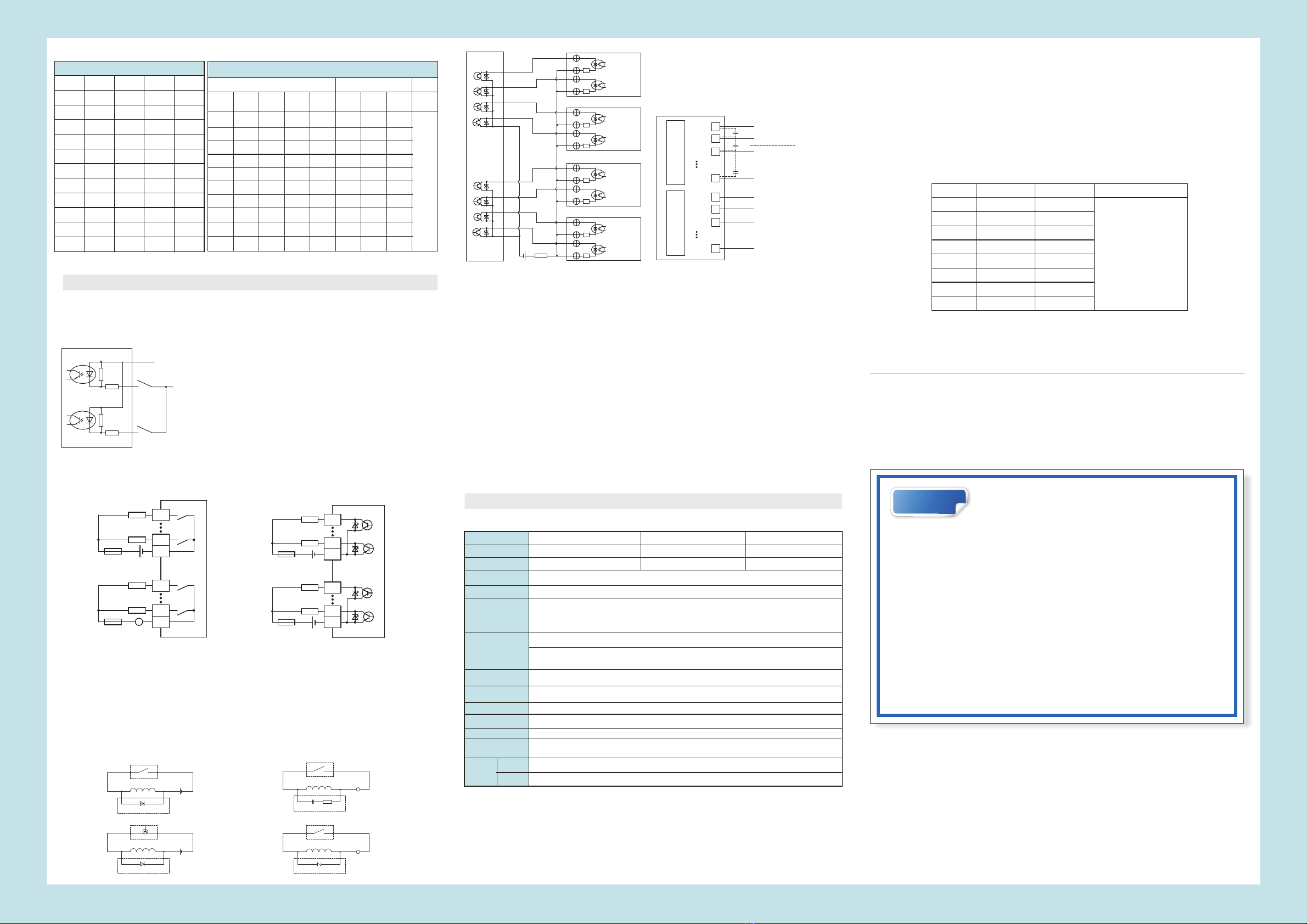

Device allocation and power-down retention instructions

X00-X13 12 points

X00-X27 24 points

Y00-Y13 12 points

Y00-Y23 20pints

Auxiliary relay M

Status S

[S0-S9] 10 points original state/ [S10-S999] 990 points, maintain/ [S1000-S4095] 3096 points, general

Timer T

[T0-T199] 200 points, 100ms, general / [ T250-T255] 6 points, 100ms, maintain/

[T246-T249] 4 points, 1ms accumulation, maintain / [T256-T319] 64 points, 1ms, general use/

[T200-T245] 46 points, 10ms, general use/

* 10ms timer is affected by scan cycle. If scan cycle is 12ms, the timer will work every 12ms.

