A

WARNING

Malfunction of unit, rigging slip or loss of footing may cause

user to slip resulting

in

injury.

TO

AVOID

IN.JURY:

Always have a firm and secure footing when using the Series

637 Lever Hoist.

Inspect Hoist -Before each use and at specified

intervals as directed

in

inspection section.

WARNING

Use as directed above. Failure to do so may cause injury to

you or others.

1.

Do not exceed capacity shown on the identification plate.

2.

Do not use to lift people or loads over people.

3.

Do not use unless the Hoist's frame and chain form a

straight line between hooks.

4.

Do not use if the frame is

in

contact with any object.

5.

Do not use if the unit is damaged or malfunctions.

6.

Do not use extension

on

lever. Use hand power only.

7.

Do not use if chain is twisted, kinked or damaged.

Safety Procedures

1.

The hoist must

be

kept clean to assure proper

opertion. Before use, check to

be

sure the load chain

is

clean, that there

is

no

foreign material

in

the liftwheel

area and that the lever operates freely.

2.

When preparing to pull or tension a load,

be

sure the

attachment to each hook is firmly seated

in

the hook

saddle. Avoid off-center loading of any kind, especially

loading

on

the tip of the hook.

A

WARNING

ALLOWING THE LOAD TO BEAR AGAINST THE HOOK

LATCH AND/OR HOOK TIP CAN RESULT

IN

LOSS OF LOAD.

TO

AVOID

IN.JURY:

DO

NOT ALLOW THE LOAD TO BEAR AGAINST THE HOOK

LATCH AND/OR HOOK

TIP.

APPLY LOAD TO HOOK BOWL

OR

SADDLE

ONLY.

3.

When pulling or tensioning, move the load only enough

to slightly load the unit, then check to

be

sure that the

attachments to the hooks and load are firmly seated.

Continue movement only after you are assured the

load

is

free of

all

obstructions.

4.

Do

not load beyond the rated capacity. Overload

can

cause immediate failure or cause damage resulting

in

future failure, even at less than rated capacity.

5.

The hoist has been designed for hand powered

operation

only.

Do

not use

an

extension

on

the lever.

Lever pulls of 35 pounds(15.9Kg.)

on

the 3/4 ton unit,

40 pounds(18.1Kg.)

on

the 1-1/2 ton unit, 73

pounds(33.1 Kg.)

on

the 3 ton unit and 77

pounds(34.9Kg.)

on

the 6

ton

unit, will result

in

rated capacity

on

the unit. Any greater pull

is

an

indication of either

an

overload or

an

incorrectly

maintained unit.

A

WARNING

POWER OPERATION

MAY

CAUSE DAMAGE OR PRE-

MATURE WEAR THAT

IN

TURN MAY CAUSE A PART TO

BREAK AND ALLOW THE LOAD TO FALL.

TO

AVOID

IN.JURY:

OPERATE THE HOIST USING HAND POWER ONL

Yi

6.

Do

not use this hoist or any other material handling

equipment for lifting or moving people, or lifting loads

over people.

7.

Stand clear of

all

loads and warn other people of your

intention to move a load

in

their area.

8.

Do

not leave a load

on

the unit unattended.

9.

Do

not take

up

the load chain to the point where the

end ring or lower hook block becomes jammed

against the frame.

10.

Read warnings

and

instructions

on

the lever before

each use.

11.

Do

not wrap the load chain around the load and hook

onto itself as a choker chain sling or bring the load

in

contact with the hoist. Doing this will result

in

the

loss of the swivel effect of the hook which could

result

in

twisted chain and a jammed liftwheel. Also,

the chain may

be

damaged at the hook.

12.

Do

not hold the load chain while operating the hoist.

Should the hoist not operate properly, serious injury

may occur.

13.

Do

not operate the hoist unless

it

is

rigged to pull

in

a

straight line from hook to hook, and the frame is free

to swivel

on

the upper hook. Refer to Figure

2.

14.

When there

is

a load

on

the hoist, do not pull or turn

the free chaining knob. Doing this will allow the

load to

be

released

in

a sudden and uncontrolled

manner and may cause injury to you and/or property

damage.

15.

Never operate the hoist when flammable materials or

vapors are present. Contact between metal parts

may produce sparks that can cause a fire or

explosion.

16.

STAY

ALERT! Watch what you are doing and use

common sense.

Do

not use the hoist when you are

tired, distracted or under the influence of drugs,

alcohol or medication causing diminished control.

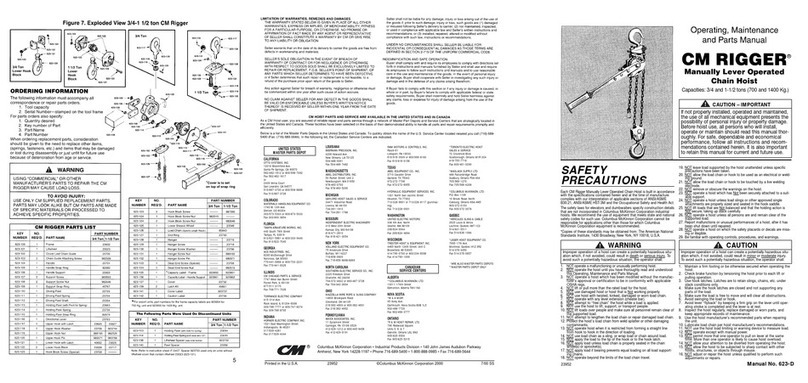

INSPECTION

AND

MAINTENANCE

INSPECTION

To

maintain continuous and satisfactory operation, a

regular inspection procedure must

be

initiated so that

worn or damaged parts can

be

replaced before they

become unsafe. The intervals of inspection must

be

determined

by

the individual application and are based

upon the type of service to which the hoist

is

subjected.

