Bollhoff Portable C RIVSET User manual

Portable C

RIVSET ®

(10 - 50 kN)

WELTAC ®

(10 - 50 kN)

HE.18644_A © 04/2020 R&D-2

H

E.18644_A

©

04

/

2020 R

&

D-

2

HE.18642

Böllhoff Automation GmbH

Archimedesstr. 1 - 4 • D-33649 Bielefeld

BöllhoffAutomation GmbH Tel. +49 (0)521 / 44 82- 611

Archimedesstr. 1 - 4 Fax +49 (0)521 / 44 82- 297

D-33649 Bielefeld Mail: fuegetechnik@boellhoff.com

Instruction Manual US

Mode d´emploi CDN

Bedienungsanleitung D

Instruction Manual GB

Mode d´emploi F

Istruzioni d’uso I

Návod na obsluhu SK

Serialnumber

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

Kapitel

chapter

Seite

page

Beschreibung der Komponenten

Description of the components

Description des composants I

Übersicht Werkzeuge / C-Köpfe

Overview tools / C-heads

Vue d‘ensemble des outils / têtes C II

Techn. Zeichnung / Typenschilder / Ladegeräte / Akkus

Technical drawing / Decals / Charging unit / Battery

Croquis techniques / plaques signalétiques / chargeur / batterie III

Allgemeine Hinweise / General information / Renseignements d‘ordre général IV

Display und i-press / Display and i-press / Affichage et i-press V

Demontage des Kopfes

Disassembly of the head

Désassemblage de la tête VI

Nieten / Riveting / rivetage VII

Nieten mit Gurtzuführung TF 3 oder TF5 / Wartungshinweise

Riveting with the tape feed mechanism TF3 or TF5 / Service maintenance

Rivetage avec le méc. d‘alimentation de sangle TF3 ou TF5 / Maintenance VIII

Gurtzuführung TF 3 oder TF5 / Wartungshinweise

tape feed mechanism TF3 or TF5 / Service maintenance

mécanisme d‘alimentation de sangle TF3 ou TF5 / Maintenance

IX

Einstellung der Gurtzuführung

Set up belt feed

Réglage d‘alimentation de sangle X

Einfädeln des Nietgurtes

Insert tape feed

Insertion de sangle XI

Nietvorgang mit Gurtzuführung

Riveting cycle with belt feed

Cycle de rivetage avec alimentation de sangle XII

Übersicht Gurtzuführung TF3 / TF5

Overview tape feed mechanism TF3 / TF5

Vue d‘ensemble du mécanisme d‘alimentation de sangle TF3 / TF5 XIII

Beschreibung der Werkzeugindikation

Description of the tool indication

Description de l‘indication de l‘outil XIV

Wichtige Sicherheitshinweise

Important safety information

Informations importantes relatives à la sécurité 1-2

Bedienungsanleitung

Instruction manual

Notice d‘instructions 3-6

Wichtige Sicherheitshinweise

Important safety information

Informations importantes relatives à la sécurité 1-2

Bedienungsanleitung

Instruction manual

Notice d‘instructions 3-6

Bedienungsanleitung

Instruction manual

Notice d‘instructions

Istruzioni d’uso

Návod na obsluhu

1-4

1-4

1-4

1-4

1-3

Konformitätserklärung

Declaration of conformity

Déclaration de conformité 1

US

CDN

D

GB

F

I

SK

CE

originalbedienungsanleitung

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

optional:

