10 | Page Rev 2-0 8/1/2018

Use the following chart to select the switch position for the desired

function:

To:

Set the Rotary Selector

Switch to:

Display ammonia concentration in PPM

Display ammonia concentration in PPM

Display the firmware revision

Program the ammonia High alarm set point

Program the ammonia Low alarm set point

Display ammonia concentration in PPM (See Section Testing your system)

Display Electrochemical Sensor Zero offset

Note: If the rotary selector switch is left in a position other than “0”

without pushing an “UP” or “DOWN” button for more than 5

minutes, the digital display will begin to display ammonia

concentration. If this happens, return the selector switch to the “0”

position, then set the switch to the desired position. For example, if

you set the rotary selector switch to position “3” to program the

alarm set point, and if, after 5 minutes of inactivity the display

reverts to displaying ammonia concentration. Move the switch to

“0”, then back to “3” to continue programming the alarm set point.

Caution: Before closing the detector enclosure, be sure to

return the rotary selector switch to position “0” to

correctly display ammonia concentration.

Additional functions are available through the rotary

selector switch when the detector is in program mode

(program LED on).

To:

Set the Rotary

Selector Switch to:

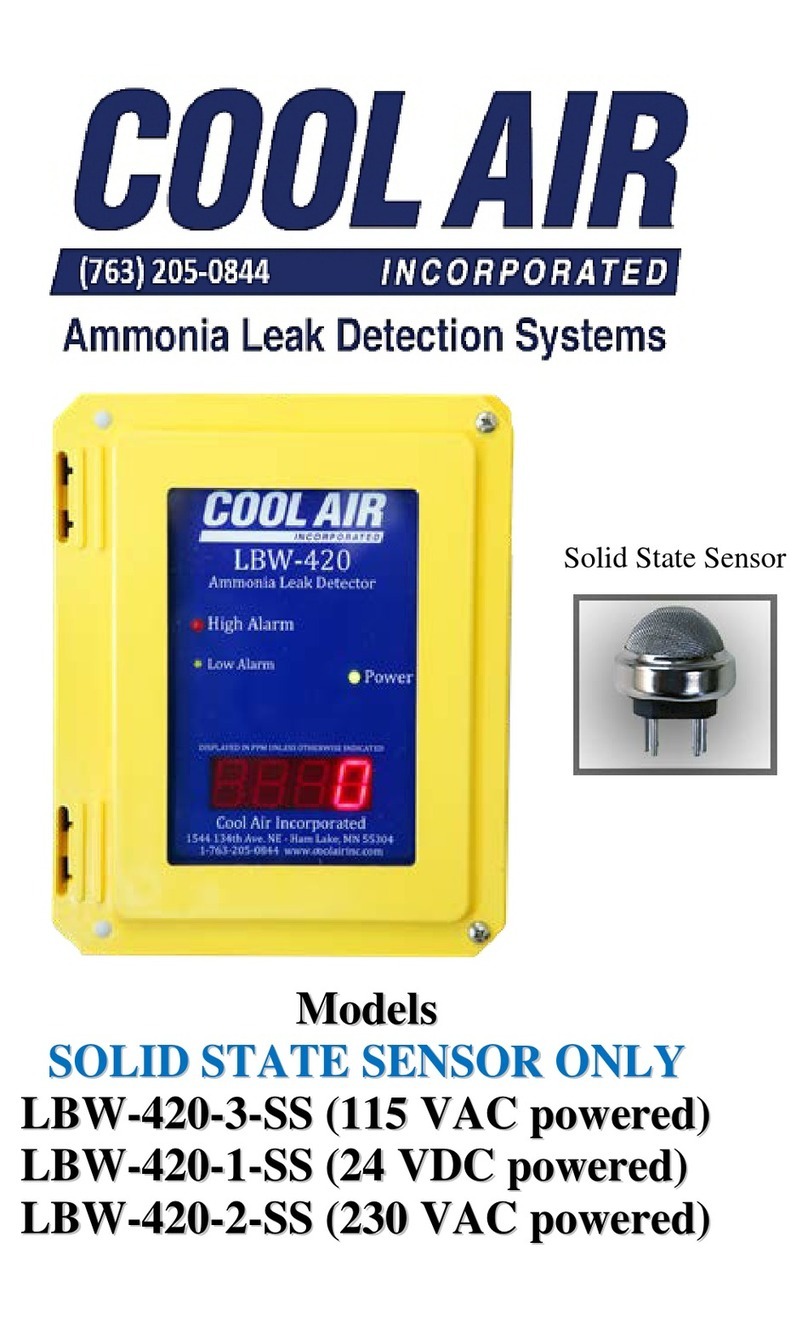

Display ammonia sensor temperature (Solid State Sensor Only)

