5

BB7000 Worksheet

To build a machine with a 4" diameter bar,

choose components from columns A and C.

To build a machine with a 5" diameter bar,

choose components from columns B and C.

NOTE: Contact your factory representative

for additional information and lead times.

(C) Components, both sizes

Component Part number

Hydraulic power unit - 15 hp:

3-phase/230V/60 Hz 25343 _______

3-phase/460V/60 Hz 25344 _______

3-phase/550V/50 Hz 25345 _______

3-phase/575V/60 Hz 25346 _______

3-phase/440V/50 Hz 25347 _______

3-phase/220V/50 Hz 25348 _______

3-phase/380V/50 Hz 25349 _______

3-phase/200V/50 Hz 25350 _______

Hydraulic power unit - 25 hp:

3-phase/230V/60 Hz 25408 _______

3-phase/460V/60 Hz 25409 _______

3-phase/550V/50 Hz 25410 _______

3-phase/575V/60 Hz 25411 _______

3-phase/440V/50 Hz 25412 _______

3-phase/220V/50 Hz 25413 _______

3-phase/380V/50 Hz 25414 _______

3-phase/200V/50 Hz 25415 _______

Main disconnect 600V, 3-phase for 15

hp and 25 hp electric powered hydrau-

lic power units (optional):

-4___________

Hydraulic motor:

3.6 in3 25472 _______

5.4/5.6 in3 25473 _______

7.1/7.3 in3 25474 _______

8.8/8.9 in3 25475 _______

10.6/11.3 in3 25476 _______

12.9/14.3 in3 25477 _______

16.4/17.9 in3 25478 _______

Hydraulic fitting kit, 3/4" 25587 _______

Tool kit 15762 _______

Facing head assembly: 19096 _______

(A) Components, 4" bar

Component Part number

Rotational drive assembly:

15606 _______

Collet for 4" dia. bar 16869 _______

Mechanical axial feed assembly:

4" dia. bar 16853 _______

Bearing support assembly (at least two

recommended):

End-mount bearing support ass'y:

4" diameter bar 16849 _______

ID-mount bearing support ass'y:

10" - 20" 21232 _______

10" - 30" 21926 _______

10" - 40" 21927 _______

20" - 35" 18886 _______

20" - 49.25" 19565 _______

20" - 63.5" 19566 _______

Boring bar assemblies, 4" dia. bars:

8 ft (2.4 m) 18763 _______

10 ft (3.1 m) 16829 _______

12 ft (3.7 m) 16830 _______

14 ft (4.3 m) 16831 _______

16 ft (4.9 m) 16832 _______

18 ft (5.5 m) 16833 _______

20 ft (6.1 m) 16834 _______

Tool carrier assembly, 4" dia. bar:

16822 _______

Tool head assembly:

4" boring head assembly:

8" - 30" ID 16847 _______

8" - 20" ID 18767 _______

(B) Components, 5" bar

Component Part number

Rotational drive assembly:

15606 _______

Mechanical axial feed assembly:

5" dia. bar 20352 _______

Bearing support assembly (at least two

recommended):

End-mount bearing support ass'y:

5" diameter bar 15574 _______

ID-mount bearing support ass'y:

35" - 50" 21294 _______

20" - 35" 18885 _______

20" - 49.25" 18884 _______

20" - 63.5" 18883 _______

Boring bar assemblies, 5" dia. bars:

8 ft (2.4 m) 20344 _______

10 ft (3.1 m) 20346 _______

12 ft (3.7 m) 20347 _______

14 ft (4.3 m) 20348 _______

16 ft (4.9 m) 20349 _______

18 ft (5.5 m) 20350 _______

20 ft (6.1 m) 20351_______

Tool carrier assembly, 5" dia. bar:

15567 _______

Tool head assembly:

5" boring head assembly:

9" - 40" ID 15537 _______

9" - 28" ID 18690 _______

8

BB7000 Components

Order # Description

Hydraulic motor

High torque, low speed

hydraulic motor mounts

directly to the rotational

drive assembly. Motor ports

are 7/8-14 SAE O-ring type.