NG2

RIVSET ®

RIVSET ®WELTAC ®

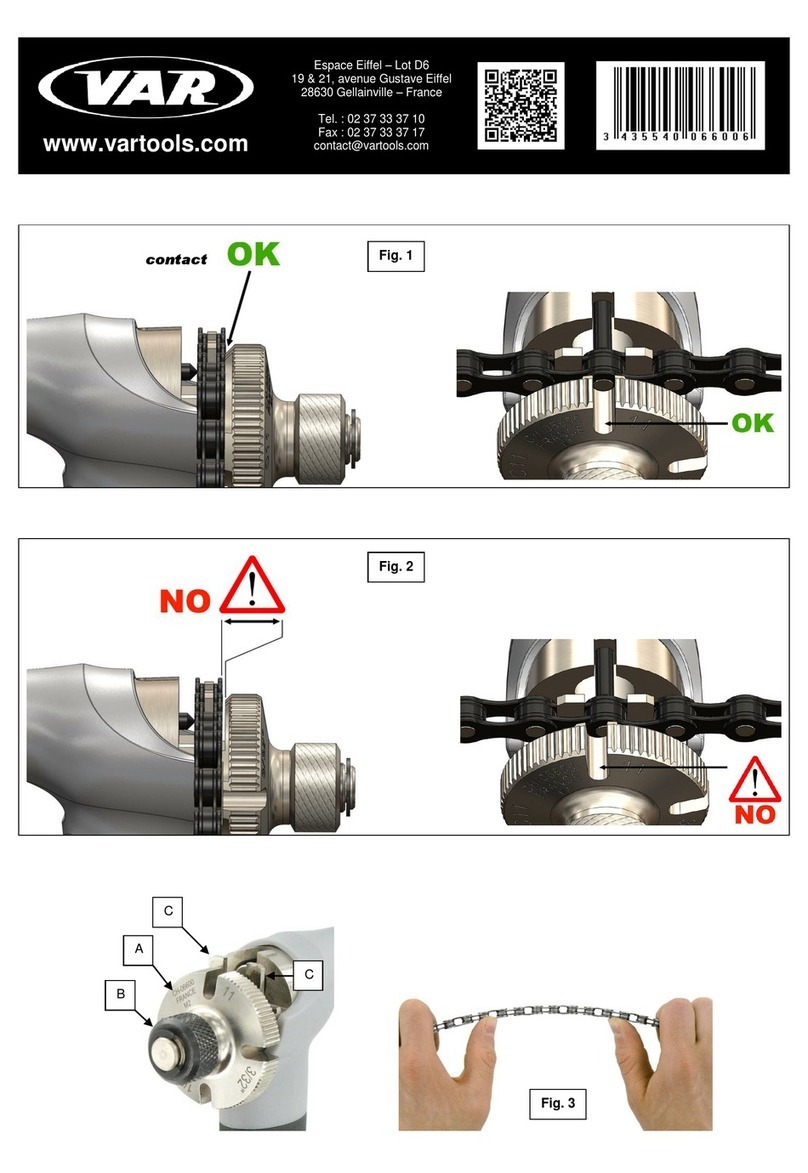

8a Stempel und Matrize zum Nieten

Punch and die for riveting

Poinçon et matrice pour le rivetage

8b Gurtzuführung zum Nieten

Riveting with the tape feed mechanism

Mécanisme d‘alimentation de sangle pour le rivetage

optional:

NG

2

8a

Stempel

und

Matrize

zum

Nieten

Punch and die

f

or rivetin

g

Poinçon et matrice pour le rivetag

e

RI

VS

ET

®

WE

LT

AC

®

Mé

can

i

sme

d‘

a

li

men

t

a

ti

on

d

e san

gl

e pour

l

e r

i

ve

t

a

ge

I

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

10 - 50 kN

Krafteinstellung

Force adjustment screw

Ajustage de pression

ACHTUNG! Garantiesiegel

Bei Beschädigung Garantieverlus

t

ATTENTION! Warranty seal

If broken loss of Warranty

HE.17537

A

AC

AC

A

AC

AC

A

AC

A

AC

C

C

AC

AC

A

C

AC

A

HT

HT

HT

H

HT

H

HT

H

H

H

T

T

T

H

H

H

H

HT

HT

UNG!

UNG!

UNG!

UNG!

UNG!

UN

UNG

N

NG

NG!

NG

G

G

!

UNG!

UNG!

Garantiesi

Garanties

Garanties

Garanties

Garan

G

Garantie

Garanties

a

a

arantie

ar

ranties

ra

ant

a

an

ntiesi

t

i

e

e

i

i

Garantiesi

Garantiesi

eg

egel

e

g

g

e

e

e

e

g

Bei Beschä

digung Gar

gg

antieverlu

st

ATTENTION!

Warranty seal

If broken loss of Warranty

HE.17537

ACHTUNG! Garantiesiegel

Bei Beschädigung Garantieverlus

t

ATTENTION! Warranty seal

If broken loss of Warranty

HE.17537

HE.17537

batch# e.g.

304711

datecode e.g.

P = 2020; R = April

consecutive# e.g.

„142“ = tool # 142

datecode

Year Code Month Code Month Code

2018 M Jan. N July V

2019 N Feb. P Aug. W

2020 P Mar. Q Sept. X

2021 Q Apr. R Oct. Y

2022 R May S Nov. Z

2023 S June T Dec. 1

Auf dem Knapp 46

D-42855

Remscheid

304711

PR

142

13

10 11

xx

2

4

56

9

7

= see Tab. 1

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

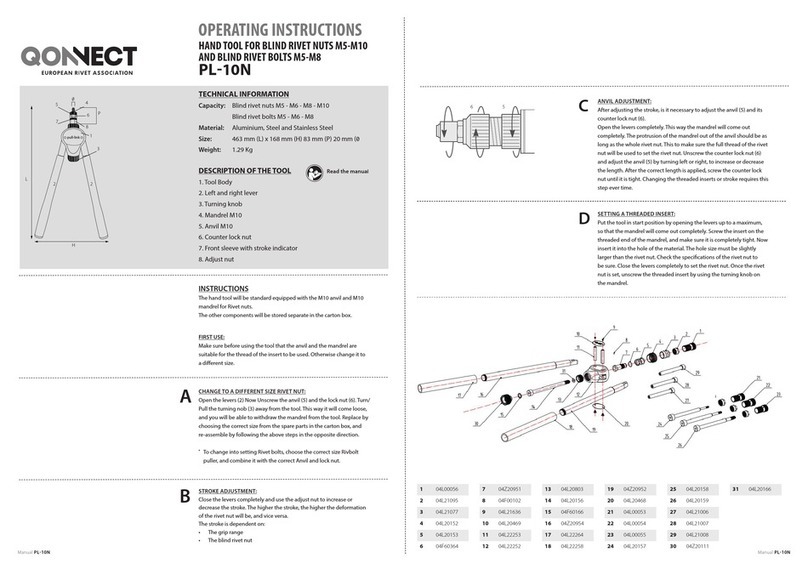

Artikelnummer Klauke Zuführung Nietgröße [mm] a

[mm]

see

pict.

f

[mm]

see

pict.