EX3G-43HB 43H/43(50)KH-24M/

Programming reference

DI X

DO Y

[M0-M383] 384 points, general / [M384-M1535] 1152 points, maintain/ [M1536-M7679] 6144 points, general/

[M8000-M8511] 512 points, special

EX3G-70H-44M

EX3G-70KH/100HA-60M

◆

Counter C

[C0-C15] 16 points, genera / /

[C200-C219] 20 points, general use/[C220-C234] 15 points, maintain use/

[C235-C245 single phase single count], [C246-C250 single phase double count] ,[C251-C255 double phase double count]

use [C16-C199] 184 points, maintain use

Data register V,Z

[V0-V7] [Z0-Z7] 16 points, used while modifying address

[D0-D127] 128 points, general / [D128-D7999] 7872 points, maintain /

[D8000-D8511] 512 points, special use

Nested pointer

[N0-N7] 8 points, master use

Constant

K

H

16 bits -32,768-32,767/32 bits -2,147,483,648-2,147,483,647

16 bits 0-FFFFH/32 bits 0-FFFFFFFFH

Tips……………………….........………………………...............……01

Product Features…………………………………………...………02

Product Information……………………………………..…………03

Electric Parameter………………………………………….………04

Mechanical Design…………………………………………......….05

Electric Design……………………………………….............…….06

Equivalent circuit……………………………………………………07

Analog Wiring…………………………………………...........……..08

Anti-interference Processing…………………….……………..09

Programming Reference…………………………………………10

Data Reference………………………………………………...……11

Shenzhen Coolmay Technology Co., Ltd

Tel.: 0755-86950416

86960332

26051858

26400661

Fax: 0755-26400661-808

QQ: 800053919

Website: https://en.coolmay.com/

Version: 2020/6

Catalog

X00-X35 30 points

Y00-Y35 30 points

[I0□□~I5□□] 6 points, input interruption use/ [I6□□~I8□□] 3 points, timer interruption use/

