1

ITEM PAGE NO.

MASTER PARTS DEPOTS AND SERVICE CENTERS. i

SAFETY PRECAUTIONS . . . . . . . . . . . . . ii

HOIST SAFETY IS UP TO YOU. . . . . . . . iii

GENERAL INFORMATION

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 2

REPAIR/REPLACEMENT POLICY . . . . . . 3

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . 3

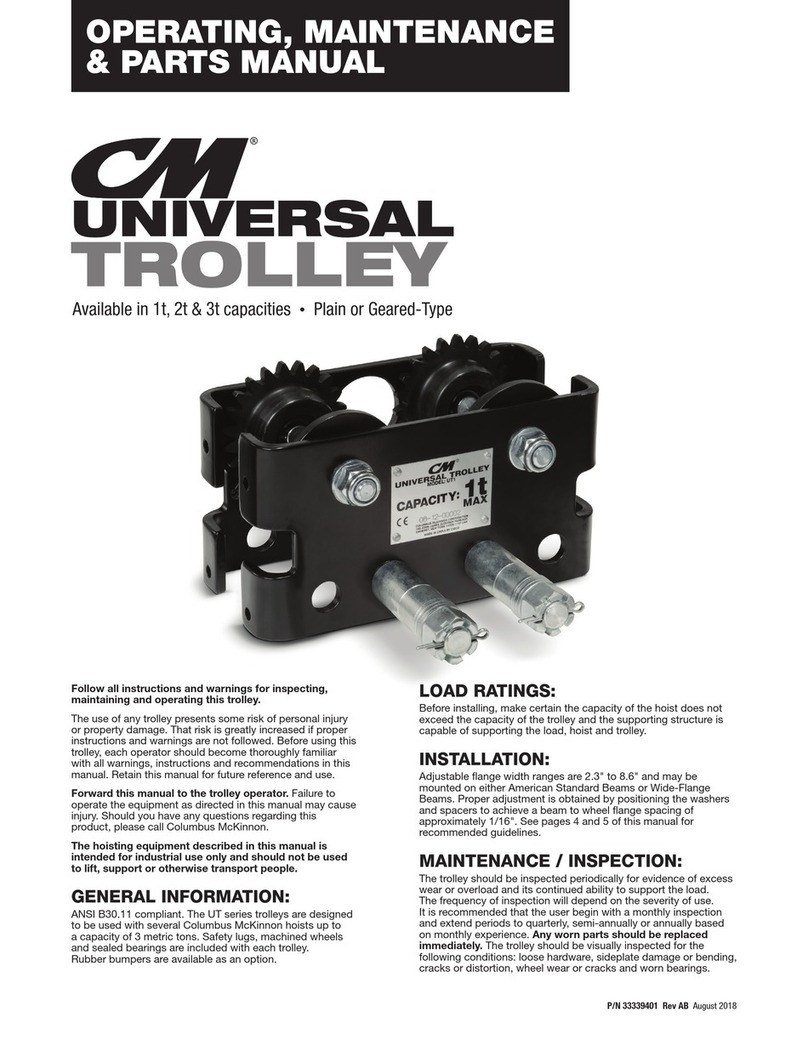

INSTALLATION

UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLING THE SUSPENSION

HOOK SUSP NSIONS . . . . . . . . . . . . . . . . . . 4

LUG SUSP NSIONS . . . . . . . . . . . . . . . . . . . . . 6

MOUNTING TROLLEY ON HOIST. . . . . . 6

INSTALLING TROLLEY SUSPENDED

HOIST ON BEAM. . . . . . . . . . . . . . . . . . . . .7

INSTALLING BREATHER . . . . . . . . . . . . . . . . 8

POWER SUPPLY SYSTEM . . . . . . . . . . . . . . . 8

ELECTRICAL CONNECTIONS

SINGL SP D DUAL VOLTAG

HOISTS (AND MOTOR DRIV N TROLL YS) . 9

ALL HOISTS. . . . . . . . . . . . . . . . . . . . . . . . . 9

CH CKING FOR TWIST IN LOAD CHAIN . 10

CH CKING FOR AD QUAT VOLTAG . . 10

CHECKING LIMIT SWITCH OPERATION . . . 10

CHAIN CONTAINER. . . . . . . . . . . . . . . . . . . . 10

CONTROL CORD . . . . . . . . . . . . . . . . . . . . . . . 10

OPERATING INSTRUCTIONS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ALL HOISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

HOIST WITH PLAIN TROLLEY . . . . . . . . . . . . 11

HOIST WITH GEARED TROLLEY . . . . . . . . . . 11

HOIST WITH MOTOR DRIVEN TROLLEY . . 11

SAFETY PROCEDURES. . . . . . . . . . . . . . . . . . . 11

ITEM PAGE NO.

MAINTENANCE

INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FR QU NT INSP CTIONS . . . . . . . . . . . . . . 12

P RIODIC INSP CTIONS . . . . . . . . . . . . . . . 12

HOOK INSP CTION . . . . . . . . . . . . . . . . . . . 12

LOAD CHAIN . . . . . . . . . . . . . . . . . . . . . . . . . 13

PROT CTOR . . . . . . . . . . . . . . . . . . . . . . . . . . 13

LUBRICATION

HOIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TROLL Y. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