Stanznietkopf

Partnumber Klauke Feeding Rivetsize [mm] Riveting head

Réf. Klauke Rivet Dimension rivet Tête de rivetage

BH100NGM TF3 3 35 84 SNKT35D84TFBH

BH101NGM TF5 5 35 84 SNKT35D84TFBH

BH102NGM TF3 3 220 81 SNKT220D81TFBH

BH103NGM TF5 5 220 81 SNKT220D81TFBH

BH104NGM TF3 3 35 108 SNKT35D108TFBH

BH105NGM TF5 5 35 108 SNKT35D108TFBH

BH106NGM TF3 3 80 84,5 SNKT80D85TFBH

BH107NGM TF5 5 80 84,5 SNKT80D85TFBH

BH108NGM TF3 3 131 147 SNKT131D147TFBH

BH109NGM TF5 5 131 147 SNKT131D147TFBH

BH110NGM TF3 3 220 133,5 SNKT220D134TFBH

BH111NGM TF5 5 220 133,5 SNKT220D134TFBH

Zulässige Nietgeometrie für TF: / Permissible rivet geometry for TF: / Géométrie de rivet admissible pour TF:

TF3: TF5:

J 3,3 x 5,0 CSR H4* C 5,3 x 5,0 CSR H4 K 5,3 x 7,0 CSR H4 P 5,2 x 5,0 CS H4 HD2 5,3 x 5,0 CS H4 HD3 5,2 x 5,5*

J 3,3 x 6,0 CSR H4 C 5,3 x 5,5 CSR H4 K 5,3 x 7,5 CSR H4 P 5,2 x 6,0 CS H4* HD2 5,3 x 5,5 CS H4*

J 3,3 x 7,0 CSR H4 C 5,3 x 6,0 CSR H4 K 5,3 x 8,0 CSR H4* P 5,2 x 7,0 CS H4* HD2 5,3 x 6,0 CS H4*

C 5,3 x 6,5 CSR H4 K 5,3 x 9,0 CSR H4* P 5,2 x 8,0 CS H4* HD2 5,3 x 7,0 CS H4*

K 5,3 x 10,0 CSR H4*

* = Achtung maximale und minimale Setzkraft prüfen / Attention check maximum and minimum setting force /

Contrôle d‘attention force de réglage maximale et minimale

Der Lieferant des Handgerätes übernimmt keine Gewährleistung für die Qualität der damit erzeugten Verbindung! / The supplier of the handtool does not

guarantee the quality of the joint created with it! / Le fournisseur de l‘outil à main ne garantit pas la qualité de la connexion créée avec celui-ci !

Alle anderen Nietformate müssen beim Lieferanten angefragt werden. / All other rivet formats must be requested at the supplier. /

Tous les autres formats de rivets doivent être demandés au fournisseur.

Zulässige Nietgeometrie für SNSM: / Permissible rivet geometry for SNSM: / Géométrie de rivet admissible pour SNSM:

SNS3M: SNS5M:

S 3,3 x 3,0 CSR H4* S 5,3 x 3,5 CSR H4* K 5,3 x 7,0 CSR H4 P 5,2 x 5,0 CS H4* HD2 5,3 x 4,5 CS H4 HD3 5,2 x 5,0 H4*

C 3,3 x 3,5 CSR H4* C 5,3 x 4,0 CSR H4* K 5,3 x 7,5 CSR H4 P 5,2 x 6,0 CS H4* HD2 5,3 x 5,0 CS H4* HD3 5,2 x 5,5 H4*

C 3,3 x 4,0 CSR H4* C 5,3 x 4,5 CSR H4* K 5,3 x 8,0 CSR H4* P 5,2 x 7,0 CS H4* HD2 5,3 x 5,5 CS H4* HD3 5,2 x 6,0 H4*

C 3,3 x 4,5 CSR H4* C 5,3 x 5,0 CSR H4 K 5,3 x 9,0 CSR H4* P 5,2 x 8,0 CS H4* HD2 5,3 x 6,0 CS H4* HD3 5,2 x 7,0 H4*

J 3,3 x 5,0 CSR H4* C 5,3 x 5,5 CSR H4 K 5,3 x 10,0 CSR H4* HD2 5,3 x 7,0 CS H4* HD3 5,2 x 8,0 H4*

J 3,3 x 6,0 CSR H4 C 5,3 x 6,0 CSR H4 K 5,3 x 12,0 CSR H4*

J 3,3 x 7,0 CSR H4 C 5,3 x 6,5 CSR H4

* = Achtung maximale und minimale Setzkraft prüfen / Attention check maximum and minimum setting force /

Contrôle d‘attention force de réglage maximale et minimale

Der Lieferant des Handgerätes übernimmt keine Gewährleistung für die Qualität der damit erzeugten Verbindung! / The supplier of the handtool does not

guarantee the quality of the joint created with it! / Le fournisseur de l‘outil à main ne garantit pas la qualité de la connexion créée avec celui-ci !

