6

Once the specified delay time has expired the second stage

valve will be energized.

When the second stage of the thermostat is satisfied, the inducer

motor is reduced to low speed and the second stage gas valve

is de-energized.

On the 50M58-707 control, the circulator will remain at high heat

speed for 30 seconds following the opening of the second stage

gas valve and then is reduced to low heat speed.

When the first stage of the thermostat is satisfied, the first stage

gas valve is de-energized and the HEAT delay-to-fan-off begins

timing.The inducer will postpurge for an additional 15 seconds,

then the inducer and humidifier will turn off. Upon completion

of the HEAT delay-to-fan-off period, the 50M58-707 circulator

is turned off. The electronic air cleaner on the control is also

de-energized at this time.

If flame is not detected during the trial-for-ignition period or if the

flame is detected/sensed and then lost before completion of 10

seconds of establishment, the gas valve is de-energized, the

ignitor is turned off, and the control goes into the “retry” sequence.

The “retry” sequence provides a 60-second wait with the inducer

interpurge following an unsuccessful ignition attempt (flame not

detected). After this wait, the ignition attempt is restarted. Two

retries will be attempted before the control goes into system

lockout.

If flame is established for more than 10 seconds after ignition,

the 50M58-707 controller will clear the ignition attempt (or retry)

counter. If flame is lost after 10 seconds, the control will restart

the ignition sequence.

A momentary loss of gas supply, flame blowout, or a shorted or

open condition in the flame probe circuit will be sensed within

2.0 seconds.The gas valve will de-energize and the control will

restart the ignition sequence.Recycles will begin and the burner

will operate normally if the gas supply returns, or the fault condi-

tion is corrected, before the last ignition attempt. Otherwise, the

control will go into system lockout.

If the control has gone into system lockout, it may be possible to

reset the control by a momentary power interruption of 10 seconds

or longer. Refer to SYSTEM LOCKOUT AND DIAGNOSTIC

FEATURES.

