Clinch Rivets CR-2 User manual

Page 1 of 11

CR-2 Instruction Manual

Effective Dec 19th 2013

Page 2 of 11

Contents:

Tool Properties

Technical Specifications

Safety Instructions

Tool Preparation

Operating Instructions

Maintenance and Service

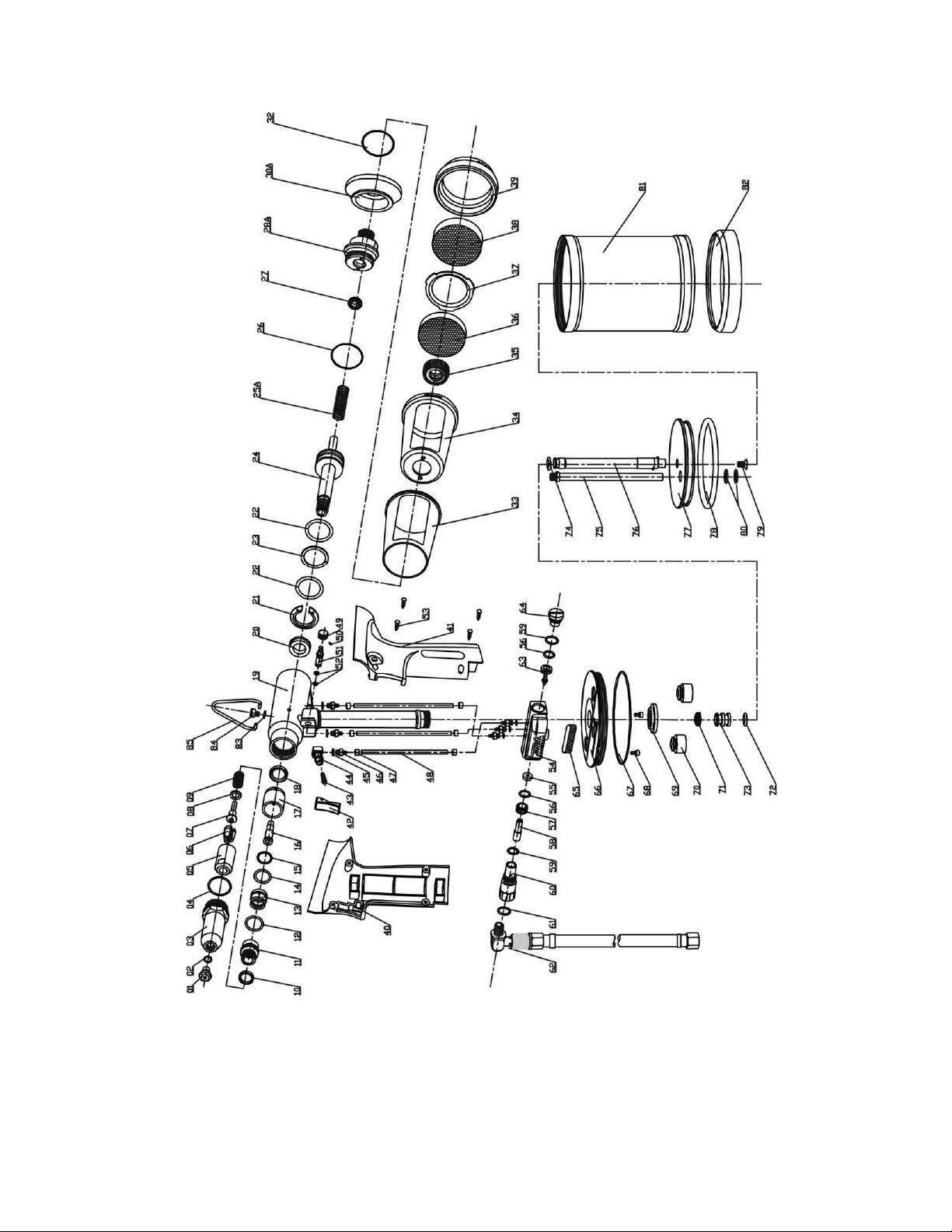

Exploded Drawing

Parts List

3

4

5

6

7

8

10

11

Page 3 of 11

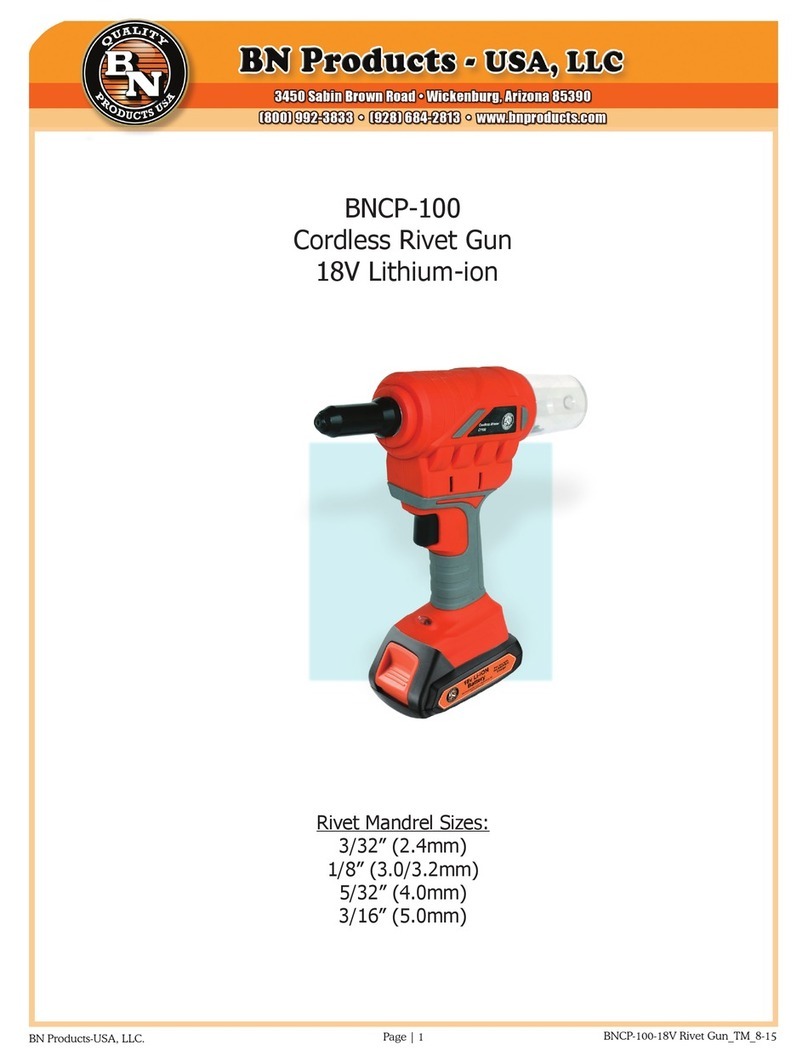

Tool Property:

Light weight

High-speed operation, high power

Low noise

Shock absorption

Long stroke

Easy maintenance

Sets standard rivets up to 3/16” diameter into any materials

Designed for high strength blind rivet with 3/16” diameter i.e. monobolt, interlock, etc

Adjustable vacuum system for powering on and off mandrel retention function

The tool can operate without the mandrel container

The tool can mount the rivet in single operation

Effective air pressure is 44 to 102 psi

Max pull force is 2473 lb

CNC machined quality components ensures long life

Mandel container can be turned easily for cleaning

Page 4 of 11

Technical Specification:

Rivet size: Diameter 0.125 –1.89 inches for standard rivets

Diameter 0.189 inches for high strength structural blind rivet

Air pressure: 11.0 –15.4 lbf

Stroke: 0.787 inches

Pull force @ 5 Bar: 2472 lb

Weight: 3.20 lb

Page 5 of 11

Safety Instructions:

Please read the following instructions carefully.

Never dissemble the tool without reading the following safety instructions.

Always use the tool in accordance with the specified safety instructions. Direct any

queries regarding safety and operation to our company.