Alle anderen Nietformate müssen beim Lieferanten angefragt werden. / All other rivet formats must be requested at the supplier. /

Tous les autres formats de rivets doivent être demandés au fournisseur.

Für Portable 2in1 Anwendungen gilt: mit dem SNS5M lassen sich zusätzlich WELTAC®Verbindungselemente setzen - Verbindungselemtgeometrie auf

Anfrage. / For Portable 2 in1 applications the following applies: the SNS5M can also be used to set WELTAC®fasteners - fastener geometry on request. /

Pour les applications Portable 2 en 1, le SNS5M peut également être utilisé pour fixer les fixations WELTAC®- géométrie des fixations sur demande.

RIVSET ®

RIVSET ®WELTAC ®

Artikelnummer Klauke Zuführung Nietgröße [mm] a

[mm]

see

pict.

f

[mm]

see

pict.

Stanznietkopf

Partnumber Klauke Feeding Rivetsize [mm] Riveting head

Réf. Klauke Rivet Dimension rivet Tête de rivetage

BH200NGM SNS3M 3 35 53 SNKT35D53MBH

BH201NGM SNS5M 5 35 53 SNKT35D53MBH

BH202NGM SNS3M 3 130 147 SNKT130D147MBH

BH203NGM SNS5M 5 130 147 SNKT130D147MBH

BH204NGM SNS3M 3 220 81 SNKT220D81MBH

BH205NGM SNS5M 5 220 81 SNKT220D81MBH

II

originalbedienungsanleitung

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

160.3

84

f

26.4

34.4

35

a

75

8

1

3

2

35

a

75

422

330.8

75

67

55

28

108

f

248

32.5 22.5 21

Use tool only with 18V Makita Battery

Li-ion

BL1850(B) 45 min.

RAL4

BL1840(B) 36 min.

RAL40

BL1830(B) 22 min.

RAL2

BL1815 15 min.

RAL1

10 - 40°C

®

Li-ion & Ni-MH 7.2-18V

DC18RC

Alle Bedienungsanleitungen auch unter www.klauke.de abrufbar

All manuals are also available on www.Klauke.com

RIVSET ®

RIVSET ®WELTAC ®

76.3

Fastening

HE.18643

Portable C

RIVSET ®

WELTAC ®

10 - 50 kN • 18V

For use only with 18V Makita Battery

HE.18642

Böllhoff Automation GmbH

Archimedesstr. 1 - 4 • D-33649 Bielefeld

Riveting with the tape

feed mechanism

III

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

<70dB

<2,5m/s2

+40°C

-20°C

2,7 kg

1

2

3

20-50 kN

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

30% max.

PRESS

PRESS

PRESS

on/off

PRESS

CLICK

1. 2.

WARNING

Read all safety warnings, instructions, illustrations and specifications provided with this

power tool.

Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

N

O

C

H

I

L

D

R

E

N

<

1

6

A

T

W

O

R

K

•

IV

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

OIL

i

Presswerkzeuge und Zubehör

für die Sanitär- und Heizungsinstallation

®

SAFETY

3 years or

10.000 operations

®

WEEE

2012/19/EU

HE.17537

®

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

PRESS

PRESS

PRESS

PRESS

*1 Error codes:

1 Overcurrent fuse

2 Overcurrent comparator

3 Overheat board

4 Overheat battery

5 Battery empty, operation stop

6 Faulty crimp

motor in operation

7 Faulty crimp

motor not in operation

8 Low battery

9 Battery empty

10 RTC battery low

11 Tool deactivated

12 Service necessary

13 RTC not found

14 BT unit not found

16 Pressure sensor not found

17 Burst pressure exceeded

18 Battery temperature too low

1 Überstrom durch

Überstromsicherung

2 Überstrom durch Komparator

3 Boardtemperatur zu hoch

4 Akkutemperatur zu hoch

5 Akkuspannung während der

Operation zu gering

6 Fehlpressung bei

laufendem Motor

7 Fehlpressung bei

stehendem Motor

8 Niedrige Akkuspannung

9 Akku leer

10 RTC-Batterie leer

11 Werkzeug deaktiviert

12 Service nötig

13 RTC nicht verfügbar

14 BT-Modul nicht verfügbar

16 Drucksensor nicht verfügbar

17 Berstdruck überschritten

18 Akkutemperatur zu gering

*2 (2Hz)

P 3 bar

P 3 bar

ERROR CODE:

**** TOTAL:

t = 0.07 h

Q = 21.12 Ah

n = 174

USER 3:

RD3 Singleklick

NEXT SERVICE:

9826 OPs

Singleclick

to change:

bar / psi

to change:

kN / lbf

pressure change:

Fn 35 kN

pressure change:

LH for -RH for

+

Fn 50 kN

Cycles

(until next service)

Since manufacturing:

operating houres

Capacity

# crimps

Bluetooth (if connected) *2

Battery charging level

Current pressure

Pressure max.

