CONTJENT§

1.Brief instruction........................................................................................................................i

2.Main specifications.................................................................................................................1

3.Machine installation................................................................................................................i

4.1nstalling the motor

..................................................................................................................2

5.Connecting between the pedal and clutch lever....................................................................

6.1nstalling the presser foot lift control plate...............................................................................2

?.Installing the bobbin winder....................................................................................................3

8.1nstalling the thread stand.......................................................................................................3

9.0peration preparation.............................................................................................................3

1

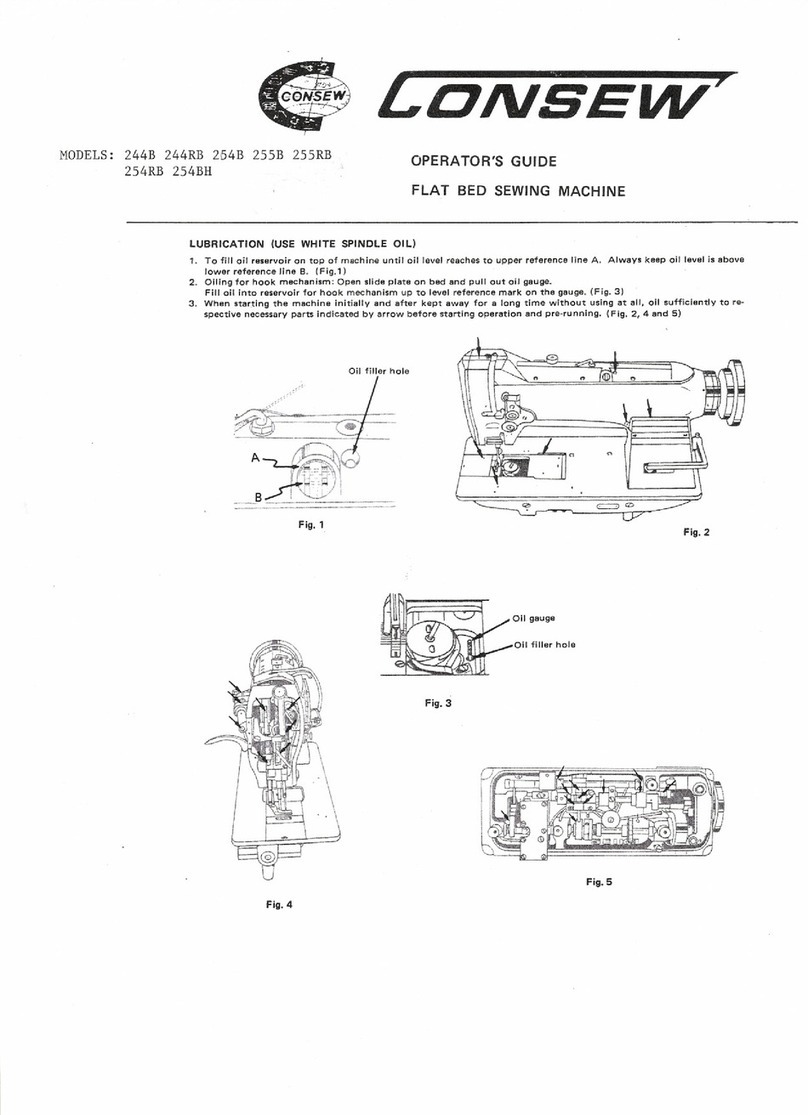

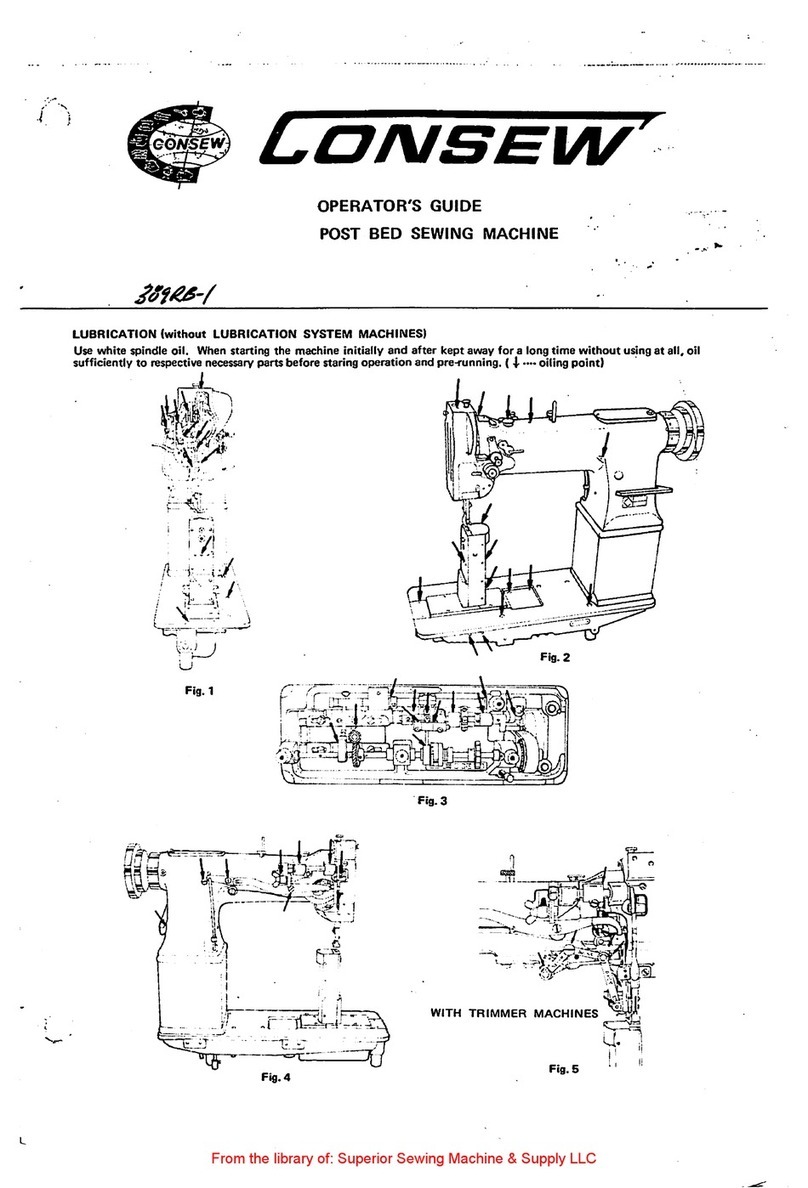

O.Lubrication............................................................................................................................4

i 1.Trial running..........................................................................................................................4

i2.1nsialling the needle.............................................................................................................4

13.Coordination among the needle, thread and materiaL.......................................................5

14.Threading the needle thread................................................................................................5

i

5.

Adjusting the tension of bobbin thread and needle thread...................................................5

i6.Winding the bobbin thread and adjustment.........................................................................6

17.Stitch length, forward and backward feed............................................................................?

i 8.Adjusting presser foot pressure.........................................................................................

..

i 9.Adjusting the amount of presser foot lift............................................................................

20.Adjusting the timing of feed..................................................................................................8

21.Adjusting the timing between needle and hook....................................................................8

22.1nstalling the hook positioning bracket and hook..................................................................8

i .Machine body....................................................................................................................

9~i0

2.Upper shaft and thread

take-up

mechanism..................................................................i

1-12

3.Needle bar, rocking shaft, presser foot mechanism........................................................i

3-

i 4

4.Vertical shaft, lower shaft mechanism.............................................................................

15-16

5.Feed mechanism.............................................................................................................

17-·ts

6.Threading mechanism.....................................................................................................

19~20

?.Accessories ....................................................................................................................

21

From the library of: Superior Sewing Machine & Supply LLC