NOTE

DO

NOT MOVE ECCENTRIC MORE THAN ABOUT 1116" ROTATION

AT

A TIME. THEN TIGHTEN

SET

SCREWS AND CHECK FOR RESULTS.

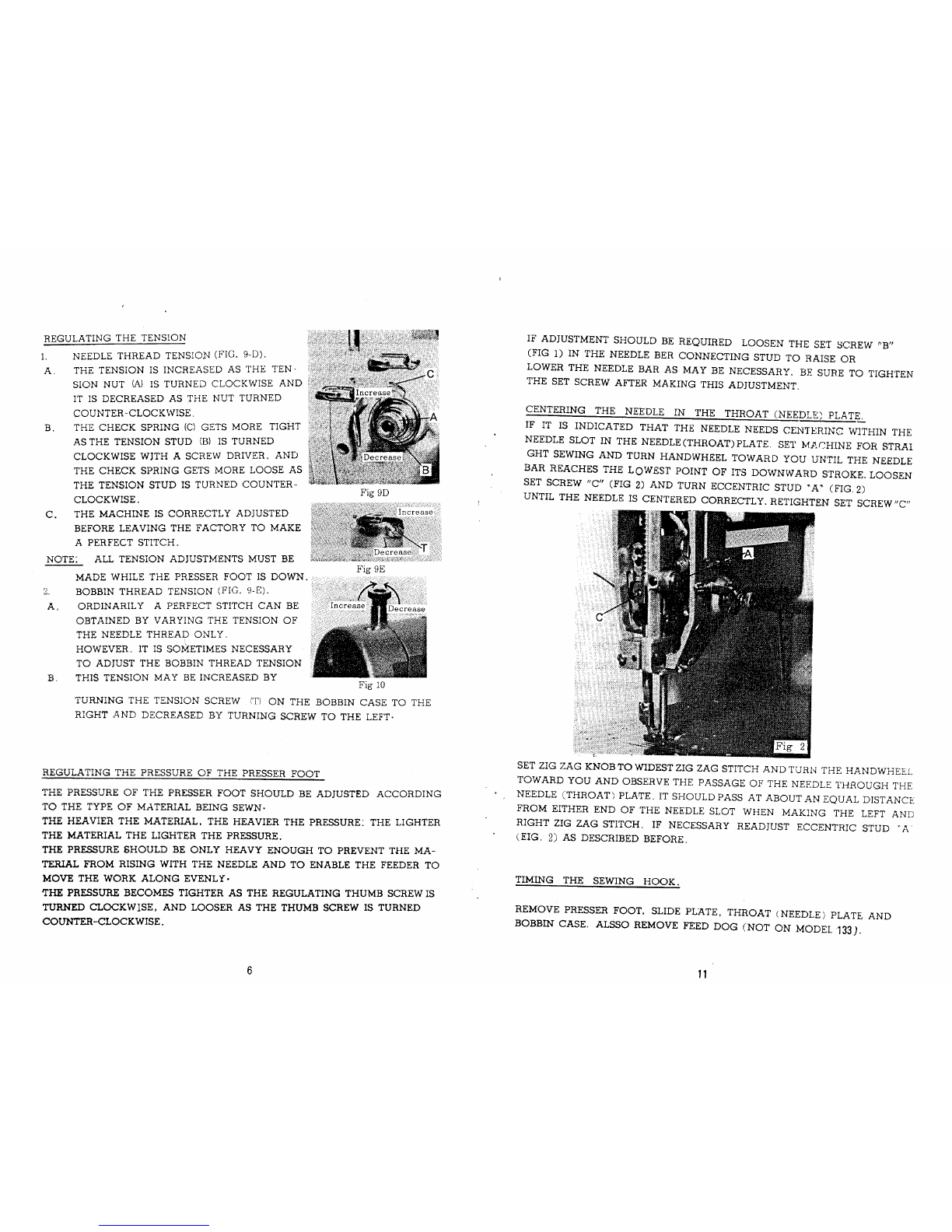

TIMING THE MOVEMENT

OF

THE NEEDLE BAR FRAME.

SET ZIG ZAG KNOB

FOR

STRAIGHT STITCH, TURN HANDWHEEL AND OBSERVE

TRAVEL THE NEEDLE INTO AND OUT

OF

THE NEEDLE SLOT IN THE

THROAT (NEEDLE) PLATE. IF THE NEEDLE SHOULD NOT

BE

CENTERED IN

THE SLOT, MAKE ADJUSTMENTS SUGGCSTED IN PARAGRAPH

ON

CENTERING

OF

NEEDLE

NOW ADJUST THE NEEDLE

TO

PRODUCE WIDEST ZIG ZAG STITCH. TURN-

ING

THE

HAND

WHEEL TOWARD

YOU.