Error code *1

bar / psi

bar / psi

bar / psi

kN / lbf

Fn 35 kN

kN / lbf

Fn 50 kN

kN / lbf

3 sec.

3 sec.

3 sec.

1

2

3a

4

3b

3d

3e

3c

3e

5

6

7

BT

F 0.3 kN

Fn 0.3 kN

BT

V

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

CLICK

1. 2.

VI

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

Demontage des Kopfes / Disassembly of the head / Désassemblage de la tête

PRESS

PRESS

1

2

1

2 x

1

2

1

1

2

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

CLICK

1. 2.

RIVSET ®WELTAC ®

Nieten / Riveting / Rivetage

SW2

MT= 3Nm

SW2

MT= 3Nm

Nietstempel/Riveting die/Rivet piston

SNS3M 3 mm Niet/rivet

SNS5M 5 mm Niet/rivet

SNS3M - 5500.322.048.5 SNS5M - 5500.322.048.6

Art.-Nr.

Item N°.

N° d‘article

Bezeichnung

description

déscription

Art.-Nr.

Item N°.

N° d‘article

Bezeichnung

description

déscription

5500.322.041.2

HE.12077

Stempel

Punch

Piston

5500.322.040.9

HE.12083

Stempel

Punch

Piston

5500.322.041.1

HE.12080

Distanzring

Spacer

Bague de distance

5500.322.041.1

HE.12080

Distanzring

Spacer

Bague de distance

5500.322.041.0

HE.12079

Ringmagnet

Ring magnet

Bague magnétique

5500.322.041.0

HE.12079

Ringmagnet

Ring magnet

Bague magnétique

5500.322.041.3

HE.12078

Rundfeder

Elastomer spring

Ressort élastomère

5500.322.039.0

HE.12084

Rundfeder

Elastomer spring

Ressort élastomère

VII

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

PRESS

PRESS

HE.3875

(71074308203)

2x HE.3875

(71074308203)

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

CLICK

1. 2.

RIVSET ®

4x

SW 2,5

MT= 5 Nm

SW 6

1.

2.

Gurtzuführung / Tape feed mechanism /

mécanisme d‘alimentation de sangle

TF3 max. 35 kN

TF5 max. 50 kN

Nieten mit Gurtzuführung TF 3 oder TF5 / Wartungshinweise

Riveting with the tape feed mechanism TF3 or TF5 / Service maintenance

Rivetage avec le mécanisme d‘alimentation de sangle TF3 ou TF5 / Maintenance

VIII

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

10 - 50 kN

Krafteinstellung

Force adjustment screw

Ajustage de pression

1.

PRESS

PRESS

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

RIVSET ®

TF3: # HE.15848

TF5: # HE.15849

TF3: # HE.15848

TF5: # HE.15849

-12°C bis +40°C

-12°C bis +40°C

3 sek.

®

Gurtzuführung TF 3 oder TF5 / Wartungshinweise

tape feed mechanism TF3 or TF5 / Service maintenance

mécanisme d‘alimentation de sangle TF3 ou TF5 / Maintenance

IX

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

1. 2.

RIVSET ®

Einstellung der Gurtzuführung / Set up belt feed / Réglage d‘alimentation de sangle

SW 2

X

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

CLICK

1. 2.

CLICK

RIVSET ®

Einfädeln des Nietgurtes / Insert tape feed / Insertion de sangle

SW 2

S

W

2

XI

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

HE.3875

(71074308203)

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

CLICK

1. 2.

RIVSET ®

Nietvorgang mit Gurtzuführung / Riveting cycle with belt feed

Cycle de rivetage avec alimentation de sangle

XII

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

PRESS

PRESS

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

RIVSET ®

5500.322.025.4

HE.11787

TF5

7107.430.820.4

HE.8941

5500.322.020.4

HB.9894

7102.815.840.0

WE.1701

3801.700.000.1

HE.8956

TF3

7107.430.820.4

HE.8941

5500.322.016.4

HB.7223

7102.815.840.0

WE.1701

TF3

TF5

Art.-Nr.

Item N°.

N° d‘article

Bezeichnung

description

déscription

Menge

Qty.

qté.

TF3 Grundkörper für (TF3 und TF5)

Body for (TF3 and TF5)

Bloc pour (TF3 et TF5)

1

5500.322.016.4

HB.7223

Gurtschiene für Ø3,2 mm,Ø3,4 mm Stanzniet

Guide bar for Ø3,2 mm, Ø3,4 mm self pierce rivets

Barre-guide pour rivets poinçonnants Ø3,2 mm, Ø3,4 mm

1

3801.700.000.1

HE.8956

Stempel Ø3,2 mm,Ø3,4 mm Stanzniet

Punch for Ø3,2 mm, Ø3,4 mm self pierce rivets

Poinçon pour rivets poinçonnants Ø3,2 mm, Ø3,4 mm

1

7107.430.820.4

HE.8941

Mitnehmer Schraube

Advance pawl

Vis d‘entraîneur

1

7102.815.840.0

WE.1701

Schraube (ISO 4762-M3x6/8.8)

Screw (ISO 4762-M3x6/8.8)

Vis (ISO 4762-M3x6/8.8)

4

Art.-Nr.

