Copyright © 2019 by Cool Air Incorporated. All rights reserved.

S

Se

er

rv

vi

ic

ce

e

S

Sw

wi

it

tc

ch

h

(

(S

Se

er

rv

vi

ic

ce

e

M

Mo

od

de

e)

)

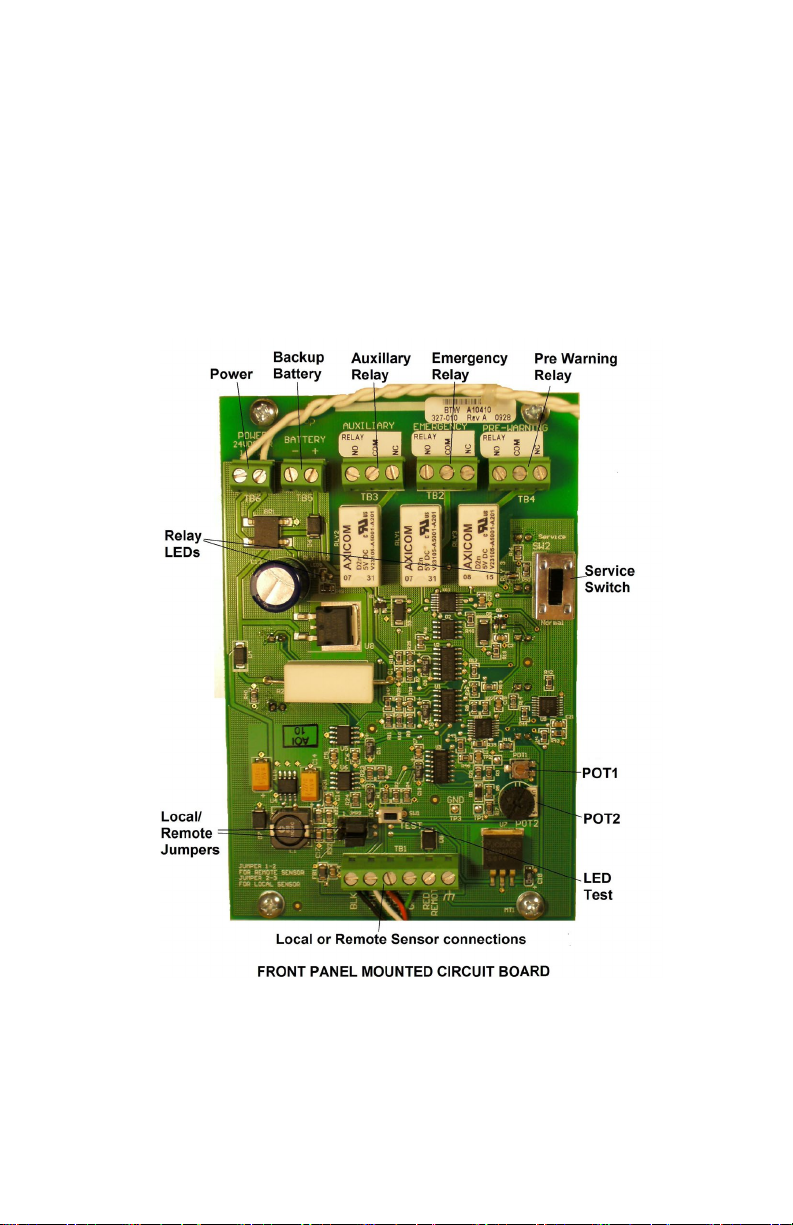

The detector can be set to one of two modes: normal operating mode

or service mode. The detector is in normal operating mode when the

service Switch is in the “Normal” position. When the service switch

is in the “Service” position, the detector continues to function as

usual, however the alarm, pre-alarm, and auxiliary relays are

disabled. This allows the detector to be serviced, tested, and

calibrated without tripping the alarm relays and setting off the alarms.

When the detector is in the service mode, the “Service” LED on the

front panel flashes yellow. After 30 minutes in service mode, the

“Minimal Contamination” and “Early Warning” LEDs will also be lit.

This is done as a reminder to set the service switch back to the

“Normal” mode.

