7.1 DRYING MODE MAIN SCREEN ..........................................................................................................................................21

7.2 DRYING MODE RELATED SETTINGS ..................................................................................................................................22

7.3 DRYING PROFILE AND DRYING PROCESS PARAMETERS ...................................................................................................23

7.4 FINISH MODE ...................................................................................................................................................................25

7.5 UNIT DISPLAYED AND PRINTED MEASUREMENT .............................................................................................................25

7.6 PRINTOUT INTERVAL........................................................................................................................................................26

7.7 DRYING PROCESS WIZARD ...............................................................................................................................................26

7.8 DRYING PROCESS PERFOMRED WITH USE OF DRYING MODES DATABASE ......................................................................26

7.9 DRYING PROCESS .............................................................................................................................................................27

7.10 END RESULT PROGNOSIS ...............................................................................................................................................31

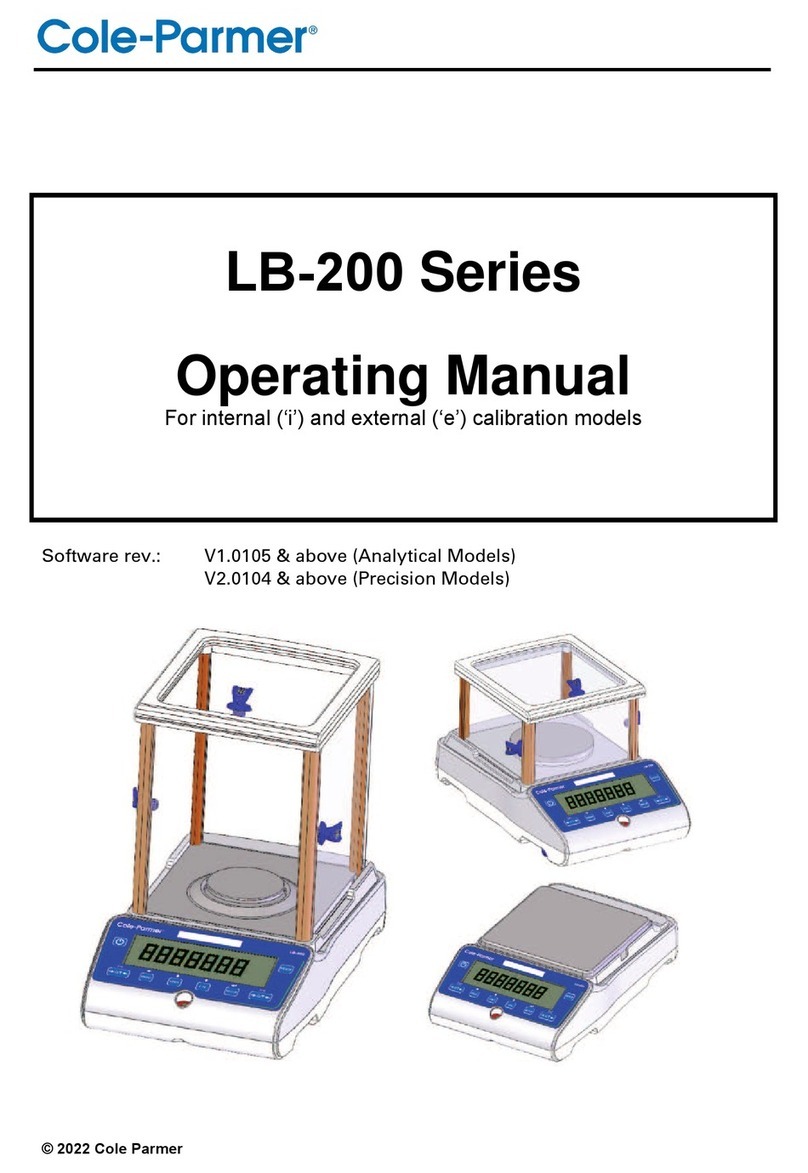

8. WEIGHING MODE.................................................................................................................................................. 32

8.1 WEIGHING MODE MAIN SCREEN .....................................................................................................................................32

8.2 GOOD WEIGHING PRACTICE ............................................................................................................................................33

8.3 UNITS ...............................................................................................................................................................................33

8.4 WEIGHING UNIT AVAILABILITY ........................................................................................................................................34

8.5START UNIT SELECTION....................................................................................................................................................34

8.6 USER-DEFINED UNIT ........................................................................................................................................................35

8.7 ZEROING ..........................................................................................................................................................................35

8.8 TARING.............................................................................................................................................................................35

8.9 WEIGHING PROFILE .........................................................................................................................................................37

8.10 <WEIGHING> -READOUT MODE SETTINGS....................................................................................................................38

8.11 PROXIMITY SENSORS .....................................................................................................................................................40

8.12 AUTOTARE .....................................................................................................................................................................40

8.13 PRINT MODE ..................................................................................................................................................................41

8.14 MINIMUM SAMPLEWEIGHT..........................................................................................................................................42

8.15 INTEGRATION WITH TITRATORS ....................................................................................................................................45

9. ADJUSTMENT........................................................................................................................................................ 45

9.1 EXTERNAL ADJUSTMENT..................................................................................................................................................45

9.2 USER ADJUSTMENT..........................................................................................................................................................46

9.3 REPORT PRINTOUT...........................................................................................................................................................46

9.4 ADJUSTMENT OF THE DRYING CHAMBER TEMPERATURE ...............................................................................................46

9.5 TEMPERATURE TEST ........................................................................................................................................................49

10. WORKING MODES- GENERAL INFORMATION ........................................................................................... 50

10.1 RUNNING WORKING MODE...........................................................................................................................................50

10.2 WORKING MODES ACCESSIBILITY ..................................................................................................................................51

11. DATABASES...................................................................................................................................................... 51

11.1 DATABASE CONNECTED OPERATIONS ...........................................................................................................................51

11.2 PRODUCTS .....................................................................................................................................................................53

11.3 USERS.............................................................................................................................................................................53

11.4 PACKAGING....................................................................................................................................................................53

11.5 CUSTOMERS...................................................................................................................................................................54

11.6 DRYING PROGRAM ........................................................................................................................................................54

11.7 DRYING PROCESS REPORTS............................................................................................................................................54

11.8 AMBIENT CONDITIONS ..................................................................................................................................................55

11.9 WEIGHING RECORDS .....................................................................................................................................................55