P/N: 57017, Rev. 3 Page i

TABLE OF CONTENTS

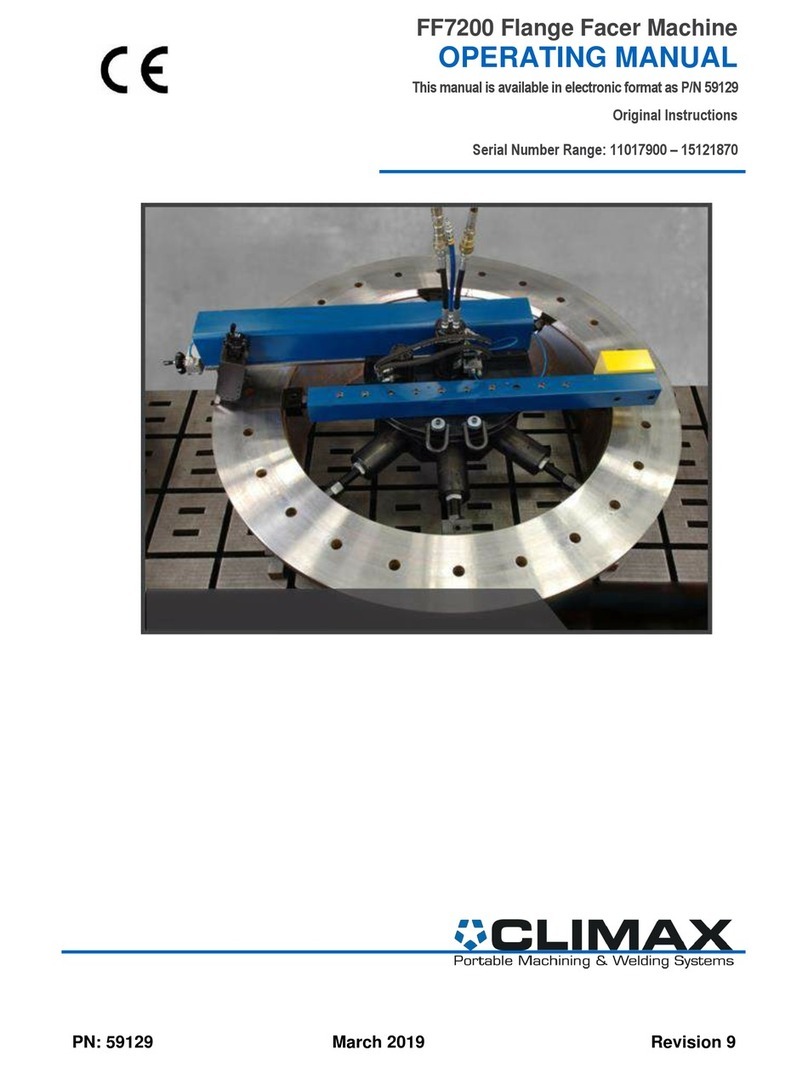

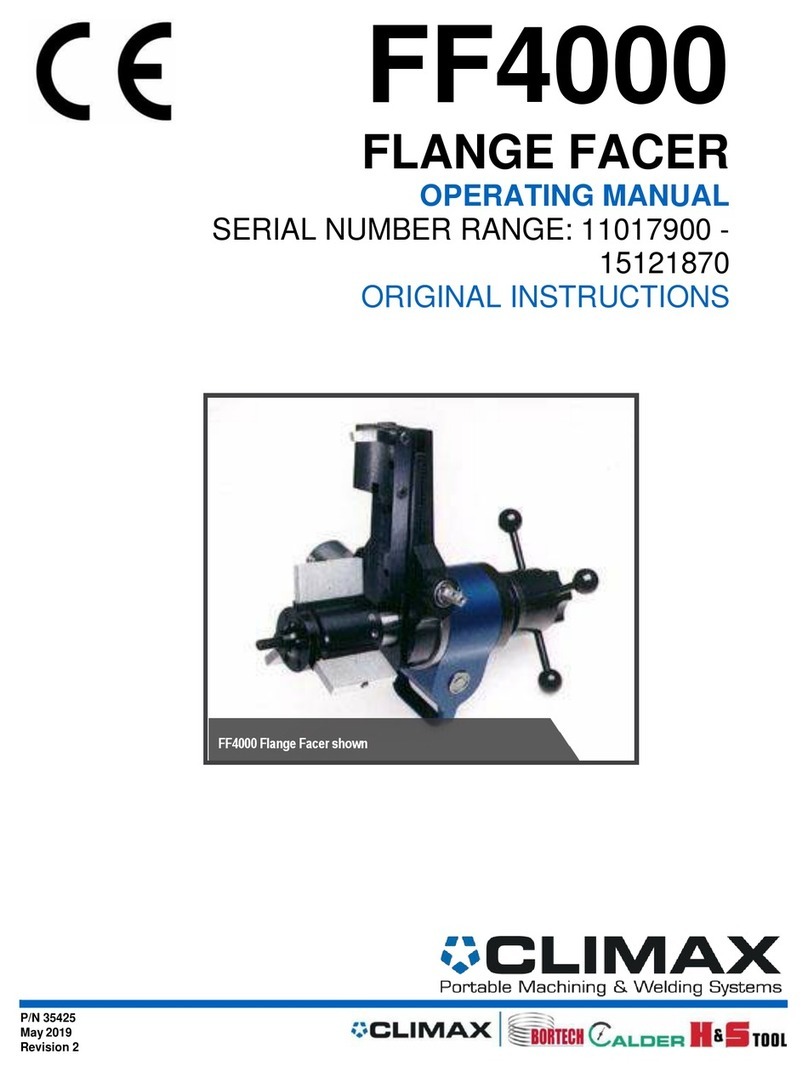

1INTRODUCTION ....................................................................................................................1