Zero adjust for the Electrochemical sensor

Program the ammonia sensor 4 – 20mA Range

Set the Service Mode Time out

Set the Display start value. 0PPM, 10PPM, or 25PPM

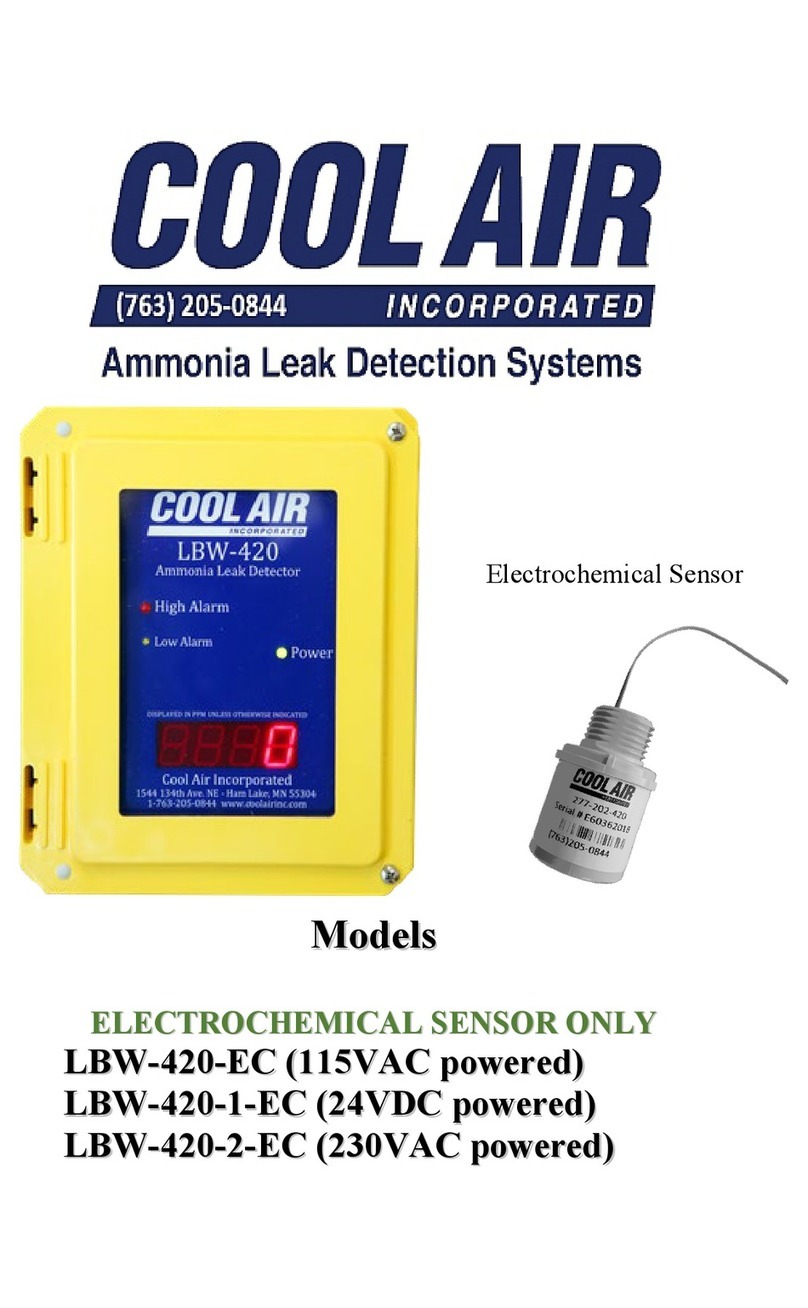

Select for Solid State Sensor or Electrochemical Sensor