4

SECTION 1: GENERAL INFORMATION

INTRODUCTION

This manual contains information on installing, operating

and maintaining Coinco's BillPro Series bill acceptors.

This manual is intended for owners, route operators and

shop-level technicians as a primary source of informa-

tion. Taking time to read this manual and becoming

familiar with this information will help you obtain the best

performance from your Coinco bill acceptor.

MODELS

BillPro Series bill acceptors are self-contained units

designed to work with MDB vendors. Listed below are

some of the models available:

BP2BX BillPro bill acceptor, 2 bill acceptance

($1 & $5), Bottler mask & MDB

interface only

BP4BX BillPro bill acceptor, 4 bill acceptance

($1, $5, $10 & $20), Bottler mask &

MDB interface only

BP4SX BillPro bill acceptor, 4 bill acceptance

($1, $5, $10 & $20), Snack mask &

MDB interface only

BP2BX and BP4BX bill acceptors are primarily used in

cold drink vendors which use MDB interface. The

BP4SX bill acceptor are primarily used in MDB snack,

coffee or food machines.

BillPro units support MDB communication only.

FOR YOUR RECORDS

A label indicating the model number and serial number is

affixed to the back of the bill acceptor. Refer to the

model and serial number whenever you call upon your

Coinco Service Center for information or service. The

first four digits of the serial number contain the manufac-

turing date code which indicates the beginning of the

warranty period.

EXAMPLE: Serial number 260300135. First and

second digits indicate the week of manufacture. The

third and fourth digits indicate the year (the 26th

week of 2003).

FEATURES

• Modular design

• Illuminated Inlet

• Flash programmable memory

• Exceptional acceptance rate

• Anti-jam software

• Flex stack bill box

• Center drive belt

• Scalloped bill path for wet bill acceptance

• State-of-the-art electronic logic system

• Programmable acceptance of the following bills:

$1, $5, $10 and $20.

• Vandal resistant design protects against: saltwater,

bill pullback, counterfeit bills.

• Utilizes standard mounting

• 34 V Multi-Drop Bus interface

• High impact, non-corrosive plastic construction

• Easily accessible bill path

• Self-diagnostics communicated via status light

• Manufactured and supported by Coinco.

• Made in the U.S.A.

AFTER UNPACKING

After unpacking the unit, inspect it for any possible

shipping damage. If the unit is damaged, notify the

shipping company immediately. Only the co-signee (the

person or company receiving the unit) can file a claim

against the carrier for shipping damage. We recommend

that you retain the original carton and packing materials

to reuse if you need to transport or ship your acceptor in

the future.

If the bill acceptor is being stored or used as a spare,

always keep it in its shipping carton when not in use.

This will keep it clean and offer the best protection for

the unit.

