p/n 003-960, Issue 4

STANDARD RECOMMENDED PROCEDURE 003-960 | ISSUE 4 | OCTOBER 2017 | PAGE 1 OF 18

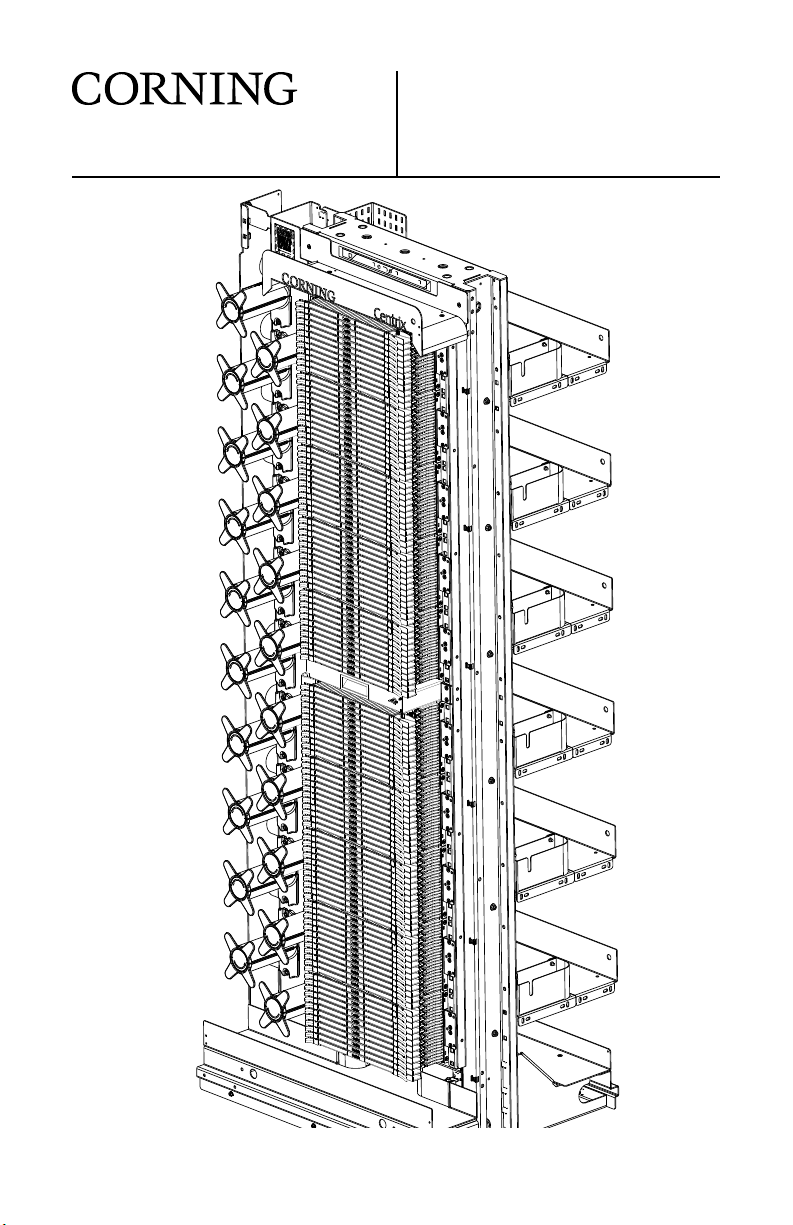

Jumper Routing in

Centrix™ System Frame

related literature |

003-948 Centrix System Housing Installation

003-949 Centrix System Pigtailed Housing with Pigtailed Cassette

Installation

003-950 Centrix System Frame Installation

003-951 Centrix System Stubbed Housing Installation

