sewerin EX-TEC SNOOPER H User manual

Instructions

Wir sichern Lebensqualität.

Operating-

102729

Measurable success by Sewerin equipment

You settled on a precision instrument.

A good choice!

Our equipment stands out for guaranteed safety, optimal output and efficiency.

They correspond with the national and international guide-lines.

These operating instructions will help you to handle the instrument quickly and

competently.

Please pay close attention to our operating instructions before usage.

In case of further queries our staff is at your disposal at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

D-33334 Gütersloh

: +49 - (0) - 52 41/9 34-0

FAX : +49 - (0) - 52 41/9 34-4 44

http:// www.sewerin.com

1

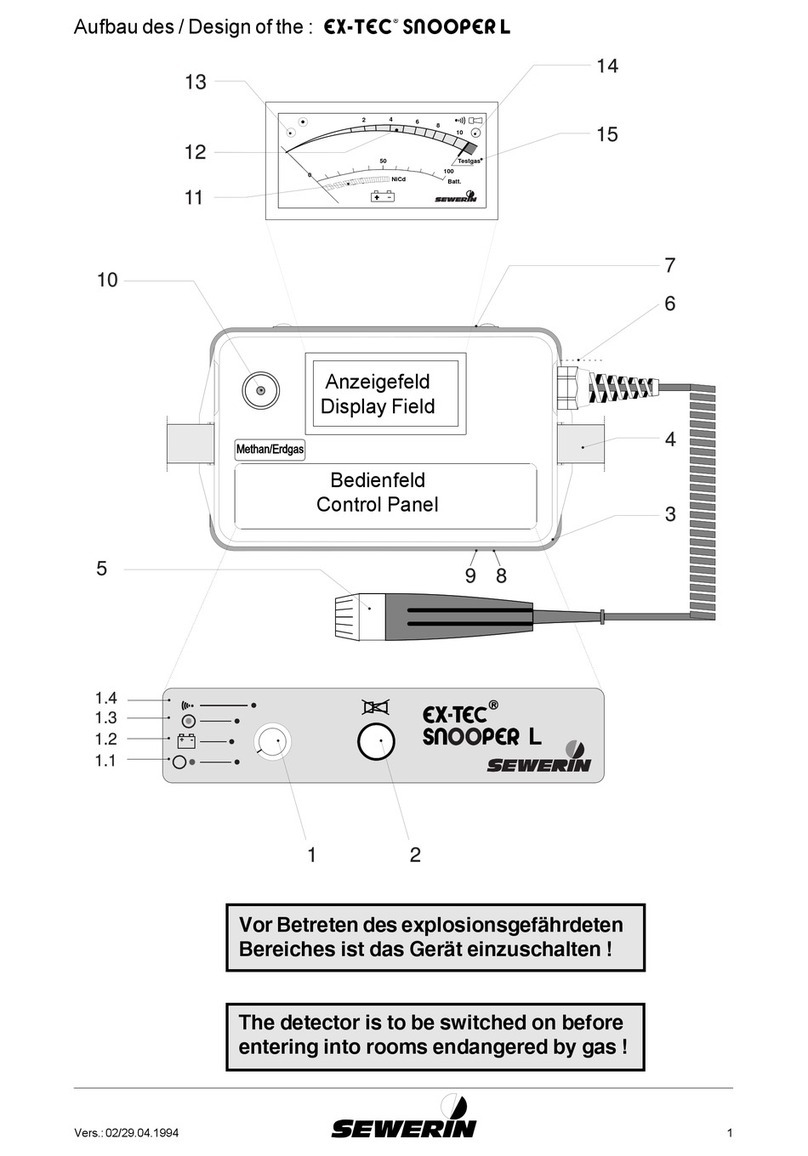

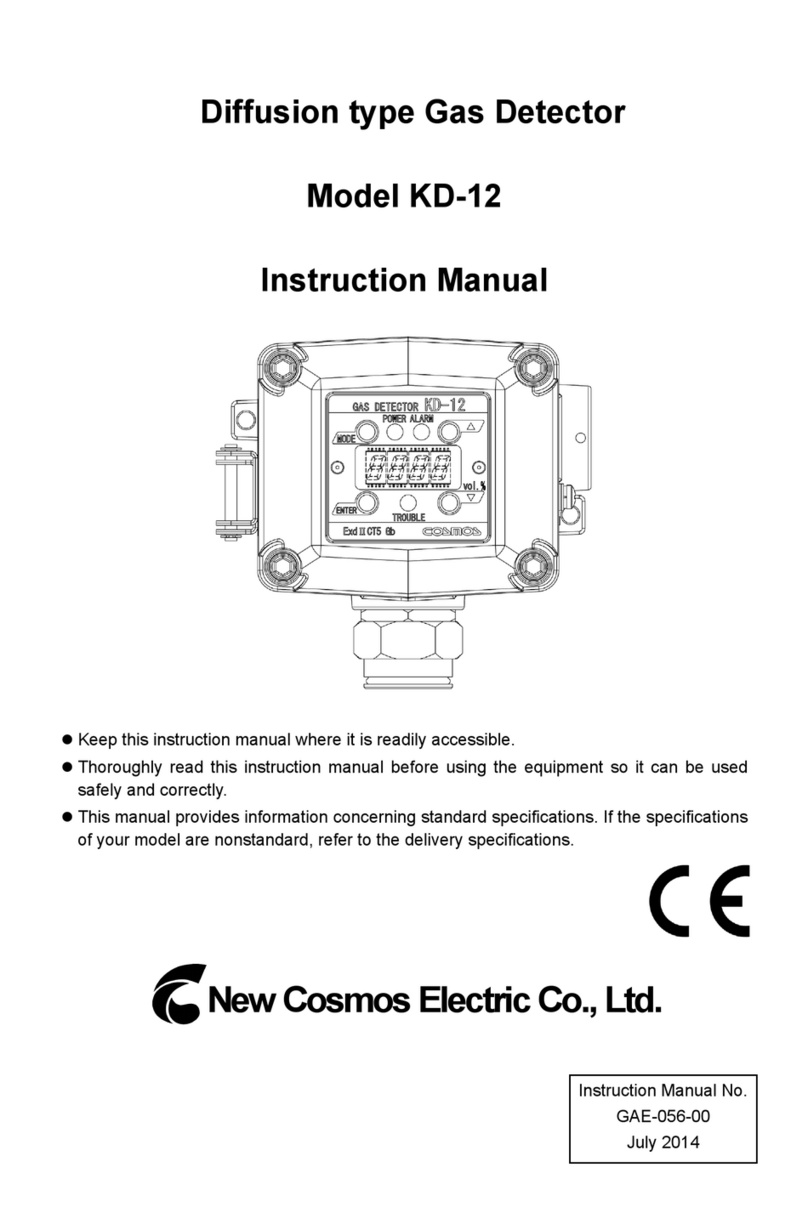

Design of the: EX-TEC® SNOOPER H

2

Notes

3

EX-TEC® SNOOPER H

Operating InstructionsOperating Instructions

Operating InstructionsOperating Instructions

Operating Instructions ................

................

........ pages 3 - 32pages 3 - 32

pages 3 - 32pages 3 - 32

pages 3 - 32

102729 - 05/27.11.1998

4

For your safety *For your safety *

For your safety *For your safety *

For your safety *

Thelawgoverningtechnicalequipment(theLawontheSafetyofAppliances)

of 24.06.1968 (BGBl.I, page 717) as amended by the Amendment Law of

13.08.1979 (BGBl.I, page 1432) requires the following matters to be drawn

to your attention:

Comply with the Operating Instructions.Comply with the Operating Instructions.

Comply with the Operating Instructions.Comply with the Operating Instructions.

Comply with the Operating Instructions.

Before operating or adjusting the appliance you must be thoroughly familiar

with this operating manual. You must comply with it in every respect.

The appliance is designed only for the application described and for

industrial (commercial) use.

Liability for Function or DamageLiability for Function or Damage

Liability for Function or DamageLiability for Function or Damage

Liability for Function or Damage

Liability for the functioning of the appliance passes to the owner or operator

in all cases in which the appliance has been improperly maintained or

repaired by persons not associated with SEWERIN Service or if it has been

used for a purpose not in accordance with its designated application.

You should therefore always use original SEWERIN accessories with the

EX-TEC® SNOOPER H.

Hermann Sewerin GmbH accepts no responsibility for damage due to a

failure to comply with the foregoing instructions. The guarantee and liability

terms of the Hermann Sewerin GmbH terms of sale and supply are not

extended by the foregoing.

We reserve the right to make technical changes in the course of continued

development.