Item N°.

N° d‘article

Bezeichnung

description

déscription

Menge

Qty.

qté.

TF5 Grundkörper für (TF3 und TF5)

Body for (TF3 and TF5)

Bloc pour (TF3 et TF5)

1

5500.322.020.4

HB.9894

Gurtschiene für Ø4,8 mm,Ø5,3 mm Stanzniet

Guide bar for Ø4,8 mm, Ø5,3 mm self pierce rivets

Barre-guide pour rivets poinçonnants Ø4,8 mm, Ø5,3 mm

1

5500.322.025.4

HE.11787

Stempel Ø4,8 mm,Ø5,3 mm Stanzniet

Punch for Ø4,8 mm, Ø5,3 mm self pierce rivets

Poinçon pour rivets poinçonnants Ø4,8 mm, Ø5,3 mm

1

7107.430.820.4

HE.8941

Mitnehmer Schraube

Advance pawl

Vis d‘entraîneur

1

7102.815.840.0

WE.1701

Schraube (ISO 4762-M3x6/8.8)

Screw (ISO 4762-M3x6/8.8)

Vis (ISO 4762-M3x6/8.8)

4

Gurtzuführung / Tape feed mechanism

mécanisme d‘alimentation de sangle

TF3 35 kN max.

TF5 50 kN max.

XIII

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

Tab. 2

Wann/When/Quand/Quando/

cuándo/Wanneer/Когда/это

происходит/Kiedy/quando

Warum/Why/Pourqoui/Porquê/

¿por qué?/Waarom/Причина/

Dlaczego/Perché

20 sec

nach Arbeitsvorgang

after working cycle

après opération de travail

Después del proceso de trabajo

após o processo de trabalho

na bedrijfscyclus

после цикла опрессовки

po zakończeniu pracy

dopo il processo di lavoro

20 sec/2Hz

nach Arbeitsvorgang

after working cycle

après opération de travail

Después del proceso de trabajo

após o processo de trabalho

na bedrijfscyclus

после цикла опрессовки

po zakończeniu pracy

dopo il processo di lavoro

20 sec/5Hz

während der Übertemperatur

while exceeding the temp. limit

pendant surchauffe

en caso de temperatura excesiva

durante a temperatura excessiva

tijdens te hoge temperatuur

при высокой температуре

внутри корпуса

przy przegrzaniu

superando il limite di temperatura

Werkzeug zu heiß

Unit too hot

outil surchauffé

Herramienta demasiado caliente

ferramenta demasiado quente

gereedschap te heet

Перегрев инструмента

urządzenie za gorące

Utensile troppo caldo

1 x 1 x

nach Arbeitsvorgang

after working cycle

après opération de travail

Después del proceso de trabajo

após o processo de trabalho

na bedrijfscyclus

после цикла опрессовки

po zakończeniu pracy

dopo il processo di lavoro

Fehler: der notwendige Pressdruck wurde nicht

erreicht. Es handelt sich um eine manuelle

Unterbrechung der Pressung bei stehendem Motor.

Error: the required pressure has not been reached.

The operator has interrupted the pressing cycle

manually while the motor was not running.

ERREUR: Pression necessaire pas atteinte.

Il s‘agît d‘une interruption manuelle de la

sertissage au moteur arrêté.

Error: No se ha alcanzado la presión necesaria

o el operador ha interrumpido el ciclo a mano

mientras el motor ha parado.

Falha: a pressão de prensagem necessária não

foi alcançada. Trata-se de uma interrupção manual

da prensagem com o motor parado.

Foutmelding: De benodigde persdruk wordt niet

bereikt. De gebruiker heeft de verkrimping hand-

matig stopgezet aangezien de motor niet actief is.

Ошибка: не было достигнуто требуемое усилие

опрессовки или оператор прервал процесс

опрессовки вручную, когда двигатель остановился.

Błąd: konieczne ciśnienie nie zostało osiągnięte.

Użytkownik przerwałcykl pracy ręcznie w chwili,

gdy silnik nie byłwłączony

Errore: la pressione richiesta non è stata raggiunta.

L‘operatore ha interrotto manualmente il ciclo di

pressatura mentre il motore non è in funzione.

3 x 3 x

nach Arbeitsvorgang

after working cycle

après opération de travail

Después del proceso de trabajo

após o processo de trabalho

na bedrijfscyclus

после цикла опрессовки

po zakończeniu pracy

dopo il processo di lavoro

Schwerwiegender Fehler: Pressdruck wurde bei

laufendem Motor nicht erreicht.

Serious Error: The pressure has not been reached

while the motor was running.

Erreur Grave: Pression pas atteinte au moteur courant.