OBSERVE VIBRATION (SIDEWISE

MOVEMENT'

OF

THE NEEDLE BAR. THE

NEEDLE.

BAR

ON

ITS UPWARD MOVE-

MENT SHOULD BEGIN

TO

VIBRATE WHEN THE POINT

OF

THE NEEDLE IS

NO

LESS

THAN ABOUT 3/32'' ABOVE THE THROAT PLATE AND SHOULD END

TO

VIBRATE WHEN THE NEEDLE HAS REACHED APPROXIMATELY THE SAME

POSITION

ON

ITS DOWNWARD MOVEMENT.

TO

ADJUST VIBRATION

OF

THE

NF.EDLE

BAR. LOOSEN SET SCREW

"H"

(FIG.

5)

IN VIBRATOR CAM AND

SLIGHTLY TURN THIS CAM

ON

ITS SHAFT TIGHTEN SET SCREWS AND

CHECK

FOR

RESULTS. REPEAT THIS PROCEDURE IF THE RESULTS SHOULD

NOT

BE

SETISFACTORY

14

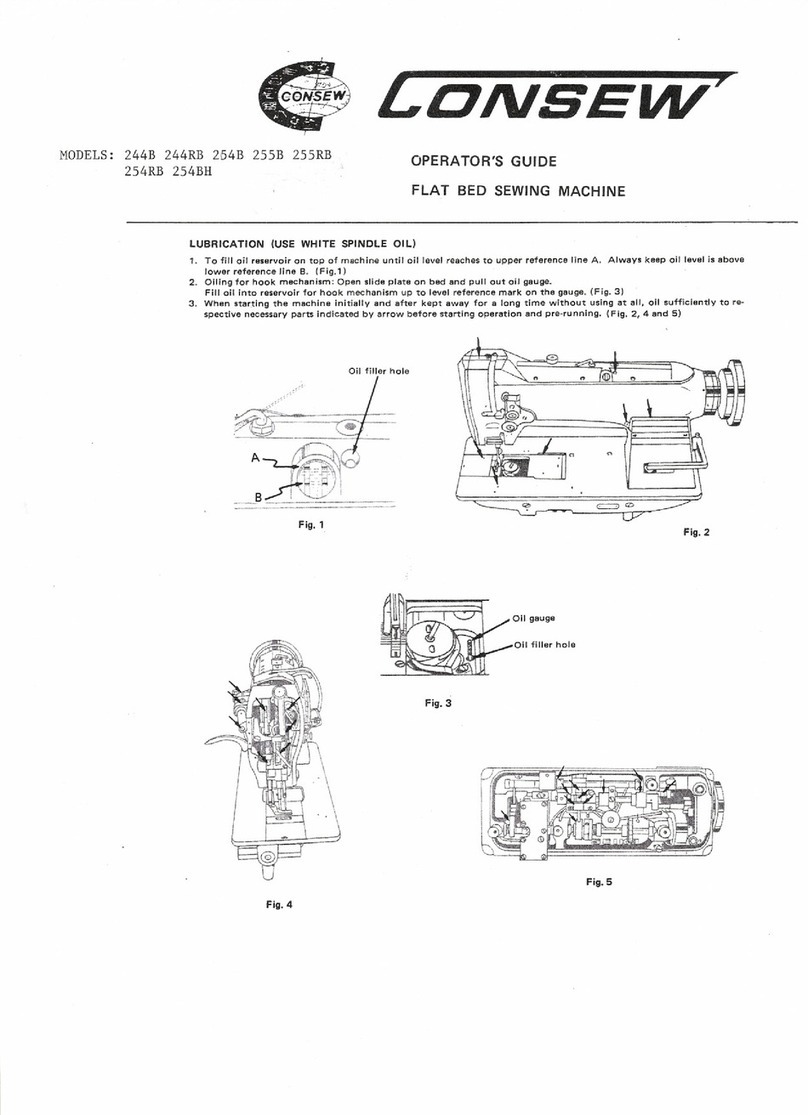

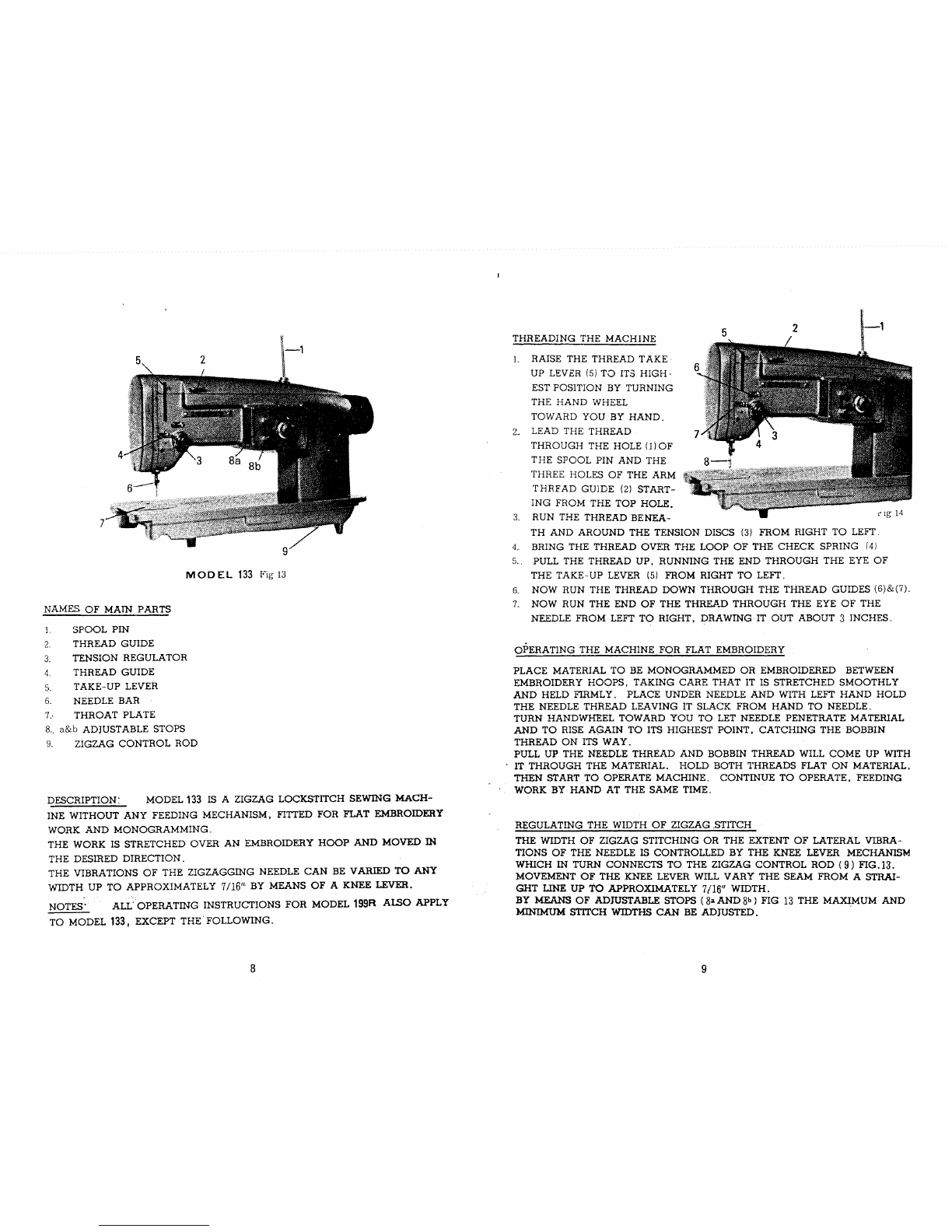

WINDING THE BOBBIN

1,

PLACE THE BOBBIN

(3)

ON

SPINDLE

WINDER.

2,

PASS THE THREAD THROUGH THE

HOLE

(4)

OF

THE BOBBIN WINDER

THREAD GUIDE AND THROUGH THE

TENSION DISCS(5)FROM THE

REAR

3,

PULL

THEEND

OF

