1.3 Caracteristici tehnice

Casete pentru sisteme cu 2 sau 4 tevi, potrivite pentru instalarea in tavanul

fals. Designul placut este potrivit pentru cele mai sofisticate destinatii,

unde este necesara economia de spatiu si silentiozitatea.

1.4 Componente

Structura.

Carcasa izolata, inaltime maxima (287 mm) si dimensiuni compatibile

cu modulele standard pentru tavanul fals (600x600 mm si 600x1200 mm),

create special pentru o instalare si utilizare facila a racordurilor hidraulice

si electrice, usor accesibile incepand cu zona grilei frontale .

Carcasa.

Grila.

Ventilatorul.

Pompa de condens

Evacuare condens

1.3 Technical characteristics

Water boxes for two and four pipe systems, suitable for installation in

false ceilings. The pleasant design is suitable for the most sophisticated

settings where space and silence are the main requirements.

1.4 Components

Structure. For insulated recess fitting, limited depth (287 mm) and

dimensions compatible with the standard double-ceiling modules

(600x 600 mm and 600x1200 mm); specially designed for easy in-

stallation and maintenance of the hydraulic and electrical connec -

tions, accessible starting from the front panel grille.

Casing. Panels in insulated galvanized sheet; combined air in-

take/suction grille; manual adjustment for diffusion of air on the

four sides; possibility of closing one or two air intake sides; suc -

tion in middle with regenerable filter; precut holes for connection

to an external air intake and for connection to a branch duct for

conditioning an adjoining room (in this case a decompression in

the adjoining room must be guaranteed in order to ensure suction

of the air on the Box).

Combined air diffusion/suction grille with air filter and manu-

ally adjustable air diffusion on the 4 sides with suction in mid -

dle.

Fan. Centrifugal turbine with direct feed. The motors, mounted on elas -

tic suspension and equipped with internal thermal safety, are 3-speed.

Lift pump with float and detection at 3 levels (On-Off-Alarm) of con -

densation for lift in the upper part of the box. Discharge occurs by

gravity, outside the appliance (lift height up to 600 mm).

Combined air diffusion/suction grille with air filter and manually

adjustable air diffusion on the 4 sides with suction in middle.

