8

1.3 USING THE ACCESSORIES

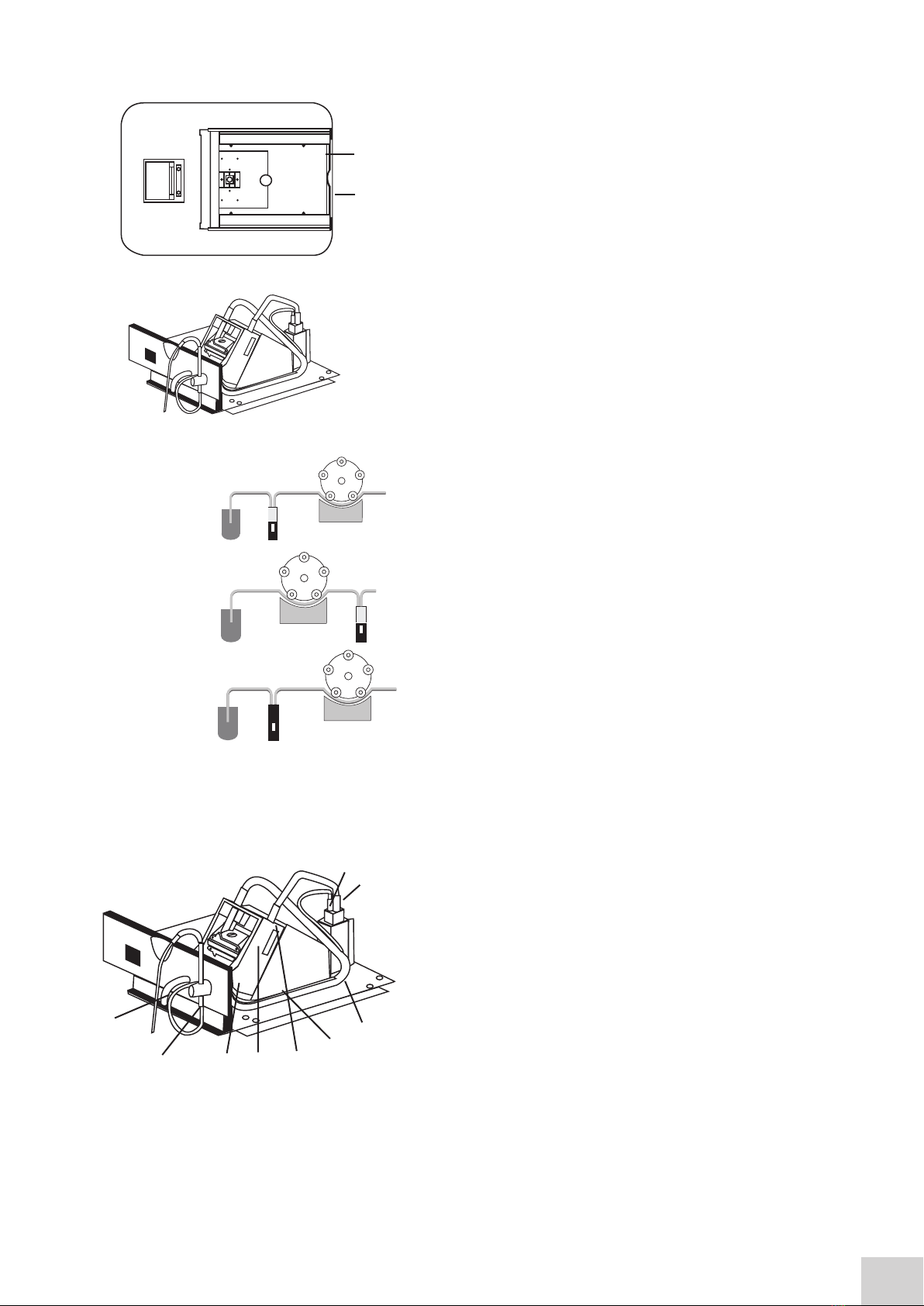

1.3.1 Automatic 8 cell turret

When the automatic 8 cell turret is in use the 8 cell turret

icon is displayed in the bottom right hand corner of the

screen. The current cell position is displayed adjacent to

the 8 cell turret icon. The 0 position should always be used

for the zero calibration sample.

To perform measurements using the automatic 8 cell turret, insert the cuvettes containing the samples

into turret positions 1 to 7. Insert the cuvette containing the blank solution into turret position 0. Enter

the required measurement mode and set up the required measurement parameters. Press the key below

the calibrate to zero icon. The instrument will automatically move the turret around to position zero to

perform the measurement. Once the calibration is complete the measure sample icon will appear and

the turret will return to its original starting position.

Press the key below the 8 cell turret icon to highlight

the icon and the two arrow icons above. Press the keys

adjacent to the arrow icons to increase or decrease

the current cell position of the turret, until the required

sample position has been selected. Press the key below

the measure sample icon. The instrument will perform a

reading and display the result on the screen.

To measure the next sample select the next turret position and press the key below the measure sample

icon. Repeat this process until all the samples have been measured. To adjust the wavelength press the

key below the 8 cell turret icon and use the arrow icons to adjust the wavelength.

