3

Where an oxidizer (such as nitrous oxide or oxygen) is used, the manifold and cylinders

must be kept clean. No oil, grease, or combustible substances should come in contact with

oxygen or nitrous oxide storage or handling equipment. Such materials in contact with

oxygen or nitrous oxide are readily ignitable and, when ignited, will burn intensely.

Never lift gas cylinders with a magnetic lifting device.

Never use an open flame when leak testing.

Always open valves slowly when high-pressure gases are being used.

Always be sure that a cylinder contains the correct gas before connecting it to any manifold.

Always leak-test any manifold or distribution pipeline before using.

Always be sure that the gas in a pipeline is the correct gas for the intended use.

Always close all cylinder valves before disconnecting cylinders from a manifold.

Always remove all empty cylinders from a manifold before connecting full cylinders.

Always test cylinders to be sure the cylinders are full before connecting to a manifold.

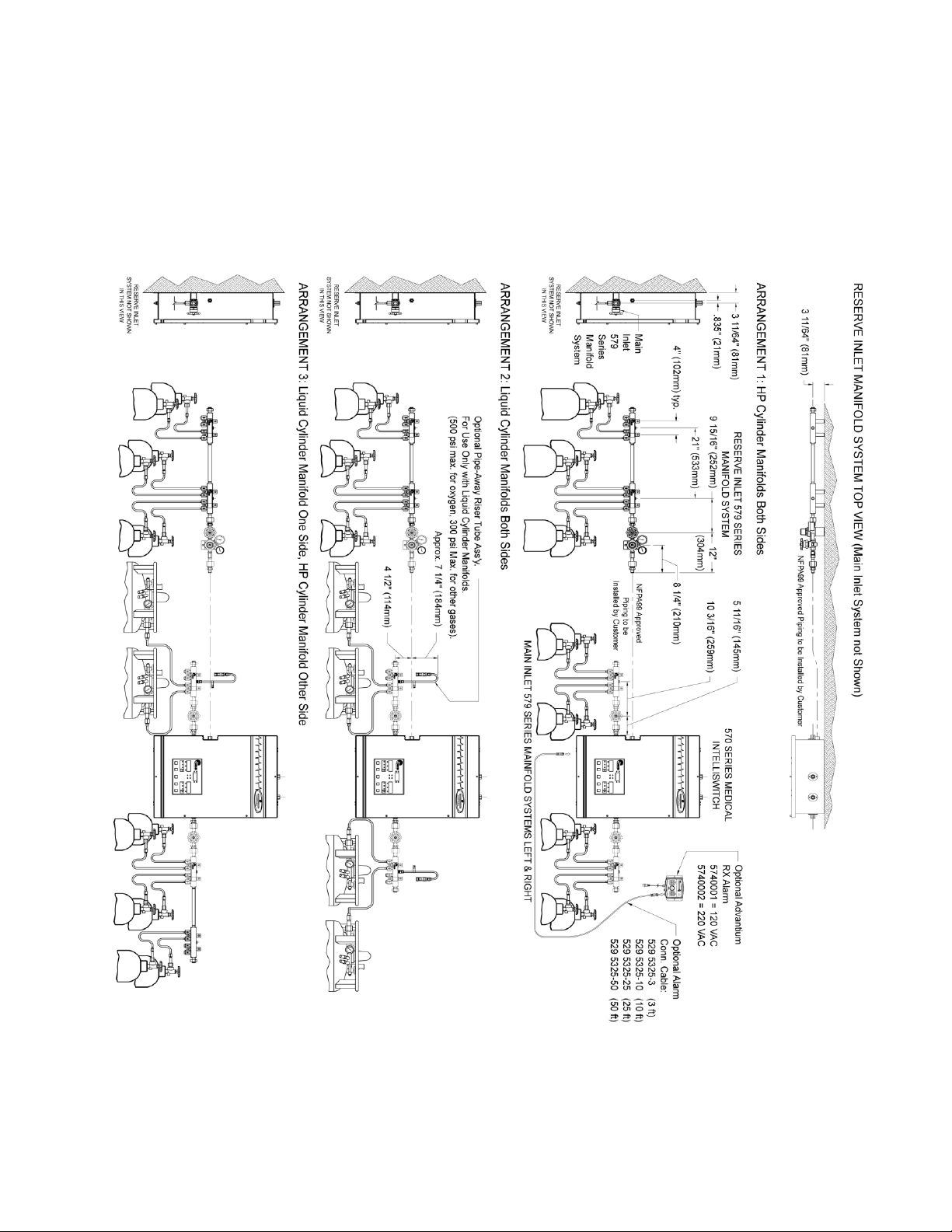

All gas distribution piping systems must meet the appropriate standards for the intended service. For

the United States, some applicable safety rules and precautions are listed below:

1. N.F.P.A. Standard 99, Health Care Facilities

2. Local Ordinances

3. O.S.H.A. Standard 29 CFR

4. C.G.A. Pamphlet C-4, American National Standard Method of Marking Portable Compressed

Gas Containers to Identify the Material Contained.

5. C.G.A. Pamphlet G-4, Oxygen –Information on the properties, manufacture, transportation,

storage, handling, and use of oxygen.

6. C.G.A. Pamphlet G-4.1, Equipment Cleaned for oxygen service.

7. C.G.A. Pamphlet G-4.4, Industrial Practices for Gaseous Oxygen Transmission and Distribution

Piping Systems.

8. C.G.A. Pamphlet G-5, Hydrogen –Information on the properties, manufacture, transportation,

storage, handling, and use of hydrogen.

9. C.G.A. Pamphlet G-6, Carbon Dioxide –Information on the properties, manufacture,

transportation, storage, handling, and use of carbon dioxide.

10. C.G.A. Pamphlet G-6.1, Standard for Low Pressure Carbon Dioxide Systems at Consumer Sites.

11. C.G.A. Pamphlet P-1, Safe Handling of Compressed Gases in Containers.

12. C.G.A. Pamphlet P-2, Characteristics and Safe Handling of Medical Gases.

13. C.G.A. Pamphlet C-9, Standard Color Marking of Compressed Gas Containers for Medical Use.

14. C.G.A. Pamphlet M-1, Guide for Medical Gas Systems at Customer Sites

15. C.G.A. Pamphlet E-10, Maintenance of Medical Gas and Vacuum Systems in Health Care

Facilities.