——

EX3G HMI PLC All-in-One User Manual

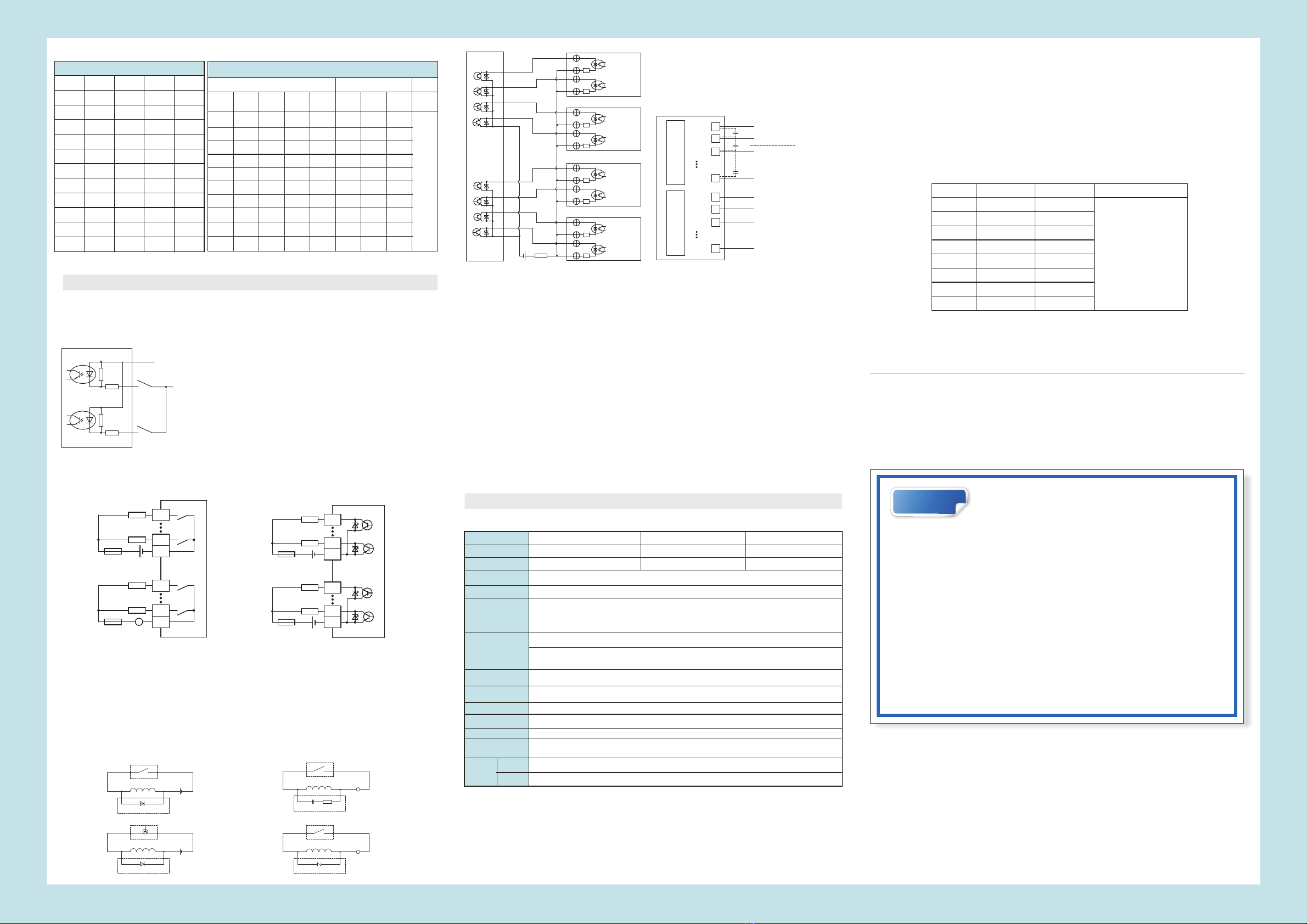

Figure 6 Input wiring

Figure 7 Equivalent circuit of relay output Figure 8 Equivalent circuit of transistor output

Figure 9 Inductive load absorption circuit

Figure 10 Pulse output wiring

Note: All internal circuit in the figure are taken as reference.

※

Equivalent Circuit

The PLC input (X) is an externally powered DC24V sinker (passive NPN) and the input signal is isolated

from the power supply. Connect COM to positive 24V of external power supply while using.

Figure 7 shows the equivalent circuit diagram of the relay output module. The output terminals are several

groups and each group is electrically isolated. Different groups of output contacts are connected to different

power circuits.

COM0

Y003

Y000

COM1

Y007

Y004

DC24V

Fuse

Load

AC0~220V

~

sinker output

DC24V

DC24V

COM0

Y003

Y000

COM1

Y007

Y004

COM0

Y1

COM2

Y10

COM1

Y4

R=200Ω C=0.22uF,250VAC

RC

~

COM1

Y5

~

FWD 1N404

FWD 1N404

PLC relay output

inductive load

AC220V power supply

AC220V power supply

varistor 10D471k (undercurrents)

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

-

R

COM1

Y4

Y5

Y6

Y7 Direction

Pulse

COM0

Y0

Y1

Y2

Y3

PLC internal

equivalent

circuit

DC24V(5V drive must string 2kΩ resistor)

GND

AD0

AD1

AD15

+

104p

GND

DA0

DA1

DA7

AD

AD COM terminal

( )AD 1

104p +( )AD 2

* Please consider adding 104p ceramic capacitor or external

magnetic ring filter to increase anti-interference ability if analog

inputs are unstable.

104p

+( )AD 16

-

DA COM terminal

+( 8)DA

+( 2)DA

+( 1)DA

* Analog input is AD0-AD15 and output is DA0-DA7. Negative

terminals are connected to GND of input and output respectively.

One negative voltage output will occupy 2 DA and max 4 negative

voltage outputs can be optional. (Only connect DAx and GND.

Please be subject to the test report in your package. )

The equivalent circuit of the transistor PLC output is shown in Figure 8. Seen from the figure, the output

terminals are several groups, and each group is electrically isolated, and different groups of output contacts can

be connected to different power circuits. The transistor output can only be used for DC 24V load circuits. Output

wiring is NPN, COM cathode.

For the inductive load connected to the AC circuit, the RC transient voltage absorption circuit should be

considered on the external circuit. For the inductive load of the DC loop, adding a freewheeling diode should be

considered, as shown in Figure 9.

Stepping or servo motor wiring is shown in Figure 10. 5V drive must connect a 2KΩ resistor on DC24V.

