7

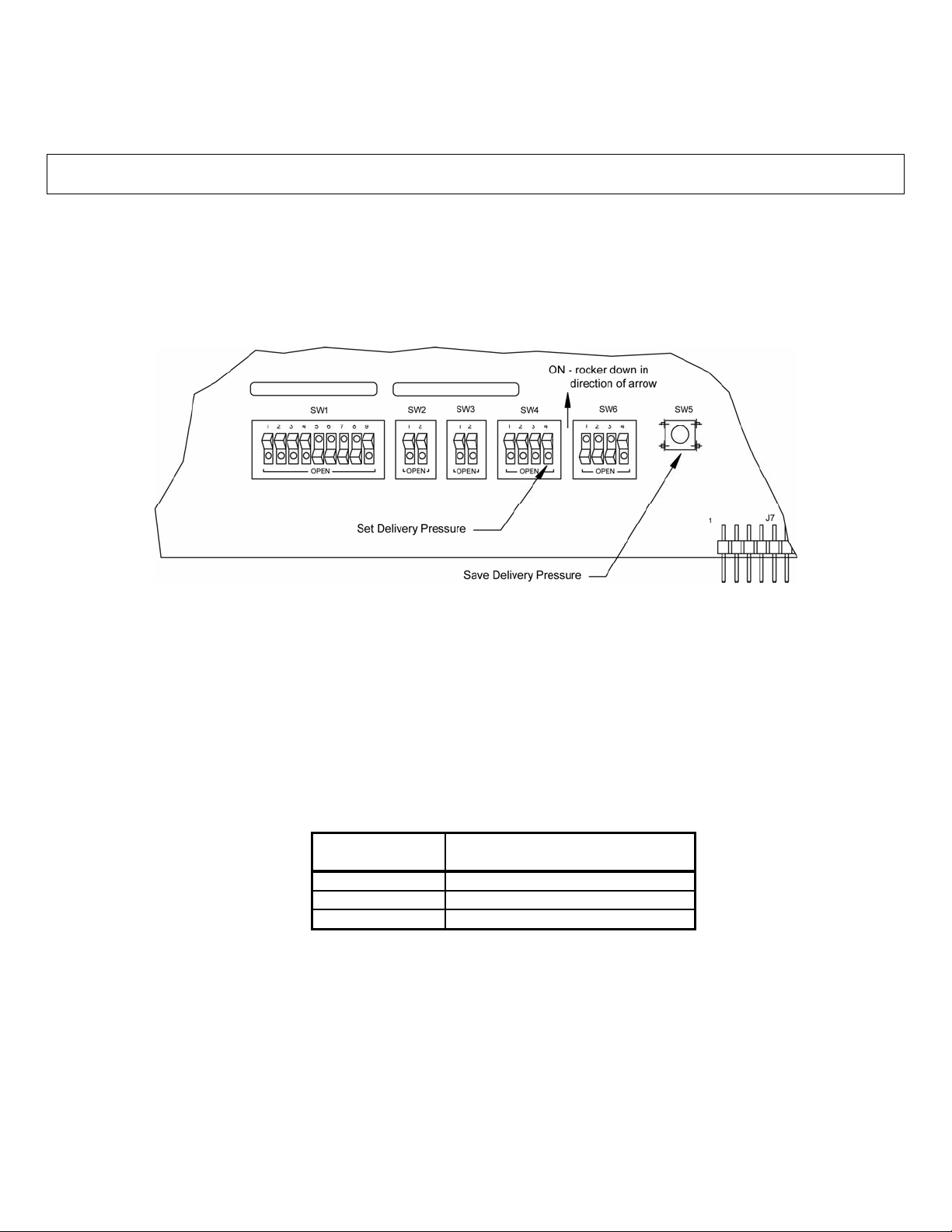

REPAIR ADJUSTMENTS

Resetting Switchover Pressure ----------------------------------------------------------------------------------------------------------------- Page 19

