CAT850XLR 4 Rev. 2/3/15

Drain Daily

RegulatorOilerQuick CouplerLeader

Hose

Nipple

Do Not Install

Quick Coupling

Here

Nipple

Filter

Air Supply

Whip Hose

AIR SUPPLY

Tools operateonawiderangeofairpressures. It is required that

air pressure measures 90 psig at the tool with the trigger fully

depressedandnoloadappliedtothetool.Higherpressure(over90

psig;6.2bar)raisesperformancebeyondtheratedcapacityofthe

tool,whichwillshortentoollifeandcouldcauseinjury.

Alwaysuseclean,dryair.Dust,corrosivefumesand/orwaterinthe

airlinewillcausedamagetothetool.Drainthewaterfromairlines

andcompressorpriortorunningtool.Cleantheairinletfilterscreen

weekly.Therecommendedhookupprocedurecanbeviewedinthe

abovefigure.

Theairinletusedforconnectingairsupplyhasstandard1/4"NPT.

Linepressureshouldbeincreasedtocompensateforunusuallylong

airhoses(over25feet).Minimumhosediametershouldbe3/8"I.D.

andfittingsshouldhavethesameinsidedimensionsandbetightly

secured.

Ensureanaccessibleemergencyshutoffvalvehasbeeninstalledin

theairsupplylineandmakeothersawareofitslocation.

LUBRICATION

Lubricatetheairmotordaily with highqualityairtooloil.If no air

line oiler is used, run 1/2 oz. of oil through the tool.The oil can

be squirted into the tool air inlet or into the hose at the nearest

connectiontotheairsupply,thenrunthetool.Arustinhibitiveoilis

acceptableforairtools.

WARNING:After an airtoolhasbeenlubricated,oilwilldischarge

throughtheexhaustportduringthefirstfewsecondsofoperation.

Theexhaustportmustbecoveredwithatowelbeforeapplyingair

pressuretopreventseriousinjury.

OPERATION

Letthetooldothework.Donotputextremepressureonthetool.

This will only slow down the speed of the cutting wheel, reduce

cuttingefficiency,andputanadditionalburdenonthemotor.Start

thetooloffthework,setitdownontheworkevenlyandmovein

thedirectiondesiredtomakethecut.Whenfinishedcutting,liftoff

theworkbeforestoppingthemotor.

Alwaysusetherequiredwheelguardtopreventinjuryfrombroken

cut-offwheelparts.If a guard has withstood a wheel breakage,

discontinue its use and replace it with a new guard. It may be

damaged. Position the guard between the cut-off wheel and the

operator.Usebarrierstoprotectothersfromwheelfragmentsand

cuttingsparks.

to guard

against flying rust and chips (users and bystanders). Use only

Even small projectiles

caninjureeyesand cause blindness.Acut-offwheelthatbreaks

can cause very serious injury. Daily measure the tool speed with

atachometertomakesurethespeedisnotgreaterthantheRPM

markedonthecut-offwheel.

with a speed lower than the tool speed.

NOTE:Beforecutting,testcut-offwheelbybrieflyrunningthetool

atfullthrottle,underabarrier(suchasaheavyworktable)tostop

anypossiblebrokenwheelparts.

NOTE:Always shut off air supply, drain hose of air pressure and

disconnecttoolfromairsupplywhennotinuse,beforechanging

accessoriesorwhenmakingrepairs.

TROUBLESHOOTING

Otherfactorsoutsidethe tool may causelossofpowerorerratic

action.Reducedcompressoroutput,excessivedrainontheairline,

moistureorrestrictionsinairpipesortheuseofhoseconnections

ofimpropersizeorpoorconditionsmayreduceairsupply.Gritor

gum deposits in the tool may cut power and may be corrected

by cleaning the air strainer and flushing out the tool with gum

solventoiloranequalmixtureofSAE#10andkerosene.Ifoutside

conditionsareinorder,disconnecttoolfromhoseandtaketoolto

yournearestauthorizedservicecenter.

WARRANTY

CornwellQualityToolsCompany(“Cornwell”)warrantsthisproductagainstdefectsinmaterialandworkmanshipforaperiodofONE(1)YEARfromthedateoforiginalretailpurchase.

Subjecttotheconditionsandlimitationssetforthbelow,Cornwellwill,atitsoption,eitherrepairorreplaceanypartoftheproduct(s)thatprovesdefectivebyreasonofimproper

workmanshipormaterials.

This warranty does not cover any damage to this product that results from accident, abuse, misuse, natural or personal disaster, or any unauthorized disassembly, repair, or

modification.Repairs,disassemblyandmodificationareonlyauthorizedtobemadebyCornwelloraCornwellAuthorizedWarrantyCenter.

WARRANTY SERVICE

Inordertohaveyourtoolrepaired,returnthetooltoanyCornwellAuthorizedWarrantyCenter,freightprepaid.Pleaseincludeacopyofyourproofofpurchaseandabriefdescription

oftheproblem.Thetoolwillbeinspectedandifanypartorpartsarefoundtobedefectiveinmaterialorworkmanship,theywillberepairedfreeofcharge,andtherepairedtoolwill

bereturnedtoyoufreightprepaid.