The intervals indicated below are based

on

normal

service.

The inspections are divided into two general

classifications designated as "frequent" and "periodic".

Frequent Inspections

These inspections are usually visual examinations

by

the

operator. Frequent inspections are to

be

performed daily

or before each use and they are to include:

a.

Braking mechanism for evidence of slippage.

S

b.

Operation of the directional lever for free movement.

c.

Load chain for lubricant, wear, damaged links or

foreign material.

d.

Hooks for damage, cracks, twists, latch engagement

and latch operation.

Periodic Inspections

These are visual inspections of external and internal

conditions

by

a designated person making records to

provide the basis for continuing evaluation of the

condition of the tool. The periodic inspection should

include those items listed under frequent inspection as

well as the following:

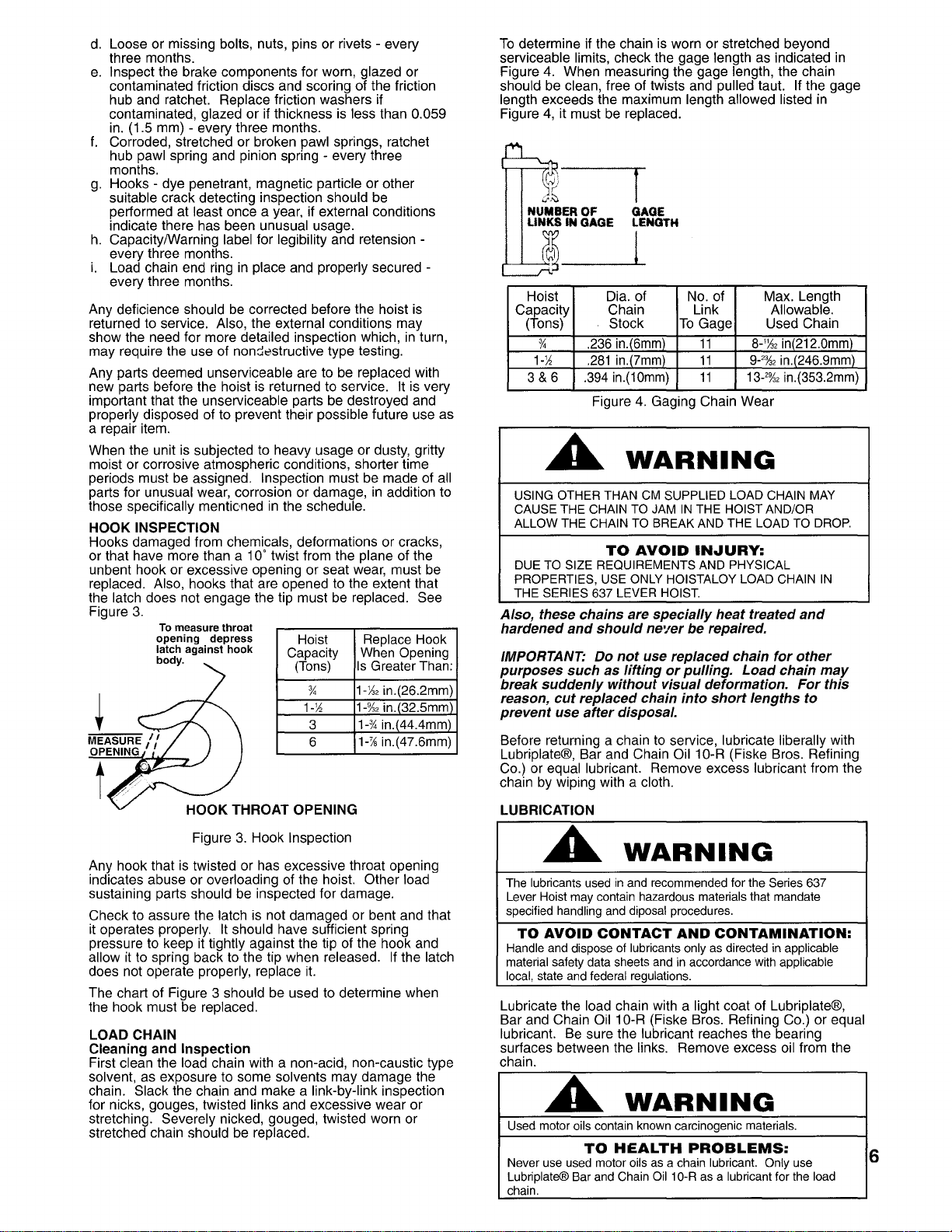

a.

Chain for excessive wear or stretch (see page

6)

every three months.

b.

Worn, cracked or distorted parts such as lower hook

block, upper hook block, upper hook pin, chain guide

roller, stripper, side plates, gear cover, gears,

bushings, lever, brake cover, free chaining knob,

ratchet hub pawl, cam guide, friction hub and lever

ratchet hub -every three months.

c.

Inspect for wear

on

the tip of the pawls, teeth of the

ratchet, and pockets of the liftwheel -every three

months.