Never connect the tool to any medium other than compressed air. Set the air pressure

between 42 to 101 psi.

Do not use the tool for purpose other than installing rivets.

The tool must be maintained in a safe working condition at all times and examined at

regular intervals for damage.

Do not dismantle this tool without prior reference to the maintenance and service

instructions.

Always disconnect the air pipe from the tool inlet before maintenance and service.

Do not point tool towards people or persons.

When using the tool, wear safety glasses.

Page 6 of 11

Tool Preparation:

The tool must be connected to an air filter. This unit filters the compressed air to separate dirt

and condensate. A pressure regulator with a preferred setting of 87 psi must be installed. Air

supply must be free of moisture and particles.

Use dry and clean materials (hose, couplings, fittings, etc.) to connect the tool to the filter.

Check for leakage in the compressed air supply. If here is leakage, replace the damaged hoses

or coupling. Drain the condensate from the filter. Also check the dirt filter.

Check the compressed air supply pressure. The tool must be fitted with correct nosepiece (01)

and pusher (07) before operating.

Page 7 of 11

Operating Instruction:

1. Connect the air supply, switch ON/OFF vale (48) to ON position. (See figure 1)

2. Adjust the vacuum security system clockwise or counter-

clockwise. Air suction will allow the rivet to be held in any orientation.

(See figure 2)

Attention: If you don’t want to use vacuum system, you can turn

vacuum security system clock wise and turn it off.

