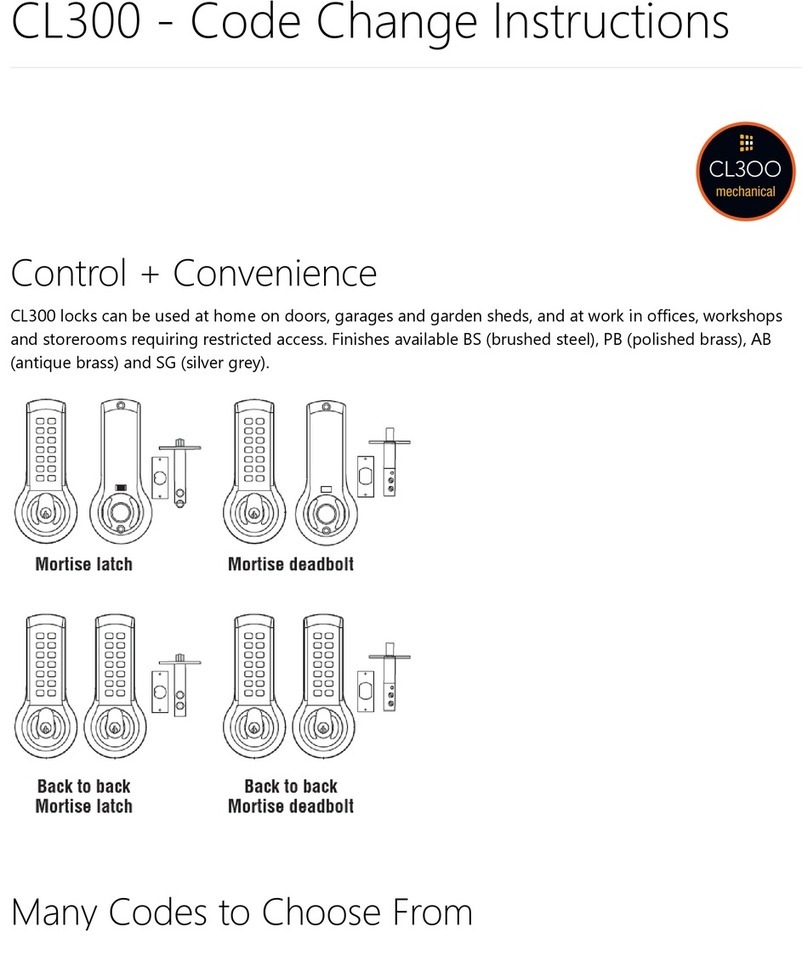

CL100 and CL200 locks can be used at home on doors, garages

and garden sheds, and at work in ofces, workshops and

storerooms requiring restricted access. Available in Silver

Grey, Polished Brass and Stainless Steel.

MANY CODES TO CHOOSE FROM

The CL100 and CL200 code chamber consists of 13 buttons from

which the code is selected, and a ‘C’ button which is used to re-set

the chamber after an incorrect entry, and which must always be used

as the rst digit of a code. Buttons may only be used ONCE in a code.

For example, 1212 is not possible.

A CL100 and CL200 code, or combination, can be entered in any

order or sequence; e.g. 1234 can be 4321 or 1342 or whatever

sequence is most convenient to remember. With 13 buttons, a total

of 8,191 different codes are available, any of which can be entered in

any sequence.

Remove the CL100 or CL200 lock from the door by unscrewing the

2 screws in the back plate.

Press the ‘C’ button to reset the chamber and place the lock case on

a at surface with the buttons down.

Remove the 2 red screws and carefully lift off the code chamber

plate. Check that all 14 springs are held in place on the plate.

Note that the coloured code tumblers correspond in position to the

existing code. The silver non-code tumblers ll the other positions.

The C tumbler is not coloured.

Hold the lock in your hand and depress the ‘C’ button. Keeping

the ‘C’ button depressed, use tweezers to re-position the tumblers

to correspond with your new code. The square notches of ALL

tumblers MUST face outwards, with the square tips ON TOP: See

diagram below. DO NOT force the tumblers in.

Replace the code chamber plate carefully with the 2 red screws.

Check the operation of the new code, and make a written note of

it before re-installing the lock.

Insert the spindle, with the spring on the code side.

On latchbolt locks the spindle must engage the latch

as follows:

MAINTENANCE

No maintenance of the working parts is necessary. DO NOT OIL.

To maintain the nish the lock should be cleaned regularly with a

soft cloth. A silicone spray or similar, should be used to provide a

protective lm against grit and grime.

GUARANTEE

If any Codelocks mechanical lock should develop a fault, at any time

due to manufacturing, just call the Codelocks Helpline and arrange for

it to be repaired free of charge.

CODE CHANGE INSTRUCTIONSCONTROL + CONVENIENCE

NB: Holding the ‘C’ button depressed whilst re-positioning

the tumblers is ESSENTIAL to avoid damaging the internal

mechanism. DO NOT attempt to reposition the ‘C’ tumbler.

Surface

Deadbolt

Back to Back

Mortice Latch

Mortice Latch

with Hold Open Feature

Mortice

Deadbolt

Key Override

Option

16

7

8

2

3

4

5

Generally codes are set in the range of 4 to 7 digits, and the total

number of codes in this range is 5434. The lock is factory set with a

randomly selected 6 digit code starting with the ‘C’ button.

The code is not recorded by the factory. The code can be changed as

often as required to any other 6 digit code. Every new code must start

with the ‘C’ button. Using the spare tumblers, the code length can be

changed to 5 or 7 digits.

Shorter codes are not recommended.

+ 1 digit = 13 codes

+ 2 digits = 78 codes

+ 3 digits = 286 codes

+ 4 digits = 715 codes

+ 5 digits = 1,287 codes

+ 6 digits = 1,716 codes

+ 7 digits = 1,716 codes

+ 8 digits = 1,287 codes

+ 9 digits = 715 codes

+ 10 digits = 286 codes

+ 11 digits = 78 codes

+ 12 digits = 13 codes

+ 13 digits = 1 code

Total codes

8,191

C

C

C

C

C

C

C

C

C

C

C

C

C

Door hung on right viewed from outside

Door hung on left viewed from outside

Coloured code tumblers

with square notch

in low position

Silver non-code tumblers

with square notch

in high position

Section through lockcase

showing square notches in

tumblers facing outwards