4-channel pulse are Y0, Y1, Y6, Y7, and customized 5-channel are Y0, Y1, Y6, Y7 and Y10.

PLC anti-jamming processing

1. Strong electricity and weak electricity should be separated wiring and not common ground. When there is

strong electric interference, add magnetic ring on the power supply. And do correct and effective grounding

according to the type of the chassis.

2. When the analog is disturbed, 104 ceramic capacitors can be added for filtering, and a correct and effective

grounding can be performed.

More details please refer to Methods of Coolmay PLC anti jamming processing

* , " - "

PLC analog wiring

Two-wire system: The positive pole of the power supply is connected to that of the transmitter, and the negative

pole of the transmitter is connected to the AD side, and the negative pole of the power supply

is connected to the GND. Generally it is the wiring method of the 4-20MA/0-20MA transmitter.

Three-wire system: The positive pole of the power supply is connected to that of the transmitter. The negative of

the power supply and that of the signal output are the same terminal. The transmitter signal

output is connected to the AD terminal.

Four-wire system: The positive and negative terminals of the power supply are connected to those of the

transmitter respectively, and the positive and negative of the transmitter signal outputs are

connected to the AD and the GND terminal respectively.

The two wires of the temperature analog are connected to the AD and the GND terminal respectively. If it is a

three-wire PT100, it needs to be connected in two lines. The GND common terminal of the analog input and

output can be shared.

Load

Load

Load

Load

Load

Load

Load

Fuse

Fuse

Fuse

PLC relay output

inductive load

PLC relay output

inductive load

DC24V power supply

PLC transistor output

inductive load

DC24V power supply

Figure 11 PLC analog wiring

Direction

Pulse

Direction

Pulse

Direction

Pulse

DA

TIPS Please read carefully the related manuals before using our

products, and use this product under the environmental

conditions specified in this manual.

1. Power on after confirmed the voltage (24VDC, >18W) and right wiring to avoid damage.

2. Tighten the screws or the rail while mounting the product to avoid falling off.

3. Avoid wiring or plug the cable with electricity, or it is easy to cause electric shock or circuit

damage. When the product emits odor or abnormal sound, please immediately switch off the

power. While processing screw holes or wiring, do not drop the metal chips and wire head into

the ventilation hole of the controller, which may cause product failure and disoperation.

4. Do not tie power cables and communication cables together or close and keep them at a

distance of 10cm or more. Strong and weak currents need to be separated and correctly

grounded. In severe interference situations, input and output cables of the communication and

high-frequency signals should use shielded cables to improve anti-jamming performance. The

grounding terminal FG on this unit must be properly grounded to improve the anti-interference

ability.

5. DI is an externally powered DC24V sinker (passive NPN), and the input signal is isolated from

the power supply. Connect S/S to 24V of external power supply while using.

6. DO (transistor) COM is common cathode.

7. Please do not disassemble the product or change the wiring. Or it will possible to cause

breakdown, malfunction, loss, or fire.

8. While installing or disassembling the product, ensure to turn off all power. Or it may cause

malfunction and breakdown.

* Programming software

PLC: compatible with Mitsubishi PLC programming software GX WORKS 2.

HMI: Coolmay HMI programming software

* Detailed information, please refer to

“Coolmay EX3G HMI PLC All-in-One Programming Manual”,

“EX3G HMI PLC All-in-One User Manual”,

“Coolmay HMI User Manual”,

“Mitsubishi FX3G Programming Manual”

The soft elements power retentive of HMI PLC all-in-one is permanently retentive, i.e., all the soft

elements in the holding area are not lost if the module is powered off. The real-time clock uses a

rechargeable battery to ensure that the clock is the current time. All power retentive functions must ensure

that the voltage is 23V or higher when DC24V power supply with loads, and the PLC power-on time is

longer than 2 minutes. Otherwise, the power retentive functions will be abnormal.

◆

No Register

address

D8050

D8051

D8052

D8053

D8054

D8055

D8056

D8057

Range of set

value

0-4000

0-4000

0-4000

0-4000

0-4000

0-4000

0-4000

0-4000

Output type

※

◆

※

Registers read directly: D[8030]-D[8045] are the input values of [AD0~AD15].The constant scan-time will change to D8059

and started by M8039 (version 26232 and higher). It supports max 15 analog inputs when there exist thermocouple type, and

AD4[D8034] is the ambient temperature of thermocouples. It supports max 16 analog inputs without thermocouples.