THE THREAD AND

WIND ITAROUND THE EMPTY BOBBIN Fig- 4

SEVEN

OR

EIGHT TIMES FROM THE BOTTOM

UP

AS

SHOWN

BY

THE ARROW IN

FIG.

4.

4,

PUSH THE BOBBIN WINDER LEVER (1)

DOWN

UNTIL

THE BOBBIN WINDER WHEEL (2) PRESSES AGAINST

THE DRIVE BELT.

5,

START THE MACHINE AND THE THREAD WILL

BE

WOUND UP

ON

THE BOBBIN. WHEN THE BOBBIN IS

FULL, IT WILL RELEASE AUTOMATICALLY

AND

STOP

TURNING.

6,

CUT

OFF

THE THREAD AND REMOVE THE BOBBIN FROM

THE SPINDLE.

7,

YOU

CAN

EASILY ADJUST THE MAXIMUM QUANTITY

OF

THREAD

TO

BE

WOUND UP

ON

THE BOBBIN BY ADJUST-

ING THE SCREW(7)WHICH CONTROLS LATCH(6).

8,

IF THE THREAD DOES

NOT

WIND EVENLY

ON

THE

BOBBIN. ADJUST THE POSITION

OF

THE BOBBIN WINDER

THREAD GUIDE(4)BY MOVING IT

TO

THE RIGHT

OR

· LEFT AFTER LOOSENING THE SCREW.

9,

LOOSEN THE TENSION

FOR

FINE

THREAD BY TURNING

THE NUT IN COUNTERCLOCKWISE DIRECTION.