Resetting Delivery Regulator Pressure Tolerance ------------------------------------------------------------------------------------------- Page 21

Resetting Units of Measure --------------------------------------------------------------------------------------------------------------------- Page 22

Resetting Keypad Security Lockout ----------------------------------------------------------------------------------------------------------- Page 23

Resetting Remote Alarm Outputs-------------------------------------------------------------------------------------------------------------- Page 24

Enabling Remote Setup-------------------------------------------------------------------------------------------------------------------------- Page 26

Changing AC Input Power---------------------------------------------------------------------------------------------------------------------- Page 27

Setting Communication Mode------------------------------------------------------------------------------------------------------------------ Page 29

REPAIR PARTS (REPAIR)

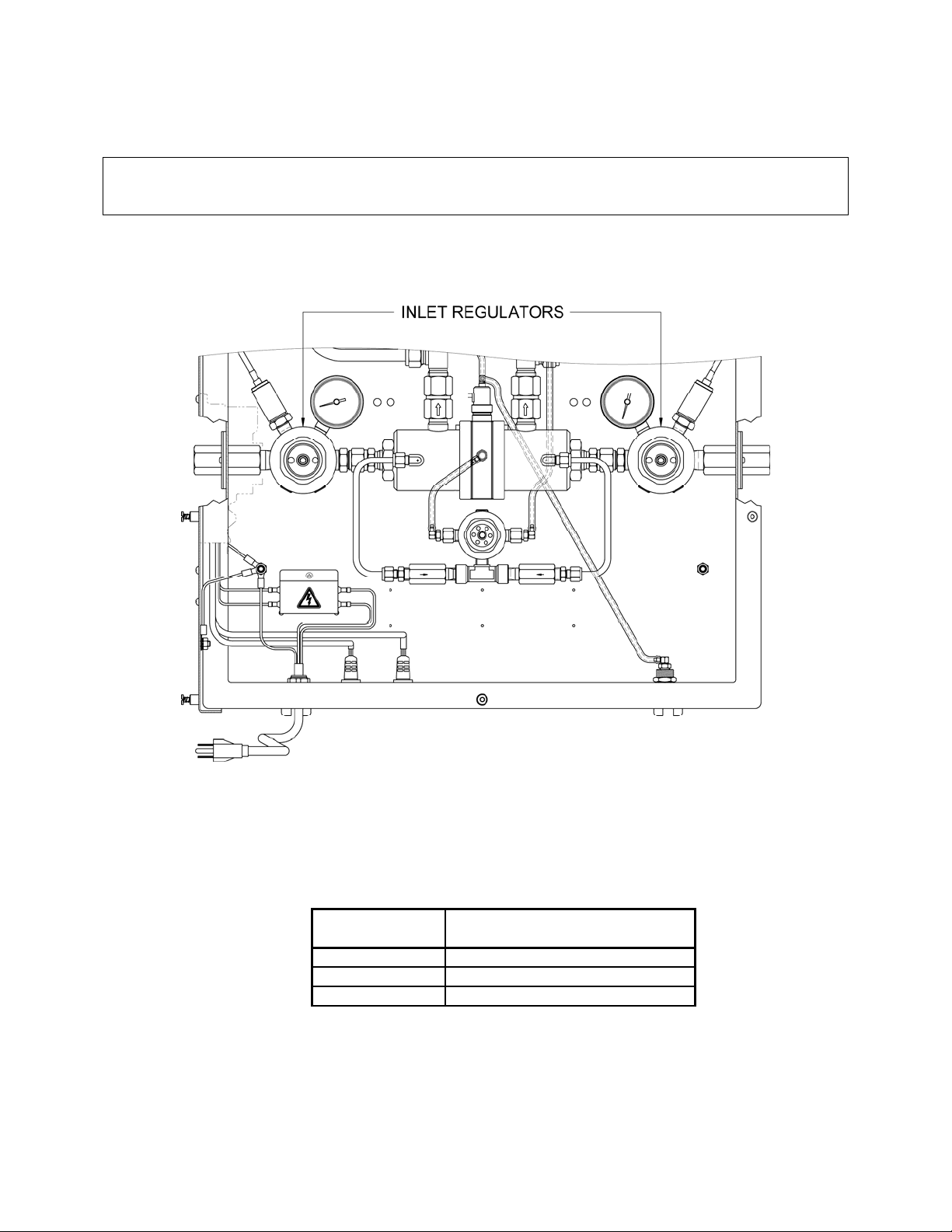

INLET REGULATORS FOR N2O AND CO2 SERVICE:

8056761-41 ------Regulator, for 55 psi delivery pressure units (with Chloroprene Seat)----------------------------------------------- Page 31

8056765-41 ------Regulator, for 100 psi and 180 psi delivery pressure units (with Chloroprene Seat)------------------------------- Page 31

INLET REGULATORS FOR OXYGEN, HELIUM, AND NITROGEN SERVICE:

8056760-41 ------Regulator, for 55 psi delivery pressure units (with Viton® Seat) ---------------------------------------------------- Page 31

8056764-41 ------Regulator, for 100 psi and 180 psi delivery pressure units (with Viton® Seat) ------------------------------------ Page 31

INTERNAL CABLE ASSEMBLIES:--------------------------------------------------------------------------------------------------------- Page 37

8355031 ----------Power Cord Assembly ----------------------------------------------------------------------------------------------------- Page 39

8355028 ----------Remote Alarm--------------------------------------------------------------------------------------------------------------- Page 41

8355027 ----------Serial Port-------------------------------------------------------------------------------------------------------------------- Page 42

8355030 ----------Power Cable (between fuse block and circuit board) ------------------------------------------------------------------ Page 43

