IF 1630 • 01/13 Copyright © 2013, Cooper Industries, Inc. Page 1

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

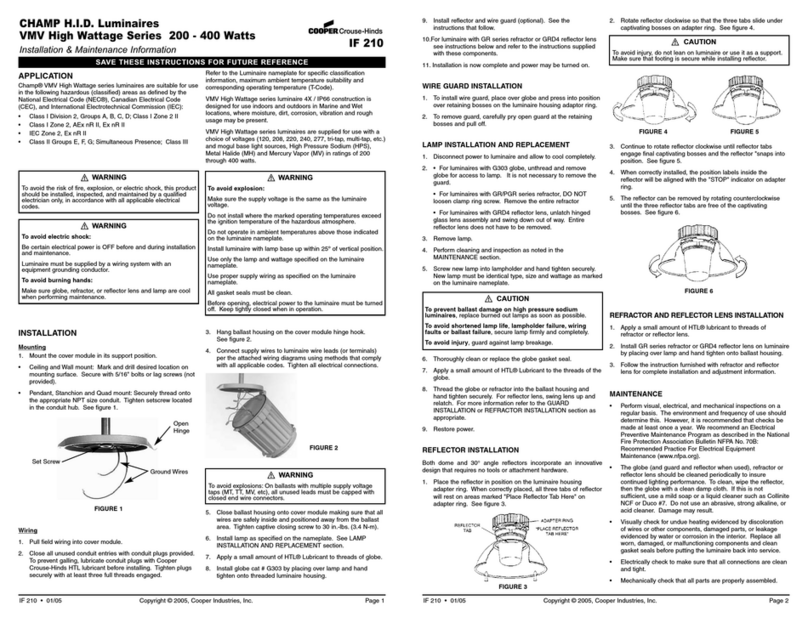

APPLICATION

The LED N2LPS SS Emergency Lighting System is designed to automatically provide

illumination to designated areas during failure or interruption of power to the normal

lighting system. The N2LPS SS is factory-assembled and wired, and consists of one

battery and two light fixtures.

When properly installed, the following marine rated N2LPS SS emergency lighting

systems are UL and cUL listed for use in:

• N2LPS12222 SS Power Supply - Class I, Division 2, Groups B, C, D

• N2LPS12220 SS Power Supply - Class I, Division 2, Groups B, C, D; NEMA 4X

The N2LPS SS power supply consists of a battery supply and battery recharging

system housed inside a 316 stainless steel enclosure with all the circuitry to

automatically turn on emergency DC lighting fixture(s) when the normal power

supply fails. A pilot light indicates when normal power is being supplied to the unit. A

“push-to-test" pushbutton switch is provided for periodic testing of the unit.

The light fixture used on the N2LPS SS system is a rugged, epoxy coated corrosion-

resistant assembly, fully adjustable and lockable, and houses a high output MR16

LED lamp, which is included with the fixture.

DETAIL INDICATION LOGIC IS GIVEN BELOW:

Immediately after supply power is initiated, the indicating lamp will blink/pulse to indicate

that the unit is charging. Once installed with supply power, the N2LPS SS requires 72 hours

to charge the battery. Once the unit has completed charging, the pilot light will stop blinking

and go to steady.

Every six months, the unit will automatically perform a 90 minute battery discharge test. At

the completion of the test, if it is determined not to have met the 90 minute requirement or

if the battery connection is not adequate, the pilot lamp will blink twice, indicating battery

failure. Every 30 days, the unit will also automatically perform a 30 second self-test. If the

battery or board has been compromised the indicator light will blink accordingly.

NOTE: Ambient temperature at which N2LPS SS power supply is rated is 0ºC to +40ºC

to maximize battery capacity. Ambient temperature at which N2LPS SS S904 is rated

is 0°C to +55°C to maximize battery capacity. Lighting fixtures are permitted in higher,

+55ºC ambient temperature areas for more freedom in selecting remote installation

location.

National Electrical Code®is a registered Trademark of the National Fire Protection

Association.

WARNING

To avoid personal injury, electric shock, or equipment failure:

1. Do not use this equipment for other than intended use.

2. Do not use accessory equipment not recommended by the manufacturer.

3. Electrical power must be turned OFF before and during installation and

maintenance.

4. Equipment should be mounted in locations and at heights where it will not

readily be subjected to tampering by unauthorized personnel.

5. Do not mount near heat producing equipment.

6. In Class I areas, install and seal all equipment in accordance with the

National Electrical Code articles pertaining to hazardous (classified)

locations, plus any other applicable codes.

7. Install only wiring systems with an equipment grounding conductor (which

may be the conduit system) to supply the N2LPS SS.