3. Direct the riveter with rivet to the hole and then pull the trigger. The stems

automatically reverse to the collector and the rivet is set.

Fig 1

Fig 2

Page 8 of 11

Priming:

After 100,000 cycles, the stroke is reduced and rivets are not set by one operation, then the

tool needs to be oiled. Please use the attached bottle of lubrication oil in the box.

1. Disconnect air supply to tool and switch ON/OFF valve (48) to OFF position.

2. Remove seal screw (84) and seal (83). (See figure 3)

3. Screw the priming pump oil into the bleed screw hole.

Press down and release several times until resistance is felt.

(See figure 4)

4. Remove the priming pump and the excessive oil will

flow out. Clean out the excessive oil and replace the seal

screw and seal.

Fig 3

Fig 4

Page 9 of 11

Head Cleaning and Oiling:

Every 10,000 cycles the tool should be oil on the jaws. (See figure 5)

1. Disconnect air supply and air valve switch.

2. Dismantle the riveter head by wrench.

3. Use wrench to disassemble head components and cleaning these parts, and then

lubricate them before assembling. (See figure 5)

Trouble Shooting

Symptoms

Possible Causes

Solutions

The jaws cannot release the

mandrel

The nosepiece, jaws, jaw

carrier and out cylinder

may not be assembled

correctly

The spring may be worn

out or broken

The oil may be insufficient

There is oil or air leakage

somewhere

Check the nosepiece,

jaws, jaw carrier and out

cylinder

Replace the defective

coupling and components

Add hydraulic oil

The rivet cannot be put into

the tool nosepiece

The stem may be

obstructed

The vacuum system may

not be in good condition

Check the jaws

Adjust the vacuum

security system to the

optimal volume

The tool works very slowly or

requires more than one

trigger-pull to set the rivet.

Hydraulic oil level is low

The air pressure is low

The nosepiece is filled

with dust and particles

Add hydraulic oil

Adjust air pressure to the

specific range

Clean and oil

Fig 5

Page 10 of 11

Page 11 of 11

Parts list:

PART NO.

DESCRIPTION

PART NO.

DESCRIPTION

CR-2-01

Nosepiece

CR-2-44

On/Off base

CR-2-02

O-ring (meas. 9*1)

CR-2-45

O-ring (meas.6*1)

CR-2-03

Nosepiece casing

CR-2-46

Air interface

CR-2-04

O-ring (meas.22*2)

CR-2-47

Tie ring

CR-2-05

Jaw housing

CR-2-48

Air tube

CR-2-06

Jaws

CR-2-49

Regulatable button

CR-2-07

Pusher

CR-2-50

Retaining screw (meas.3*3)

CR-2-08

Washer

CR-2-51

Vacuum valve

CR-2-09

Jaw pusher spring

CR-2-52

O-ring (meas.4*6*1)

CR-2-10

Lock ring

CR-2-53

Tapping screw (meas.3*10)

CR-2-11

Housing

CR-2-54

Air valve body

CR-2-12

Polyurethane ring (meas.16*2)

CR-2-55

Air valve ring

CR-2-13

Set nut

CR-2-56

O-ring (meas.9.5*12.5*1.5)

CR-2-14

Polyurethane ring (meas.14.3*2)

CR-2-57

Air valve base

CR-2-15

O-ring (meas.13*16*1.5)

CR-2-58

Subordinate tube

CR-2-16

Vacuum sleeve

CR-2-59

O-ring (meas.11.5*14.5*1.5)

CR-2-17

Seal plastic housing

CR-2-60

Connecting base

CR-2-18

Seal (meas.20.5*13.5*3.5)

CR-2-61

O-ring (meas.14*2.4)

CR-2-19

Head assembly

CR-2-62

On/Off assembly

CR-2-20

Lip seal (meas.14*11*6.3)

CR-2-63

Air valve rod

CR-2-21

Retaining nut

CR-2-64

Screw plug

CR-2-22

O-ring (meas.26.7*30.26*1.78)

CR-2-65

Silencer

CR-2-23

Lip seal (meas.22*30*6)

CR-2-66

Cylinder cover

CR-2-24

Axis

CR-2-67

O-ring (meas.66*2)

CR-2-25A

Restore Spring

CR-2-68

Bolt

CR-2-26

O-ring (meas.35*1.5)

CR-2-69

Rock nut

CR-2-27

EL (meas.8*14.2*5)

CR-2-70

Buffer

CR-2-28A

End cap

CR-2-71

Lip seal (meas.8*14*6)

CR-2-30A

Stem collector adaptor

CR-2-72

O-ring (meas.11.5*1.5)

CR-2-32

O-ring (meas.47*1.5)

