9

Location

Do not install this equipment in the same enclo-

sure with a liquid electrolyte battery unless

ventilation is provided. Various gasses emitted

from the battery will cause both premature and

intermittent circuit failure.

Choose a protected mounting location for the

Transmitter enclosure. Attach it to a back plane

or other supporting structure. Special consider-

ation must be given to installations where the

sensors or electronics will be exposed to strong

radio frequency radiation or strong magnetic

fields. Contact the factory for applications

assistance.

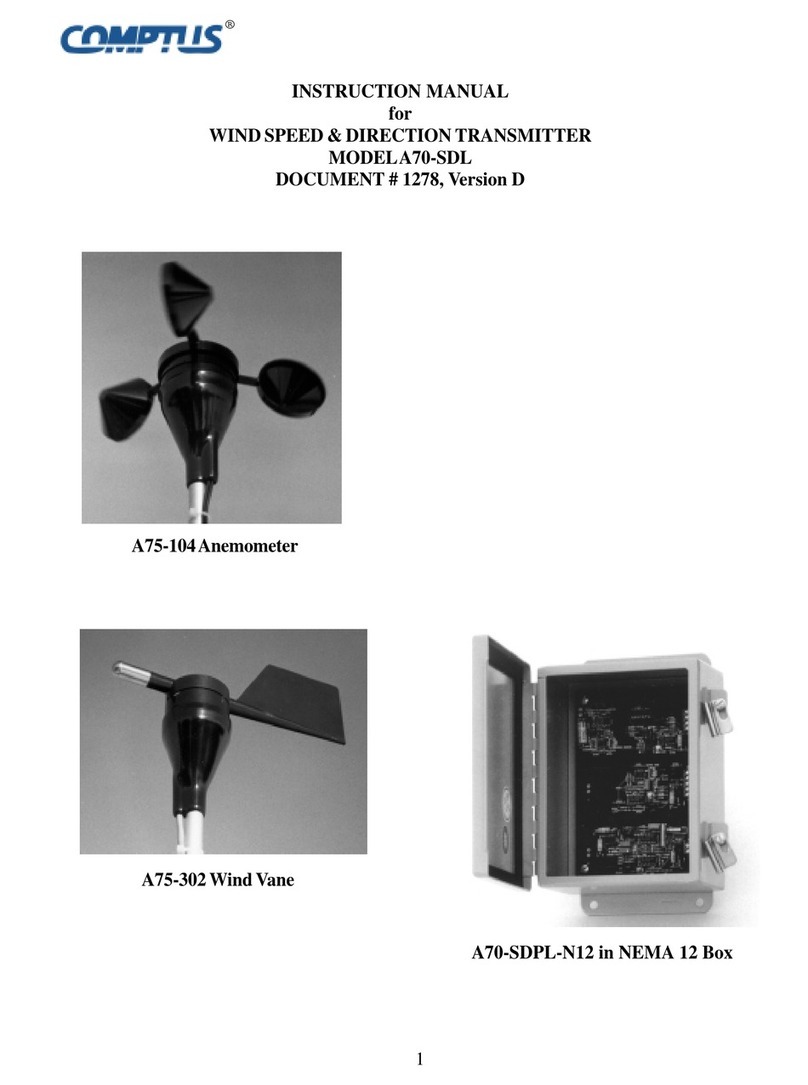

The wind vane should be mounted at the point at

which it is desired to sample the wind. Typi-

cally, it is located as high as feasible and well

clear of obstructions.

Do not mount the wind vane directly above a

vertical wall as this location often has turbulent

air flow.

It may be mounted on an existing structure, on a

natural formation, or on a mast or tower. It is

desirable to mount the vane so that the support-

ing structure will not influence the wind charac-

teristics in its immediate vicinity. If the sensor

is mounted above a roof top or similar building

structure, it should be high enough so that the

wind deflected off the structure will not affect it,

typically 5 to 10 feet or more.

If mounted to the side of a supporting structure it

should be mounted at least ten structure diam-

eters away from the structure in order to take the

sensor out of the disturbed air around the struc-

ture. It should be mounted toward the prevailing

wind, and be positioned so that the influence of

structural members is minimized.

A preferred mounting which is commonly used

is a telescopic tower for installations up to forty

or fifty feet high; a tower commonly used for TV

antenna support, consisting of concentric pieces

oftubing approximatelytenfeetlong,guyedat each

section,issuitable. Abovethisheightself-supporting

orguyed lightweight structural towerscanbeused.

If the “S” mast is to be mounted on a metallic

tower consideration must be given to galvanic

corrosion which occurs between dissimilar

metals. Attachment to galvanized steel towers

using stainless steel hose clamps is acceptable.

For other combinations of metals recommended

practice is to electrically insulate the “S” mast

from the tower with a plastic bushing or sheet.

Alternatively fabricate a “S” mast from the same

material as the tower. This consideration is

especially important in locations exposed to salt

spray and air.

Lightning Protection

The Transmitter electronics has integral metal

oxide varistors for protection from lightning

induced surges, electrostatic discharge and other

atmospheric discharges. Wind blown aerosols

such as sand and snow can generate electrostatic

charges with consequences similar to lightning

discharges. The A96 Series of gas tube surge

arrestors can safely dissipate much higher energy

discharges than the internal varistors.

Aconsequenceoftherapid rise time of electrostatic

dischargesis theinductanceofthe grounding

systemandinterconnectingwiringisgenerallyof

moreconcernthan resistance. Gas tube surge

arrestorsshould be placedas close tothe device

theyare intended to protect to minimize the induc-

tanceinthewiring.

In highly exposed systems the sensors should be

protected by gas tube surge arrestors located as

closely as possible to them, typically 12 inches

or less. The Transmitter electronics can benefit

from another set of gas tube surge arrestors

located where the sensor wiring enters the

controlbuilding. Gas tubesurgearrestorsare

recomended for any system with underground

wiring.