SEA GATE 1 DG R2BF User manual

67410179 REV. 14 - 04/2021

GATE 1 DG R2BF

CONTROL UNIT FOR SLIDING GATES, SWING GATES, BARRIERS AND GARAGE DOORS

SEA USA Inc.

10850 N.W. - 21st - unit 160 - Doral - MIAMI

Florida (FL) - 33172 - USA

Telephone - : ++1-305.594.1151 ++1-305.594.7325

Toll free: 800.689.4716

www.sea-usa.com

IMPORTANT SAFETY INFORMATION

Clean and grease parts in movement (wheels, counter-connecting rod, release, etc.)

Check for corroded parts and replace if necessary

Check if the screws and all mounting hardwares are properly tighten

Check the conditions of wear and tear of the devices in movement

Check the correct drain of the rainwater

Check the integrity of the connection cables

Inspect the track for any signs of cracking or separation

Ensure that the gate moves freely

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

Check and confirm the proper operation of all safety devices (photocells, edge sensors etc)

Check and confirm the operation of all installed accessories

Check and confirm the operation of the manual release

Check the battery conditions and be sure that connections are free of corrosion

Verify the functionally of the battery backup, or power failure option

GENERAL SAFETY PRECAUTIONS

The following precautions are an integral and essential part of the product and must be supplied to the user;

Read them carefully as they contain important indications for the safe installation, use and maintenance.

1. These instruction must be kept and forwarded to all possible future users of the system.

2. This product must be used only for that which it has been expressly designed.

3. Any other use is to be considered improper and therefore dangerous.

4. The manufacturer cannot be held responsible for possible damage caused by improper or unreasonable use.

5. Avoid operating in the proximity of the hinges or moving mechanical parts.

6. Do not enter the path of the moving gate while in motion.

7. Do not obstruct the motion of the gate as this may cause a situation of danger.

8. Do not allow children to play or stay within the path of the moving gate.

9. Keep remote control or any other control devices out of the reach of children, in order to avoid possible involuntary

activation of the gate operator.

10. In case of break down or malfunctioning of the product, disconnect from the main power source. Do not attempt to

repair or intervene directly, contact only qualified personnel for repair.

11. Failure to comply with the above may create a situation of danger.

12. All cleaning, maintenance or repair work must be carried out by qualified personnel.

13. In order to guarantee that the system works efficiently and correctly it is important to have the manufacturer's

instructions on maintenance of the gate and operator carried out by qualified personnel.

14. In particular, regular checks are recommended in order to verify that the safety devices are operating correctly.

All installation, maintenance and repair work must be documented and made available to the user.

IMPORTANT SAFETY INSTRUCTIONS

WARNING – TO REDUCE THE RISK OF INJURY OR DEATH:

1. READ AND FOLLOW ALL INSTRUCTIONS.

2. Never let children operate or play with gate controls. Keep the remote control away from children.

3. Always keep people and objects away from the gate. NO ONE SHOULD CROSS THE PATH OF THE MOVING GATE.

4.Test the gate operator monthly. The gate MUST reverse on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the force or the limit of travel, retest the gate operator. Failure to

adjust and retest the gate operator properly can increase the risk of injury or death.

5. Use the emergency release only when the gate is not moving

6. KEEP GATES PROPERLY MAINTAINED. Read the owner’s manual. Have a qualified service person make repairs to

gate hardware.

7. The entrance is for vehicles only. PEDESTRIANS MUST USE SEPARATE ENTRANCE.

8. Every gate operator installation MUST have secondary protection devices agains entrapments, such as edge

sensors and photo beams more in particulary in places where the risk of entrapments is more likely to occur

9. SAVE THESE INSTRUCTIONS

OPERATORS PERIODIC MAINTENANCE

TURNING OFF THE POWER

BY MAIN SOURCE TURNED-OFF

TURNING ON THE POWER

!

YEARLY

YEARLY

YEARLY

YEARLY

YEARLY

ALL THE ABOVE DESCRIBED OPERATIONS MUST BE MADE EXCLUSIVELY BY AN AUTHORIZED INSTALLER

2

GENERAL SAFETY INFORMATION

An appliance shall be provided with an instruction manual.

The instruction manual shall give instructions for the installation, operation, and user maintenance of the appliance.

The installation instructions shall specify the need for a grounding-type receptacle for connection to the supply and

shall stress the importance of proper grounding.

The installation instructions shall inform the installer that permanent wiring is to be employed as required by local

codes, and instructions for conversion to permanent wiring shall be supplied.

INFORMATION SHALL BE SUPPLIED WITH A GATE OPERATOR FOR:

a. The required installation and adjustment of all devices and systems to effect the primary and secondary protection

against entrapment (where included with the operator).

b. The intended connections for all devices and systems to effect the primary and secondary protection against en-

trapment. The information shall be supplied in the instruction manual, wiring diagrams, separate instructions, or the

equivalent.

VEHICULAR GATE OPERATORS (OR SYSTEMS)

A vehicular gate operator shall be provided with the information in the instruction manual that defines the different

vehicular gate operator Class categories and give examples of each usage. The manual shall also indicate the use for

which the particular unit is intended as defined in Glossary, Section 3. The installation instructions for vehicular gate

operators shall include information on the Types of gate for which the gate operator is intended.

A gate operator shall be provided with the specific instructions describing all user adjustments required for proper

operation of the gate. Detailed instructions shall be provided regarding user adjustment of any clutch or pressure relief

adjustments provided. The instructions shall also indicate the need for periodic checking and adjustment by a qualified

technician of the control mechanism for force, speed, and sensitivity.

Instructions for the installation, adjustment, and wiring of external controls and devices serving as required protection

against entrapment shall be provided with the operator when such controls are shipped with the operator.

Instructions regarding intended installation of the gate operator shall be supplied as part of the installation instructions

or as a separate document. The following instructions or the equivalent shall be supplied where applicable:

IMPORTANT INSTALLATION INSTRUCTIONS

1. Install the gate operator only when:

a. The operator is appropriate for the construction of the gate and the usage Class of the gate

b. All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet

(1.22 m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings

anywhere in the gate, and in that portion of the adjacent fence that the gate covers in the open position

c. All exposed pinch points are eliminated or guarded

d. Guarding is supplied for exposed rollers

2. The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a

separate access opening. The partial access opening shall be designed to promote pedestrian usage. Locate the gate

such that persons will not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

3. The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent

structures when opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access

areas.

4. The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do

not over-tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

5. The gate operator controls must be placed so that the user has full view of the gate area when the gate is moving and

AWAY FROM THE GATE PATH PERIMETER.

6. Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and

where the user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or

easily accessible controls shall have a security feature to prevent unauthorized use.

7. The Stop and/or Reset button must be located in the line-of-sight of the gate. Activation of the reset control shall not

cause the operator to start.

8. A minimum of two (2) WARNING SIGNS shall be installed, one on each side of the gate where easily visible

9. FOR GATE OPERATORS UTILIZING A NON-CONTACT SENSOR:

a. See instructions on the placement of non-contact sensors for each Type of application

b. Care shall be exercised to reduce the risk of nuisance tripping, such as when a vehicle, trips the sensor while the

gate is still moving

c. One or more non-contact sensors shall be located where the risk of entrapment or obstruction exists, such as the

perimeter reachable by a moving gate or barrier

3

10. FOR A GATE OPERATOR UTILIZING A CONTACT SENSOR:

a. One or more contact sensors shall be located where the risk of entrapment or obstruction exists, such as at the

leading edge, trailing edge, and postmounted both inside and outside of a vehicular horizontal slide gate.

b. One or more contact sensors shall be located at the bottom edge of a vehicular vertical lift gate.

c. One or more contact sensors shall be located at the pinch point of a vehicular vertical pivot gate.

d. A hardwired contact sensor shall be located and its wiring arranged so that the communication between the sensor

and the gate operator is not subjected to mechanical damage.

e. A wireless contact sensor such as one that transmits radio frequency (RF) signals to the gate operator for

entrapment protection functions shall be located where the transmission of the signals are not obstructed or

impeded by building structures, natural landscaping or similar obstruction. A wireless contact sensor shall

function under the intended end-use conditions.

f. One or more contact sensors shall be located on the inside and outside leading edge of a swing gate. Additionally, if

the bottom edge of a swing gate is greater than 6 inches (152 mm) above the ground at any point in its arc of travel,

one or more contact sensors shall be located on the bottom edge.

g. One or more contact sensors shall be located at the bottom edge of a vertical barrier (arm).