Error grave: No se ha alcanzado presión mientras

el motor estaba en marcha

Falha grave: a pressão de prensagem não foi

alcançada com o motor em funcionamento.

Urgente foutmelding: De persdruk werd bij een

werkende motor niet bereikt.

Серьезная ошибка: не было достигнуто требуемое

усилие опрессовки во время работы двигателя

Poważny błąd: konieczne cisnienie nie zostało

osiagnięte podczas pracy silnika

Errore grave: la pressione non è stata raggiunta

mentre il motore è in funzione.

D GB F E NLP RUS PL I

XIV

originalbedienungsanleitung

WORK SERVICE DON´T DO General

safety rules

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

US

SAFETY

ALERT

SYMBOL

This symbol is used to call your attention to

hazards or unsafe practices which could result

in an injury or property damage. The signal

word, defined below, indicates the severity of

the hazard. The message after the signal word

provides information for preventing or avoiding

the hazard.

DANGER

Immediate hazards which, ifnot avoided, WILL

result in severe injury or death.

WARNING

Hazards which, ifnot avoided, COULD result in

severe injury or death.

CAUTION

Hazards or unsafe practices which, ifnot avoided,

MAY result in injury or property damage.

WARNING

Read and understand all ofthe

instructions and safety infor-

mation in this manual before

operating or servicing this tool.

Failure to observe this warning

could result in severe injury or

death.

WARNING

Electric shock hazard:

This tool is not insulated. Do

not use this unit on or near

energized electrical parts.

Failure to observe this warning

could result in severe injury or

death.

WARNING

Wear eye protection when

operating or servicing this

tool.

Failure to wear eye protec-

tion could result in serious

eye injury from flying debris or

hydraulic oil.

WARNING

Skin injection hazard:

Do not use hands to check for

oil leaks. Oil under pressure

easily punctures skin. Ifinjured,

seek medical attention imme-

diately to remove oil.

Failure to observe this warning

could result in serious injury,

gangrene, or death.

WARNING

Do not use solvents or flam-

mable liquids to clean the tool

body. Solvents or flammable

liquids could ignite and cause

serious injury or property

damage.

WARNING

An inproperly set rivet can cause a mechanical

failure.

• Use proper riveting die and matrice in com-

bination with the right force setting. Improper

combinations can result in an mechanical

failures.

• The reliefvalve sounds and the ram automati-

cally retracts to indicate a completed rivet-

ing cycle. Ifyou do not hear the sound ofthe

relieve valve or the ram does not automati-

cally retract, the mechanical connection must

be inspected.

Failure to observe these warnings could result

in severe injury or death.

IMPORTANT SAFETY INFORMATION

1

translation of the

original instruction manual

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

US

WARNING

Pinch points:

• Remove battery before

changing die, matrice, or

head.

• Keep hands away from the

riveting tool head when

riveting.

Failure to observe these warn-

ings could result in severe injury

or death.

WARNING

Do not dispose ofbatteries in a fire. They will

vent fumes and may explode.

Failure to observe this warning could result in

severe injury from harmful fumes or burns from

flying debris.

WARNING

Inspect tool, dies & matrice and head before

use. Replace any worn or damaged parts. A

damaged or improperly assembled tool can

break and strike nearby personnel.

Failure to observe this warning could result in

severe injury or death.

CAUTION

• Do not use this tool for continuous use. After

150 to 200 cycles, allow the tool to cool for

15 minutes.

• Do not secure this tool in a vise. This tool is

designed for hand-held operation.

• This tool shall not be used in damp or wet

environments. Damage may result when the

electrical components are soaked.

• Use this tool for the manufacturer’s intended

purpose only.

Failure to observe these precautions may result

in injury or property damage.

CAUTION

Do not allow anything to contact the battery

terminals.

• Do not immerse the batteries in liquid. Liquid

may create a short circuit and damage the

battery. Ifbatteries are immersed, contact

your service center for proper handling.

• Do not place the battery into a pocket, tool

pouch, or tool box with conductive objects.

Conductive objects may create a short circuit

and damage the battery.

• Do not place a battery on moist ground or

grass. Moisture may create a short circuit and

damage the battery.

Failure to observe these precautions may result

in injury or property damage.

CAUTION

• Do not store the battery at more than 122 °F

(50°C) or less than –4 °F (–20 °C). Damage to

the battery can result.

• Do not use another manufacturer’s charger.

Other manufacturers’ chargers may over-

charge and damage the battery.

• Do not attempt to open the battery. It con-

tains no user-serviceable parts.

Failure to observe these precautions may result

in injury or property damage.

CAUTION

Do not perform any service or maintenance

other than as described in this manual. Injury or

damage to the tool may result.

Failure to observe this precaution may result in

injury and property damage.

Note: Keep all decals clean and legible, and replace

when necessary.