CR-2-73

Air tube piston

CR-2-33

Stem collector outer

CR-2-74

Piston ring

CR-2-34

Stem collector body

CR-2-75

Transfer tube

CR-2-35

Retaining nut

CR-2-76

Piston rod

CR-2-36

Silencer

CR-2-77

Cylinder piston

CR-2-37

Stem collector end cap

CR-2-78

O-ring (meas.74.6*86*5.7)

CR-2-38

Silencer

CR-2-79

Bolt (meas.6*10)

CR-2-39

Silencer cap

CR-2-80

O-Ring

CR-2-40

Handle (left)

CR-2-80

Cylinder

CR-2-41

Handle (right)

CR-2-82

Base cover

CR-2-42

Trigger

CR-2-83

BS (meas.5.7*10*1)

CR-2-43

Trigger valve

CR-2-84

Seal screw

CR-2-85

Hook

Note: Part numbers 25, 28, 30, and 62 have been upgraded, and part numbers 29 and 31 were

removed after December 2013.

This manual suits for next models

1

Table of contents

Other Clinch Rivets Rivet Tools manuals

Popular Rivet Tools manuals by other brands

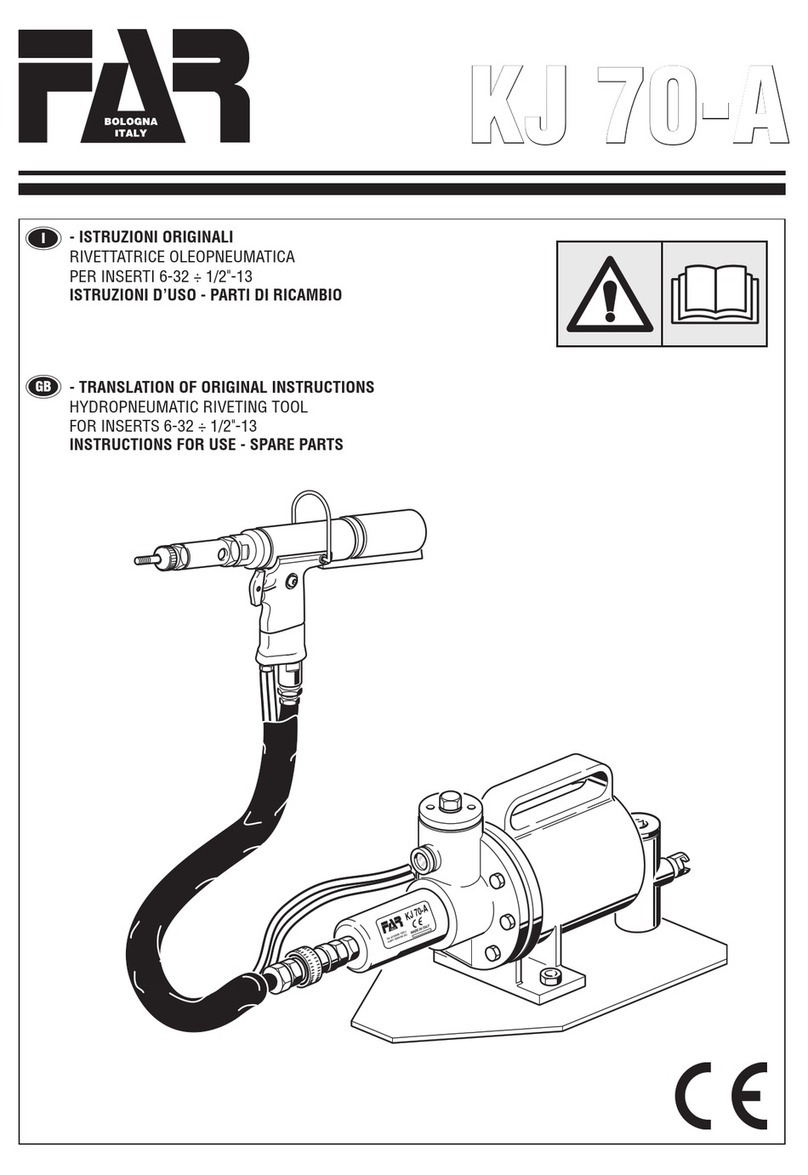

FAR

FAR KJ 70-A TRANSLATION OF ORIGINAL INSTRUCTIONS

Gesipa

Gesipa PowerBird Operating manual with spare parts list

TKR Group

TKR Group VAS 6790/1 Original instructions

Gesipa

Gesipa FireBird Gold Edition operating instructions

Titgemeyer

Titgemeyer RIVETEC RL 50 operating manual

FAR

FAR KJ 73-A TRANSLATION OF ORIGINAL INSTRUCTIONS