INSTRUCTION REGARDING INTENDED OPERATION OF THE GATE OPERATOR SHALL BE PROVIDED AS PART OF THE USER

INSTRUCTIONS OR AS A SEPARATE DOCUMENT. THE FOLLOWING INSTRUCTIONS OR THE EQUIVALENT SHALL BE PROVIDED

NOTICE

As for misunderstandings that may arise refer to your area distributor or call our help desk. These instructions are part

of the device and must be kept in a well known place. The installer shall follow the provided instructions thoroughly.

SEA products must only be used to automate doors, gates and wings. Any initiative taken without SEA USA Inc. explicit

authorization will preserve the manufacturer from whatsoever responsibility. The installer shall provide warning notices

on not assessable further risks. SEA USA Inc. in its relentless aim to improve the products, is allowed to make

whatsoever adjustment without giving notice. This doesn’t oblige SEA to up-grade the past production. SEA USA Inc.

can not be deemed responsible for any damage or accident caused by product breaking, being damages or accidents

due to a failure to comply with the instructions herein. The guarantee will be void and the manufacturer responsibility

will be nullified if SEA USA Inc. original spare parts are not being used. The electrical installation shall be carried out by

a professional technician who will release documentation as requested by the laws in force. Packaging materials such

as plastic bags, foam polystyrene, nails etc must be kept out of children’s reach as dangers may arise.

TO RESPECT THE LAWS IN FORCE IT IS RECOMMENDED TO USE THE ENCODER WITH THE ELECTRONIC CONTROL UNIT

UL 325 ED. 6th ENTRAPMENT PROTECTION REQUIREMENTS

VEHICULAR GATE OPERATOR CLASSES

Residential Vehicular Gate Operator-Class I: A vehicular gate operator (or system) intended for use in garages or

parking areas associated with a residence of one-to-four single families

Commercial/General Access Vehicular Gate Operator-Class II: A vehicular gate operator (or system) intended for

use in a commercial location or building such as a multi-family housing unit (five or more single family units), hotel,

garages, retail store, or other buildings accessible by or servicing the general public

Industrial/Limited Access Vehicular Gate Operator–Class III: A vehicular gate operator (or system) intended for

use in an industrial location or building such as a factory or loading dock area or other locations not accessible by or

intended to service the general public

Restricted Access Vehicular Gate Operator–Class IV: A vehicular gate operator (or system) intended for use in an

industrial location or building such as a factory or loading dock area or other locations not accessible by or intended to

service the general public

THIS VEHICULAR GATE OPERATOR MUST BE INSTALLED WITH AT LEAST TWO INDEPENDENT ENTRAPMENT PROTECTION MEANS

AS SPECIFIED IN THE TABLE BELOW

HORIZONTAL SLIDE

VERTICAL LIFT - VERTICAL PIVOT

ENTRAPMENT

PROTECTION

TYPES

TYPE A

TYPE B1

TYPE B2

TYPE C

Inherent entrapment protection system

Non-contact sensors such as photoelectric sensors or equivalents

Contact sensors such as edge sensors or equivalent devices

Inherent force limiting, inherent adjustable clutch or inherent pressure relief device

TYPE D Actuating device requiring constant pressure to maintain opening or closing motion of the gate

SWING

VERTICAL BARRIER (ARM)

A , B1*, B2* or D A , B1*, B2*, C or D

GATE OPERATORS CATEGORY (Effective January, 12 2016)

4

NOTES:

1. The same type of device shall not be used for both entrapment protection means. Use of a single device to cover both

the opening and closing directions is in accordance with the requirement; however, a single device is not required to

cover both directions. Tice installer is required to install entrapment protection devices in each entrapment zone

2. FOR VERITICAL BARRIERS ONLY: Barrier gate operators (arm) that is not intended to move toward a rigid objact

closer than 16 inches (406 mm) are not required to be provided with a means of entrapment protection

* B1 and B2 means of entrapment protection MUST be MONITORED

Changes to UL 325 ED. 6th for Gate Operators

Starting on Jan. 12, 2016, new UL 325 changes take effect, bringing a series of new mandates for the gate

operator industry. Here’s a quick guide to the key modifications

1. ENTRAPMENT-PROTECTION DEVICES: Gate operators are required to have a minimum of two independent means of

entrapment protection where the risk of entrapment or obstruction exists. A manufacturer can use two inherent-type

systems, two external-type systems, or an inherent and an external system to meet the requirement. However, the

same type of device cannot be used for both means of protection.

2. MONITORING REQUIRED: An external non-contact sensor or contact sensor may be used as a means of entrapment

protection. However, the sensor must be monitored once every cycle for:

a. the correct connection to the operator

b. the correct operation of the sensor

If the device is not present, not functioning, or is shorted, then the gate operator can only be operated by constant

pressure on the control device. Portable wireless controls will not function in this case.

3. ENTRAPMENT RISK IDENTIFICATION: As in the past, it’s up to the installer to examine the installation and determine

where a risk of entrapment or obstruction exists. Manufacturers are required to provide instructions for the placement

of external devices, but they give only examples of suggested entrapment protection in their installation manuals. If the

installer identifies a risk of entrapment or obstruction, at least two independent means of entrapment protection are

required.

4.TERMINOLOGY CHANGE: The terms «primary» and «secondary» have been removed in the description of entrapment

protection devices. This was done to emphasize that all entrapment protection devices are equally important.

5. THE END OF TYPE E: Type E (audible alarm) devices can no longer be used for entrapment protection. This change

was made because the Type E device is really a warning device, not an entrapment-protection device. Also, all gate

operator classes are now required to have an audio alarm that sounds when two successive obstructions are

encountered via a contact-type system.

6. ACCESS CONTROL LOCATION FOR EMERGENCY USE: An exception has been added in the manufacturer’s instructional

requirements for the location of controls that operate the gate.

The instructional requirements state that these controls must be at least 6' away from any moving part of the gate. In the

new exception, «Emergency access controls only accessible by authorized personnel (e.g., fire, police, EMS) may be

placed at any location in the line-of-sight of the gate».

7. BARRIER-ARM OPERATOR EXCEPTION: An exception has changed for barrier-arm gate operators requiring entrapment

protection. The previous exception stated that a barrier-arm operator did not require entrapment protection if the arm

did not move toward a rigid object closer than 2". The distance has been reduced to 16" so it more closely aligns with the

industry-defined entrapment protection provisions in ASTM F2200.

8. GATE OPERATOR CLASS II AND CLASS III DEFINITIONS: The definitions for installation classes for gate operators were

modified. Class II now includes commercial locations accessible to the general public. Class III was refined to specify

industrial locations not accessible to the general public. These changes, while seemingly minor, may affect which gate

operator is suitable for a particular installation location.