EXCLUSIONS AND LIMITATIONS

THISWARRANTYANDTHE REMEDIESSETFORTHABOVEARE EXCLUSIVEANDIN LIEUOFALL OTHERWARRANTIES,REMEDIESANDCONDITIONS,WHETHERORAL ORWRITTEN,

EXPRESSORIMPLIED.CORNWELLSPECIFICALLYDISCLAIMSANYANDALLIMPLIEDWARRANTIES,INCLUDING,TOTHEEXTENTPERMITTEDBYAPPLICABLELAW,ANYWARRANTIES

OFMERCHANTABILITYANDFITNESSFORAPARTICULARPURPOSE.IFCORNWELLCANNOTLAWFULLYDISCLAIMIMPLIEDWARRANTIESUNDERTHISLIMITEDWARRANTY,ALLSUCH

IMPLIEDWARRANTIESARELIMITEDINDURATIONTOTHEDURATIONOFTHISWARRANTY.

INNOEVENTSHALLCORNWELLBELIABLETOTHEPURCHASERORTOTHEUSEROFACORNWELLPRODUCTFORANYSPECIAL,INCIDENTALORCONSEQUENTIALDAMAGESBASED

UPON BREACH OFWARRANTY, BREACH OF CONTRACT, NEGLIGENCE, TORT, ORANY OTHER LEGAL THEORY. SUCH DAMAGES INCLUDE,WITHOUT LIMITATION, EXPENSES, LOST

REVENUES,LOSTSAVINGS,LOSTPROFITS,ORANYOTHERINCIDENTALORCONSEQUENTIALDAMAGESARISINGFROMTHEPURCHASE,USEORINABILITYTOUSETHECORNWELL

PRODUCT.

Somestatesdonotallowtheexclusionorlimitationofincidentalorconsequentialdamagesorexclusionsorlimitationonthedurationofimpliedwarrantiesorconditions,sotheabove

limitationsorexclusionsmaynotapplytoyou.Thiswarrantygivesyouspecificlegalrights,andyoumayalsohaveotherrightsthatvarybystate.

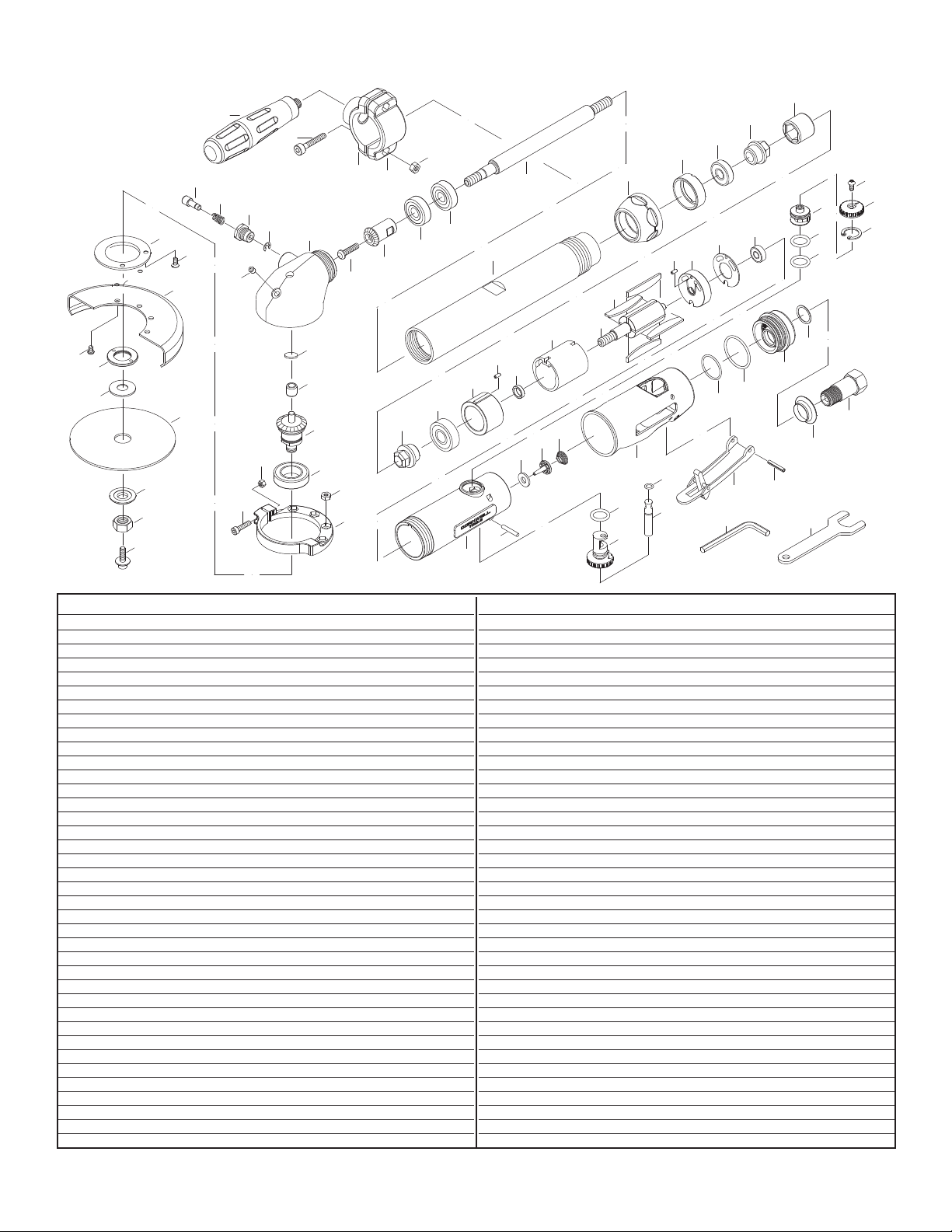

RepairkitsandreplacementpartsareavailableformanyCornwellproducts,regardlessofwhetherornottheproductisstillcoveredbyawarrantyplan.