Document: LT0709 QE20 Service Manual

Issue 1.0 13 June 2023 Page iii

TABLE OF CONTENTS

1. Introduction .................................................................................................... 1-1

1.1 Introduction and Scope.................................................................................................... 1-1

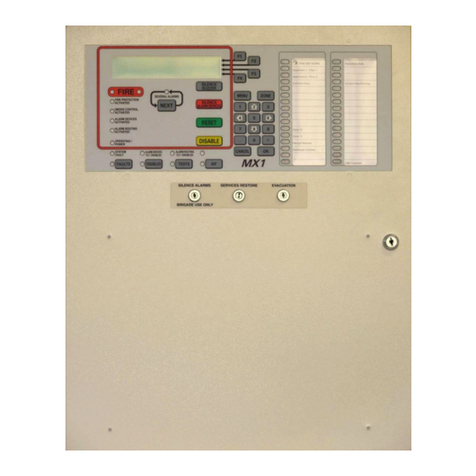

1.2 Description of QE20 ......................................................................................................... 1-1

1.3 Specifications – QE20 Panel............................................................................................ 1-5

1.4 Other QE20 & Product Manuals ...................................................................................... 1-6

1.4.1 VIGILANT QE20 Manuals .............................................................................................. 1-6

1.4.2 Other VIGILANT Manuals .............................................................................................. 1-7

1.4.3 Third Party Manuals ....................................................................................................... 1-7

2. Maintenance ................................................................................................... 2-1

2.1 Regular Testing................................................................................................................. 2-1

2.2 Battery Recharging........................................................................................................... 2-1

2.3 Battery Charging Voltage................................................................................................. 2-2

2.4 Disabling Earth Fault........................................................................................................ 2-2

3. Fault Finding .................................................................................................. 3-1

3.1 Fault Finding ..................................................................................................................... 3-1

3.2 Module Fault LED Indications ......................................................................................... 3-2

3.2.1 Controller Module LED Indications.................................................................................3-2

3.2.2 MUI Module LED Indications.......................................................................................... 3-2

3.2.3 MKI Module LED Indications .......................................................................................... 3-3

3.2.4 8 Zone & 8 WIP Extender Module LED Indications .......................................................3-3

3.2.5 Amplifier Module LED Indications .................................................................................. 3-5

3.2.6 Splitter Module LED Indications ..................................................................................... 3-7

3.2.7 RS485 Network Module LED Indications ....................................................................... 3-8

3.2.8 WIP / Input Module LED Indications ............................................................................3-10

3.2.9 Relay Output Module (ROM) LED Indications .............................................................3-12

3.2.10 Power Supply Module (PSE) LED Indications .............................................................3-13

3.2.11 PIB LED Indications ..................................................................................................... 3-14

3.2.12 VIF LED Indications......................................................................................................3-14

3.2.13 ATA LED Indications .................................................................................................... 3-14

3.2.14 Fibre Switch LED Indications .......................................................................................3-15

4. Diagnostics Facilities .................................................................................... 4-1

4.1 Connecting to the Controller ........................................................................................... 4-1

4.2 Off Command .................................................................................................................... 4-2

4.3 His Commands.................................................................................................................. 4-3

4.4 Script Diagnostics ............................................................................................................ 4-4

4.5 Log Menu ........................................................................................................................... 4-5

4.6 Module Diagnostics.......................................................................................................... 4-5

5. Configuration & Firmware Updates .............................................................. 5-1