Consew 175 Manual

Other Consew Sewing Machine manuals

Consew

Consew 206RBL User manual

Consew

Consew 199R User manual

Consew

Consew CN 2230 R Datasheet

Consew

Consew P1206RB Technical manual

Consew

Consew 104-10T User manual

Consew

Consew CP206R User manual

Consew

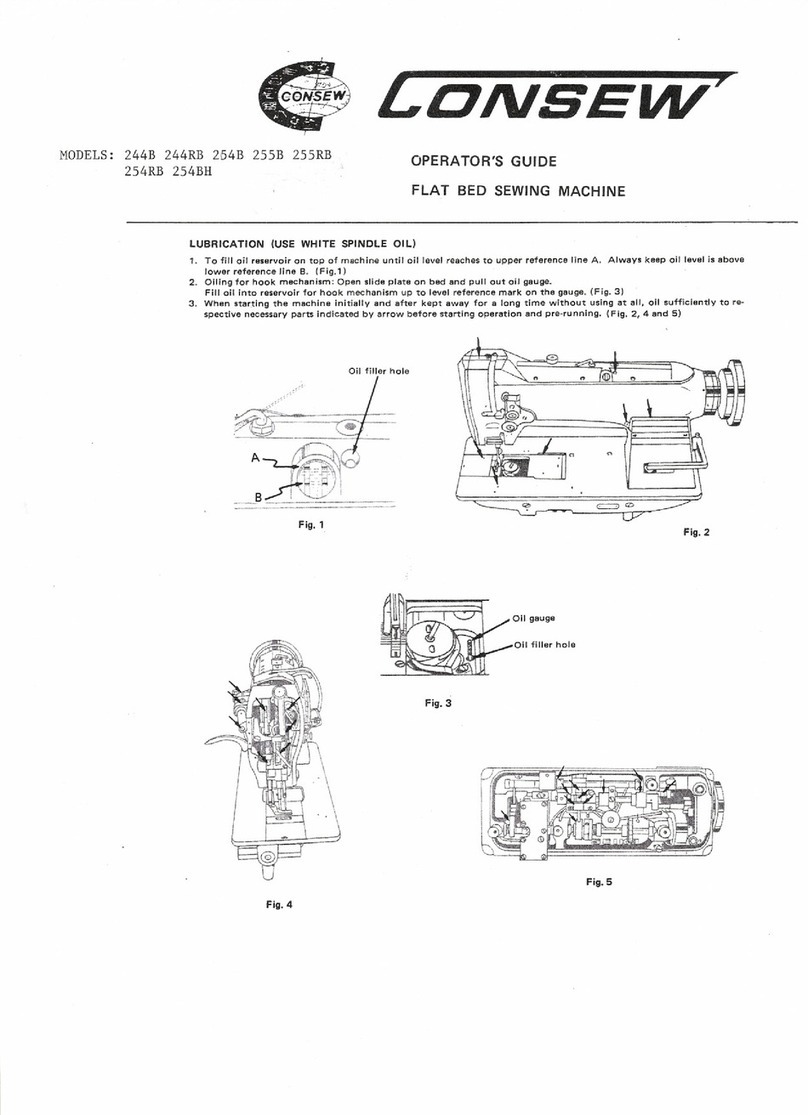

Consew 244B Manual

Consew

Consew 733R-5 Use and care manual

Consew

Consew Premier 1541S-CC User manual

Consew

Consew 277RFS-3 Datasheet

Consew

Consew 223 User manual

Consew

Consew 206RB User manual

Consew

Consew 226R User manual

Consew

Consew 30 Use and care manual

Consew

Consew 328RB-1 User manual

Consew

Consew 99 User manual

Consew

Consew 222 User manual

Consew

Consew 18 Use and care manual

Consew

Consew 332 User manual

Consew

Consew DLS600 User manual