HERMANN SEWERIN GMBH

* All references to laws, statutes and norms relate to the legislation of the Federal Republic of

Germany.

5

ContentsContents

ContentsContents

Contents pagepage

pagepage

page

For your safetyFor your safety

For your safetyFor your safety

For your safety ........................................................................................................................................................................

........................................................................................................................................................................

.................................................................................... 44

44

4

1.01.0

1.01.0

1.0 TheThe

TheThe

The EX-TEC® SNOOPER H ....................................................................................................................

....................................................................................................................

.......................................................... 66

66

6

1.1 Purpose ........................................................................................ 7

1.2 Tests ............................................................................................. 7

2.02.0

2.02.0

2.0 OperationOperation

OperationOperation

Operation ........................................................................................................................................................................

........................................................................................................................................................................

.................................................................................... 88

88

8

2.1 Switching on ................................................................................. 8

2.2 Measuring operation ..................................................................... 9

2.3 Concentration-dependent signal ................................................ 10

2.4 Alarms ......................................................................................... 11

2.5 Manual zero-point adjustment...................................................... 11

2.6 Battery monitoring....................................................................... 12

2.7 Switching off ............................................................................... 12

3.03.0

3.03.0

3.0 Charging techniqueCharging technique

Charging techniqueCharging technique

Charging technique..................................................................................................................................

..................................................................................................................................

................................................................. 1313

1313

13

4.04.0

4.04.0

4.0 Inspection, testing and maintenanceInspection, testing and maintenance

Inspection, testing and maintenanceInspection, testing and maintenance

Inspection, testing and maintenance........................................................................

........................................................................

.................................... 1515

1515

15

4.1 Test Set ...................................................................................... 16

4.2 Function testing .......................................................................... 17

5.05.0

5.05.0

5.0 AdjustmentAdjustment

AdjustmentAdjustment

Adjustment................................................................................................................................................................

................................................................................................................................................................

................................................................................ 1818

1818

18

6.06.0

6.06.0

6.0 Changing the sensor systemChanging the sensor system

Changing the sensor systemChanging the sensor system

Changing the sensor system..................................................................................................

..................................................................................................

................................................. 2121

2121

21

7.07.0

7.07.0

7.0 TT

TT

Technical notesechnical notes

echnical notesechnical notes

echnical notes................................................................................................................................................

................................................................................................................................................

........................................................................ 2222

2222

22

8.08.0

8.08.0

8.0 TT

TT

Technical dataechnical data

echnical dataechnical data

echnical data ....................................................................................................................................................

....................................................................................................................................................

.......................................................................... 2323

2323

23

9.09.0

9.09.0

9.0 AccessoriesAccessories

AccessoriesAccessories

Accessories............................................................................................................................................................

............................................................................................................................................................

.............................................................................. 2424

2424

24

10.010.0

10.010.0

10.0 Error messagesError messages

Error messagesError messages

Error messages ..............................................................................................................................................

..............................................................................................................................................

....................................................................... 2525

2525

25

11

11

11.01.0

1.01.0

1.0 Wearing partsWearing parts

Wearing partsWearing parts

Wearing parts ......................................................................................................................................................

......................................................................................................................................................

........................................................................... 2626

2626

26

EC-TEC-T

EC-TEC-T

EC-Type Examinations Certificateype Examinations Certificate

ype Examinations Certificateype Examinations Certificate

ype Examinations Certificate ....................................................................................................

....................................................................................................

.................................................. 2727

2727

27

Declaration of conformityDeclaration of conformity

Declaration of conformityDeclaration of conformity

Declaration of conformity ................................................................................................................................

................................................................................................................................

................................................................ 2929

2929

29

TT

TT

Test reportsest reports

est reportsest reports

est reports................................................................................................................................................................................

................................................................................................................................................................................

........................................................................................ 3030

3030

30

6

1.01.0

1.01.0

1.0 TheThe

TheThe

The EX-TEC® SNOOPER H

☞Please fold out the illustration inside the frontPlease fold out the illustration inside the front

Please fold out the illustration inside the frontPlease fold out the illustration inside the front

Please fold out the illustration inside the front

cover !cover !

cover !cover !

cover !

