Granudos 45/100-CPR Touch XL + Touch + S5

Dosing unit

Index: 02 Date modified: 06/06/2019 OI No.: BA SW 003-02 Granudos 45-100 CPR Touch+Touch+S5-Dosiereinheit EN.docx Page 2 of 58

Table of contents

1About these instructions / general ............................................................................................................ 4

1.1 Scope of applicability........................................................................................................................ 4

1.2 Target group ..................................................................................................................................... 4

1.3 Symbols used .................................................................................................................................... 4

1.4 Warranty........................................................................................................................................... 6

1.5 Further information .......................................................................................................................... 6

2Safety ........................................................................................................................................................ 7

2.1 Intended use ..................................................................................................................................... 7

2.2 Safety notices.................................................................................................................................... 7

2.2.1 Handling of chemicals, risks to humans and the environment ............................................. 7

2.2.2 Protective measures and rules of conduct ............................................................................ 8

3Product description - scope of delivery...................................................................................................... 9

3.1 Scope of delivery / options ............................................................................................................... 9

3.2 Product description .......................................................................................................................... 9

3.2.1 Functioning of the GRANUDOS 45/100, dosing unit ............................................................. 9

3.2.2 Upright column with a rotatable drum holder (standard) .................................................. 12

3.2.3 Chlorine dosing (standard) .................................................................................................. 13

3.2.4 Dissolving unit (standard).................................................................................................... 14

3.2.5 Acid dosing (standard)......................................................................................................... 16

3.2.6 Buffertank............................................................................................................................ 17

3.2.7 Granudos Control unit ......................................................................................................... 18

3.2.8 Dust extraction (optional).................................................................................................... 18

3.3 Identification of device / nameplate .............................................................................................. 19

3.4 Technical data................................................................................................................................. 20

3.4.1 Requirements for the calcium hypochlorite granulate ....................................................... 22

3.5 Transport / storage......................................................................................................................... 22

4Installation ............................................................................................................................................... 23

4.1 Select the installation site............................................................................................................... 23

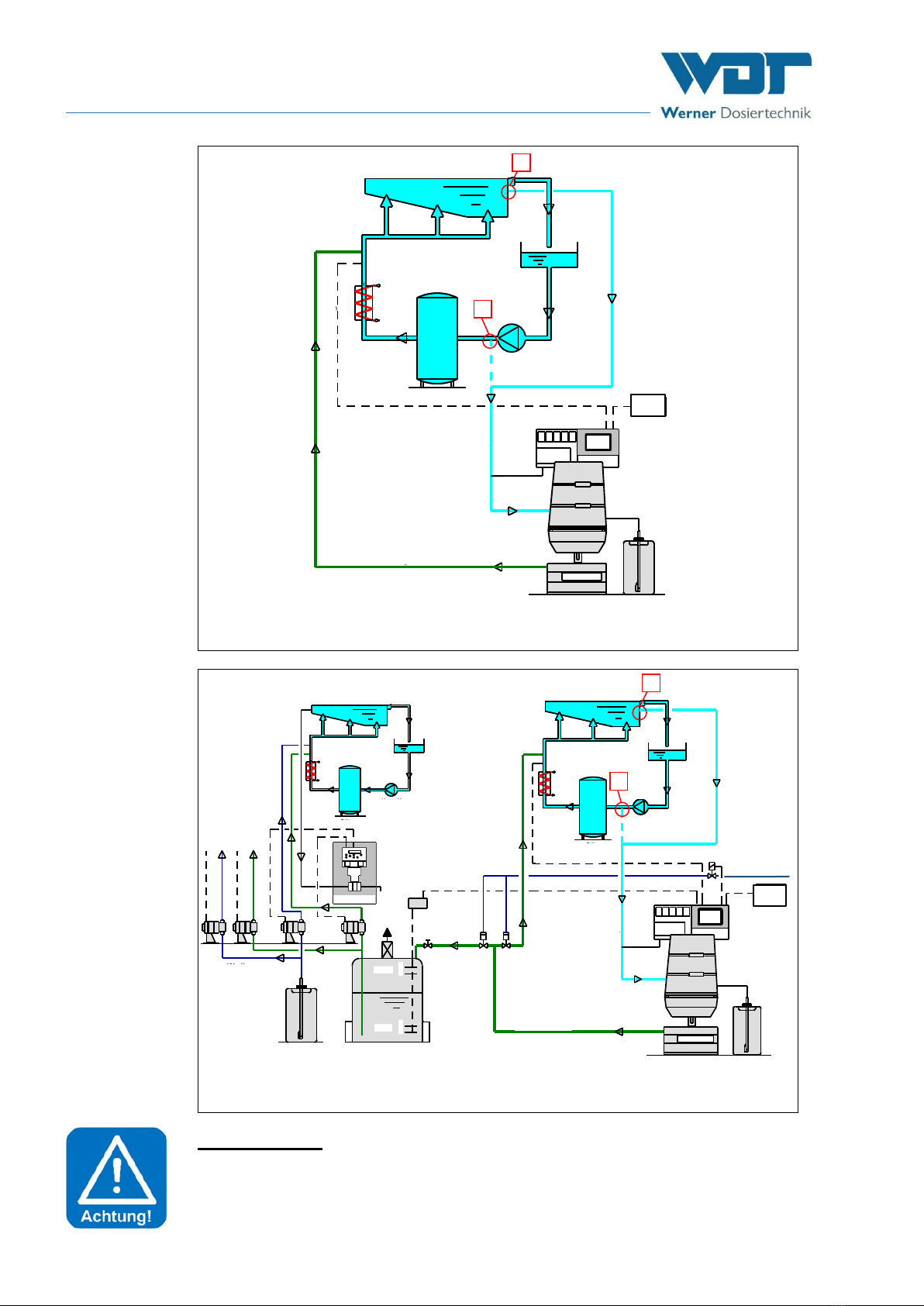

4.2 Installation instructions / installation suggestion........................................................................... 23

4.3 Mechanical installation................................................................................................................... 25

4.3.1 Installation of the GRANUDOS 45/100 dosing system ........................................................ 25

4.3.2 Installation of the buffertank (option) with / without protective tub ................................ 25

4.4 Hydraulic installation ...................................................................................................................... 26

4.4.1 Installation of the dissolving and measuring water supply ................................................. 28

4.4.2 Installation of the dosing line .............................................................................................. 30

4.4.3 Installation of the overflow line for the flushing tank......................................................... 30

4.4.4 Connect buffertank (optional)............................................................................................. 30

4.5 Electric installation.......................................................................................................................... 31

4.5.1 Open and close the housing, GRANUDOS CPR Touch and Touch ....................................... 31

4.5.2 Open and close the housing, GRANUDOS S5....................................................................... 32

5Commissioning ........................................................................................................................................ 33

5.1 Commissioning - remarks ............................................................................................................... 33

5.2 Commissioning................................................................................................................................ 33

5.2.1 Installation of peristaltic pump, roller support ................................................................... 33

5.2.2 Prepare acid dosing for operation....................................................................................... 34

5.2.3 Attach/change the drum ..................................................................................................... 35

5.2.4 Venting of the booster pump and the piping to the GRANUDOS 45/100........................... 39

5.2.5 Setting the water flow in the dissolving unit....................................................................... 40

5.2.6 Setting the water level in the flushing tank......................................................................... 41