003-959 Centrix System Splitter/CWDM Cassette Installation

003-961 Centrix System Accessories Installation

Table of Contents

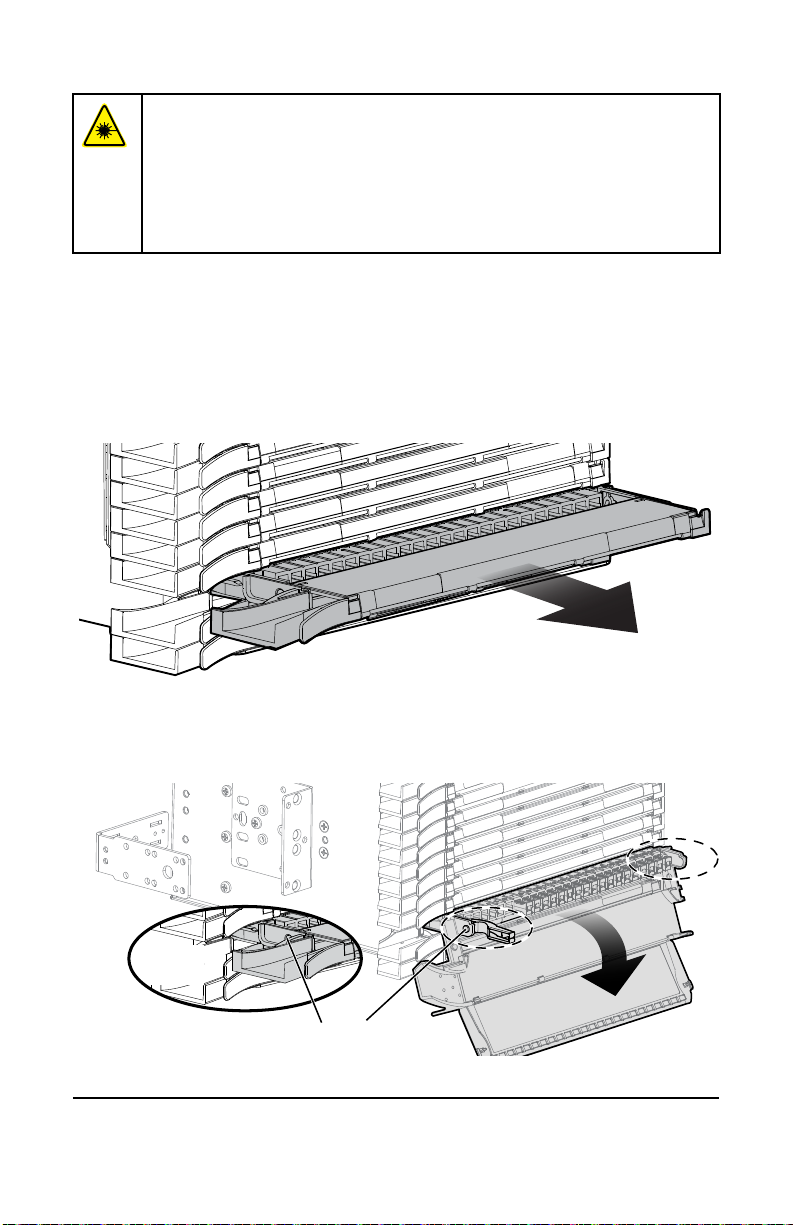

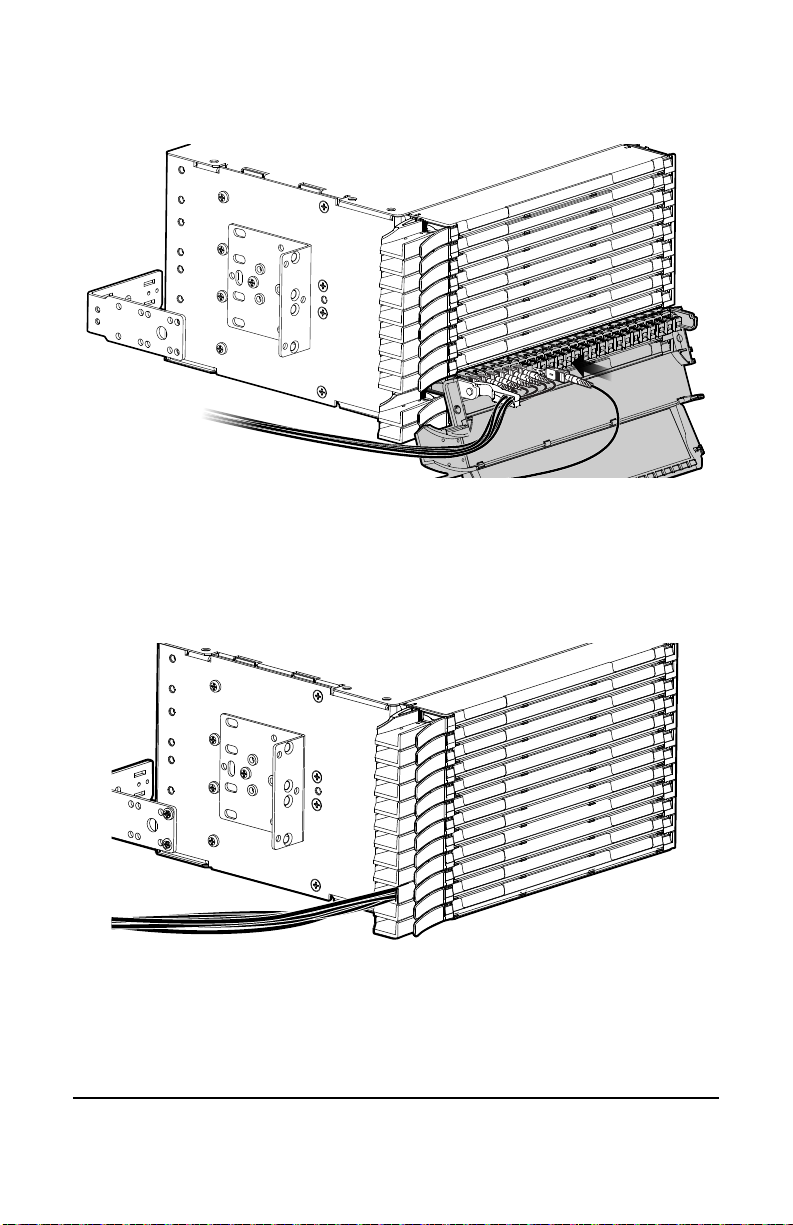

1. Connect Jumpers .......................................... 2

2. Jumper Routing and Slack Storage when Cross-connecting

in the Same Frame ......................................... 5

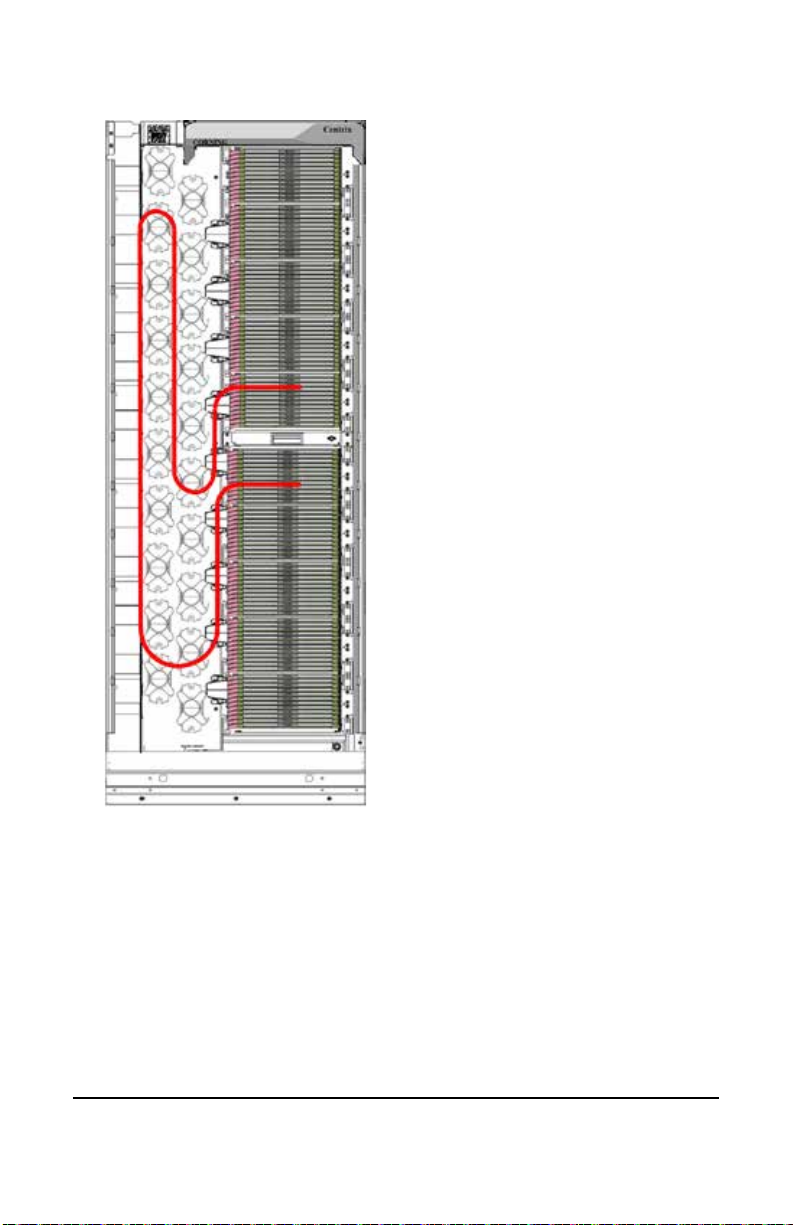