5

1

2

3

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

4

4.1

4.2

4.3

5

5.1

6

6.1

7

7.1

Connections

Jumpers

Connections on CN1

Start

Partial opening Start

Stop

Photocells 1 and 2

24V AUX

Timer

Flashing lamp

Safety edge

10K Photocell

Buzzer

Safety loop

Relay on 24VAUX output

External receiver

Latch opening/closing

Connections on CN2

Motor connection

Three-phase module

Courtesy light

Connections on CN3

Control unit power supply

Connections on CN4

Synchronized photocells

Connections on CN5

Encoder

INDEX

8

8

9

9

9

9

9

9

9

10

10

10

10

11

11

12

12

12

12

13

13

13

13

13

13

14

14

CHAPTER PAGE

14

14

14

15

15

16

16

16

16

17

18

18

18

19

20

21

23

25

25

26

28

38

CHAPTER PAGE

8

8.1

8.2

9

9.1

10

11

11.1

11.2

11.3

12

12.1

12.2

13

14

15

16

17

18

19

--

--

Connections on CN6/CN7

Pre-wired limit switch

Non pre-wired limit switch

Connections on CMS

Master / Slave

RECEIVERS on CNA/CNS

Connections on EXP

SEM 2 management unit

Temperature probe

Potentiometer

Additional functions

Amperometric management

Surge Protector circuit

Display/programming

Basic Menu

Input management

Working times

Logics

Password

Receivers - remote controls

Menu table

Alarms indications

6

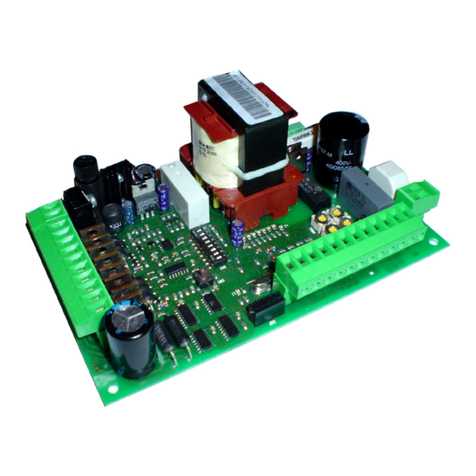

INPUT OUTPUT

MOTOR

CAPACITOR

COUTESY LIGHT

POWER SUPPLY

24V~

ENCODER

PRE-WIRED

LIMIT-SWITCH

NOT PRE-WIRED

LIMIT-SWITCH

RX RECEIVER

RF FIX RECEIVER

PROGRAMMING

EXTERNAL MODULE

MASTER / SLAVE

JOLLY 3

SEACLOUD

MOTOR CONTROL

TRIAC

COURTESY LIGHT

AND MOTOR RELAY

MOTOR EXCHANGE

RELAY

FUSE 6.3AT ON 230V

10AT ON 115V

1A ACCESSORIES

FUSE

POWER

TRANSFORMER

POWER SUPPLY

WORKING TEMPERATURE

STAND-BY ABSORPTION

EXTERNAL BOX

6,10 inches

3,35 inches

--------

--------

--------

--------

-

-

DISPLAY

CN1

14 15 16 17 18 19 20

N

98

7

6

5

4

3

2

110 13

12

11

R1

F1

T1

R2

CN6CN7

JOLLY 3

CNA CNSCNS

EXP

CN4

CNP

UP DOWN OK

CMS

TR1

CN5

CN3 CN2

F2

L

CN1

CN2

CN3

CN4

CN5

CN6

CN7

CNA

CNS

CNP

EXP

CMS

JOLLY

T1

R1

R2

F1

F2

TR1

COMPONENTS

230 Vac 50/60 Hz

115Vac 50/60 Hz

30 mA

7,20x9,37x4,72 inches

IP55

TECHNICAL DATA

-4°F +122°F

7

Partial opening Start

Photocell 2

Safety Edge

Common

Common

Photocell 1

1 - CONNECTIONS

Italiano

ENGLISH

International registered trademark n. 804888

3 - JUMPERS

OPTIONAL

Start

Stop

Antenna

Flashing lamp (-)

AUX

* (24V 500 mA max)

* 24V 500 mA max

(Accessories)

Opening Limit Switch (green)

Closing Limit Switch (yellow)

Common (white)

* 24V (red)

Common

Opening Limit Switch (green)

Closing Limit Switch (yellow)

* The maximum indicated load of 500 mA refers to the maximum load distributed

on all 24V outputs included the absorption of the receiver on board (30 mA)

On the 24V AUX output it is possible to connect a maximum load of 500 mA

WARNING: The control unit is designed

for the automatic detection of not used

N.C. inputs (Photocells, Stop and Limit

switch) except for the SAFETY EDGE

input. The excluded inputs during the

self-programming can be restored

through the «INPUT STATUS CHECK»

menu (chapter 15) without need to repeat

the control unit programming

NOTE:

The herein reported functions are available starting from Software Revision 03.03 of this

control unit and it is compatible with JOLLY 3 programmer

2 - JUMPERS

CN1

98

7

6

5

4

3

2

110 13

12

11

CN4

24Vac *

Max. 150 mA

CN5

CN6

1

CN1

98

7

6

5

4

3

2

110 13

12

11

+

-

+

-

+

-

+

-

14 15 16 17 18 19 20

CN2

M

ENCODER

ANT COM START PEDST STOP COM PH1 PH2 EDGE 24VAUX COM 24V(FL) (FL)-

Courtesy light (phase)

LIGHT LIGHTN MCL MN MOP CAPACITOR

Courtesy light (neutral)

Closing Motor 1

Neutral Motor 1

Opening Motor 1

Motor 1 capacitor

CNA

RADIO MODULE

CONNECTOR

PROGRAMMING

BUTTONS

UP DOWN OK

EXTERNAL MODULE

CONNECTOR

EXP

CNS CNP

OPEN PROGRAMMER

(Firmware update)

JOLLY 3

JOLLY3/SEACLOUD

CONNECTOR

CN7

CN3

N

Neutral

Line

L

green or black

white or blue

brown or red

1

Partial opening Start

Photocell 2

Safety Edge

Common

Common

Photocell 1

Start

Stop

Antenna

Flashing lamp (-)

AUX

* (24V 500 mA max)

* 24V 500 mA max

(Accessories)

Common

WARNING: CONNECT ALL DEVICES WITH SWITCHED-OFF CONTROL UNIT

8

3 - CONNECTIONS ON CN1

Common

Common

Photocell 1

Common

Photocell 2

Partial Opening START

Italiano

ENGLISH

International registered trademark n. 804888

TX1

TX2

24V

CN1

13

12

11

10

9

CN1

8

7

6

5

4

3

2

1

Start

Stop

Antenna

RX1

RX2

3.1 - START (N.O.)

On clamps 2 and 3

The automation can be opened or closed through an impulse

transmitted to this input (via key button, keyboard, etc.). To

connect other Start devices (for ex. the magnetic loop) refer to

the respective instructions

Note 1: For details on the logics that can be associated to the

START button, see chapter 17 (LOGICS)

Note 2: If this contact is engaged during the pause (eg. Timer),

the gate will not close until releasing

3.2 - PARTIAL OPENING START (N.O.)

On clamps 2 and 4

The input allows to obtain the partial opening. It is possible to

manage the opening space through the menu-90 or through

the JOLLY 3. It is also possible to manage the partial opening

pause time through the menu- 91

Note 1: For details on the logics that can be associated to the

PARTIAL OPENING START button, see chapter 17 (LOGICS)

Note 2: If this contact is engaged during the pause (eg. Timer),

the gate will not close until releasing

3.3 - STOP (N.C.) On clamps 5 and 6

If this button is pressed the engine stops immediately in whatever condition or position it is. A new Start

command will be required to restore the movement.

Note: After the Stop command, the engine will always re-start in closing

3.4 - PHOTOCELL 1 AND PHOTOCELL 2

+ = 24V max 500mA (clamp 12) COM = 0V (clamps 2 - 6 - 11)

Ph1 = Photocell 1(clamp 7) PH2 = Photocell 2 (clamp 8)

Note 1: To perform the self-test, connect the TX positive to the clamp 10 (AUX) and activate the Phototest

function on menu-94; From the 95-PHOTOTEST menu it is possible to activate the self-test also on a

single photocell, choosing from the menu options.

Note 2: The default settings are: 97-PHOTOCELL 1 = «closing»; 98-PHOTOCELL 2 = «opening»;

for further functions and management, see menu-97 and menu-98

3.6 - TIMER (N.O.)

On clamp 4 (Partial Opening Start) or on clamp 8 (Photocell 2)

It can be enabled through menu-92 or via JOLLY 3. It opens and keeps the automation open until the

contact is released. When released, the operator will wait for the pause time set then will close again

Note 1: If connected to the Partial Opening Start, this command will also be disabled on the remote control

Note 2: When the timer is active, in the event of a safety device intervention, a Start command will be

required to restore the movement

Note 3: In case of a power failure when the gate is open, if the TIMER is still active, the gate automatically

closes; if no longer active, a new Start impulse will be required

IMPORTANT: on menu 89-TRAFFIC LIGHTS RESERVATION it is

possible to activate the priority in opening or closing to be associated

to the START and the PARTIAL OPENING START buttons

(only with SEM management unit)

3.5 - 24V AUX OPTIONS max 500mA

From menu 94-24VAUX or through the JOLLY 3 it is possible to choose when to have voltage on the AUX

output. It is advisable to connect the photocell power supply to the AUX output and set menu-94 on "IN

CYCLE AND PHOTOTEST" option, to save energy in stand-by. On the AUX output it is also possible to connect

a relay (i.e. in paragraph 3.12) for the connection and the management of additional accessories (electric

brake, additional warning lights, etc.)

9

Italiano

ENGLISH

International registered trademark n. 804888

Common

Safety Edge

Lamp FL(-)

EXAMPLE OF

LAMP AND

SAFETY EDGE

CONNECTION

GREY

WHITE

BLUE

Photocell 10K

BROWN

Common

Edge

EXAMPLE OF 10K PHOTOCELL

AND BUZZER CONNECTION

-

+

24V 500 mA max

CN1

13

12

11

10

9

24V 500 mA max

CN1

13

12

11

10

9

Safety Edge

3.7 - 24V FLASHING LIGHT - MAX 3W

On clamps 12 and 13

It warns of the gate movement by performing 1 blink per

second on opening, 2 blinks per second on closing and

remaining on steady during pause. Through the flashing

light it is also possible to read the alarm signals linked to the

Stop, Photocell1, Photocell2 and Edge devices. From

menu 86-FLASHING LIGHT or JOLLY3 it is possible to

modify its functions.