ItemItem

ItemItem

Item DescriptionDescription

DescriptionDescription

Description FunctionFunction

FunctionFunction

Function

1 detector key key position:

ñswitch detector on

ñmanually set zero point

òswitch detector off

2 LCD display display of:

lbattery capacity

lminimum sensitivity

lreadings

lerror messages

3 buzzer acoustic warning

4 alarm lamp optical warning

5 sensor cap changing sensors for:

lmanual probe

lswan-neck (large)

lswan-neck (small)

6 hole service button for:

lswitching off acoustic

signal

ladjustment mode

7 charging contacts connection to

charging adapter

7

1.11.1

1.11.1

1.1 PurposePurpose

PurposePurpose

Purpose

The EX-TEC® SNOOPER H gas detector is intended for the

following purposes:

lleak detection in spaces, shafts or channels

linspecting new installations or repairs

llocating leaks in installation pipes

linspecting fittings, flanges, threads or seams

A smell of gas may possibly be due to gas penetration of the

building or space via gaps in walls, cable ducts or other routes.

These should also be inspected.

If the continuous acoustic signal (item 3) sounds and the

measurement-range limit of 1.00 vol.% is displayed (item 2) on

entering a space (e.g. a building, shaft, channel or the like), then

the following precautionary measures must be taken:

☞Do not operateDo not operate

Do not operateDo not operate

Do not operate electrical switches !electrical switches !

electrical switches !electrical switches !

electrical switches !

Open windows and doors !Open windows and doors !

Open windows and doors !Open windows and doors !

Open windows and doors !

TT

TT

Turn off the gas supply !urn off the gas supply !

urn off the gas supply !urn off the gas supply !

urn off the gas supply !

1.21.2

1.21.2

1.2 TT

TT

Testsests

estsests

ests

The EX-TEC® SNOOPER H is explosion-proof in accordance with

European norms (CENELEC):

EC prototype test: PTB 96 ATEX 2167

Certificate: II 2 G EEx ib d IIC T3

Test institute: Physikalisch-Technische

Bundesanstalt, Braunschweig

8

2.02.0

2.02.0

2.0 OperationOperation

OperationOperation

Operation

2.12.1

2.12.1

2.1 Switching onSwitching on

Switching onSwitching on

Switching on

lpush the on/off key (item 1) upwards for

approx. 2 seconds.

lthe optical and acoustic control signals

(items 3 and 4) operate for approx. 2

seconds

lall segments of the LCD display are

tested

ldisplay of remaining operating time, e.g.

6 hours - one segment per hour

ldisplay of minimum sensitivity

10 ppm or

100 ppm

lstart of sensor warm-up phasesensor warm-up phase

sensor warm-up phasesensor warm-up phase

sensor warm-up phase and

automatic zero-point adjustment

(approx. 2 minutes)

lthe zero point and one segment flash

lat the end of the warm-up phase the

acoustic signal (item 3) sounds

9

lstart of optimization phaseoptimization phase

optimization phaseoptimization phase

optimization phase (approx. 2

minutes); minimum sensitivity of 10 or

100 ppm is set

lonly the zero point still flashes and the

acoustic signal (item 3) sounds at brief

intervals (approx. every 5 seconds)

☞TheThe

TheThe

The gas detector can now be usedgas detector can now be used

gas detector can now be usedgas detector can now be used

gas detector can now be used

forfor

forfor

for leak detection, but its minimumleak detection, but its minimum

leak detection, but its minimumleak detection, but its minimum

leak detection, but its minimum

sensitivity hassensitivity has

sensitivity hassensitivity has

sensitivity has notnot

notnot

not yet been set.yet been set.

yet been set.yet been set.

yet been set.

lonce the zero point stops flashing the

optimisation phase is complete

☞TheThe

TheThe

The EX-TEC® SNOOPER H

is nowis now

is nowis now

is now

ready for leak-detection operation.ready for leak-detection operation.

ready for leak-detection operation.ready for leak-detection operation.

ready for leak-detection operation.

2.22.2

2.22.2

2.2 Measuring operationMeasuring operation

Measuring operationMeasuring operation

Measuring operation

lin the 0 ... 100 ppm range resolution is in

steps of 10 ppm

(example: 30 ppm)

linthe100 ...1,000 ppm range resolution

is in steps of 20 ppm

(example: 120 ppm)

linthe0.10 ...1.00 vol.%rangeresolution

is in steps of 500 ppm

(example: 0.15 vol.%)