Fittings are included with the

hydraulic power unit. Reverse

motor rotational by switching

the hydraulic hoses at the

motor. Motors can be used

on both 4" and 5" diameter

bar machines. Hydraulic fluid

lubricates the motor during

operation. RPM ratings are

maximum for boring bar at 20

gpm (75.8 L/min). Torque

ratings are constant.

Calculated values shown.

25472 Motor, hydraulic - 3.6 in3,

97 bar rpm, 390 ft-lb

25473 Motor, hydraulic - 5.7 in3,

61 bar rpm, 625 ft-lb

25474 Motor, hydraulic - 7.3 in3,

48 bar rpm, 806 ft-lb

25475 Motor, hydraulic - 8.8 in3,

40 bar rpm, 966 ft-lb

25476 Motor, hydraulic - 11.4 in3,

31 bar rpm, 1240 ft-lb

25477 Motor, hydraulic - 13.7 in3,

25 bar rpm, 1596 ft-lb

25478 Motor, hydraulic - 18.2 in3,

19 bar rpm, 2150 ft-lb

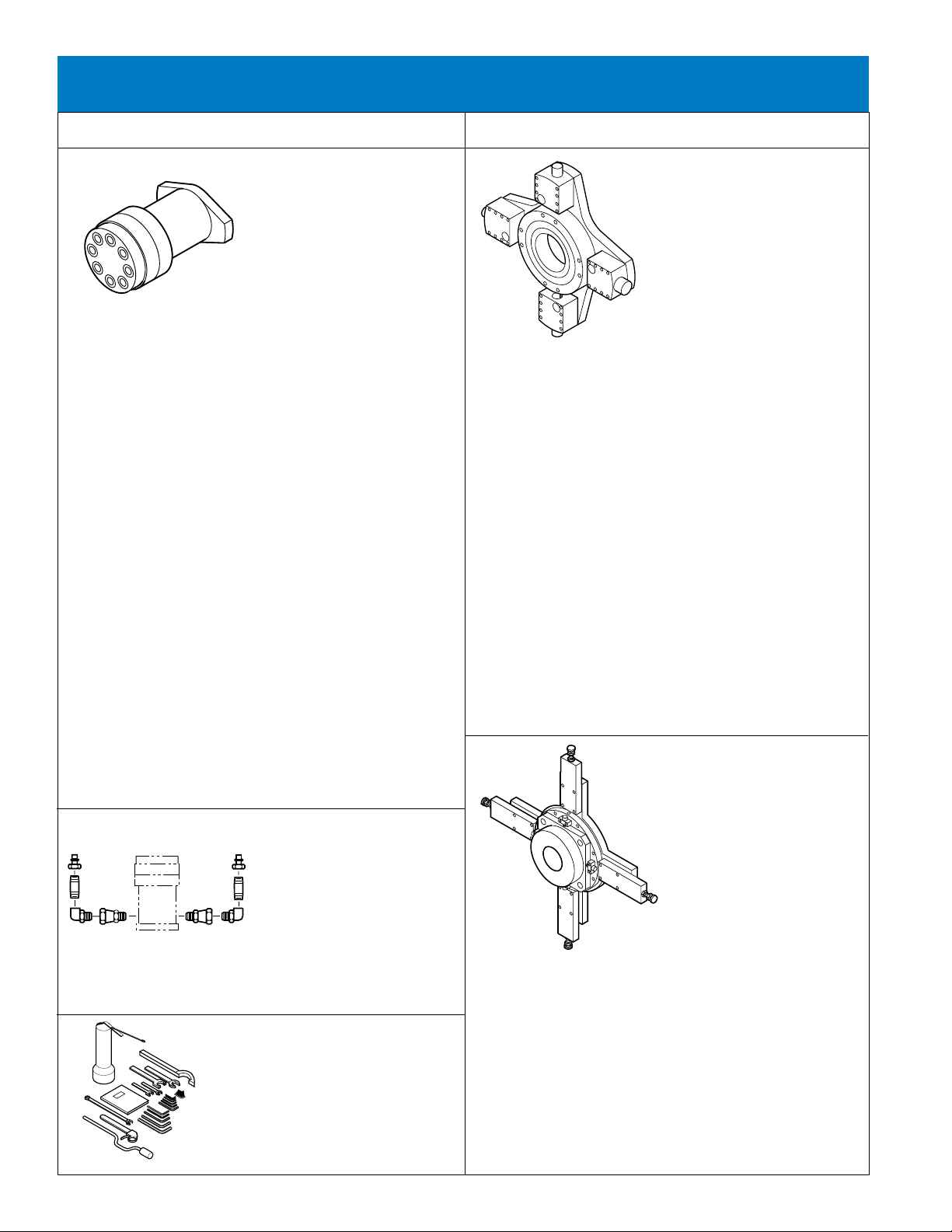

25587 Hydraulic motor fitting kit

3/4" fittings Kit includes

fittings needed to connect

any hydraulic motor listed

above to hydraulic power

units that have 3/4" female

quick disconnect fittings.

Fittings are included with

every Climax hydraulic power

unit.

15762 Tool kit

Complete set of tools needed

to operate the BB7000

Portable Boring Bar.

Individual parts listed below.

Order # Description

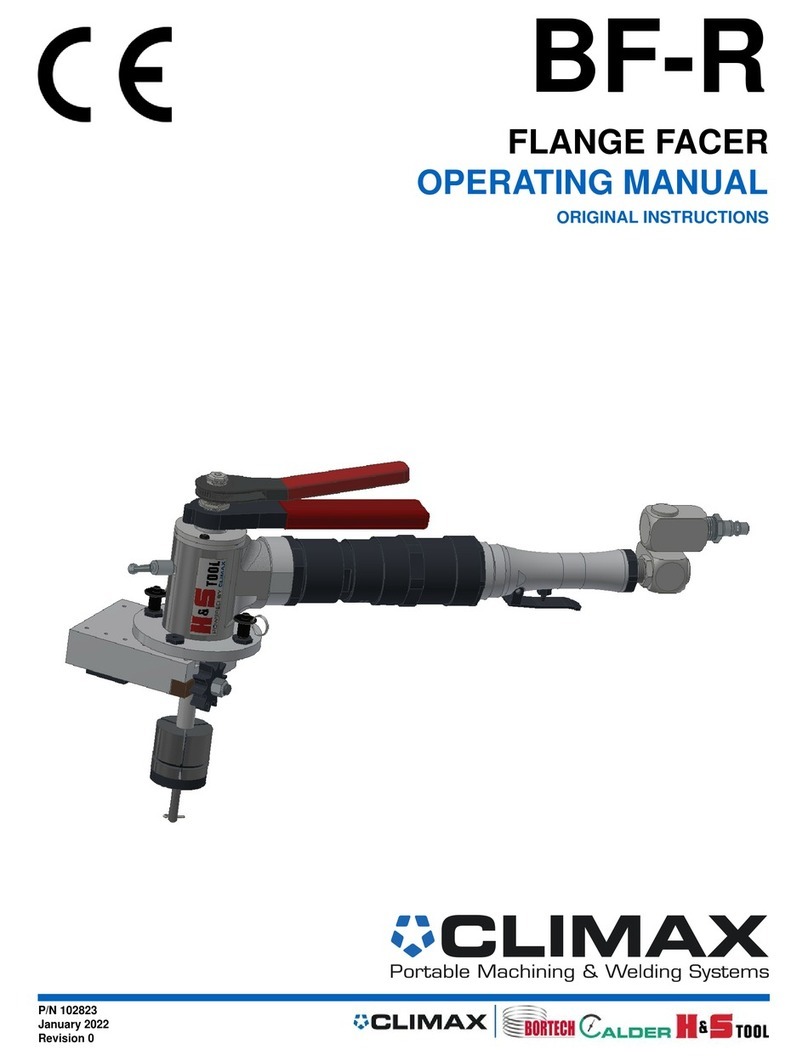

ID-mount self-aligning

bearing support assembly

with jaws Support assembly

mounts to the inside bore of

the work piece. Bar is held in

place by a self-aligning bearing

assembly. Center the bar by

adjusting the four jaws on the

support spider. Adjustments

can be made from outside the

bore.