Furthermore it is possible to manage the pre-flashing

function from menu 85- PRE-FLASHING

3.8 - SAFETY EDGE

On clamps 9 and 11

If activated, the safety edge opens the contact causing a partial inversion of the motion both in opening and

closing. The function can be managed from menu 100-SAFETY EDGE 1 and 102-EDGE 1 DIRECTION

Note 1: among the menu-100 options there is the 8K2 balanced edge (single or double): the edge contact

will be controlled by a specific resistance value which detects any possible short-circuit of the device. If the

device is unbalanced, a specific alarm will appear on the display

Note 2: the safety edge functions can also be managed through the JOLLY 3

Note 3: Photocell 2 input can be set on Safety Edge 2 (see menu 98-PHOTOCELL 2) so the input will work

as a second Safety Edge (for further settings see menu-103)

Lamp FL(-)

!

24V 500 mA max

CN1

13

12

11

10

9

3.10 - BUZZER 24V

On clamps 12 and 13

The Buzzer is a sound alarm that can be used as a safety device.

Use a self-oscillating 24V and 100 dB Buzzer

The Buzzer can be connected instead of the flashing light and it is

necessary to set on «BUZZER» in the menu 86-FLASHING LIGHT

The Buzzer will activate after 2 consecutive interventions of the anti-

crushing protection; to reset it press the STOP button;

In any case, the sound of the Buzzer turns off automatically after 5

minutes and the automation will stand waiting for a new command

IF BUZZER DOES NOT WORK, BE SURE THAT

MENU 86-FLASHING LIGHT IS SET ON «BUZZER»

EXAMPLE OF

TWO 10K

PHOTOCELLS

CONNECTION

GREY

WHITE

BLUE

Photocell 10K

BROWN

GREY

WHITE

BLUE

Photocell 10K

Common

Edge

BROWN

3.9 - 10K SINGLE OR DOUBLE PHOTOCELL

On clamps 9 and 11

If one or two 10K photocells are connected, the menu 100-SAFETY

EDGE 1 must be set on the respective function; 10K photocell will

work according to the settings of menu 97-PHOTOCELL 1 (or menu

98-PHOTOCELL 2 in case of two 10K photocells)

Note1: The 10K photocell gives additional protection even in the

event of a short circuit on the cables

SINGLE OR DOUBLE PHOTOCELL SETTINGS

100

UP

OK

PHOTO

10K

OK

100

UP

OK

PHOTO 10K

DOUBLE

OK

EDGE 1

EDGE 1

10

BROWN

GREEN

GREEN

GREEN

GREEN

PINK

EXAMPLE OF

SAFETY LOOP CONNECTION

C1 = OPEN CONTACT

C2 = CLOSED CONTACT

GREY

YELLOW

Italiano

ENGLISH

International registered trademark n. 804888

12 = 24 V

C (-) = 0 V

CN1

Loop1

Loop2

Loop3

98

7

6

5

4

3

2

110 13

12

11

C C2 C2C1

Loop 1

Safety Exit

Loop 2

Shadow Loop

Loop 3

Free Exit

3.11 - SAFETY LOOP

Safety Exit Loop (Loop 1)

Connection scheme of the

1 reader loop detector

7 = Photocell 1 contact (N.C.)

6 = Common

Shadow Loop (Loop 2)

Connection scheme of the

2 readers loop detector

8 = Photocell 2 contact (N.C.)

6 = Common

NOTE: Menu 98-PHOTOCELL 2

must be set on «SHADOW LOOP»

Free Exit Loop (Loop 3)

Connection scheme of the

1 reader loop detector

3 = Start contact (N.O.)

6 = Common

-

COM

NO

NC

1 2 3 4 5 67

Example: Magnetic Lock

Example:

Magnetic Lock

COM (-)

NO

NC COM

CN1

98

7

6

5

4

3

2

110 13

12

11

CN1

98

7

6

5

4

3

2

110 13

12

11

Example:

Vertical Electric Lock

+

+

+

-

+

+

EXAMPLE OF WITH RELAY CODE 23105340CONNECTION

EXAMPLE OF WITH RELAY CODE 54020285CONNECTION

Relay Type 23105340

10 - AUX 24V

(500 mA max)

11 - Common

External Power Supply

12V/24V DC (or 230V)

Relay Type 54020285

11 - Common

10 - AUX 24V (500 mA max)

External Power Supply

12V/24V DC (or 230V)

External Power Supply

12V/24V DC (or 230V)

Example: Vertical

Electric Lock

3.12 - CONNECTIONS ON THE 24V AUX OUTPUT THROUGH RELAY

On clamps 10 and 11

It is possible to connect additional accessories via relay connected to the 24V AUX output and manage

them through the menu 94-24V AUX. The menu options allow you to choose how to have voltage on the

output and, consequently, to choose the option that best manages the accessory you want to connect.

WARNING! connect the accessory AFTER selecting the option

EXAMPLE: It is possible to connect a magnetic lock (MagLock) or a vertical lock through the Relay card

code 23105340 (or old model code 54020285) to the control unit and to the external power supply (12 / 24V

DC power supply in case of 12V / 24V lock or 230V power supply in case of 230V lock)

In this case, set 94-24V AUX to «NEGATIVE BRAKE» before connecting the lock!

11

Common

LATCH CLOSING

CLOSES AND KEEPS CLOSED

LATCH OPENING

OPENS AND KEEPS OPEN

NO OTHER COMMAND ACCEPTED

Italiano

ENGLISH

International registered trademark n. 804888

EXAMPLE OF

EXTERNAL RECEIVER

CONNECTION

24V 500 mA max

(Accessories)

On clamps 4 and 6

A button for the Latch Opening or Closing function can be connected to the control unit. To activate it,

connect the N.O. contact on the Partial Opening Start (this function will be disabled). Through the menu

118-LATCH it is possible to choose between the various Latch options. To deactivate the Latch function,

press again the button used for its activation

LATCH OPENING: opens and keeps the automation open. If active, no other type of Start command is

accepted until the function is deactivated

LATCH CLOSING: closes and keeps the automation closed. If active, no other type of Start command is

accepted until the function is deactivated

Note 1: The Latch function can also be enabled on the second channel of the remote control; see

paragraph 19.2 for details

Note 2: The Latch function can also be enabled through the SEACLOUD. Please refer to the SEACLOUD

instructions for more details

12

11

6

6

34

4

CN1

98

7

6

5

4

3

2

110 13

12

11

3.14 - LATCH OPENING OR LATCH CLOSING BUTTON

CN1

98

7

6

5

4

3

2

110 13

12

11

3.13 - EXTERNAL RECEIVER

An external receiver can be connected to

the control unit according to the

connection diagram. For more details on

connections and functionalities of the

external receiver, refer to the relative

instruction manual

NO OTHER COMMAND ACCEPTED

4 - CONNECTIONS ON CN2

4.1 - MOTOR CONNECTION ON THE CONTROL UNIT

Motor 1

Motor 1 connection output

MCL = CLOSE

MN = NEUTRAL

MOP = OPEN

M

*

14 15 16 17 18 19 20

CN2

MCL MN MOP CAPACITOR

Capacitor

16 - MCL

17 - MN

18 - MOP

M

~

19

20

*

The drawing shows an external operator

for sliding gate only as an example

Closing Motor 1

Neutral Motor 1

Opening Motor 1

BLU CABLE = 230V OPERATORS

**

**

WHITE CABLE = 115V OPERATORS

12

Italiano

ENGLISH

International registered trademark n. 804888

On the 3-MOTOR menu, set

«3 THREE-PHASE-BOLLARD»

THREE-PHASE MODULE CONNECTORS

BIG 4000

THREE-PHASE

CN1 = On board power connector (220V)

CN2 = Motor connector (380V)

SFT1 = Ground connection Faston

K1 = 230V ~ 16A contactor

K2 = 230V ~ 16A contactor

T1 = Thermal switch *

!

* T1 intervention threshold:

3,7A BIG 4000 THREE-PHASE

1,8A LEPUS

CN3

N L

T1

CN1

NNF

COM

OP.

CL.

