Vision Es-Plus // Vending

MNP141GBV00 Date: 2011/04/29 Rev. 0 PAGE3OF 24

ÍNDICE

1. Symbols...............................................................................................................4

2. Operating conditions..........................................................................................4

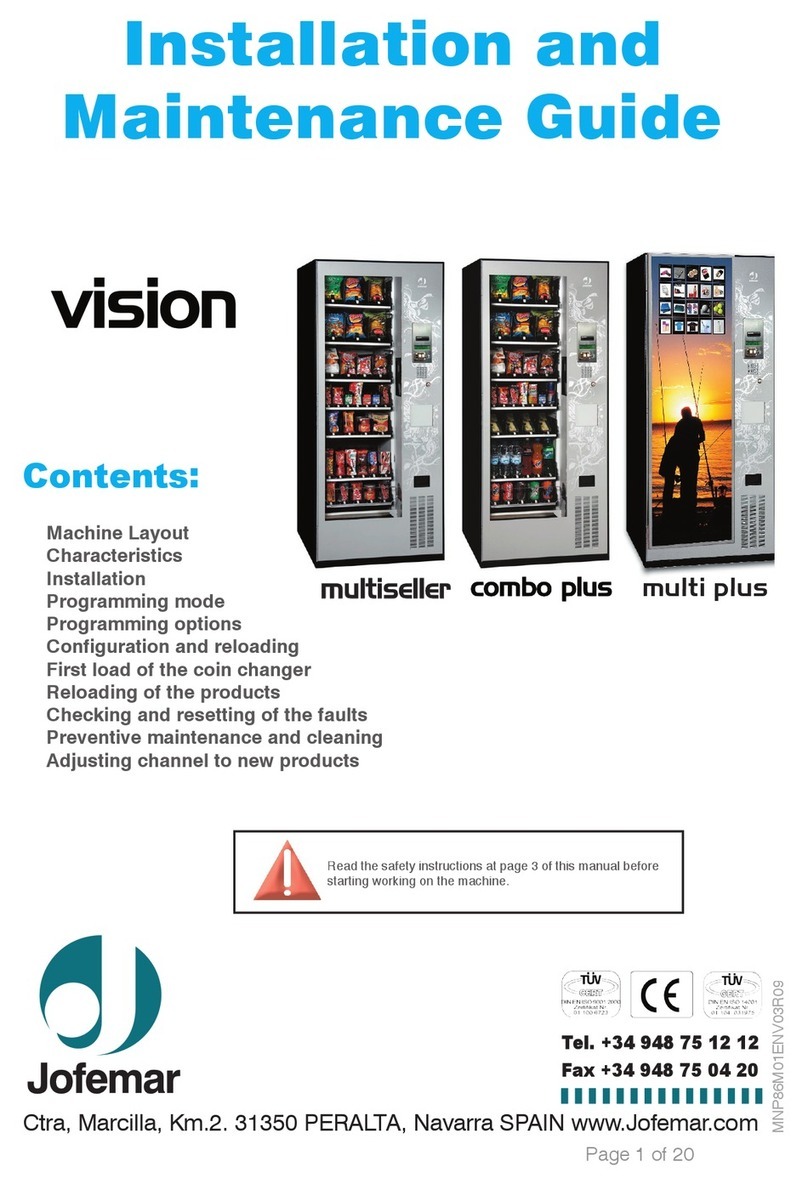

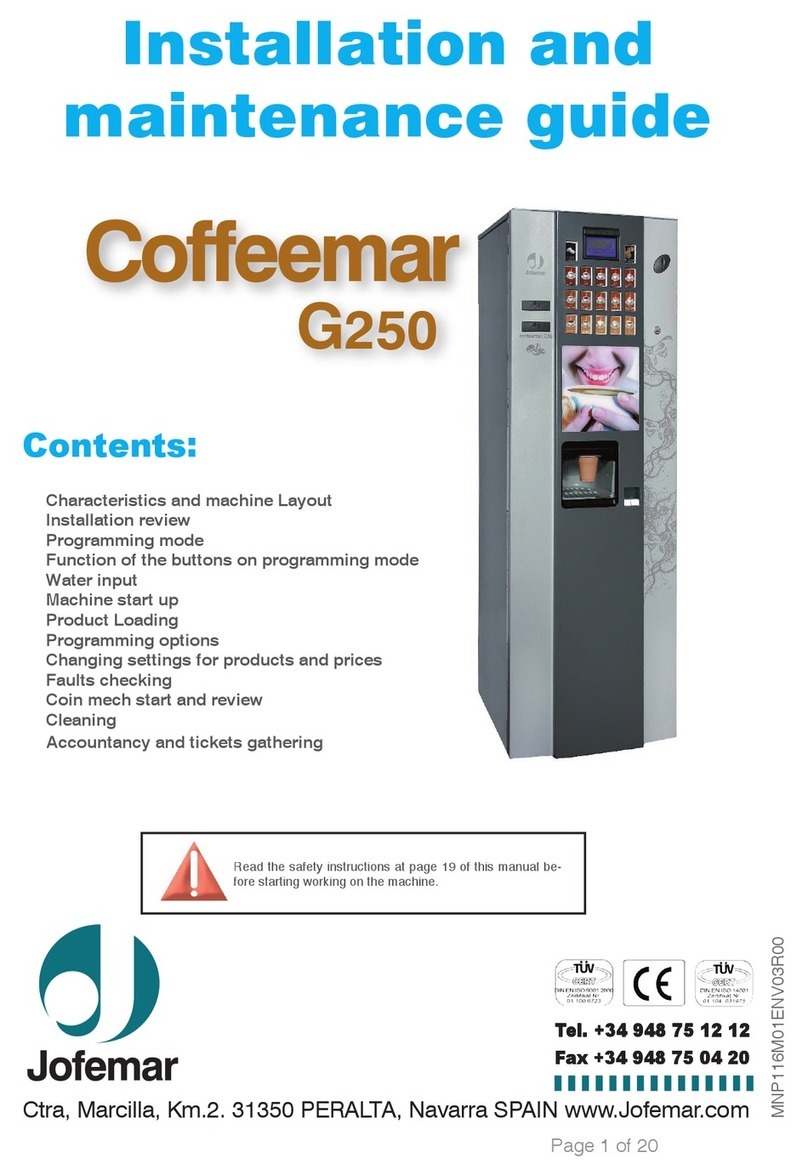

3. Description of components...............................................................................4

3.1. Main technical features...........................................................................6

3.1.1 Door......................................................................................................6

3.1.2 Cabinet.................................................................................................6

3.2. Volume and weight................................................................................11

4. Electric-electronic specifications~...............................................................12

4.1. Initial electrical installation~..............................................................12

4.2. Product dispenser channel..................................................................13

4.3. Control card............................................................................................13

4.4. Relay card...............................................................................................14

4.5. Electronic thermometer card...............................................................14

4.6. Elevator product detector photocell cards.........................................14

4.7. Electroniccontrolsystem .....................................................................14

4.8. Machine electrical drawing...................................................................16

5. Installation and start up...................................................................................17

5.1. Installation...............................................................................................17

5.2. Start up....................................................................................................17

5.3. Restocking machine trays....................................................................17

5.4. Updating the machine program...........................................................18

6. Operation...........................................................................................................19

7. Troubleshooting................................................................................................19

8. Annexes.............................................................................................................21

8.1. Transport feet and adjustable levelling feet......................................21

8.2. Cleaning and Maintenance..................................................................21

8.3. Recyclable..............................................................................................22

8.4. Environment ................................................................................23

9. Regulation.........................................................................................................23