FLOAT

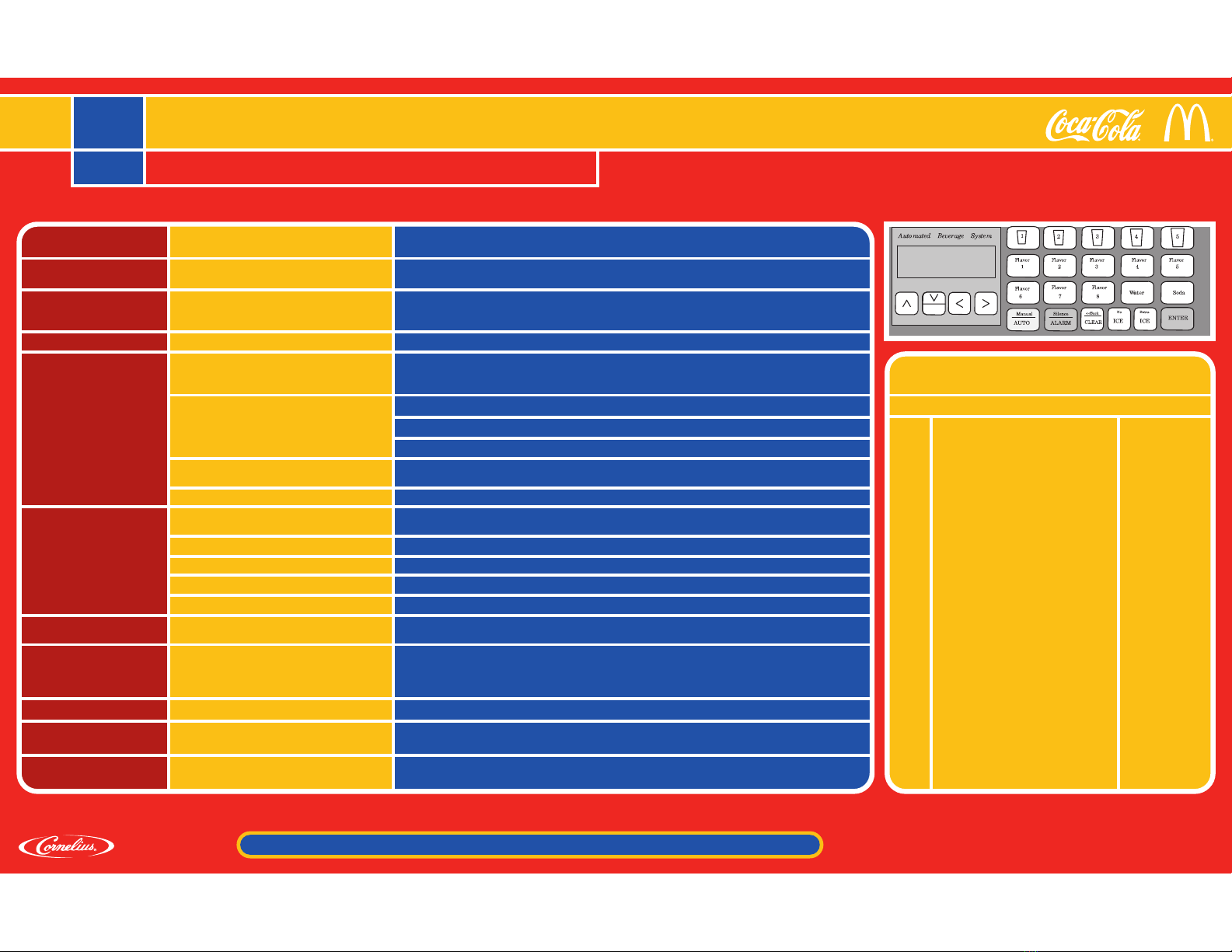

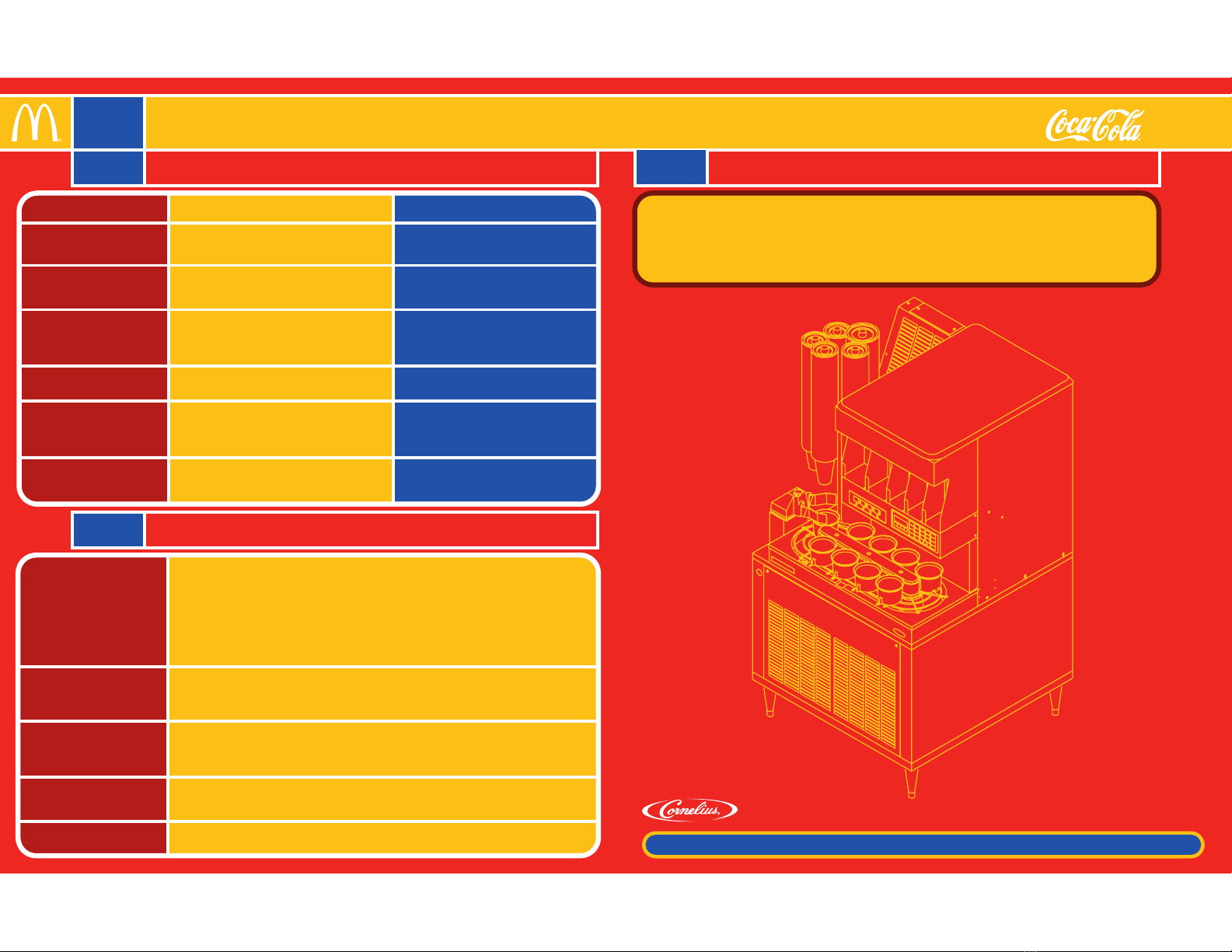

A Alarm & Warning Messages

McDonald’s® ABS Alarms and Troubleshooting04

MESSAGES

OR CONDITIONS EXPLANATION SOLUTION

COKE SMALL PARTS 1-800-241-2653

Ask for Small Parts Department. Part orders less than

$15/order are FREE. Prices subject to change.