8355032 ----------Ground Strap ---------------------------------------------------------------------------------------------------------------- Page 44

8355024 ----------Left Inlet Pressure Transducer, 570 series Medical IntelliSwitch®-------------------------------------------------- Page 45

8355025 ----------Right Inlet Pressure Transducer, 570 series Medical IntelliSwitch® ------------------------------------------------ Page 45

8355026 ----------Delivery Pressure Transducer, 570 series Medical IntelliSwitch®--------------------------------------------------- Page 45

8355034 ----------Left Inlet Pressure Transducer, 571 series Medical IntelliSwitch®-------------------------------------------------- Page 45

8355035 ----------Right Inlet Pressure Transducer, 571 series Medical IntelliSwitch® ------------------------------------------------ Page 45

8355036 ----------Delivery Pressure Transducer, 571 series Medical IntelliSwitch®--------------------------------------------------- Page 45

8309140-11 ------Solenoid Valves------------------------------------------------------------------------------------------------------------- Page 46

8355022 ----------Solenoid Valve Connector Cable, Delivery Regulator Valve (upper), 570 Series Only--------------------------- Page 47

8355023 ----------Solenoid Valve Connector Cable, Switch Valve (lower)-------------------------------------------------------------- Page 47

CIRCUIT BOARDS:

8355005 ----------Control Board, 570 series Medical IntelliSwitch®-------------------------------------------------------- Contact CONCOA

8355029 ----------Display Board, 570 series Medical IntelliSwitch® ------------------------------------------------------- Contact CONCOA

8355003 ----------Control Board, 571 series Medical IntelliSwitch® ------------------------------------------------------- Contact CONCOA

8355009 ----------Display Board, 571 series Medical IntelliSwitch® ------------------------------------------------------- Contact CONCOA

FUSE COMPONENTS:

8309200-2--------Fuse – Note: Each unit requires 2 fuses --------------------------------------------------------------------------------- Page 28

8309200-12 ------Fuse Holder

8309245-12 ------Screws for Fuse Holder - Note: Each unit requires 2

8309828 ----------Fuse Cover Plate

8309245-12 ------Screw for Cover Plate

8307270 ----------Label, Electrical Warning Symbol