Analog input register (AD,accuracy 12 bits). Support FROM demand or register read directly.

The temperature type is one digit after the decimal point, i.e. 182 = 18.2 degrees.

AD sampling

Filter cycles = (R23600~R23615)* scan time of the PLC. The default value is 100 and the data cannot be

less than or equal to zero. If R23600=1, one PLC scan cycle samples once, and the value in the first analog

input is changed once. The larger the value of R23600~R23615 is set, the more stable the result is.

D8073 is the smoothing filter coefficient of all analog inputs. The setting range is 0~999.

Analog output register (DA,accuracy 12 bits). Support TO demand or direct register assignment.

TO demand direct outputs: TO K0 K0 D500 K8 , 8 analog outputs

DA0

DA1

DA2

DA3

DA4

DA5

DA6

DA7

If D8058.0~D8058.7=0,

output type is 0-20mA.

If D8058.0~D8058.7=1,

the type is 4-20mA.

16 bits (CTU)/ / increase counter 32 bits increase and decrease counter (CTUD) High speed counter

1K

3.9K

COM

X0 0V

X1

1K

3.9K

24V

EX3G-43HB/43H/43(50)KH all-in-one COM

PIN#PLC-485-2

serial port 3PLC-485-1

serial port 2

PLC-232

serial port 3HMI-232

Optional Default Optional

8

9

Terminal 485

√(485+)

√(485-)

√

√(RXD)

√(TXD)

√(GND)

√(GND)

√(TXD)

√(RXD)

EX3G-70H/70KH/100HA all-in-one COM(EX3G-70H can't support WIFI)

PIN#

PLC-485-1

serial port 2

D 9 portb Default Optional

8

9

√(485+)

Optional and

default 232

cannot coexist

PLC-485-2

serial port 3

PLC-232

serial port 3

Optional and

default 232、

Optional WIFI

cannot coexist

Optional and

default 232、

Optional 485

cannot exist

WIFI

Optional

PLC-CAN

Optional

COM2(DB9 port near power supply)

HMI-485

HMI-232

Optional

√(485+)

√(485-)

√(485-)

√(RXD)

√(TXD)

√(GND)

√(H)

√(L)

Optional

√(RXD)

√(TXD)

√(GND)

√

√

√

√

√

√(485+)

√(485-)

1

6

2

3

5

4

7

1

6

2

3

5

4

7

COM1

DB9 port

COM1(DB9 port away from power supply)

Network

port

Network

port of

HMI and

PLC do not

occupy

serial port

signal,

and can

not coexist.

Chart 4: Pin definition

* Note: Detailed settings, please refer to "Coolmay EX3G Programming Manual".

Figure 7 shows the equivalent circuit diagram of the relay output module. The output terminals are several

groups and each group is electrically isolated. Different groups of output contacts are connected to different

power circuits.

PLC digital inputs wiring:

Ports short circuit: S/S of PLC input terminal is connected to 24V, X terminal is connected to

power supply 0V, i.e., input signal.

Two-wire system (magnetic control switch): The positive pole of the magnetic switch is

connected to PLC X terminal, and the negative pole is connected to 0V.

Three-wire system (photoelectric sensor or encoder): Sensor or encoder power supply is

connected to power supply positive, signal line is connected to X terminal. Encoder

and photoelectric sensor are NPN type (PNP is customized).

PLC digital outputs wiring:

Transistor: Output is NPN, COM is connected to the negative pole, and Y is connected to

the positive pole of the power supply with a load.

Relay: Dry contact output, COM can be connected to the positive or negative.

Data register D

[R0-R22999] 23000 points, support power retentive/ [R23000~R23999] 1000 points, system internal use

Extended file register R

Pointer JUMP,CALL branch use

[P0-P255] 256 points/ [ - ] points and higher versionP0 P1280 1281 (26232 )

Interruption

[I10□□~I60□□] 6 points, timer interruption use

FROM demand read: FROM K0 K0 D400 K16 can be read as 16-channel analog inputs.

Note Analog input range and register values please refer to Coolmay EX3G HMI PLC All in One Programming Manual: , " - - ".

※

※

TO demand direct outputs: D[8050]~D[8057] correspond to the values of [DA0~DA7].

When select negative outputs, 2 analog outputs will be covered. The configuration is as the

chart below.

(*1)

Max digital points