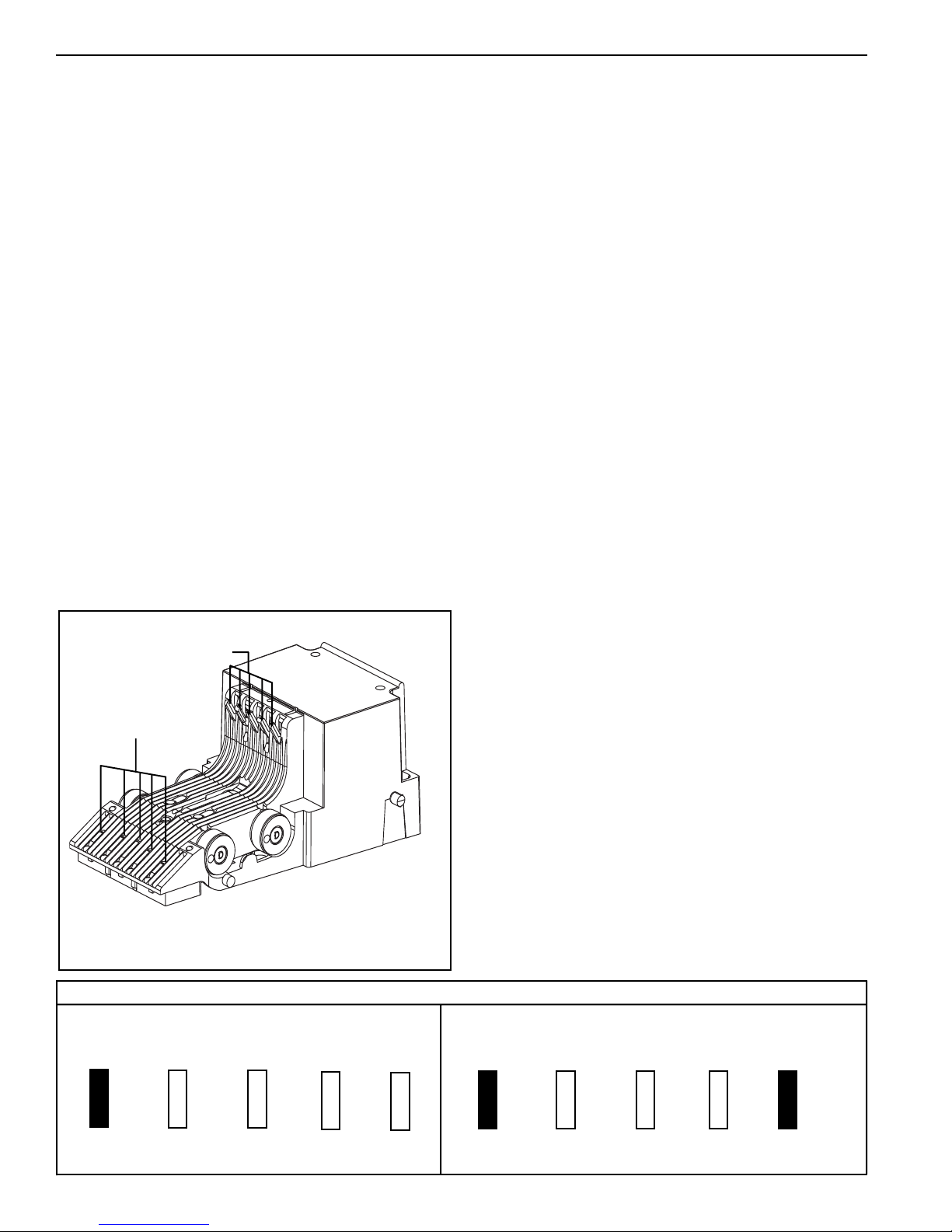

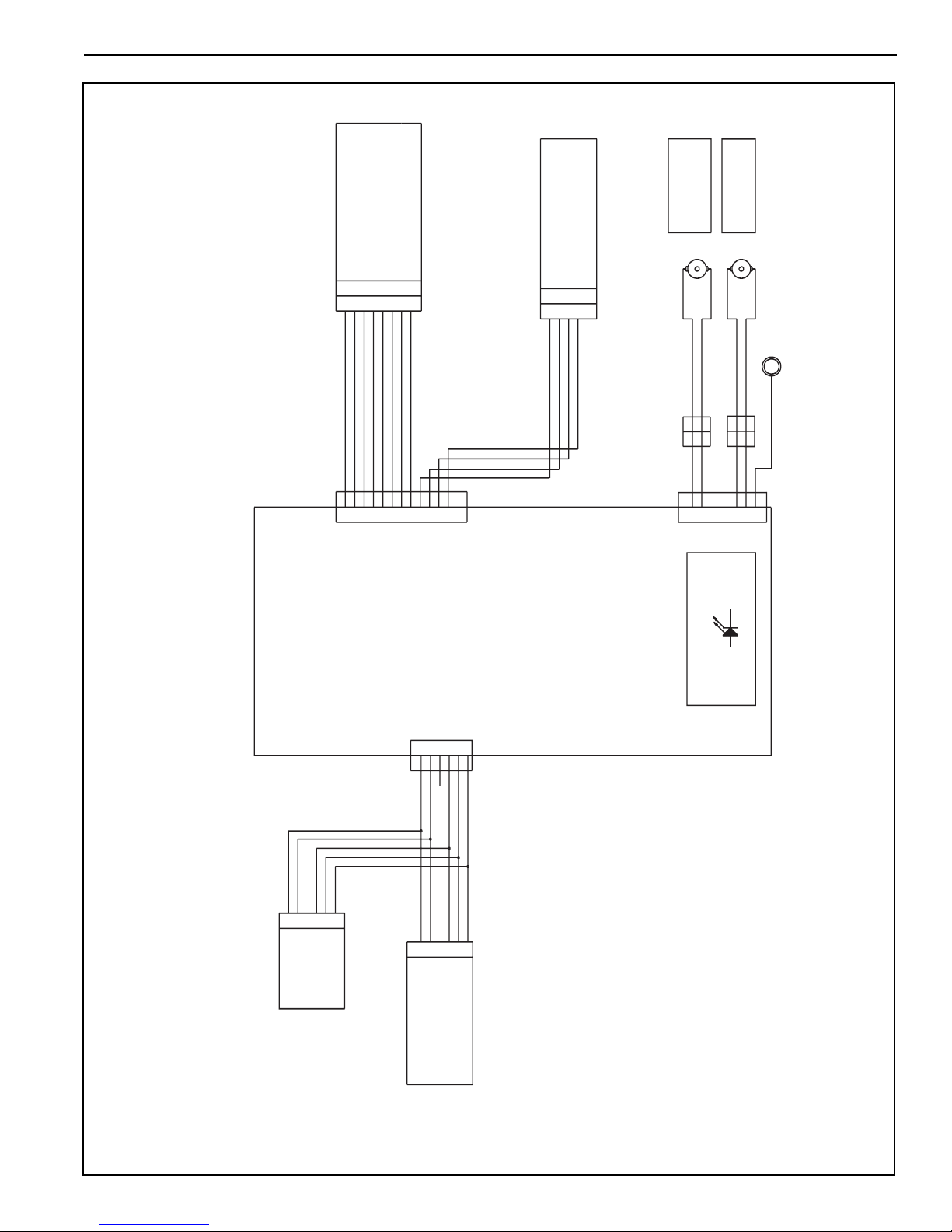

MAIN LOGIC BOARD ASSEMBLY

The main logic board contains the microprocessor which

controls all the functions of the bill acceptor based on

information from the vending machine, coin mechanism

and various bill acceptor sensors.

Also contained on the main logic board are lower optic

sensors and the power supply which receives its primary

voltage from the vending machine. The 34 VDC

(MDB) primary voltage is filtered and reduced for the

main logic board.