K2

K1

FST1

R (2T1)

S (4T2)

T (6T3)

CN2

U

V

W

16

18

17N L

14 15 16 17 18 19 20

CN2

MCL MN MOP

T S R N

14 15 16 17 18 19 20

CN2

LIGHT LIGHTN

15 - Courtesy light (neutral)

Max. 50W 230V Max. 100W 115V

CN3

N L

115V~ ± 5%

o

230V~ ± 5%

14 - Courtesy light (phase)

CN4

JP1

Tx1

JP1

Rx1

1 2 3 4 5 6

0 +12 +24 C N N

O O C

M

JP1

Rx2

JP1

1 2 3

Tx2

0 +12 +24

1 2 3 4 5 6

0 +12 +24 C N N

O O C

M

1 2 3

0 +12 +24

JP1

4.2 - THREE-PHASE MODULE CONNECTION

THREE-PHASE

SUPPLY 380V

THREE-PHASE

MODULE

Example: Timed Courtesy light from 0 up to 4 minutes

A timed courtesy light (from 0 to 240 seconds) can be connected

to the CN2, according to the aside connection diagram

See the menu 88-COURTESY LIGHT for settings

4.3 - COURTESY LIGHT CONNECTIONS (230V or 115V)

5 - CONNECTIONS ON CN3

6 - CONNECTIONS ON CN4

5.1 - CONTROL UNIT CONNECTION

6.1 - SYNCHRONISED PHOTOCELLS CONNECTION

NEUTRAL

LINE

It is possible to connect one or two pairs of synchro-

nized photocells on the CN4 connector (24Vac - max.

150 mA), according to the aside diagram (for further

details refer to the photocell instructions). It is also

possible to change the photocell settings through the

97-PHOTOCELL1 and 98-PHOTOCELL 2 menus

Fuse 3,6A delayed on 230V~ power supply

Fuse 6,3A delayed on 115V~ power supply

CAUTION!: for the connection to the power grid refer to the

regulations in force

NOTE: It is recommended to use a 10A differential switch to

protect the power supply system

NOTE: In case of unstable power supply, we recommend the use

of an external UPS of minimum 800VA

BLACK

BLACK

BLACK

BLACK

RED

RED

RED

RED

JP1 ON

TO ACTIVATE SYNCHRONIZATION

13

Italiano

ENGLISH

International registered trademark n. 804888

CN5

1

ENCODER

-

-

32

OK

48-ENCODER TOT M1

shows the total pulses

stored during programming

47-ENCODER PAR M1

shows the pulses read

during operation

UP

ENCODER PAR M1

-

-

47

-

-

XXX

OK

ENCODER

-

-

32

OK

UP

ENCODER TOT M1

-

-

48

-

-

XXX

OK

UP

ENCODER PAR M1

-

-

47

SETTING OF OPENING INTERVENTION TIME

values can be set from a minimum of 10% (rapid intervention) to a maximum of 99% (slow intervention).

If parameters are OFF (intervention excluded) the Encoder will only work in position detection mode

SETTING OF CLOSING INTERVENTION TIME

CN7

CN6

CN1

13

12

11

10

9

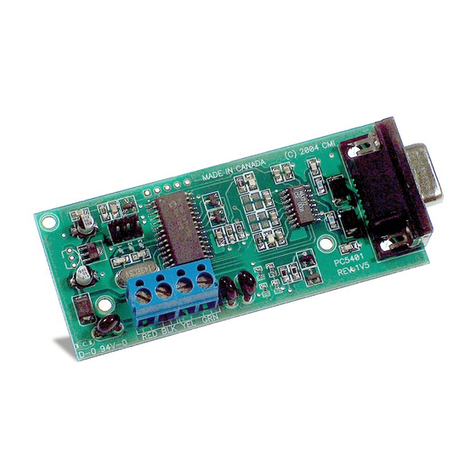

7 - CN5CONNECTIONS ON

7.1 - ENCODER CONNECTION

The ENCODER on board can be connected on CN5. In case

of non pre-wired Encoder use an appropriate adapter

respecting the cable colors

OLD TYPE ENCODER BROWN - WHITE - GREEN

NEW TYPE ENCODER RED - BLUE - BLACK

green or black

white or blue

brown or red

To enable set the menu 32-ENCODER in «ON» (if not ON by default)

SPECIAL MENU

LANGUAGE

-

-

1

M1 OP. TORQUE

-

-

28

UP

SPECIAL MENU

-

-

16

OK

-

-

ON

UP

ENCODER

-

-

32

OK

7.2 - ENCODER SETTINGS

OK

OPENING

SENSITIVITY M1

-

-

33

UP

DOWN

OK

-

-

XX%

OK

-

-

34

UP

DOWN

OK

-

-

XX%

CLOSING

SENSITIVITY M1

Example of motor with

pre-wired limit switch

Non

pre-wired

limit switch

Closing Limit Switch (yellow)

Opening Limit Switch (green)

8.1 - PREWIRED LIMIT SWITCH - CN6

The pre-wired limit switches can be connected

through the CN6 connector on the control unit, as

shown in the figure beside. The control unit can

manage mechanical, inductive or magnetic limit

switches; it is possible to set the type of limit switch

used through menu 104-SELECT LIMIT SWITCH

8.2 - - CN7NON PREWIRED LIMIT SWITCH

If a quick-fit connector is not present, the limit switch must

be connected to connector CN7 and to terminal 11

(common) of connector CN1, as shown in the figure

beside.

It is possible to set the type of limit switch used through

menu 104-SELECT LIMIT SWITCH

8 - CONNECTIONS ON CN6 and CN7

14

Italiano

ENGLISH

International registered trademark n. 804888

8.3 - IMPORTANT NOTES

1) If not connected, the limit switches must not be bridged

2) On some specific applications it will not be necessary to connect the limit switches as the control unit will

automatically detect whether they are present or not.

3) It is possible to activate the anti-intrusion function (menu 79-ANTI INTRUSION): this function is

linked to the presence of at least one limit switch, which, if released, forces the motor to re-close.

4) For a correct operation of the limit switches there must be a correspondence between the direction of

movement of the motors and the respective limit switches involved.

!

!

4

5

1

M1

M2

M1 M2

SIGB

SIGB

COM

SIGA

SIGB

SIGB

COM

SIGA

CMS

CMS

Note: use a shielded and

twisted pairs transmis-

sion cable type RS482

with a section not

2

exceeding 0.5 mm

M1

CONNECT THE FIRST CIRCUIT

ON MOTOR 1 CONTROL UNIT

2

M2

3

CONNECT THE SECOND CIRCUIT

ON MOTOR 2 CONTROL UNIT

CONNECT THE

TWO CIRCUITS

!

RESPECT THE CABLE

POLARITY

6

7

-

-

9

PROGRAMMING

M1 - MASTER M2 - SLAVE

9 - CONNECTIONS ON CMS

34-CLOSING SENSITIVITY MOTOR 1

37-SLOW-DOWN SENSITIVITY

47-PARTIAL ENCODER MOTOR 1

48-TOTAL ENCODER MOTOR 1

59-MOTOR 1 SLOWDOWN IN OPENING

60-MOTOR 1 SLOWDOWN IN CLOSING

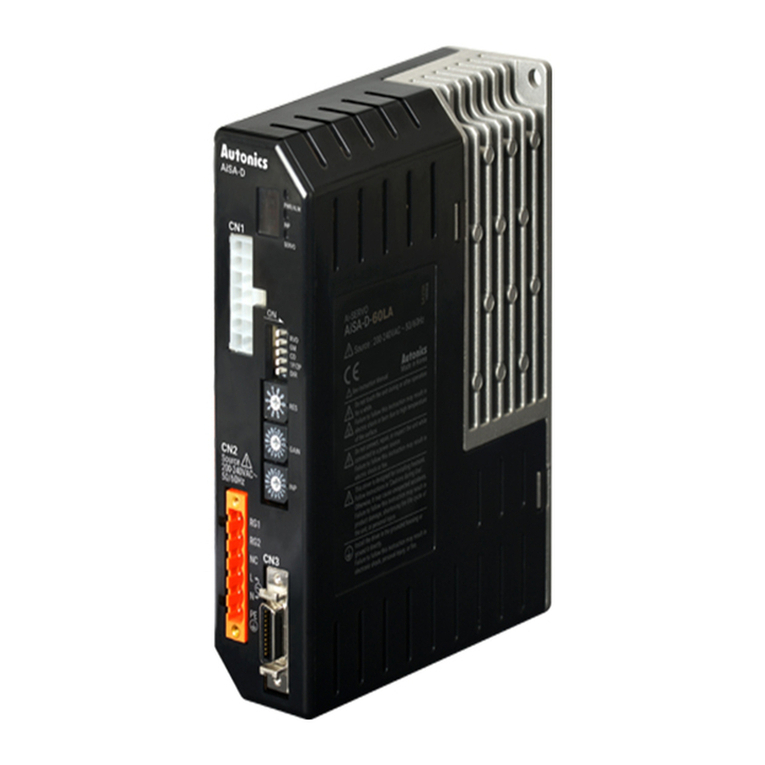

9.1 - MASTER / SLAVE CIRCUITS

It is possible to use the Master/Slave configuration on OPPOSED SLIDING GATES, OPPOSITE