2.1. Connecting Housing 1 to Housing 6 ...................... 5

2.2. Connecting Housing 5 to Housing 6 ...................... 6

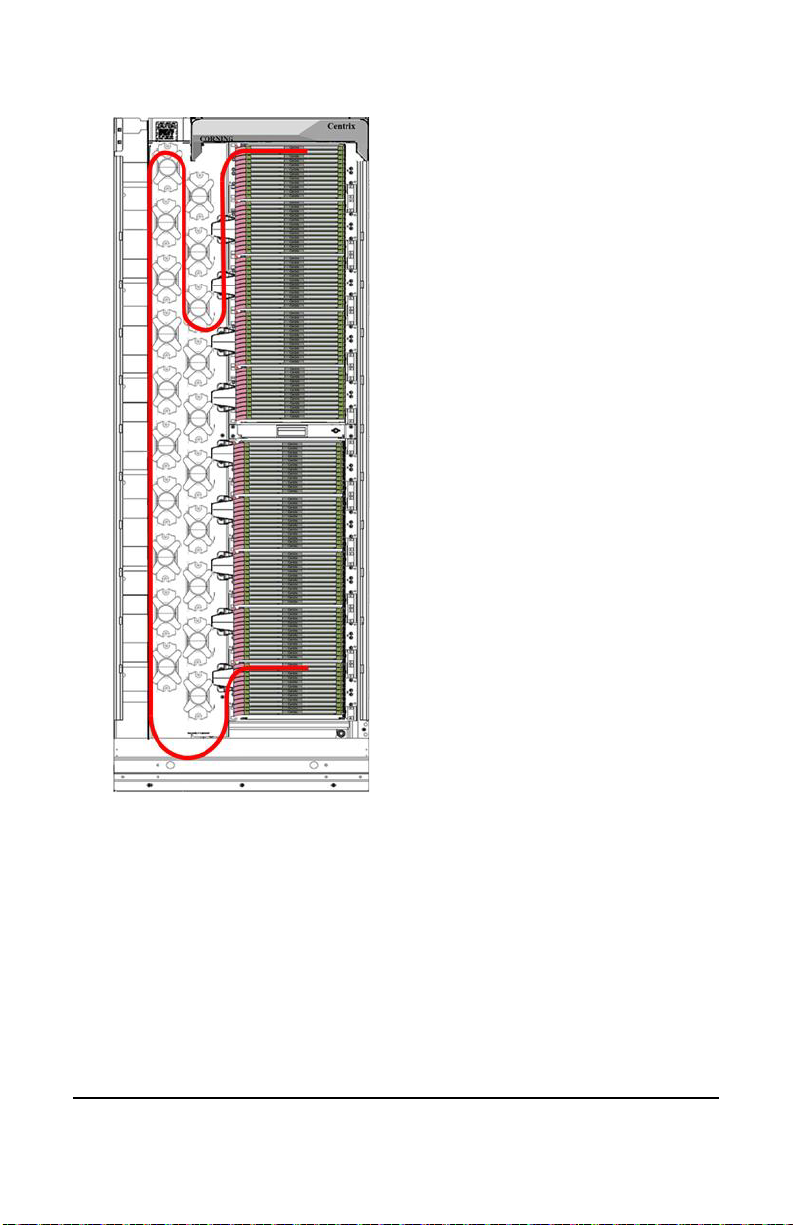

2.3. Connecting Housing 1 to Housing 10 ..................... 7

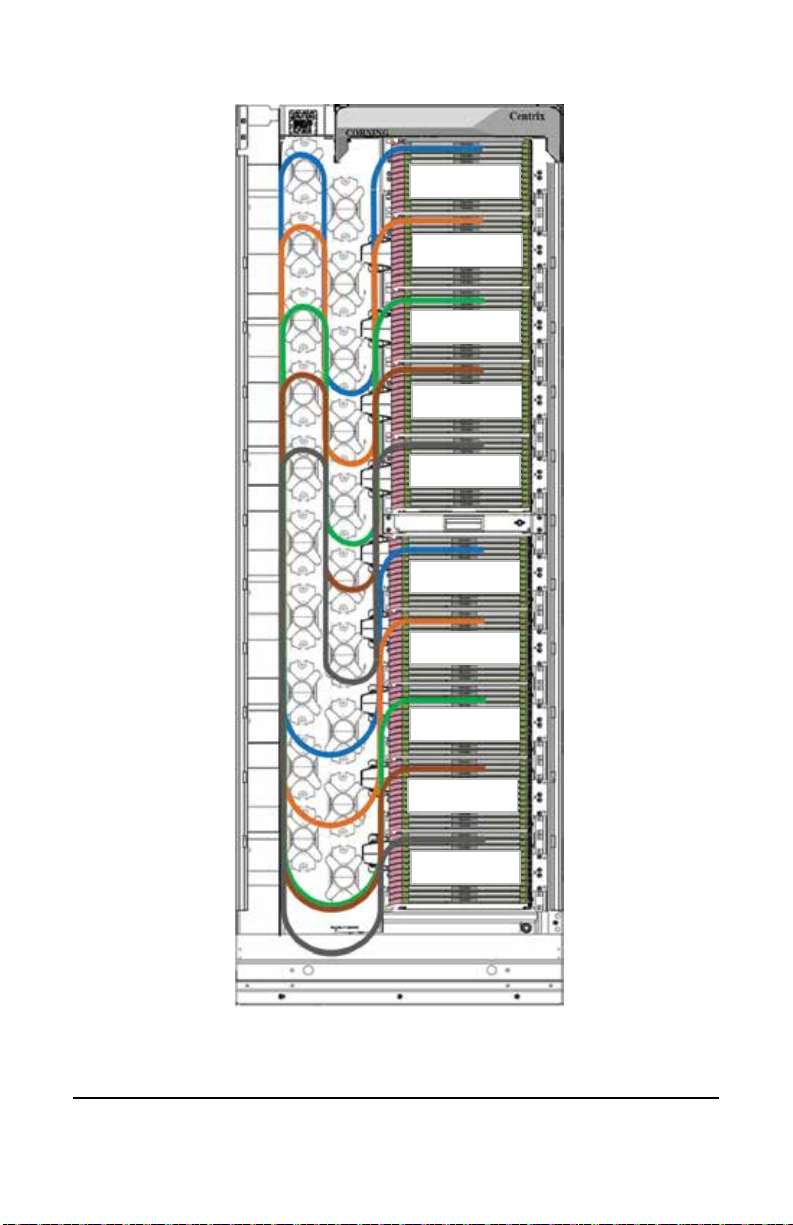

2.4. Full Frame Composite Cross-connect Routing .............. 8

3. Cross-connecting Jumpers in Adjacent Frames ................... 9

3.1. Cross-connecting Jumpers in Adjacent Rear

Cable Access Frames ................................. 9

3.2. Cross-connecting Jumpers in Adjacent Front

Cable Access Frames ................................ 10

4. Cross-connecting Jumpers Using Overhead Trough System........ 11

5. Jumper Routing and Slack Storage when Interconnecting

between Frames.......................................... 12

5.1. Initial Jumper Routing from Source Frame ................ 12

5.2. Subsequent Jumper Routing from Source Frame ........... 13

5.3. Interconnecting to Active Equipment ..................... 14

5.4. Interconnecting Jumper Routing to Active Shelves in a

Different Frame Lineup Using Overhead Trough System ..... 16

5.5. Interconnecting Jumpers between Distantly Spaced Ports .... 17

6. Connector Care and Cleaning ............................... 18