8. Free installation area of hazardous atmospheres before wiring.

9. Observe all battery handling precautions contained herein.

10. To avoid shattering: Do not operate lamp in excess of rated voltage, protect

lamp against abrasion and scratches, and against liquids when lamp is

operating. Dispose of lamp properly.

LED N2LPS SS EMERGENCY LIGHTING SYSTEM

Installation & Maintenance Information

IF 1630

IMPORTANT

Emergency lighting system should be installed, inspected, operated, and maintained by

qualified and competent personnel.

RATINGS

POWER

SUPPLY

Input • 120, 230 and 277 VAC ± 5%, 50 or 60Hz

• 0.5 Amperes maximum

Output • 12 VDC; 2.5 Amperes

• 28 Watts for 1½ hours at +40°C

Ambient Temp • N2LPS SS 0ºC to +40ºC

• N2LPS SS S904 0°C to +55°C

LAMP

FIXTURES

Input • 12 VDC

Ambient Temp. • +55ºC maximum

Operating Temp. Code • Class I, Division 2 40º - T5; 55º - T4A

IMPORTANT SAFEGUARDS - READ AND FOLLOW ALL SAFETY INSTRUCTIONS

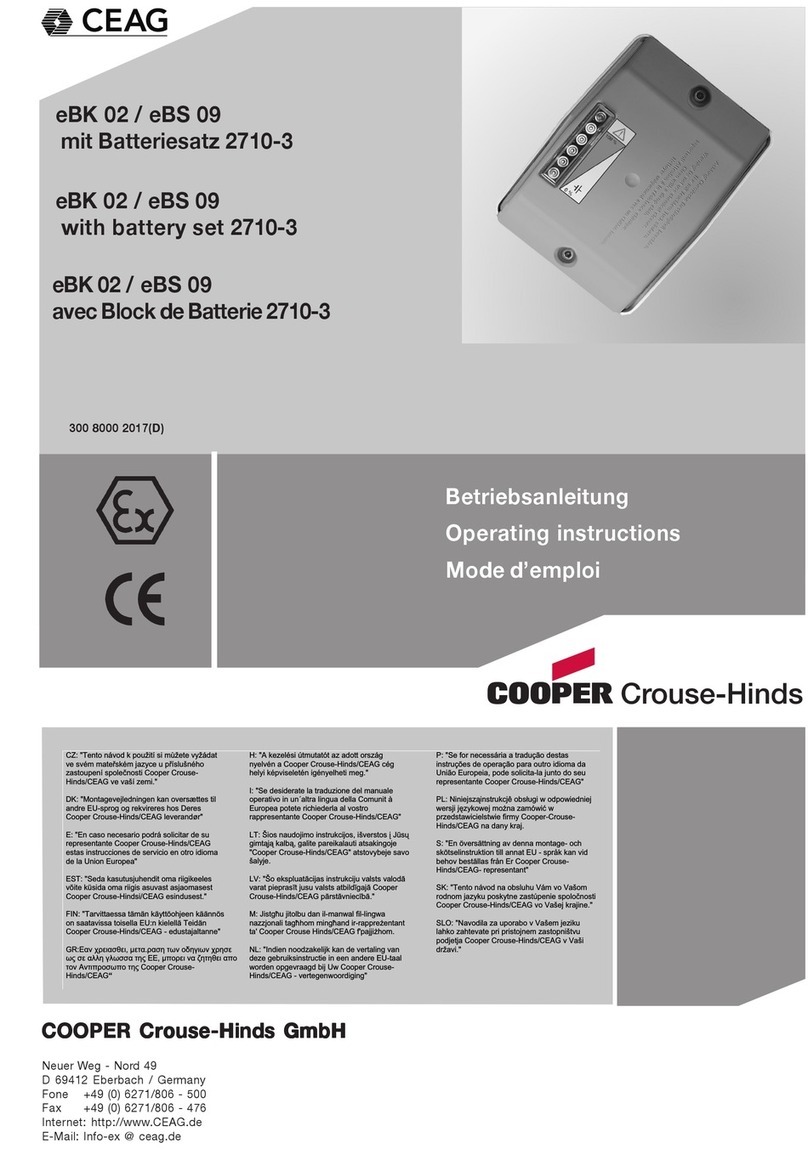

Status Indication Status Description Status Definition

No Light AC Power Removed From Circuit

* Steady Light (No blinks) Fully Charged

* - * Light Blinks Once Battery Charging

**-** Light Blinks Twice Battery Failure

***-*** Light Blinks Three Times Circuit Failure

Table 1. Detail Indication Logic