BARRIERS or BOLLARDS moved by two operators EACH MANAGED BY A CONTROL BOARD

To work in Master/Slave it is necessary to use the MASTER/SLAVE KIT (code SEA 23001220) consisting of

two circuits to be connected to the control units through the CMS connector; Then set a control unit as

Master and the other as Slave through the 105-MASTER-SLAVE menu (or the JOLLY 3 programmer)

ATTENTION: In the Master/Slave configuration it is necessary to connect all the accessory devices

(photocells, key button, safety edge, etc.) on the control unit set as MASTER which will also control the

operator movement linked to the control unit set as SLAVE. The latter will allow you to adjust only the

functions of the following menus:

3-MOTOR

5-REVERSE MOTOR

28-MOTOR 1 OPENING TORQUE

29-CMOTOR 1 CLOSING TORQUE

32-ENCODER

33-OPENING SENSITIVITY MOTOR 1

63-DECELERATION

64-ACCELERATION

65-OPENING TIME MOTOR 1

66-CLOSING TIME MOTOR 1

70-RECOVERY POSITION IN OPENING

71-RECOVERY POSITION IN CLOSING

9.2 - MASTER / SLAVE SETTING

INSTALL AND SET

THE TWO OPERATORS

INDIVIDUALLY *

before proceeding read the chapter 13 explaining the operation of the display and the menus

M1 CONTROL UNIT CONFIGURATION AS MASTER (SEE ALSO CHAPTER 13)

00000000

00000000

-

-

UP

03.03

-

-

UP

LANGUAGE

-

-

1

DOWN

MASTER

/SLAVE

-

-

105

OK

MASTER

-

-

OK

UP

UP

DOWN

-

-

5 SEC.

M2 CONTROL UNIT CONFIGURATION AS SLAVE (SEE ALSO CHAPTER 13)

00000000

00000000

-

-

UP

03.03

-

-

UP

-

-

1

DOWN

MASTER

/SLAVE

-

-

105

OK

SLAVE

-

-

OK

UP

UP

DOWN

-

-

5 SEC.

LANGUAGE

WORKING TIMES SELF-LEARNING ONLY ON MASTER

CONTROL UNIT

(FOLLOW THE PROCEDURE ON CHAPTER 16)

M1 OP. TORQUE

28

M1 OP. TORQUE

28

* Install and configure the two operators as if they were two independent installations;

then check their correct operation and the correct reading of the limit switches, if present

!

!

15

Italiano

ENGLISH

International registered trademark n. 804888

--------

--------

--------

--------

-

-

14 15 16 17 18 19 20

S

+

-

98

7

6

5

4

3

2

110 13

12

11

11.1 - «SEM 2» MANAGEMENT UNIT CONNECTIONS

24V~ / (ac/dc)

or 230V~

DS1

DS2

RL4 RL3 RL2 RL1

L4 L3 L2

IC2

- M2+

1 CNP

CN1

L1

1

2

3

4

8 7 6 5 4 3 2 1

M1

EXP

11.2 - TEMPERATURE PROBE CONNECTION THROUGH «LSE» or «LE» UNITS

P01 P02

GND

I3

D1 P11 D2 P12 I1 I2 I4

M1

124567

38910 11

M2

DS1

1 2

ON

CN1

POT ENC

CNP

+

-

D1

P11

P01

1

ON

OFF

2

Dip switch 1 = OFF

Dip switch 2 = OFF

adjust both

Dip-switch on OFF

!

--------

--------

--------

--------

-

-

14 15 16 17 18 19 20

S

+

-

98

7

6

5

4

3

2

110 13

12

11

EXP

10 - RECEIVERS CONNECTIONS ON CNA AND CNS

RESPECT

INSERTION

SIDE

CNS

CNS

RF UNI

RF UNI PG

CNA

RADIO MODULE

CNS CNS

RF FIX

CNA

RADIO

MODULE

CNS CNS

!

11 - CONNECTIONS ON EXP

SEM 2

MANAGEMENT UNIT

Connect

on

EXP

The «SEM 2» management unit can be

connected through the EXP connector

The SEM 2 unit manages:

- The TRAFFIC LIGHT functions

- The COURTESY LIGHT functions

- The V ERTIC AL EL ECTRIC L OCK

functions

- The POSITIVE AND/OR NEGATIVE

ELECTRIC BRAKE functions

- The LIMIT SWITCH status

For further details on connections,

functions or specifications of the «SEM 2»

unit, refer to the relevant TECHNICAL

INSTRUCTIONS

Through the LSE management unit (or the

LE management unit) it is possible to wire up

a TEMPERATURE PROBE to detect the

engine oil temperature; If the oil tempera-

ture falls below the set value, the probe will

activate heating up to the values defined in

the set temperature range

TEMPERATURE PROBE can be enabled

through the menu 109-THERMOMETER;

TEMPERATURE RANGES can be set on:

110-LOW TEMPERATURE THRESHOLD

111-HIGH TEMPERATURE THRESHOLD

For further details on connections,

functions or specifications of the LSE or

L E u n i t s , r e f e r t o t h e r e l e v a n t

TECHNICAL INSTRUCTIONS

Example: «LSE»

MANAGEMENT UNIT

Connect

on

EXP

TEMPERATURE PROBE screw to

replace the motor oil cap

P11 = Black

D1 = White

16

Italiano

ENGLISH

International registered trademark n. 804888

Through the LSE management unit (or LE

management unit) it is possible to connect

the «POSITION GATE», a potentiometer

able to manage the correct position of the

gate and the reversing on obstacle

POSITION GATE can be enabled on menu

32-ENCODER POTENTIOMETER ON

For further details on the LSE (or LE) unit

connections and functions refer to the ,

relevant TECHNICAL INSTRUCTIONS

P11 = Brown

D1 = White or Black *

P01 = Green or Blue *

* The cables colors change depending

on whether it is the old or the

new model of POTENTIOMETER

WARNING:

SPECIAL MENU

LANGUAGE

-

-

1

-

-

UP

SPECIAL MENU

-

-

16

OK

UP

ENCODER

-

-

32

UP

DOWN

POTENTIOMETER

-

-

OK

UP

-

-

DOWN

OK

ON

-

-

OK

UP

-

-

52

UP

I. PAR. M1

-

-

51

51-I.PAR.M1 (PARTIAL PULSES MOTOR 1) displays the current position of the operator

52-I.AP.M1 (OPENING PULSES MOTOR 1) displays the impulses with the leaf completely open and it is

possible, accessing through OK, to increase or decrease the total pulses using the UP and DOWN buttons

53-I.CH.M1 (CLOSING PULSES MOTOR 1) displays the impulses with the leaf completely closed and it is

possible, accessing through OK, to increase or decrease the total pulses using the UP and DOWN buttons

POTENTIOMETER

UP

-

-

53

I. AP. M1 I. CH. M1

OK

-

-

XX

UP

DOWN

Example:

Example: «LSE»

MANAGEMENT UNIT

To use the potentiometer

it is necessary to adjust

both Dip-switch on OFF

11.4 - «POSITION GATE» POTENTIOMETER SETTING

NOTE 1: If the potentiometer reading is reversed in respect to the operator movement , the display will

show the alarm "POTENTIOMETER DIRECTION" (see the last chapter "Alarms"); it is therefore

necessary to invert the brown cable with the green cable (or Blue) and repeat the programming

TO ENABLE POTENTIOMETER

11.3 - «POSITION GATE» CONNECTION THROUGH «LSE» or «LE» UNITS

P01 P02

GND

I3

D1 P11 D2 P12 I1 I2 I4

M1

124567

38910 11

M2

DS1

1 2

ON

CN1

POT ENC

CNP

+

-

1

ON

OFF

2

Dip switch 1 = OFF

Dip switch 2 = OFF

D1

P11

P01

!

