pump Kit (107142)

ËWater Filters

ËRear Gas Connnection (RGT)

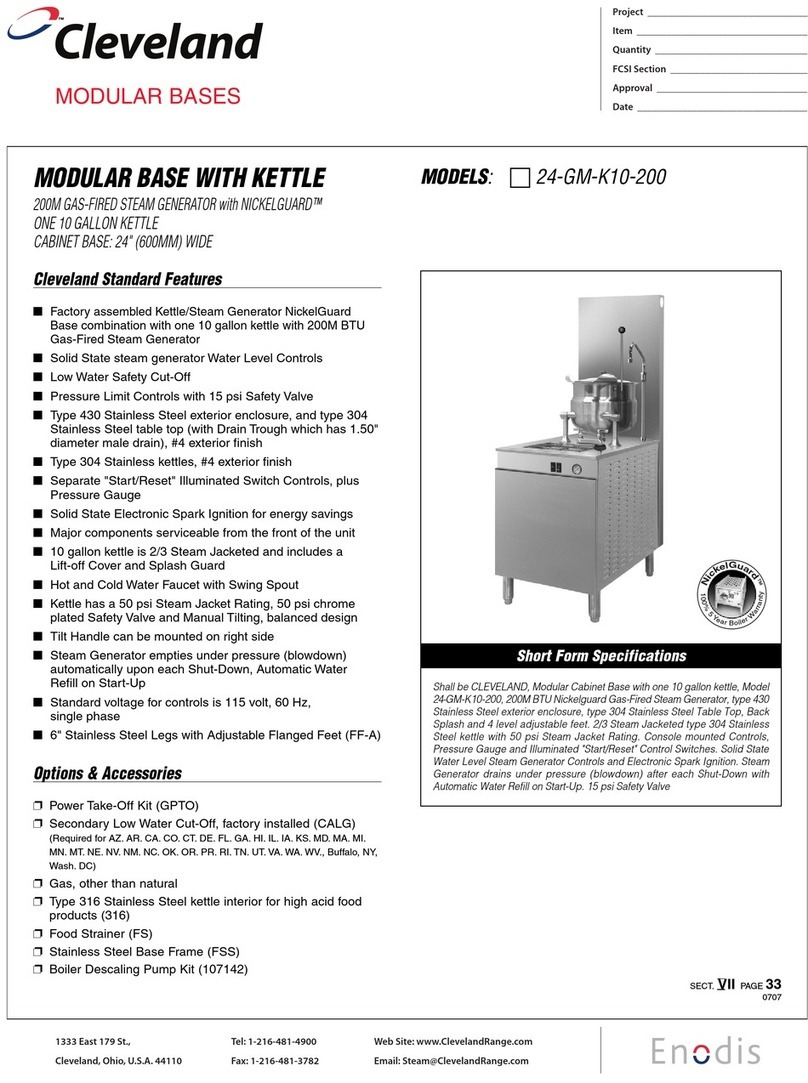

Short Form Specifications

Shown with optional

Electronic Timer

SteamPro XVI ®

LARGE COMPARTMENTS, HIGH VOLUME

300M BTU GAS FIRED STEAM GENERATOR

36” WIDE CABINET BASE DESIGN wi h NICKELGUARD™

PRESSURE/CONVECTION

STEAMERS

1

0

0

%

5

Y

e

a

r

B

o

i

l

e

r

W

a

r

r

a

n

t

y

N

i

c

k

e

l

G

u

a

r

d

™

SECT. VPAGE 3

1007