10

lthe digital display is supported by the

lower segment display:

l1st bar - from 10 ppm

2nd bar - from 100 ppm

3rd bar - from 200 ppm

4th bar - from 500 ppm

5th bar - from 0.10 vol.%

6th bar - from 0.20 vol.%

7th bar - from 0.50 vol.%

8th bar - from 1.00 vol.%

2.32.3

2.32.3

2.3 Concentration-dependent signalConcentration-dependent signal

Concentration-dependent signalConcentration-dependent signal

Concentration-dependent signal

lthe frequency of the acoustic signal

(item 3) increases as a function of the

concentration measured

lthis signal can be switched on and off

with the service key (item 6) on the back

of the detector

☞Insert the adjusting pin (supplied)Insert the adjusting pin (supplied)

Insert the adjusting pin (supplied)Insert the adjusting pin (supplied)

Insert the adjusting pin (supplied)

into the hole and press the serviceinto the hole and press the service

into the hole and press the serviceinto the hole and press the service

into the hole and press the service

key behind it (item 6).key behind it (item 6).

key behind it (item 6).key behind it (item 6).

key behind it (item 6).

lthe acoustic control signal (item 3)

sounds and the concentration-

dependent signal is switched off

lpressing the service key again switches

the signal back on

11

2.42.4

2.42.4

2.4 AlarmsAlarms

AlarmsAlarms

Alarms

la change in the gas concentration is

indicated by the LCD display (item 2)

and the concentration-dependent signal

(item 3)

lthe gas detector warns of gas

concentrations above 1.00 vol.% by

means of the continuous optical and

acoustic alarms (items 3 and 4)

lvalues exceeding 1.00 vol.% are not

displayed

☞TT

TT

To continue leak detection bringo continue leak detection bring

o continue leak detection bringo continue leak detection bring

o continue leak detection bring

the gas detector into fresh air sothe gas detector into fresh air so

the gas detector into fresh air sothe gas detector into fresh air so

the gas detector into fresh air so

that the zero point can be re-that the zero point can be re-

that the zero point can be re-that the zero point can be re-

that the zero point can be re-

established.established.

established.established.

established.

2.52.5

2.52.5

2.5 Manual zero-point adjustmentManual zero-point adjustment

Manual zero-point adjustmentManual zero-point adjustment

Manual zero-point adjustment

lthis is necessary if the current ambient

atmosphere does not permit the

automatic establishment of a zero point

☞With the detector switched on,With the detector switched on,

With the detector switched on,With the detector switched on,

With the detector switched on,

push thepush the

push thepush the

push the on/off key (item 1)on/off key (item 1)

on/off key (item 1)on/off key (item 1)

on/off key (item 1)

upwards for approx. 2 seconds.upwards for approx. 2 seconds.

upwards for approx. 2 seconds.upwards for approx. 2 seconds.

upwards for approx. 2 seconds.

lthe current ambient atmosphere is set

as a new zero pointnew zero point

new zero pointnew zero point

new zero point

lthe zero point flashes while this process

is under way (approx. 2 minutes)

12

lif the zero point cannot be set, error

message F10F10

F10F10

F10 appears.

☞Repeat the process in a cleanRepeat the process in a clean

Repeat the process in a cleanRepeat the process in a clean

Repeat the process in a clean

ambient atmosphere.ambient atmosphere.

ambient atmosphere.ambient atmosphere.

ambient atmosphere.

lto prevent the EX-TEC® SNOOPER H

from becoming too insensitive the zero-

point can be manually adjusted up to a

maximum of 1,000 ppm

2.62.6

2.62.6

2.6 Battery monitoringBattery monitoring

Battery monitoringBattery monitoring

Battery monitoring

lif the battery's discharge limit is reached

inmeasuringoperationthebatterysymbol

appears in the LCD display (item 2)

lsimultaneously with the concentration-

dependent signal an acoustic warning

tone (item 3) sounds for approx. 2

seconds; the detector can now be

operated for at least another 15 minutes

2.72.7

2.72.7

2.7 Switching offSwitching off

Switching offSwitching off

Switching off

lpush the on/off key (item 1) downwards

for approx. 2 seconds.

lthe optical and acoustic control signal

(items 3 and 4) operate for approx. 2

seconds

lthe remaining operating time is

displayed, e.g. 6 hours - one segment

per hour

13

3.03.0

3.03.0

3.0 Charging techniqueCharging technique

Charging techniqueCharging technique

Charging technique

☞TheThe

TheThe

The EX-TEC® SNOOPER H must not be recharged in anmust not be recharged in an

must not be recharged in anmust not be recharged in an

must not be recharged in an

explosive gas atmosphere !explosive gas atmosphere !

explosive gas atmosphere !explosive gas atmosphere !

explosive gas atmosphere !