A

Ad

dj

ju

us

st

ta

ab

bl

le

e

A

Al

la

ar

rm

m

P

Po

ot

te

en

nt

ti

io

om

me

et

te

er

r

There is one adjustment potentiometer that is provided to set the

Alarm set point. The Pre-Alarm (Early Warning) is adjusted at the

factory and ‘locked’ into place. The Alarm set point is also pre-set at

the factory but is field adjustable. The adjustment procedure is in the

“INSTALLATION AND SET-UP” section, on page 16.

L

LE

ED

D

T

Te

es

st

t

B

Bu

ut

tt

to

on

n

Pressing the momentary LED Test button will cause all LED’s to

light to up and all three relays to de-energize to confirm that they are

functional.

L

Lo

oc

ca

al

l/

/R

Re

em

mo

ot

te

e

J

Ju

um

mp

pe

er

rs

s

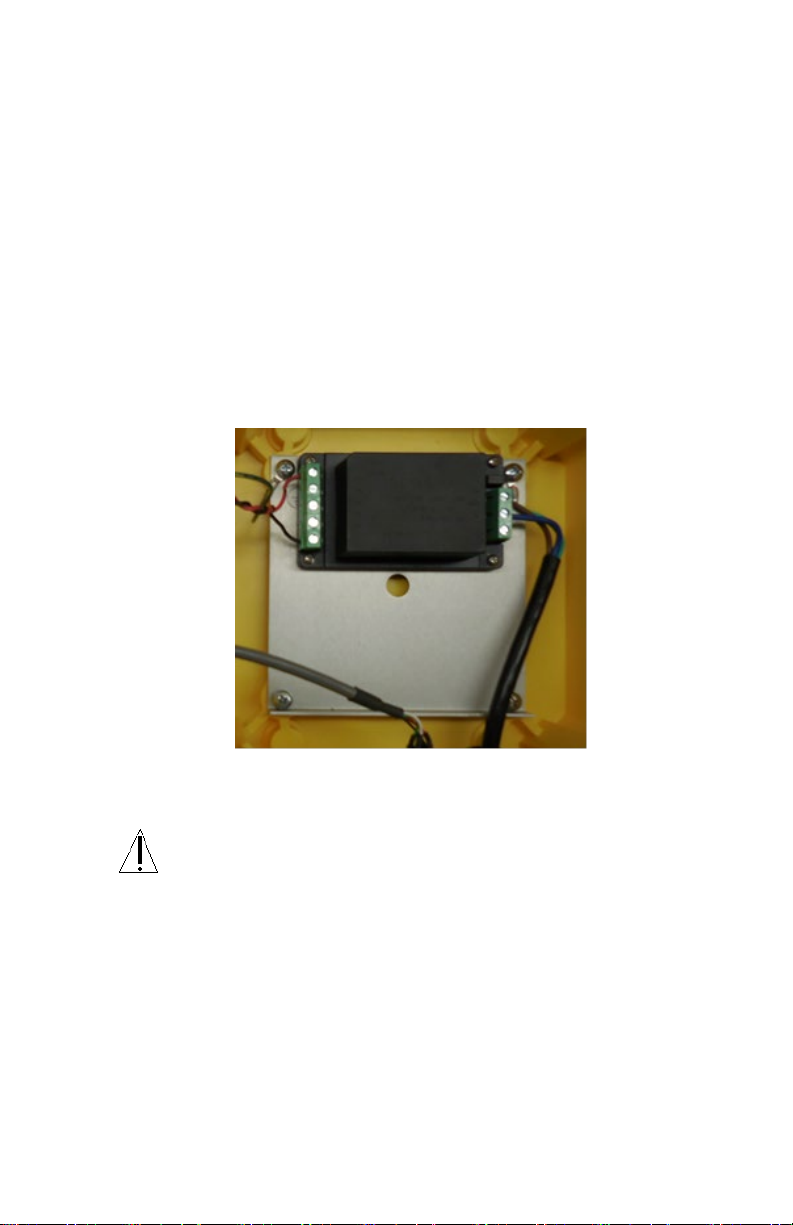

JMPR1 and JMPR2 convert from a local (enclosure mounted) sensor

to a remote sensor.For a local sensor, both jumpers must connect

pins 2 to 3, the far-right position when viewed as shown in the picture

on page 8. For a remote sensor, both jumpers must connect pins 1 to

2, the far-left position when viewed as shown in the picture on page

7.