IMPORTANT SAFETY INFORMATION

2

translation of the

original instruction manual

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

US

Index

1. Introduction

2. Warranty

3. Description of the electric-hydraulic

Riveting tool

3.1 Description of the components

3.2 Brief description of the important features

of the unit

3.3 Description of the tool indication

4. Remarks in respect of the determined use

4.1 Operation of the unit

4.2 Explanation of the application range

4.3 Mounting instructions

4.4 Service and maintenance instruction

4.4.1Service

4.4.2Cleaning

4.5 Daily Maintenance

4.6 Reference as to which spare parts can be

exchanged by the customer

5. Troubleshooting

6. Technical Data

1. Introduction

Before starting to use the tool please read

the instruction manual carefully.

Use this tool exclusively for its determined use.

Mounting and assembly of connecting material with the

help of this tool must only be performed by specially trained

personnel. The minimum age is 16 years.

This instruction manual has to be carried along during the

entire life span of that tool.

The operator has

• to guarantee the availability of the instruction manual for

the user and

• to make sure, that the user has read and understood the

instruction manual.

2. Warranty

If correct operation is guaranteed and regular service is

provided our warranty is 12 months from the time of de-

livery.

3. Description of the

electric-hydraulic Riveting tool

3.1 Description of the components

The electric-hydraulic riveting tool is hand helded and con-

sists of the following components:

Tab 1:

Pos. Description Function

1 LED (red) Indicator for battery charge

control, tool functions and

faults

2 Battery

cartridge

Rechargeable

4Ah Li-Ion battery (RAL40)

3 Retract button Button to retract the piston in

case of error or emergency

4 Trigger Switch to start working cycle

5 LED (white) To illuminate the working area

6 C-frame with reception for upper and

lower die

7 Cover Protection against debris du-

ring storage

8a Riveting dies Punch and die for riveting

8b tape feed

mechanism

tape feed mechanism for

riveting

9 Ring Loop to secure the tool and/or

for assembly purposes

10 Housing Ergonomically formed plastic

housing for perfect handling

11 Force adjust-

ment

Adjustment device the joining

force

3.2 Brief description of the important

features of the unit

The tool incorporates an automatic retraction which

returns the piston into its starting position when the

maximum operating pressure is reached.

A manual retraction allows the user to return the pis-

ton into the starting position.

The unit is equipped with a special brake which stops

the forward motion of the piston/tool kit when the trig-

ger is released.

The tool is equipped with a double piston pump which

is characterised by a rapid approach until contacting

the work piece and a slow working speed.

The head can be smoothly turned by 350° around the

longitudinal axis in order to gain better access to tight

corners and other difficult working areas.

The tool is equipped with a microprocessor which in-

dicates service intervals and low battery charges.

A white LED illuminates the working space after

activating the trigger. It automatically switches off

10 sec. after releasing the trigger. This feature can

be deactivated.

Through an optional USB adapter (accessory) a re-

port can be generated at the end of a working session

at a PC documenting the proper function of the tool.

The oil used in our tool is particularly environmentally

friendly and and has been rewarded „The Blue An-

gel“. The oil is also suitable for low temperatures and

has excellent lubrication characteristics.

All tool functions can be controlled by one trigger.

This results in an easy handling and a better grip

compared to a two button operation.

3

translation of the

original instruction manual

Portable C

RIVSET ®(10 - 50 kN) | WELTAC ®(10 - 50 kN)

HE.18644_A © 08/2019

Abb. ähnlich / pic. similar

US

The compact ergonomically formed design consists

of 2 components. The grip area is rubber coated

and therefore slip resistent. The housing design is

optimized in respect of the center of gravity which

improves the handling and supports fatique-proof

working.Li-Ion batteries do neither have a memory

effect nor self discharge. Even after long periods of

non operation the tool is always ready to operate. In

addition we see a lower power weight ratio with 50%

more capacity and shorter charging cycles compared

to NiMH batteries.

3.3 Description of the tool indication

See Tab. 2.

Prior to operating the unit the charging level of the battery

should have been tested. A low charging level can be de-

tected by the flashing of the LED for 20 s at the end of a

riveting cycle.

4. Remarks in respect of the

determined use

4.1 Operation of the unit

Cycle: see pictures in front

First the proper tool kit must be selected for the required

application.

WARNING

Do not operate the tool without workpiece/sheet

metal. This might destroy die and/or punch.

WARNING

The riveting process can be interrupted at any

moment by releasing the Trigger in case of emer-

gency.

WARNING

Do always adjust the joining force according to

your current application.

Ignoring that warning might destroy the tool kit and

might fracture and hurt nearby personell.

WARNING

Use eye protection when operating

the tool.

2K WARNING

After having terminated the wor-

king cycle and prior to changing

the head/tool kit remove battery

to avoid unintended use. Avoid

unintended starts. Make sure the

trigger is in the offposition before

inserting the battery.

CAUTION

Dress properly. Do not wear loose clothing or jewel-

lery. Keep your hair, clothing and gloves away from

moving parts.

CAUTION

Keep work area clean and organised. Cluttered and

dark areas might trigger accidents.

WARNING

Keep proper footing and balance at all times.

WARNING

Use safety gear where appropiate.

4

translation of the

original instruction manual

This manual suits for next models

1

Table of contents

Languages:

Other Bollhoff Rivet Tools manuals