When fully charged the detector has a maximummaximum

maximummaximum

maximum of 8 hours'

operating time.

For charging you need the HS charging adapterHS charging adapter

HS charging adapterHS charging adapter

HS charging adapter (see illustration),

which can be used either in the workshop or in the standby vehicle.

The following items can be connected to

the side of the charging adapter:

l230 V mains power pack ≈,

l12 V= vehicle adapter,

l24 V= vehicle adapter.

A maximum of 3 charging adapters with no

socket can be connected to the charging

adapter with a socket.

The detector has a microprocessor-controlled heuristic operating-

hours account.

If the detector is not stored in the charging adapter the NiCd battery

will spontaneously discharge.

In order to verify the capacity of the NiCd battery we recommend

youtooperate thedetectoruntiltheundervoltage alarm istriggered

(the detector automatically switches off), then recharge it. The

available battery capacity is now determined.

14

ChargingCharging

ChargingCharging

Charging

Place the EX-TEC® SNOOPER H (switched off) in the charging

adapter. They are connected via the charging contacts (item 7) and

the adapter contacts (item 2 in the illustration on page 14). An

acoustic signal sounds to indicate the start of charging.

The charging period required is calculated from the operating

hours and a display of the following type appears:

lthe detector has 5 operating hours left (=

5 bars) and will take 3 hours to become

fully charged

lif it is fully charged all the bars are visible

and the number display disappears

lthe detector can be left in the charger

until it is next needed

Spontaneous dischargeSpontaneous discharge

Spontaneous dischargeSpontaneous discharge

Spontaneous discharge

If the detector is not connected to the charger when switched off,

the nickel-cadmium battery spontaneously discharges, thus

reducing the available operating hours.

☞Short periods of operation and prolonged disuseShort periods of operation and prolonged disuse

Short periods of operation and prolonged disuseShort periods of operation and prolonged disuse

Short periods of operation and prolonged disuse

may lead in the long term to the so-called "memorymay lead in the long term to the so-called "memory

may lead in the long term to the so-called "memorymay lead in the long term to the so-called "memory

may lead in the long term to the so-called "memory

effect", in which the display indicates a higher batteryeffect", in which the display indicates a higher battery

effect", in which the display indicates a higher batteryeffect", in which the display indicates a higher battery

effect", in which the display indicates a higher battery

capacity than is actually available.capacity than is actually available.

capacity than is actually available.capacity than is actually available.

capacity than is actually available.

This can be avoided by fully discharging the detectorThis can be avoided by fully discharging the detector

This can be avoided by fully discharging the detectorThis can be avoided by fully discharging the detector

This can be avoided by fully discharging the detector

regularly (e.g. once a month), leaving it switched onregularly (e.g. once a month), leaving it switched on

regularly (e.g. once a month), leaving it switched onregularly (e.g. once a month), leaving it switched on

regularly (e.g. once a month), leaving it switched on

until it automaticuntil it automatic

until it automaticuntil it automatic

until it automatically switches off, then recharging itally switches off, then recharging it

ally switches off, then recharging itally switches off, then recharging it

ally switches off, then recharging it !!

!!

!

15

4.04.0

4.04.0

4.0 Inspection, testing and maintenanceInspection, testing and maintenance

Inspection, testing and maintenanceInspection, testing and maintenance

Inspection, testing and maintenance

DVGW work sheet G 465/IV requires detectors to be inspected,

tested and maintained.

Sensitivity testingSensitivity testing

Sensitivity testingSensitivity testing

Sensitivity testing

may be necessary several times a day, according to G 465/I,

depending on the circumstances - particularly with gas detectors

used to monitor mains pipes.

InspectionInspection

InspectionInspection

Inspection

must be carried out up to six times a year, depending on frequency

of use - and at any rate at least once a year. The following items

must be tested:

ldetector condition lzero point

lbattery condition lsensitivity (with test gas)

lintake channel

TT

TT

Test reportest report

est reportest report

est report

Test results must be recorded. A specimen form will be found on

the last page of this manual.

Servicing and maintenanceServicing and maintenance

Servicing and maintenanceServicing and maintenance

Servicing and maintenance

DVGW work sheet G 465/IV specifies that servicing and

maintenance of the detectors may be carried out only by the

following persons:

lthe SEWERIN Service Department or

lan expert authorised by SEWERIN.