Panta de 1 cm/m

1 : 100 slop

Racord tevi

Hose connection

Teava izolata pentru condens

Moisture drain pipe heat insulated

Sistem de scurgere

Drain system

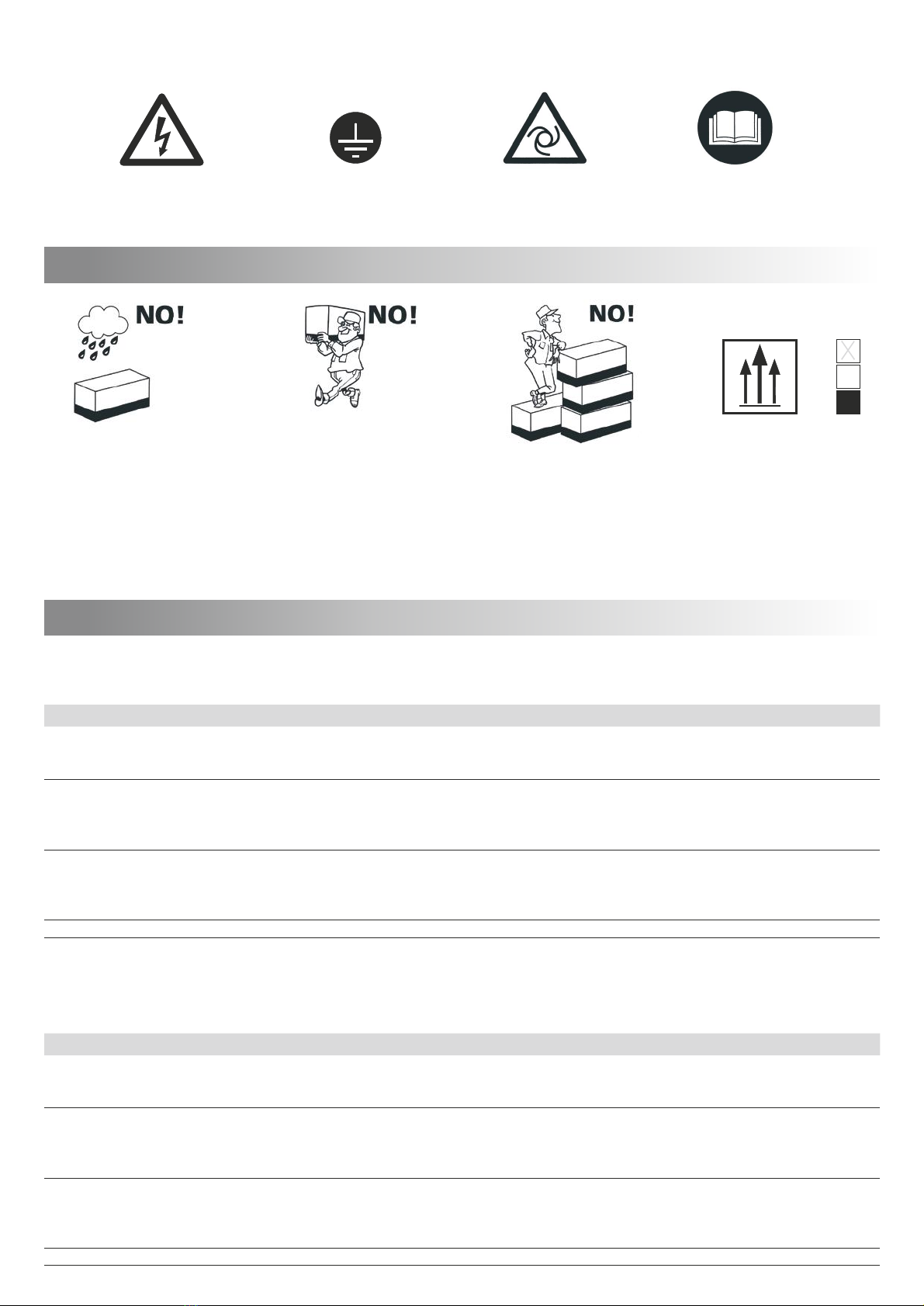

NO NO

Sifon

Odor trap

Racord la partea superioara a tevii de evacuare

Connection on the top of draining

Sistem de scurgere cu cateva unitati

Drain system with several units

50

Tavan fals / Double ceiling

Tija in forma de T (tavan fals) / T-shaped rod (double ceiling)

Baterie pentru schimb termic / Heat exchanger coil

Ventilatoare / Fan

Grila combinata aspiratie/refulare /

Combined air diffusion/suction grille

Conexiuni electrice / Electrical connection

Evacuare condens (Ø 3/4” pt. mod. 42÷54) (Ø 1/2” pt. mod. 84÷104)

Draining of condensate (Ø 3/4” for model 42÷54) (Ø 1/2” for model 84÷104)

Racord hidraulic introducere apa 2 T (M) / 2 P Coupling of water inlet (M)

3

2

1

4

5

6

7

8

9

10

11

12

Port pentru aspiratie aer proaspat (pre-perforat)

Port to suction fresh air (pre-punched)

Port pentru distribuitie aer prin tubulatura intr-o incapere alaturata

(pre-perforat)

Port to distribute air through a duct into a neighbouring room (pre-punched)

Orificiu pentru tavita de condens auxiliara

Hole for auxiliary condensing tray

13

14

15

Baterie pentru schimb termic.

Baterie de incalzire electrica.

Filtru de aer.

• Tip filtru: Din material sintetic, cu demontare rapida

• Clasa incendiu: M4 (PV LNE No 812 02 29 din 30/01/89).

• Eficienta medie : 55% (EUROVENT 4/5 ASHRAE gravimetric

52-76 NF X 44-012).

Panou electric intern de comanda si protectie.

.

Heat exchanger coil.

Copper pipes and aluminium fins with airvent on the distributors.

Electric heater.

The boxes are factory-fitted (optional) with an electric heater (heating

elements) thermally protected against any abnormal temperature in-

crease by means of two automatic or manual-reset thermostats.

Regenerable-type air filter

Accessible after opening the combined air intake/suction grille.

• Type of filter: Synthetic fabric quick-removal boxes.

• Fire class: M4 (PV LNE No. 812 02 29 to 30/01/89).

• Average efficiency: 55% (EUROVENT 4/5 - ASHRAE

gravimetric 52-76 NF X 44-012).

Internal electric control and protection board with power supply

terminal block for connection to terminals without screws and multi-

output (42÷54) auto-transformer. Outer placed electrical board (84-

104).

Racord hidraulic evacuare apa 2 T (M) /

2 P Coupling of water outlet (M)

Racord hidraulic introducere apa 4 T (M) / 4 P Coupling of water inlet 4 T (M)

Racord hidraulic evacuare apa 4 T (M) /4 P Coupling of water outlet (M)

Aerisire / Air vent

Construita cu panouri izolate din tabla galvanizata; grila combinata de

aspiratie/refulare aer; reglare manuala pentru distributia aerului in 4

directii; posibilitate de inchidere a refularii pe una sau doua parti;

aspiratie centrala prin filtre lavabile; gauri pre-perforate pentru aport aer

proaspat si pentru distributie aer prin tubulatura pentru climatizarea unui

spatiu alaturat.

Combinata de aspiratie/refulare cu filtru de aer si refulare aer cu reglare

manuala in 4 directii si cu aspiratie centrala.

Antrenare directa a ventilatorului centrifugal. Motoarele cu 3 viteze sunt

montate pe suporti elastici si sunt echipate cu protectie termica interna.

Pompa de condens cu flotor cu contacte pe 3 nivele (On-Off-Alarma)

care poate ridica condensul in partea superioara a casetei pana la o

inaltime de max. 600 mm.

Prevazut cu sistem de evacuare cu panta si sifon pentru conducta de

evacuare.

Baterie de caldura cu tevi din cupru si aripioare de aluminiu.

Baterie de incalzire electrica montata in fabrica (optional), protejata

termic impotriva oricarei cresteri anormale a temperaturii prin

intermediul a doua termostate cu resetare manuala sau automata.

Comanda si protectie cu riglete fara suruburi pentru legaturile electrice

externe si pentru legaturile la autotransformator (42÷54); panou electric in

exteriorul unitatii (84-104).

Filtru de aer, regenerabil, accesibil dupa deschiderea grilei pentru

aspiratie.