Listed below are the most common parts needed.

14461 Conveyor Backing Plate Kit $1.16

16586 Nozzle Brush $0.50

19136 Valve Nozzle $2.63

20297 Deflector, Syrup (Diffuser) $6.10

20482 Small Nut, Cup Tube $3.42

20483 Acorn Nut 6x32 $0.43

20484 Large Nut, Cup Tube $3.27

20582 Plastic Spacer for Cup Tube $0.79

20652 Cup Locator Spring $7.71

20669 Water Deflector $0.97

20763 Screw for Front Panel $0.41

20881 Clinch Stud, Cup Tube $0.29

20882 Lock Nut for Cup Tube $0.03

28074 Cup Fingers 16, 21, 42 oz. $4.75

28075 Cup Fingers 12, 32 oz. $4.93

28076 Ice Chute Brush $8.79

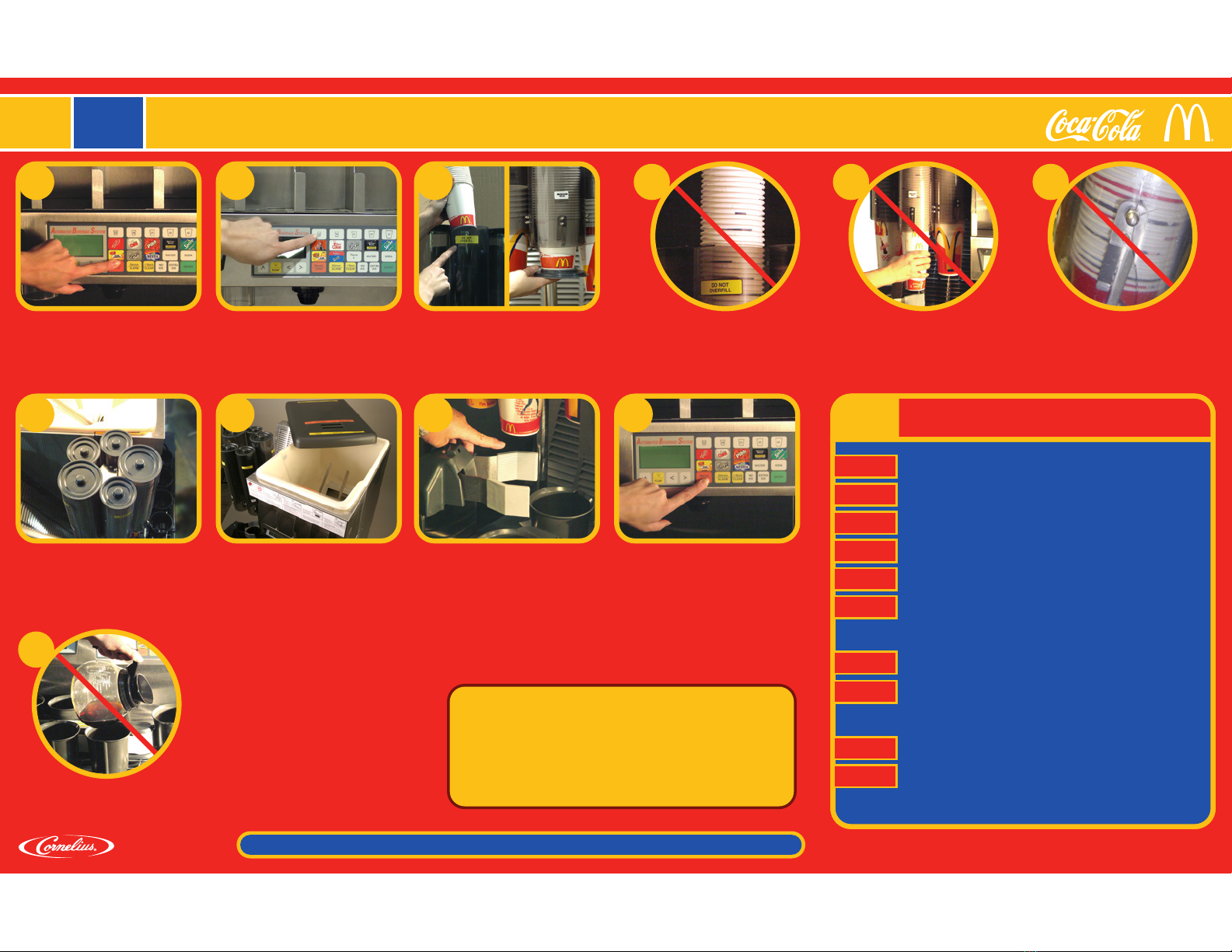

(X) CUP OUT AT STATION (Y) The cup tube for size (X) is empty at

station (Y).

Refill the empty cup tube with the correct cup size and then press ENTER to continue dispensing.

CLEAR SYRUP SOLD OUT The clear syrup (SPRITE) is sold out

(EMPTY B.I.B.).

Connect a new syrup supply and the ABS unit will continue. If the ENTER button is pressed

before the syrup supply is replenished, automatic operation will resume but only the cup and ice

will be dispensed for this flavor.

LOW ICE - REFILL SOON Ice level in the ice bin is too low. Refill the ice bin with ice. Press ENTER. Alarms may continue for up to 15 minutes.

CLEAR CUP JAM Cup(s) jammed in the conveyor at the cup

extraction position and the conveyor and

turret are unable to operate.

Remove all cups from the conveyor cup holders at the EXTRACT POSITION before pressing the

ENTER button. Another cup will be extracted and dispensing will continue.

Cup Tubes. Over stacking of cups in cup tubes. Do not fill above the top of the cup tube.

Loose or Missing Hardware. Check each cup tube to insure all hardware is present on the cup tube. Replace any missing

hardware.

Cups. Cups are packed together and will not separate.

Grabber Pads. Wet, dry off. If damaged, replace.

C02 Check bulk C02 tank, if empty go to back up C02 and turn on.

Cup Tubes. Cup tube fingers are damaged (bent), replace all four fingers.

Cups Cups are packed together and will not separate.

Cup tube fingers are damaged (bent), replace all four fingers.

Cup tubes not properly mounted. Remove and remount cup tubes.

NO CUP EXTRACTED The gripper did not or could not extract a

cup from the cup tube.

Check cup supply at the extract station and make sure the cups are not stuck. Make sure the

gripper pads are not damaged.