1.1 Limited Warranty.......................................................................................................................................1

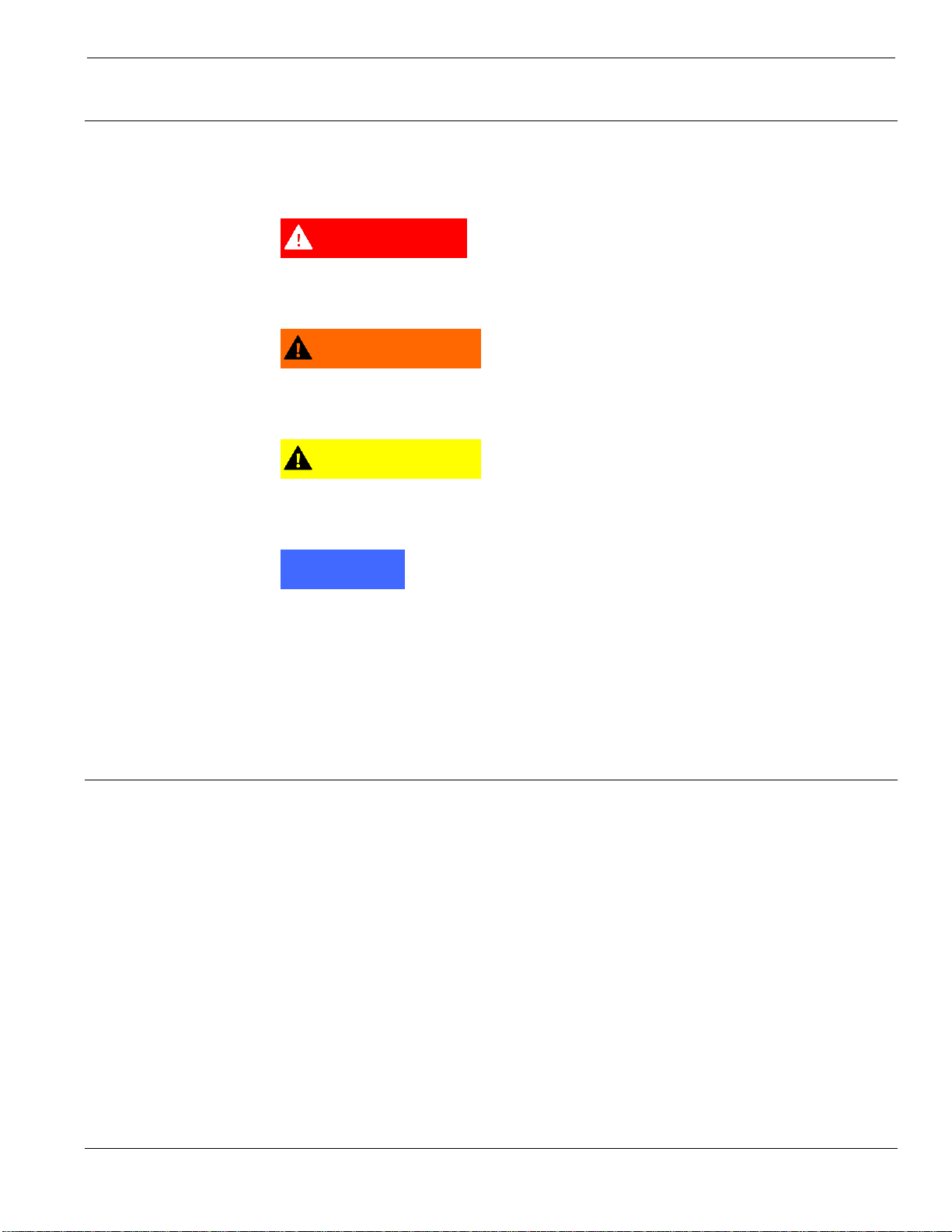

1.2 Alerts .........................................................................................................................................................2

1.3 Safety Precautions .....................................................................................................................................2

1.4 Machine Specific Safety Practices............................................................................................................. 3

1.5 Risk Assessment and Hazard Mitigation...................................................................................................5

1.6 Risk Assessment Checklist........................................................................................................................6