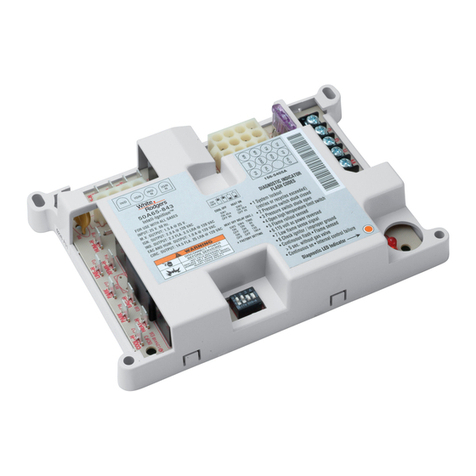

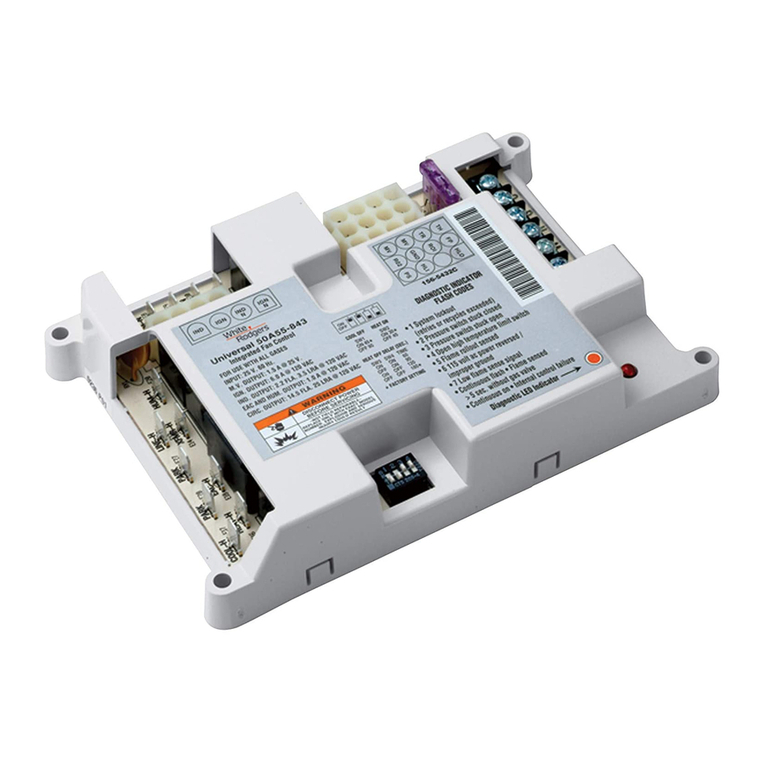

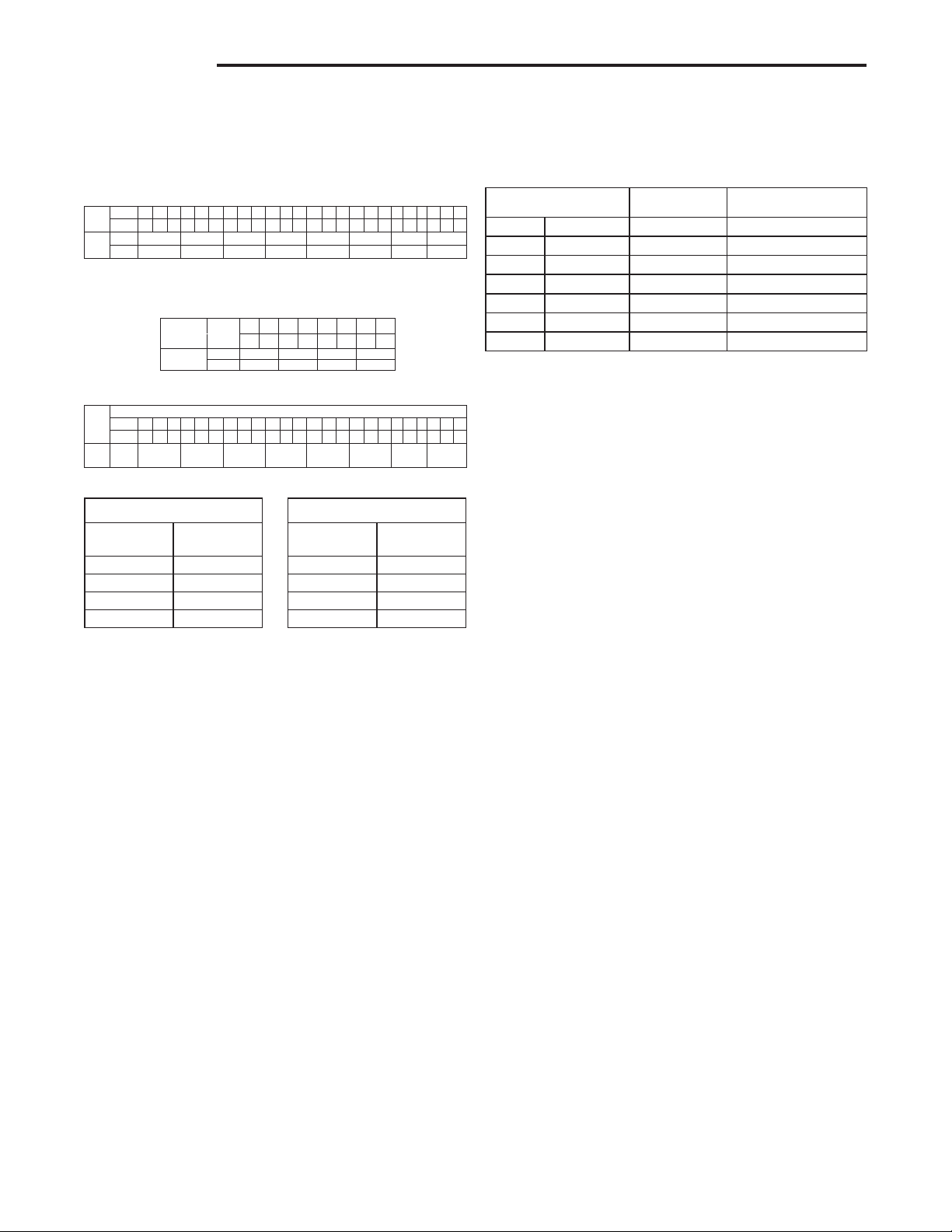

OPTION SWITCHES

Option switches on the 50M58-707 control are used to determine

the length of the delay-to-fan-off periods.The following tables show

the time periods that will result from the various switch positions.