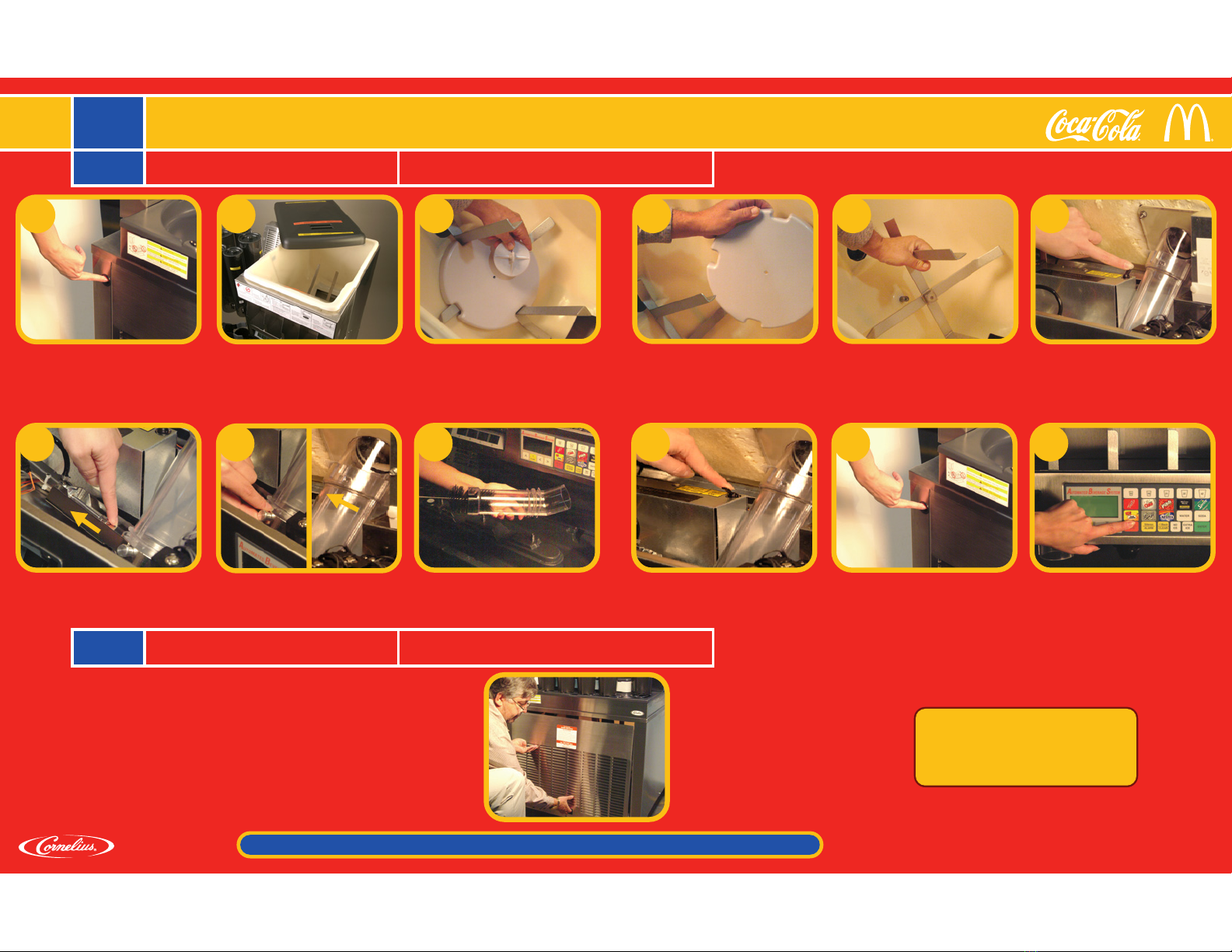

AIR OR C02 LOW OR OUT C02 supply is low or empty or air

compressor not operating.

Change C02 cylinder or have bulk tank refilled. Check cause not operating and repair.