--------

--------

--------

--------

-

-

14 15 16 17 18 19 20

S

+

-

98

7

6

5

4

3

2

110 13

12

11

EXP

MANAGEMENT SUB-MENUS

11.5 - «POSITION GATE» POTENTIOMETER PARAMETERS SETTING

NOTE 1: For a quick reverse on obstacle it is necessary to decrease the sensitivity parameters

NOTE 2: The sensitivity parameters can also be set in OFF (intervention excluded); in this case the

potentiometer will only work in pulse detection mode (it does not reverse on obstacle)

Connect

on

EXP

POTENTIOMETER

menu adjusts the intervention time in opening33-OPENING SENSITIVITY MOTOR 1

menu 34- adjusts the intervention time in closingCLOSING SENSITIVITY MOTOR 1

menu 37- adjusts the inversion time during the slow-downSLOW-DOWN SENSITIVITY

menu 38-OPENING POTENTIOMETER THRESHOLD M1 adjusts the intervention threshold in opening

menu 39-CLOSING POTENTIOMETER THRESHOLD M1 adjusts the intervention threshold in closing

menu 42-POTENTIOMETER DECELERATION THRESHOLD IN OPENING M1

menu 43-POTENTIOMETER DECELERATION THRESHOLD IN CLOSING M1

M1 OP. TORQUE

28

17

Italiano

ENGLISH

International registered trademark n. 804888

-

-

UP

OK

12

VP 1

-

-

OK

XXX

-

-

3

3

SEE CHAP. 13

12.1 - AMPEROMETRIC MANAGEMENT

AT THE SAME TIME

1

2

3

4

5

6

7

1

2

3

4

5

6

7

1 2 3 4 5 6 7

1 2 3 4 5 6 7

OUTPUT

INPUT

12 - ADDITIONAL FUNCTIONS

The control unit is equipped with an obstacle detection system, (working ONLY on ELECTRO-

MECHANICAL OPERATORS) which allows reversing in opening and closing; On electromechanical

operators, the amperometric function is set to OFF by default, but it automatically activates if values

different from OFF are set on menu 37-SLOWDOWN SENSITIVITY.

If the obstacle detection system intervenes in opening, it causes a reverse of the motion for about 2

seconds; If the obstacle detection system intervenes in closing, it causes the partial or total reopening of

the gate depending on the settings on menu 46-CLOSING INVERSION

NOTE: If the 7-PAUSE TIME menu is NOT set to OFF, the «automatic reclosing» function is active: in

case of obstacle, allows the operator to attempt the reclosing for 5 times, then a new START input

will be required to restore the motion

It is possible to adjust the torque value, i.e. the inversion force on obstacle, through the menus:

28-MOTOR 1 OPENING TORQUE adjustable from 10% to 100%

29-MOTOR 1 CLOSING TORQUE adjustable from 10% to 100%

NOTE: with high torque values (max.100%), the force required to reverse on obstacle will be greater

It is possible to adjust the sensitivity for each direction (opening or closing) through the menus:

33-MOTOR 1 OPENING SENSITIVITY

34-MOTOR 1 CLOSING SENSITIVITY

NOTE 1: with high sensitivity values ( max.100%), the inversion on obstacle will occur after 5 seconds

NOTE 2: The sensitivity parameters can also be set in OFF (intervention excluded); in this case the

amperometric management will only work according to the settings of the menu-37

ATTENTION: In case of power failure, when the power is restored the first manouevre will be at high

speed in order to allow the automatic recognition of the mechanical stop

OUTPUT

CONNECTIONS ON CONTROL UNIT

INPUT

ACCESSORIES CONNECTIONS

GROUND

WIRE

24V DC ACCESSORIES

CONTACT 1 (Eg. PHOTOCELL)

CONTACT 2 (Eg. SAFETY EDGE)

CONTACT 3 (Eg. START)

CONTACT 4

CONTACT 5

CONTACT 6

24V DC ACCESSORIES

CONTACT 1 (Eg. PHOTOCELL)

CONTACT 2 (Eg. SAFETY EDGE)

CONTACT 3 (Eg. START)

CONTACT 4

CONTACT 5

CONTACT 6

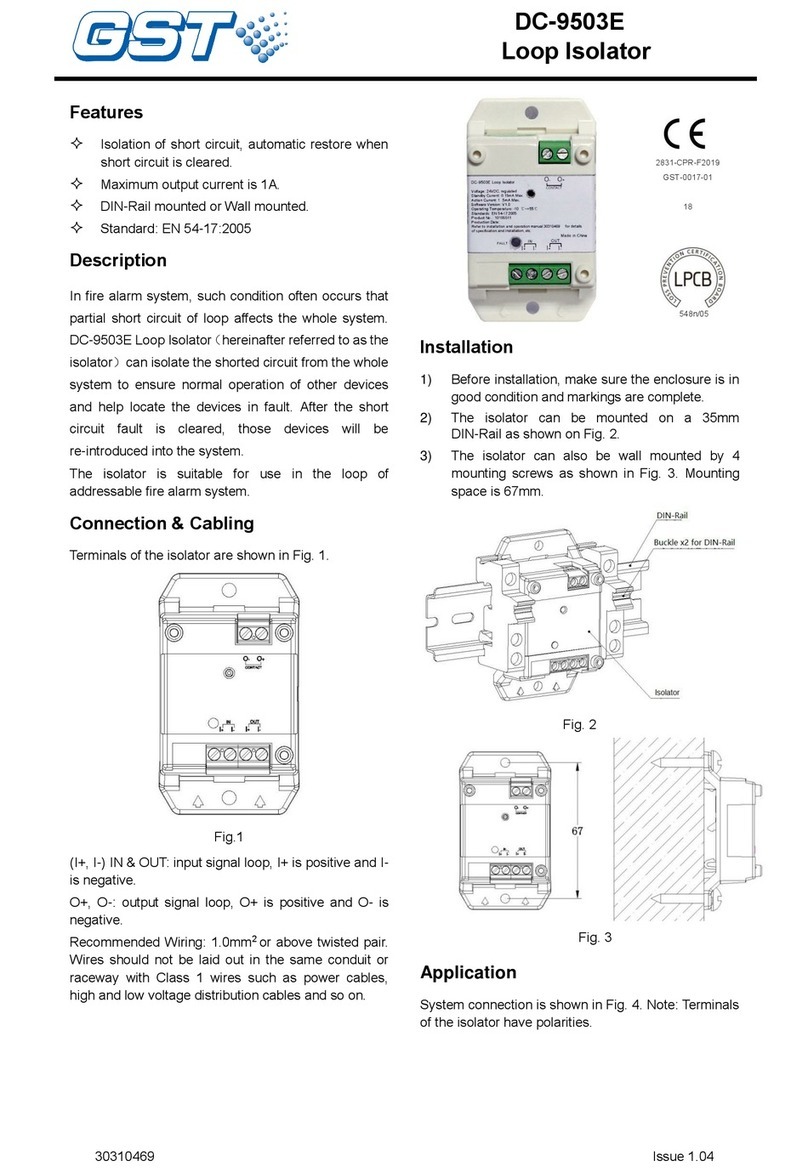

12.2 - «I/O SURGE PROTECTOR» CIRCUIT CONNECTION

It is possible to connect the «SURGE

PROTECTOR» device, to protect up

to 6 inputs + 24V power supply from

over voltages due, for example, to the

lightning strikes. Simply connect the

cable of the accessory to be protected

t o t he I N P U T o f t he S U R GE

PROTECTOR circuit and then, from

the corresponding number on the

OUTPUT terminal block, connect the

cable to the control unit

NOTE: connect the common and

the power supply negative directly

on the control unit

To view the instantaneous speed

values «VP1» (referred to the motor 1)

ACCESS THE HIDDEN «DEBUG»

M E N U a s s h ow o n t h e s id e

The view of these values allows to

11.6 - ACCESS TO THE HIDDEN «DEBUG» MENU FOR POTENTIOMETER

03.03

adjust a maximum threshold below which the potentiometer (or the encoder) intervenes. The maximum

threshold can be adjusted through menus 38-39 (while the maximum slowdown threshold can be adjusted

through menus 42-43) and must always be higher than the instantaneous speed value shown in VP1 ( )

18

Italiano

ENGLISH

International registered trademark n. 804888

13 - DISPLAY AND PROGRAMMING

!

WARNING! MAKE ALL DEVICES CONNECTIONS ON SWITCHED-OFF CONTROL UNIT

BEFORE THE PARAMETERS CONFIGURATION THROUGH DISPLAY

- - - -

- - -

- - -

SEA

SET

MENU

--

-

01000100

-

00010001

-

NEW BINGO DISPLAY

FROM SOFTWARE REV 03.02

OLD DISPLAY

PREVIOUS MANUALS

PROGRAMMING

BUTTONS UP DOWN OK

It is possible to navigate within the menus

through the programming keys UP and DOWN

(to scroll back and forth) and OK to access

submenus or to confirm a choice

13.1 - SWITCHING ON THE CONTROL UNIT

Starting from the software revision 03.02, the

electronic control unit is equipped with the new

BINGO display with different DIAGNOSTIC

symbols than the previous version. For the

old version display functions, consult

the manual of the previous revision

When a new control unit is powered on, the display shows the software revision first and the INPUT

STATUS after 5 seconds.