HEAT OFF DELAY

DIP SW S3-3

S3-4

NOMINAL

(SECONDS)

OFF-OFF 90

OFF-ON 120

*ON-*OFF 150

ON-ON 180

W2 DELAY

DIP SW S3-1

S3-2

NOMINAL

(MINUTES)

*OFF-*OFF TWO STAGE

ON-OFF 10

OFF-ON AUTO

ON-ON 20

Average Calculated

Duty Cycle %

Low to High

Stage Delay

Demand

Equals or less than

0 38 12 minutes Light

38 50 10 minutes Light to Average

50 62 7 minutes Average

62 75 5 minutes Average to Heavy

75 88 3 minutes Heavy Light

88 100 1 minute Heavy

HEAT MODE

In a typical system, a call for first stage heat is initiated by closing

the W1 thermostat contacts. The inducer blower is energized

at high speed and the control waits for the low pressure switch

contacts to close. The humidifier (optional) is also energized at

this time. Once the low pressure switch contacts close, a pre-

purge is initiated. Then the inducer changes to low speed and

the 120V ignitor is powered.

At the end of the ignitor warm-up time, the first stage of the two

stage manifold gas valve is energized (low fire). Once flame

is detected, the HEAT delay-to-fan-on period begins. After the

delay-to-fan-on period ends, the 50M58-707 control will energize

the circulator fan at low heat speed. The electronic air cleaner

(optional) will also energize at this time.

For a two-stage thermostat, a call for second stage heat (W1

and W2) after a call for first stage heat will energize the inducer

at high speed and the circulator at high heat speed.The second

stage pressure switch contacts will close and energize the second

stage gas valve (high fire).

For a single-stage thermostat, when a call for heat occurs

(W1), a 10, 20 minute or auto mode heat staging timer will be

activated (timing is selectable with option switches S1-1 and

S1-2 positions). Following this delay, the second stage heat is

energized as above.

TheAUTO model algorithm is a method of energizing the second

stage gas valve based on the recent average of the heating duty

cycle. During a typical heating day, the low to high stage delay

is determined by using the average calculated duty cycle from

the table below.

OPERATION OPERATION

Cool Motor SPEED DIP SWITCH SETTING (S1-1, S1-2, S1-3)

*1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

Position OFF OFF OFF ON OFF OFF ON ON OFF OFF ON OFF OFF OFF ON OFF ON ON ON OFF ON ON ON ON

Motor

SPEED

Cool

Ylo T4(60Hz) T3 T3 T4(60Hz) T4(60Hz) T3 T2 T2

YT4(120 Hz) T4(60Hz) T4(120Hz) T1 T2 T1 T4(120Hz) T3

*Factory default setting

Fan Motor SPEED DIP SWITCH SETTING (S2-2, S2-3, S2-4)

DIP SWITCH S2 SETTING

*2 3 4 2 3 4 2 3 4 2 3 4 2 3 4 2 3 4 2 3 4 2 3 4

Position OFF OFF OFF ON OFF OFF ON ON OFF OFF ON OFF OFF OFF ON OFF ON ON ON OFF ON ON ON ON

Motor

SPEED

Fan

GT1 T2 T3 T4(60Hz) T4(120Hz) T1 T1 T1

*Factory default setting

Heat Motor SPEED DIP SWITCH SETTING

(S1-4, S2-1)

*4 1 4 1 4 1 4 1

Position OFF OFF ON OFF ON ON OFF ON

Motor SPEED

Heat

W1 T1 T3 T3 T4(60Hz)

W2 T2 T2 T4(60Hz) T4(120Hz)

*Factory default setting