18886 4" ID-mount bearing support

assembly , 20" - 35" (508

- 899 mm) ID's

19565 4" ID-mount bearing support

assembly , 20" - 49.25" (508

- 1251 mm) ID's

19566 4" ID-mount bearing support

assembly , 20" - 63.5" (508

- 1613 mm) ID's

18885 5" ID-mount bearing support

assembly , 20" - 35" (508

- 889 mm) ID's

18884 5" ID-mount bearing support

assembly , 20" - 49.25" (508

- 1251 mm) ID's

18883 5" ID-mount bearing support

assembly , 20" - 63.5" (508

- 1613 mm) ID's

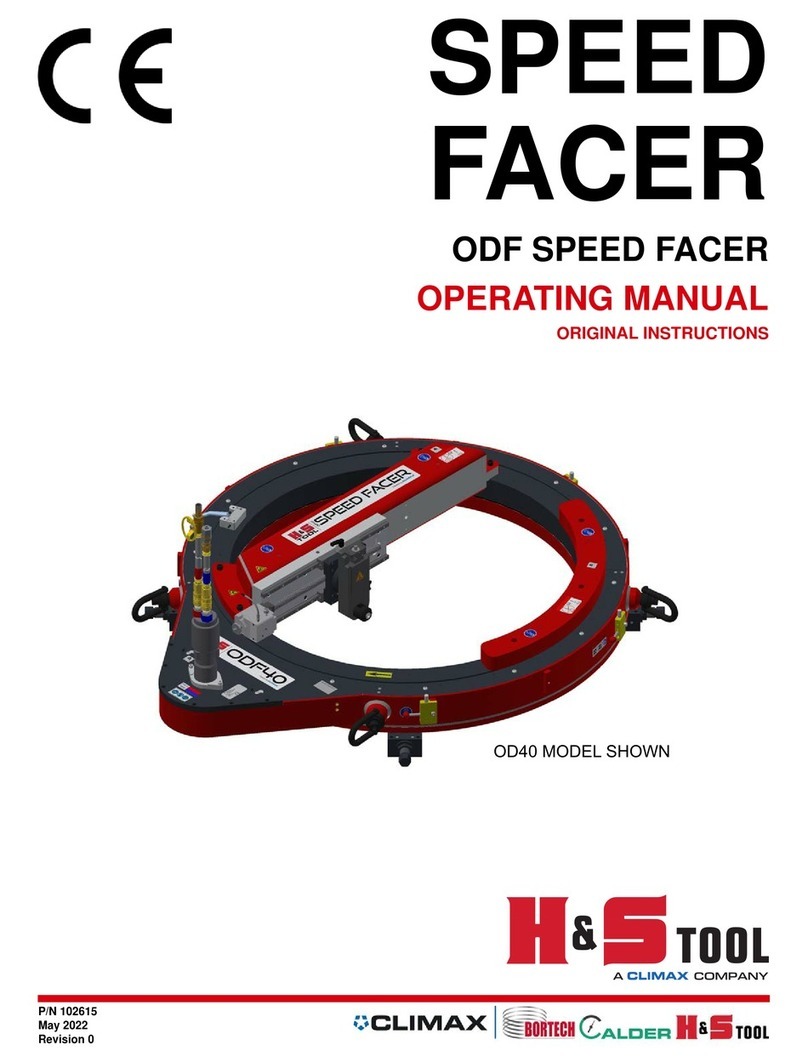

ID-mount self-aligning

bearing support assembly

with jacking screw legs

Support assembly mounts to

the inside bore of the work

piece. Bar is held in place by a

self-aligning bearing assembly.

Center the bar by adjusting

the four jacking screw legs.

Adjustments can be made from

outside the bore.

21232 4" ID-mount bearing support

assembly , 10" - 20" (254

- 508 mm) ID's

21926 4" ID-mount bearing support

assembly , 10" - 30" (254

- 763 mm) ID's

21927 4" ID-mount bearing support

assembly , 10" - 40" (254

- 1016 mm) ID's

21294 5" ID-mount bearing support

assembly , 35" - 50" (889

- 1270 mm) ID's