If a control unit is already programmed, the display immediately shows the INPUT STATUS view

ON

Power ON

NEW CONTROL UNIT OR AFTER RESET

ALREADY PROGRAMMED CONTROL UNIT

03.03

-

-

00000000

00000000

-

-

UP

1

LANGUAGE

-

-

5

SECONDS

ON

Power ON

03.03

-

-

UP

1

LANGUAGE

-

-

00000000

00000000

-

-

UP

SOFTWARE

REVISION

SOFTWARE

REVISION

INPUT STATUS

(CHAPTER 15)

BASIC PROGRAMMING

MENU

INPUT STATUS

(CHAPTER 15)

BASIC PROGRAMMING

MENU

13.2 - BASIC PROGRAMMING MENU AND SPECIAL MENU

AT THE SAME TIME

FOR 5 SECONDS

UP

DOWN

SPECIAL MENU

LANGUAGE

-

-

1

-

-

LANGUAGE

-

-

1

-

-

UP

SPECIAL MENU

-

-

16

OK

12

SPECIAL MENU

The control unit is equipped with a basic programming menu which can be accessed through the

procedure above indicated when a control unit is switched on

The control unit is also equipped with a special menu that allows the setting of various parameters and the

configuration of the accessories.

To access THE SPECIAL MENU choose one of the following 2 procedures:

28

M1 OP. TORQUE

28

M1 OP. TORQUE

19

14 - BASIC MENU FUNCTIONS

PRESS TO CONFIRM

AND RETURN TO THE

MAIN MENU

Italiano

ENGLISH

International registered trademark n. 804888

Press next Tx button

to be stored

Skip this step if no need Tx programming

Press the TX

button

to be stored

2

TRANSMITTERS

START

3

MOTOR

6

LOGIC

7

PAUSE

TIME

8

START IN

PAUSE

9

PROGRAM-

MING

10

TEST

START

1

LANGUAGE

ENGLISH

if this

message

appears

verify the receiver

connection

MISSING

RECEIVER

5

REVERSE

MOTOR

15

END

UP

OK

DOWN

MOVE THROUGH

OR

OK

UP

UP

UP

OK OK

TO CONFIRM AND EXIT

OK

MEMORIZED

!

UP

DOWN

CHOOSE THE MOTOR TYPE THROUGH

OR

OK

OK

UP

DOWN

CHOOSE «ON» TO REVERSE MOTOR

DIRECTION THROUGH OR

UP

OK

UP

OK

UP

OK

UP

OK

CHOOSE «ON» TO START THE WORKING TIMES

SELF-LEARNING THROUGH

AT THE END OF THE SELF-LEARNING

THE VIEW WILL AUTOMATICALLY

RETURN ON THE MAIN MENU

OK

The gate will perform the following cycle: CLOSE - OPEN - CLOSE

OK

CHOOSE «ON» TO TEST THE START

COMMAND THROUGH

Skip this step if a Tx has already been stored

UP

UP

OK

THE OPERATOR STARTS UP AND

THE VIEW WILL AUTOMATICALLY

RETURN ON THE MAIN MENU

PRESS TO EXIT FROM BASIC MENU AND RETURN TO

TH E «INPUT STATU S» VIEW ON THE DISPLAY

OK

OK

Skip these steps to work

in semi-automatic logic

UP

PRESS TO ACCESS

THE SPECIAL MENU

OK

16

SPECIAL

MENU

NOTE

All other parameters have

useful default settings for

the 90% of applications;

however they can be set

through the special menu

OK

14

RESET

HOLD PRESSED AND A 5 SECONDS COUNT-DOWN

WILL START; AT THE END, THE MESSAGE «INIT» WILL

APPEAR TO CONFIRM THE CONTROL UNIT RESET

OK

UP

UP

PRESS TO CONFIRM

AND RETURN TO THE

MAIN MENU

OK

PRESS TO CONFIRM

AND RETURN TO THE

MAIN MENU

OK

PRESS TO CONFIRM

AND RETURN TO THE

MAIN MENU

OK

PRESS TO CONFIRM

AND RETURN TO THE

MAIN MENU

OK

PRESS TO CONFIRM

AND RETURN TO THE

MAIN MENU

OK

PRESS

BUTTON

UP

DOWN

CHOOSE THE DESIRED WORKING

LOGIC THROUGH OR

UP

DOWN

CHOOSE THE AUTOMATIC RE-CLOSING

DELAY THROUGH OR

UP

DOWN

CHOOSE BETWEEN «ON» OR «OFF»

THROUGH OR

UP

DOWN

OR

UP

DOWN

OR

*

*

See chapter 19

before programming

remote controls

20

Other manuals for GATE 1 DG R2BF

7

Table of contents

Other SEA Control Unit manuals

SEA

SEA USER 2 24V DG R1B ALL-IN User manual

SEA

SEA GATE 1 DG R1 User manual

SEA

SEA SLIDE DG R2F User manual

SEA

SEA UNIGATE 1I User manual

SEA

SEA USER 1-24V User manual

SEA

SEA SLIDE DG R2F User manual

SEA

SEA USER 1 - 24v DG R1 User manual

SEA

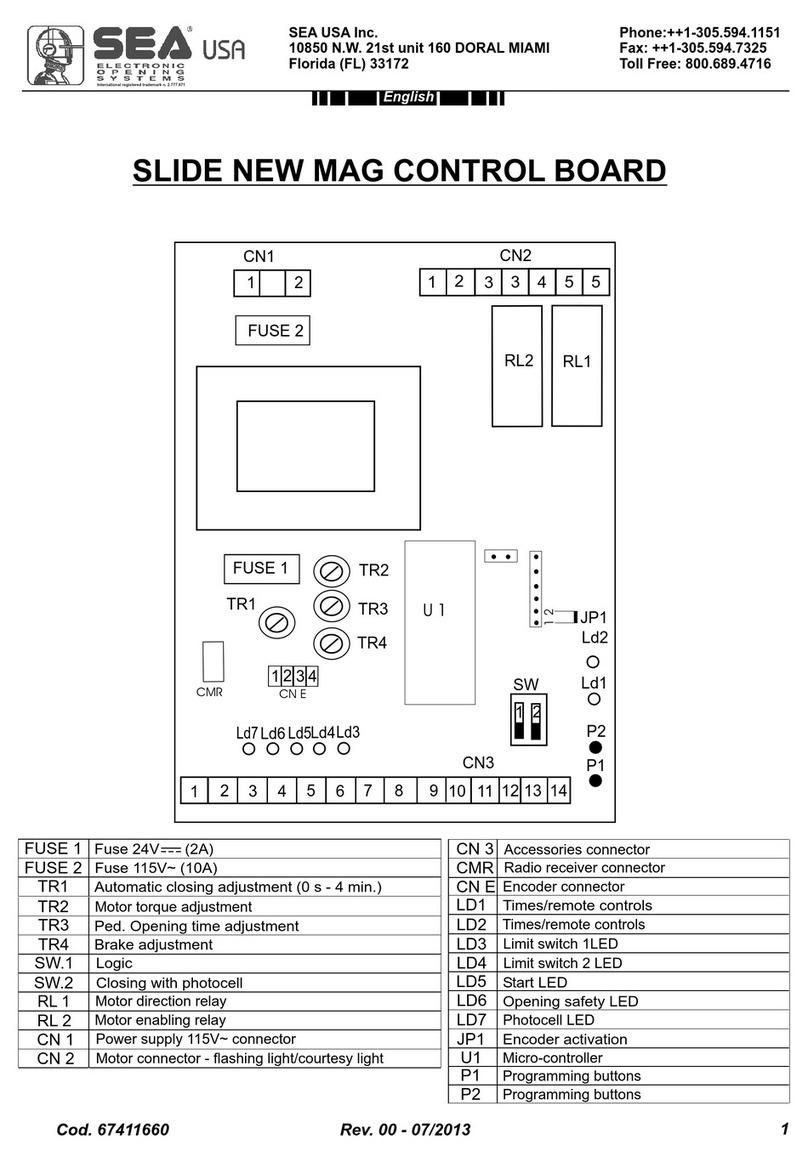

SEA SLIDE NEW MAG User manual

SEA

SEA 9521 User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA 23001157 User manual

SEA

SEA GATE 2 DG R1B User manual

SEA

SEA USER1-24V User manual

SEA

SEA USER 1 - 24v DG R1 User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA GATE 2 User manual

SEA

SEA GATE 1 DG R1 User manual

SEA

SEA GATE 1 DG R2BF User manual

SEA

SEA SWING 2 DG R2F User manual

SEA

SEA GATE 1 DG R2BF User manual