Fig.

5-A

Fig.

5-B

Fig.

5-C

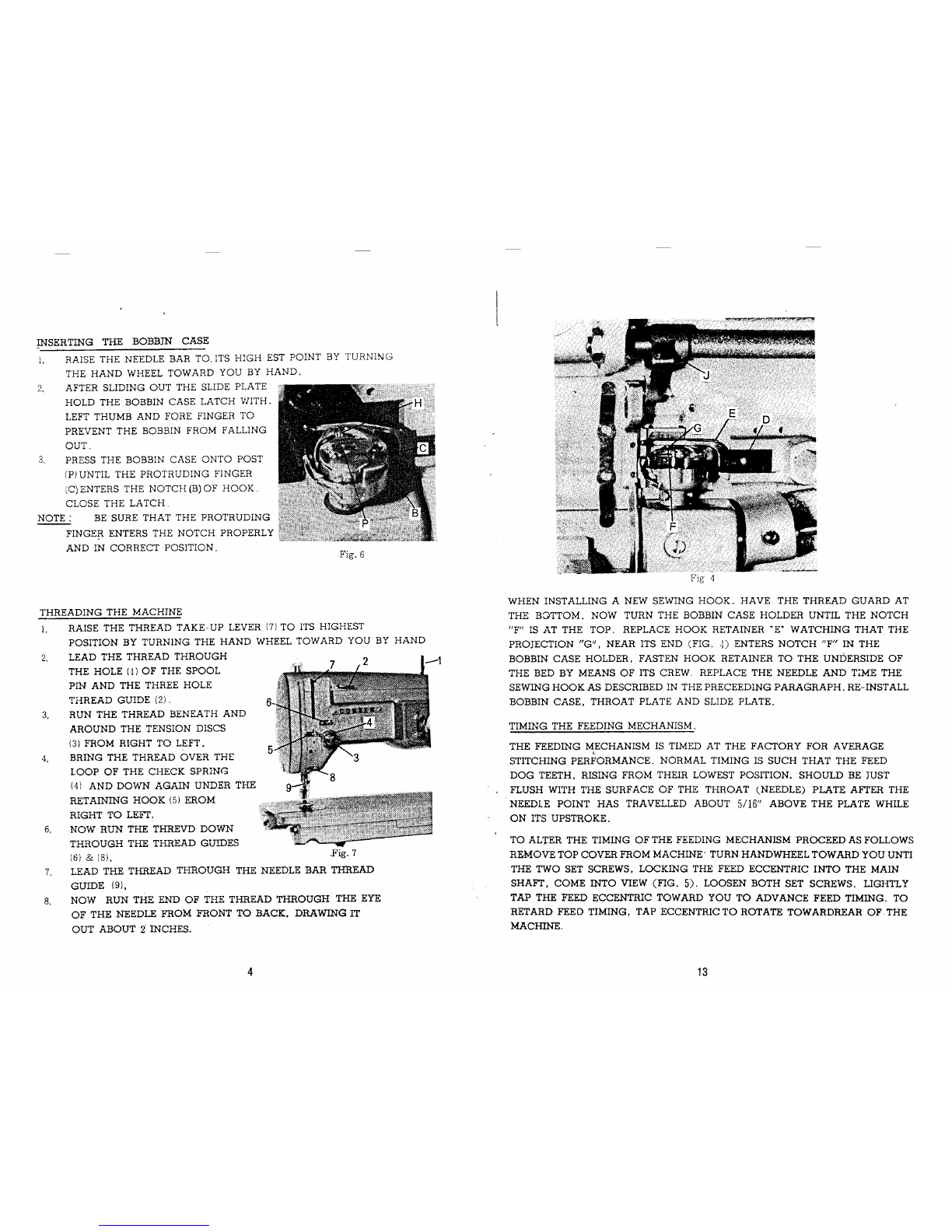

THREADING THE BOBBIN CASE

1,

HOLD THE BOBBIN CASE BETWEEN THE LEFT THUMB

AND FORE-FINGER AS SHOWN ABOVE. WITH ABOUT 2

INCHES -OF THREAD TRAILING, HOLD THE BOBBIN

BETWEEN THE THUMB AND FIRST TWO FINGERS

OF

THE

RIGHT

HAND

AS SHOWN IN FIG,

5A

.

2,

INSERT THE BOBBIN INTO BOBBIN CASE

AND

PULL THE

TRAILING THREAD INTO THE SLOT,

DOWN

AND

TO

THE

LEFT, UNTIL

IT

ENTERS THE GROOVED EYE UNDER THE

TENSION SPRING

FIG.

58,

5Co

.

3,

LEAD THREAD END

THROUGH

GUIDE HOLD

(H)

FIG.

6,

LOCATED AT FRONT

OF

BOBBIN CASE ABOVE HINGED

LATCH.

3