Cole Parmer TA-225.C User guide

Other Cole Parmer Scale manuals

Cole Parmer

Cole Parmer MB-800 Series User manual

Cole Parmer

Cole Parmer CS-200 User manual

Cole Parmer

Cole Parmer PBL-602 User manual

Cole Parmer

Cole Parmer IBS-200 User manual

Cole Parmer

Cole Parmer B2 Series User guide

Cole Parmer

Cole Parmer IPSW-400 Series User manual

Cole Parmer

Cole Parmer TA-225.C User manual

Cole Parmer

Cole Parmer IPSW Series User manual

Cole Parmer

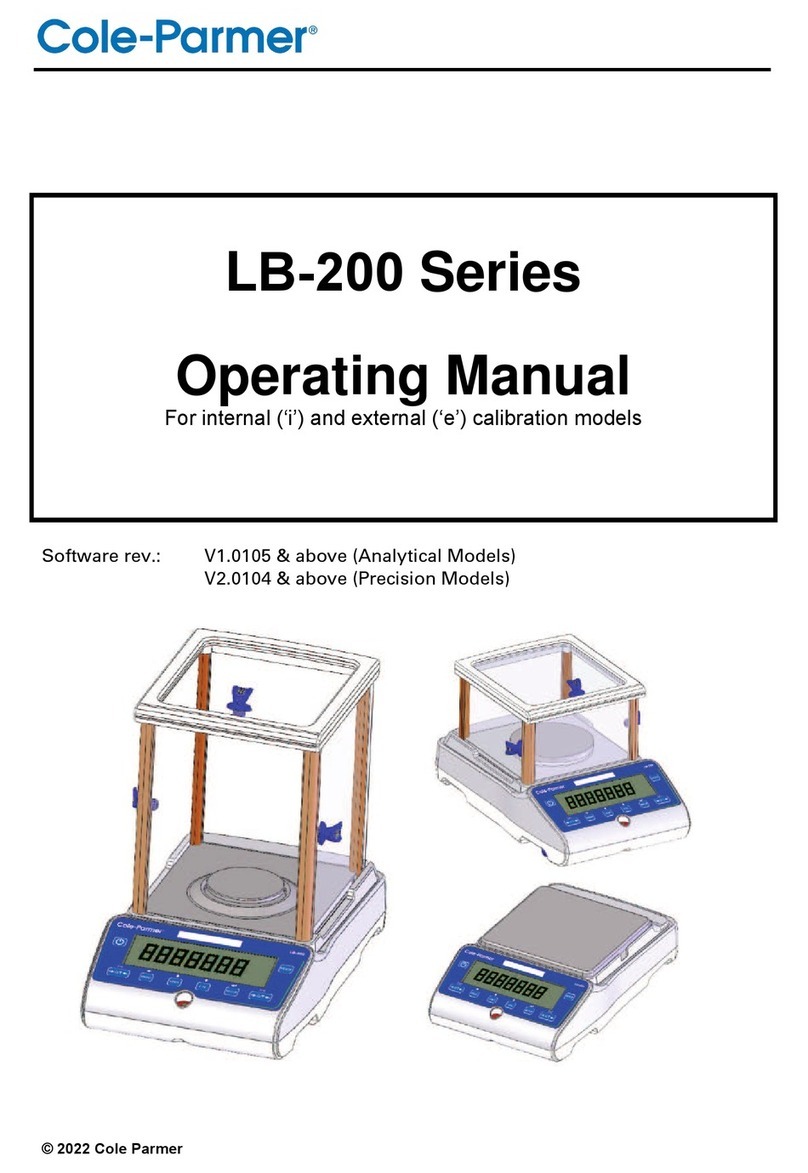

Cole Parmer LB-200 Series User manual

Cole Parmer

Cole Parmer Balance LA Series User guide