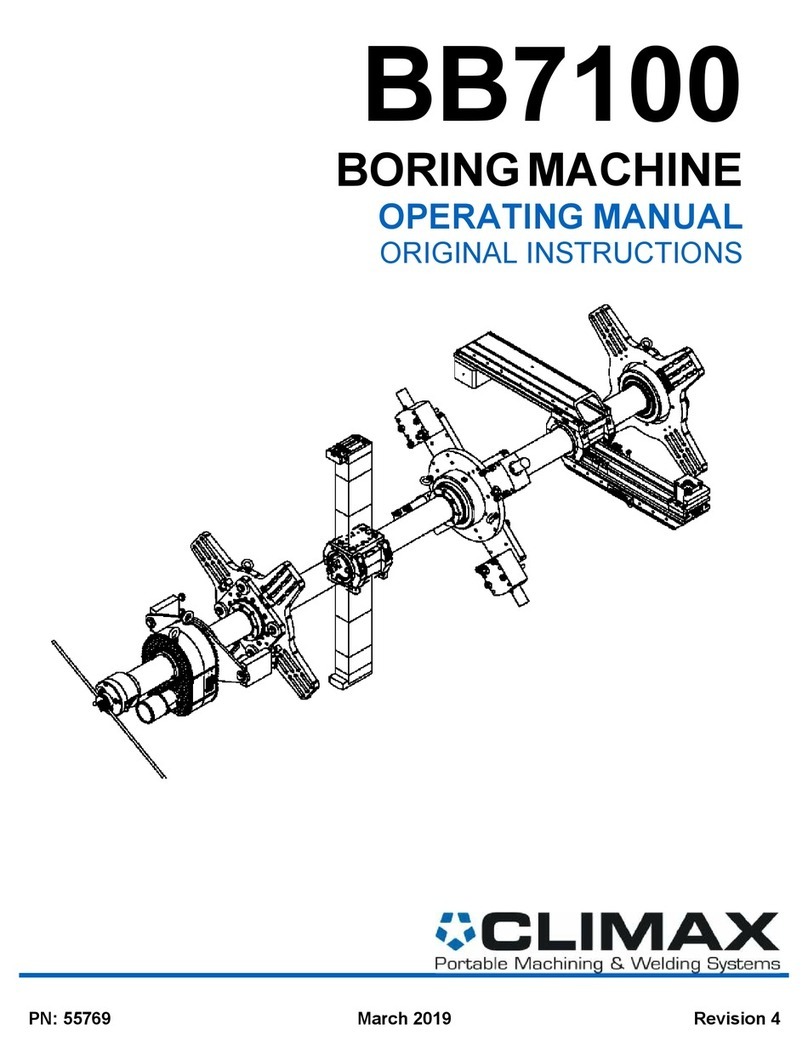

2OVERVIEW ............................................................................................................................7

2.1 About this manual......................................................................................................................................8

2.1.1 Recommended tools ..............................................................................................................................8

2.2 Receipt and inspection...............................................................................................................................8

2.3 Specifications and Dimensions.................................................................................................................. 9

2.4 Axial Feed Assembly................................................................................................................................. 14

3SETUP..................................................................................................................................15

3.1 Clamp collars.............................................................................................................................................15

3.2 About Boring Machine Support................................................................................................................. 15

3.3 Installing End-mount Bearing Support......................................................................................................16

3.3.1 To install the end-mount bearing support............................................................................................16

3.3.2 Clamping the bearing assembly to the bar...........................................................................................19

3.4 ID-mount bearing support..........................................................................................................................19

3.4.1 If mounting an end-mount bearing ......................................................................................................23

3.4.2 Clamping the bearing assembly to the bar...........................................................................................23

3.5 Preload bearing kit..................................................................................................................................... 23

3.6 RDU Setup................................................................................................................................................. 24

3.7 Mounting the Mechanical Axial Feed Unit ...............................................................................................26

3.7.1 Setting feed direction and rate.............................................................................................................27

3.7.2 Neutral (no feed)..................................................................................................................................27

3.7.3 Feed away from the axial feed unit......................................................................................................27

3.7.4 Feed toward the axial feed unit............................................................................................................28

3.7.5 Disengaging the feed under load .........................................................................................................28

3.7.6 Setting the feed rate.............................................................................................................................28

3.7.7 Stopping the feed.................................................................................................................................29

3.8 Mounting the Electric Axial Feed Assembly.............................................................................................29

3.8.1 Setting the Axial Feed Rate.................................................................................................................31

3.9 Tool Head Setup ........................................................................................................................................ 31

3.9.1 Small bore tool carrier setup................................................................................................................31

3.9.2 Small bore tool carrier boring head setup............................................................................................32

3.10 Micro-adjust boring head...........................................................................................................................33

3.11 Boring head setup ......................................................................................................................................36

3.11.1 To lock the tool carrier on the bar for other operations.......................................................................38

3.11.2 Do the following to remove the brass nut:...........................................................................................38

3.12 Install the slide arm onto the tool carrier ................................................................................................... 39

3.13 Adjusting the tool carrier for perpendicularity ..........................................................................................40

3.14 Feedbox assembly......................................................................................................................................40

3.15 Feedbox and trip arm set-up ......................................................................................................................40

3.16 Mechanical facing head setup....................................................................................................................40