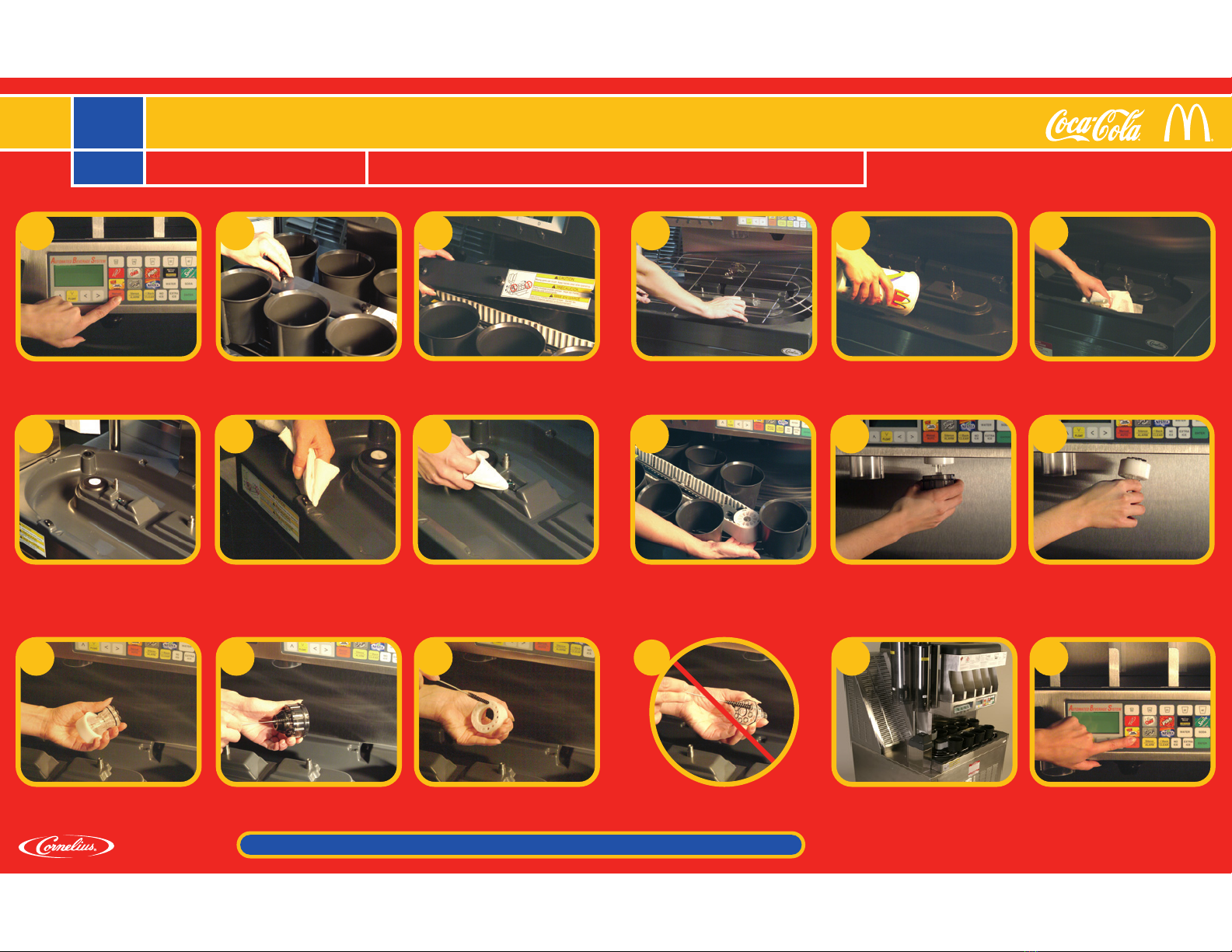

CONVEYOR NOISE Audible noise as conveyor turns. Remove conveyor and clean.

CUP HOLDERS Loose on conveyor belt. Three screws hold the cup holder firm to the conveyor belt. Tighten screws till firm

(DO NOT OVERTIGHTEN). Use kit 14461.

TURRET STALLED Turret unable to rotate clockwise or

counter-clockwise.

Clear obstruction (lid holder, cup tube or cups). Press ENTER

CONVEYOR STALLED Cup(s) jammed in the conveyor at the cup

extraction position and the conveyor and

turret are unable to operate. Does the

conveyor rotate?

Remove all cups from the conveyor cup holders at the EXTRACT POSITION before pressing the

ENTER button. Another cup will be extracted and dispensing will continue. Make sure conveyor

is installed correctly. Repair or Replace.

When an alarm occurs, press the SILENCE/ALARM button to silence the alarm. Read the display to determine the problem so that the

appropriate corrective action can be taken. LEFT and RIGHT arrows are used to scroll the alarm list and the number of unresolved warnings

and alarms are displayed with direction cues to scroll. Listed below are the Alarm and Warning messages that may appear on the display screen.

© 2008 IMI CORNELIUS

WWW.CORNELIUS.COM

620807805D Revision: B

To order job aid cards contact Coca-Cola Parts: 1-800-638-2653 Part #111099 -or- www.3Wire.com 3Wire Part #1039561