AD USTMENTS

HOIST BRAK . . . . . . . . . . . . . . . . . . . . . . . . 15

LIMIT SWITCH S. . . . . . . . . . . . . . . . . . . . 16

TROLL Y BRAK . . . . . . . . . . . . . . . . . . . 17

RECOMMENDED SPARE PARTS . . . . . . . 18

PREVENTIVE MAINTENANCE . . . . . . . . . 18

TROUBLE SHOOTING

ALL HOISTS. . . . . . . . . . . . . . . . . . . . . . . . 19

TWO SP D HOISTS. . . . . . . . . . . . . . . . . 22

MOTOR DRIV N TROLL Y. . . . . . . . . . . . 23

ELECTRICAL DATA . . . . . . . . . . . . . . . . . 24, 25

WIRING DIAGRAMS . . . . . . . . . . . . . . . 26, 28

DISASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . 29

REASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . 29

REMOVAL AND REPLACEMENT OF LOAD CHAIN29

REEVING LOAD CHAIN

3,4 AND 5 TON DOUBL R V D UNITS . . 30

5,6 AND 71/2 TON TRIPL R V D UNITS . 31

CUTTING CHAINS. . . . . . . . . . . . . . . . . . . . . . 31

TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

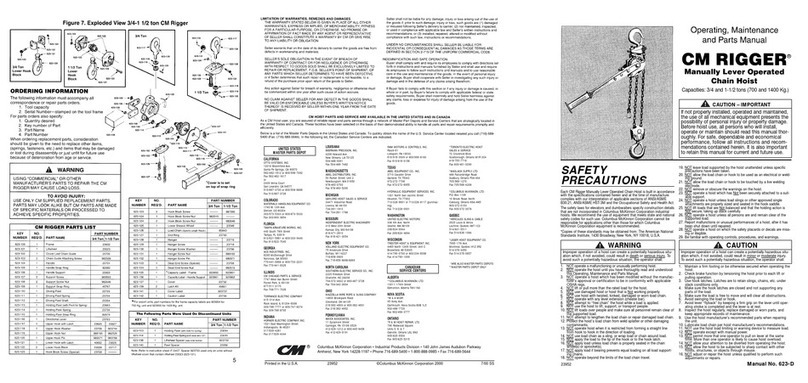

REPAIR PARTS

ORDERING INSTRUCTIONS. . . . . . . . . . . . 32

EXPLODED VIEWS AND PARTS LISTS. . 33-48

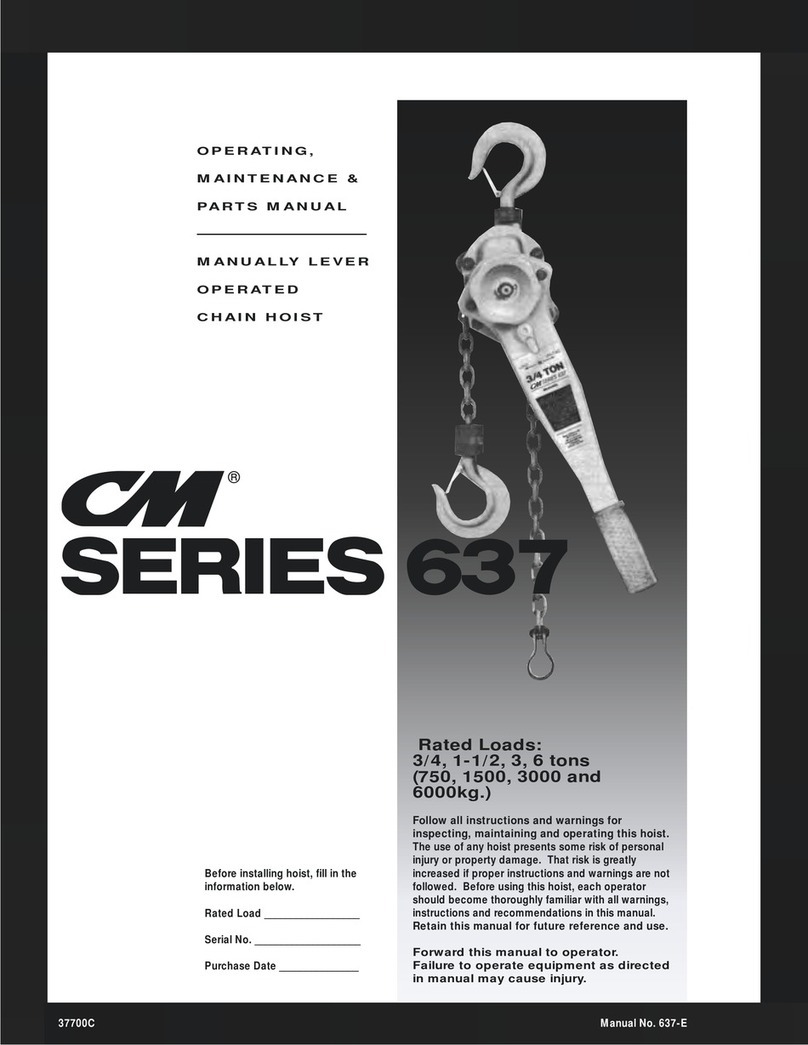

FOREWORD

This manual contains important information to help you properly install, operate and maintain your hoist for maxi-

mum performance, economy and safety.

Please study its contents thoroughly before putting your hoist into operation. By practicing correct operating proce-

dures and by carrying out the recommended preventative maintenance suggestions, you will experience long, depend-

able and safe service. After you have completely familiarized yourself with the contents of this manual, we recom-

mend that you carefully file it for future reference.

The information herein is directed to the proper use, care and maintenance of the hoist and does not comprise a

handbook on the broad subject of rigging. Rigging can be defined as the process of lifting or moving heavy loads

using hoist and other mechanical equipment. Skill acquired through specialized experience and study is essential to

safe rigging operations. For rigging information, we recommend consulting a standard textbook on the subject.

TABLE OF CONTENTS