Servicing must be carried out at least once a year. The next

scheduled date must be entered on the inspection sticker attached

to the detector (month/year).

After servicing a certificate must be completed.

16

4.14.1

4.14.1

4.1 TT

TT

Test Setest Set

est Setest Set

est Set

The zero point and sensitivity should be tested with the SPESPE

SPESPE

SPE test

set and a suitable test gas:

Pos. 1

SPESPE

SPESPE

SPE test set, used to test:

lzero point

lsensitivity

and for use with the following test gases:

methane CH4:l1.00 vol.%

propane C3H8:l1.00 vol.%

For detector settings other than methane or propane the correct

values can be found inside the cover (on page 2).

Betriebsanleitung der

Geräte beachten!

Zur Überprüfung von

Gasmeßgeräten mit Pumpe

gemäß DVGW-Richtlinie

G 465/IV

3

1

2

17

4.24.2

4.24.2

4.2 Function testingFunction testing

Function testingFunction testing

Function testing

Proceed as follows:

●screw the test gas can onto the SPESPE

SPESPE

SPE test set as far as it will

go

●connect the test head of the SNOOPER HSNOOPER H

SNOOPER HSNOOPER H

SNOOPER H or SNOOPERSNOOPER

SNOOPERSNOOPER

SNOOPER

H smallH small

H smallH small

H small to the tester hose

lswitch the EX-TEC® SNOOPER H on and wait for a stable

zero point to be established (warm-up time)

lplace the test head on the detector's sensor head

lholddown the releasebuttononthe testeruntiltheindicated

concentration has reached a stable value

Admissible display values with :

ltest gas 1.00 vol.% methane CH4:0.80 ... 1.20 vol.%

ltest gas 1.00 vol.% propane C

3H8: 0.80 ... 1.20 vol.%

If display values are outside these tolerances the detector must

be recalibrated (section 5.0 Adjustment).

18

5.0 Adjustment

The EX-TEC® SNOOPER H is factory-set with test gas. You can

adjust the detector using an appropriate test gas.

To carry out the adjustment you need:

the EX-TEC® SNOOPER H,charged

the SPE test set

the SNOOPER H or SNOOPER H small test head

1.00 vol.% methane or propane test gas in synthetic air

the adjusting pin

Carry out the process exactly the same way as function-testing

(section 4.2).

☞For a successful adjustment both

steps (adjustment of the zero point and of

sensitivity ) must be carried out !

Switching on the adjustment mode

inserttheadjustingpinintheopeningon

the back of the detector (item 6)

press the service key behind it and

simultaneously push the on/off key

(item 1) upwards for approx. 2 seconds

Table of contents

Other sewerin Gas Detector manuals

Popular Gas Detector manuals by other brands

Navim Group Company

Navim Group Company EsiWelma Sensigas URS40SS manual

AGS

AGS Merlin User & installation manual

AIR SYSTEMS INTERNATIONAL

AIR SYSTEMS INTERNATIONAL CO-91 Series manual

Aereco

Aereco S-C02/T Installation and maintenance instruction

Tecnocontrol

Tecnocontrol SE182PM user manual

Delta

Delta DG510/CG manual

Emerson

Emerson Rosemount 925FGD quick start guide

S&S Northern

S&S Northern Merlin 1000BH Installation operation & maintenance

BOREAL LASER

BOREAL LASER GasFinder FCr Operation manual

Inficon

Inficon IRwin S quick start guide

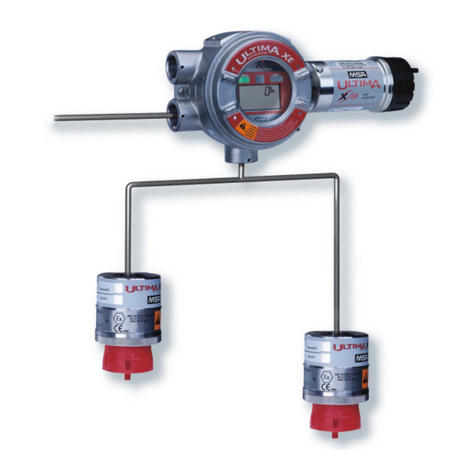

MSA

MSA Ultima X operating manual

New Cosmos Electric

New Cosmos Electric KD-12 instruction manual