1.3.1.1 Automatic 8 cell turret - supporting creation of a standard curve in quantitation

The 8 cell turret can be used to support creation of a new standard curve in the quantitation measurement

mode.

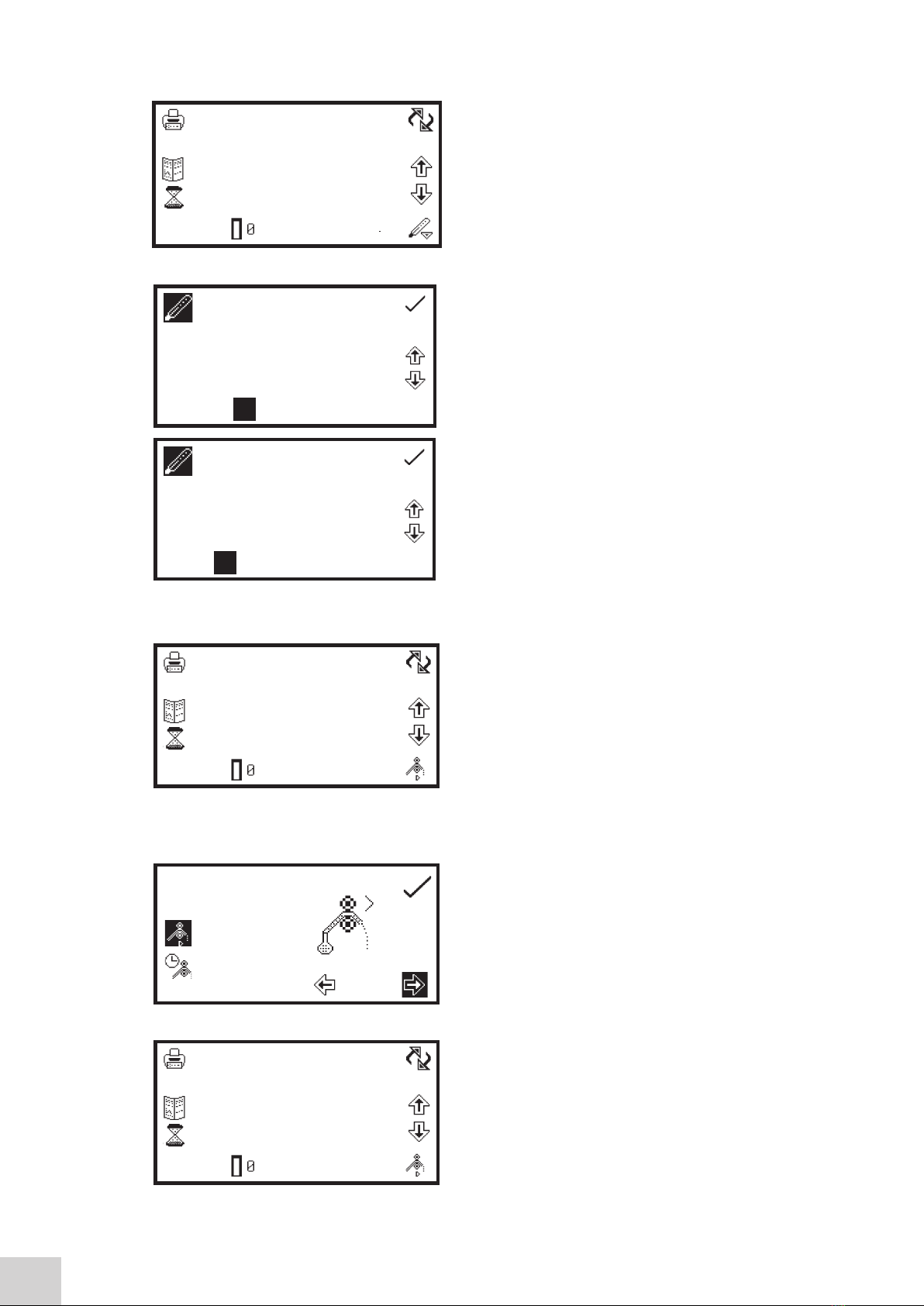

When the standard measurement screen is open the 8

cell turret icon will be displayed in the bottom left hand

corner of the screen. The current cell position is displayed

adjacent to the 8 cell turret icon. The 0 position should

always be used for the zero calibration sample.

To measure the standards using the automatic 8 cell

turret, insert the cuvettes containing the standards into

turret, insert the cuvettes containing the standards into turret positions 1 to 6 (depending on how many

standards needed). Insert the cuvette containing the blank solution into turret position 0. Press the key

adjacent to the tick icon to perform an initial calibration to zero absorbance.

Use the keys adjacent to the arrow icons to increase the turret position, until the required standard

position has been selected. Press the key adjacent to the tick icon to measure the standard. The standard

concentration and photometric value will then be displayed. The standard can be re-measured by pressing

the key adjacent to the back icon.

To measure the next standard select the next turret position and press the key adjacent to tick icon.

Repeat this process until all the standards have been measured.

0.000

0.000

500

09:02 0

ppm

ABS

nm

0.000

0.000

500

09:02 0

ppm

ABS

nm

0.000 ABS

0