CL33600 Series Cylindrical Lock

1) Warning

Table of Contents

2

Copyright © 2009 Corbin Russwin, Inc. All rights reserved.

Reproduction in whole or in part without the express written

permission of Corbin Russwin, Inc. is prohibited.

1) Warning................................................................................2

2) General Description.............................................................3

3) Specifications / Features ....................................................3

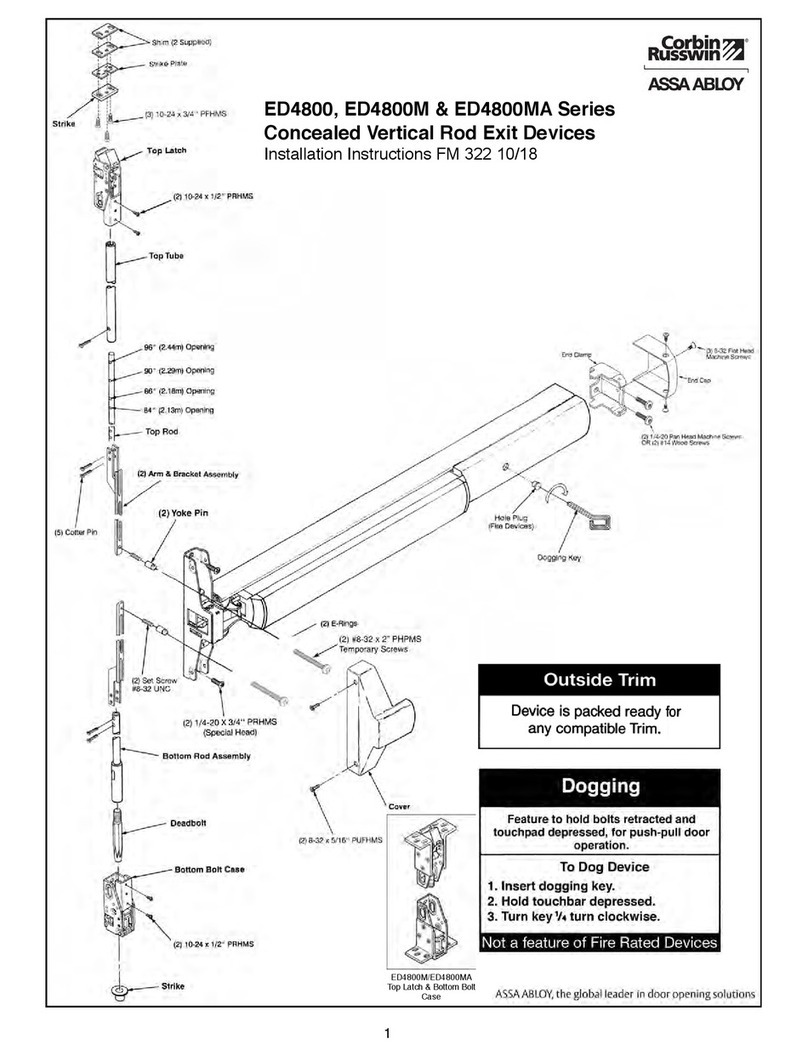

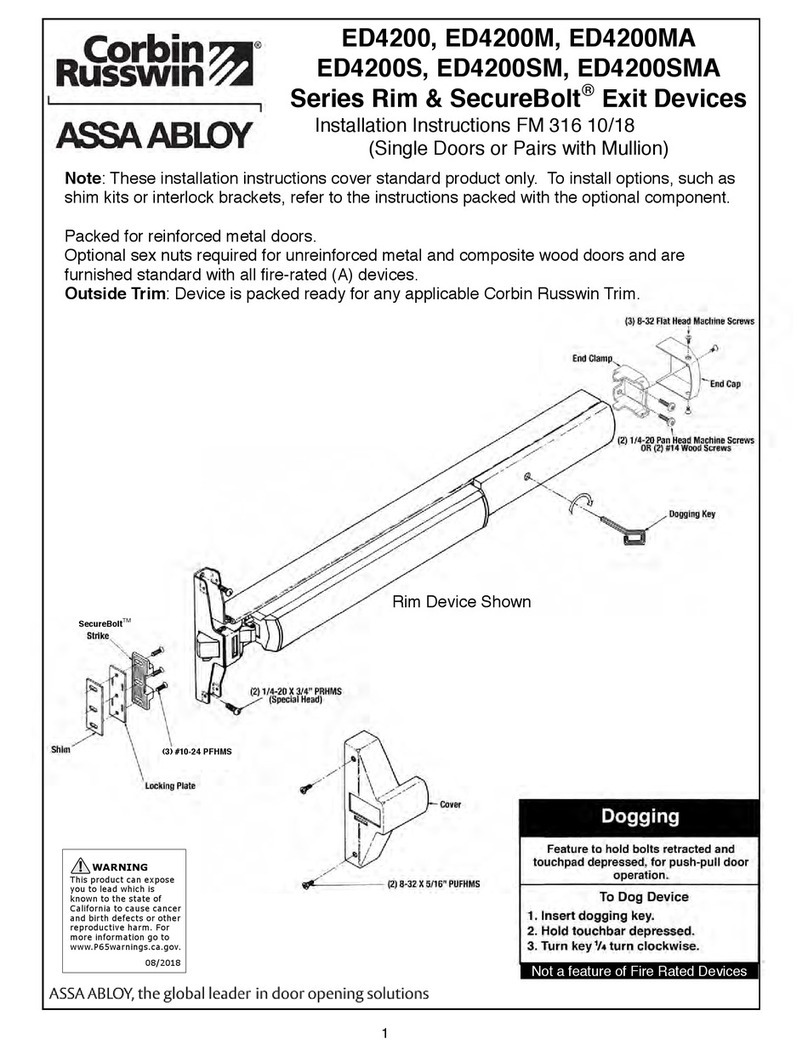

4) Product Illustration .............................................................4

5) Installation Instructions......................................................5

6) Wiring Diagrams................................................................12

7) Mechanical Operational Check.........................................16

8) Electrical Operational Check.............................................16

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a resi-

dential installation.

This equipment generates, uses and can radiate radio frequency energy and if not installed and used in accordance with

the instructions, may cause harmful interference to radio communications. However, there is no guarantee that the inter-

ference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced technician for help

The term “IC:” before the radio certification number only signifies that Industry Canada technical specifications were

met. This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations.

Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne causant des

règlements d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer

l’interférence nocive, et (2) ce dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui

peut causer l’opération peu désirée.

Warning: Changes or modications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Observe precautions for handling electrostatic sensitive devices.

!