10

13) Fitting the battery backup

The battery should be fitted connected after the system as been commissioned. Place the battery within

the housing in the space provided. Connect the small BLACK cable to the “—“ battery terminal and the

RED with black dots wire to the batteries “+” terminal. If the battery is misconnected, the battery fuse

located on the small PCB will blow.

14) Commissioning

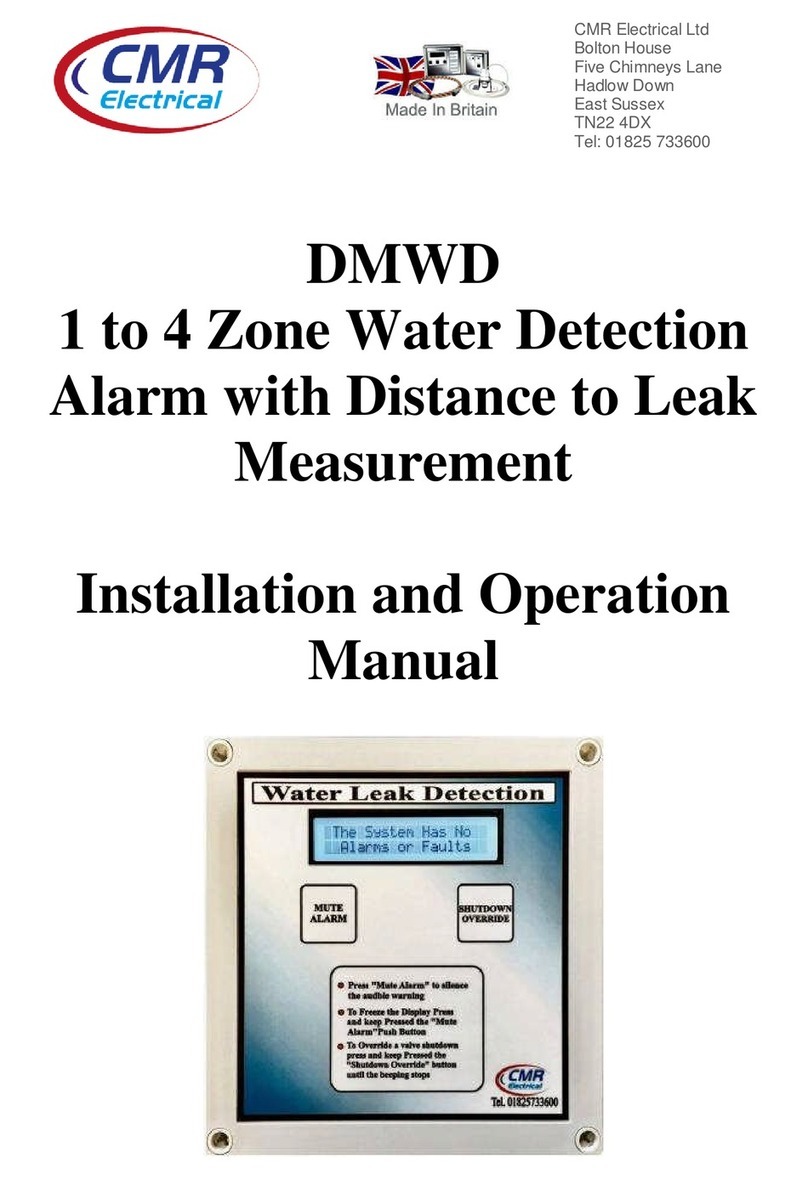

Having connected the unit as described above, turn of the mains power to the unit. The display should

show “ALL ZONES ARE CLEAR” If not, refer to the “Fault Diagnostics” below. If the unit powers up

with the audible warning going, press the mute button and wait to see if the alarm clears. If the alarm

remains after approximately 20 seconds , refer to the “Fault Diagnostics” below. With the unit powered,

unplug the End of line terminator positioned at the end of the detection cable. The controller should

display “SENSOR FAULT Zone 1 or 2 etc. ” and the audible warning device should sound, if not refer to

the “Fault Diagnostics” below, press the “Mute” button, the audible warning device should stop. Replace

the End of line terminator to return the system to normal. Using a cup of CLEAN water, immerse a small

area (50mm long) of cable into the water. The controller should display “WATER DETECTED at ZONE

1 or 2 etc.” and the audible warning device should sound, if not refer to the “Fault Diagnostics” below.

Press the “Mute” button the audible warning device should stop. Remove the water and wipe the cable

with some tissue paper. Repeat for all other zones.

15) Fault Diagnoses

Fault Possible Reason

Display is OFF and the unit appears dead 1) No power to the control unit. Test with a meter

2) The power fuse has blown. Test the fuse with a meter

The Water Detected statement remains in the

screen all the time.

1) The cable needs drying out after detecting water. Using

tissue paper dry the cable.

2) The cable has a short between the sensors due to

Contaminants. Clean the cable using water and tissue

paper dry out afterwards

3) The cable has been damaged. Visually check the cable for

damage.

4) The sensitivity of the detection system is too sensitive.

Remove the lid from the small plastic box connected to the

detection cable and turn the potentiometer until the system

resets.

5) System fault. Return to manufacture

The display appears dead and does not show

“Water Detected” even though the system has a

water detected alarm and the audible warning

device is sounding.

1) System fault. Return to manufacture

The system will not record a water detected alarm,

the Display and audible warning device do not

react to water on the cable.

1) Sensitivity could be too low or a Possible system fault.

Remove the lid from the small plastic box connected to the

detection cable and turn the potentiometer until the system

goes into alarm.

2) System fault. Return to manufacture

The display shows faulty or disconnected cable all

the time.

1) The detection or signal cable is broken or disconnected.

Check for cable faults or breaks.

2) Detection module fault. Dip part of the detection cable into a

cup of water and see if it sets up an alarm.

3) Controller fault. Press the test button to setup an alarm.

4) System fault. Return to manufacture

Horn not working 1) System fault. Return to manufacture

2)

The battery will not power the system 1) Battery discharged, disconnect a lead and test with meter.

2) Battery fuse blow, see item 10

3) Charger fault, disconnect a battery lead & check for 13.5V