特鲁利(苏州)材料科技有限公司

Trojan(Suzhou) Material technology Co., Ltd.

Add: Building 26, No. 228, Gongtang Road, Wuzhong District, Suzhou, China

目录

Foreword ................................................................................................................................................1

Brief Introduction ...................................................................................................................................3

1. Description ..................................................................................................................................3

2. Features ...................................................................................................................................... 3

3. Cautions ...................................................................................................................................... 3

4. Restrictions ................................................................................................................................. 3

5. Technical Specifications .............................................................................................................. 4

Installation ............................................................................................................................................. 5

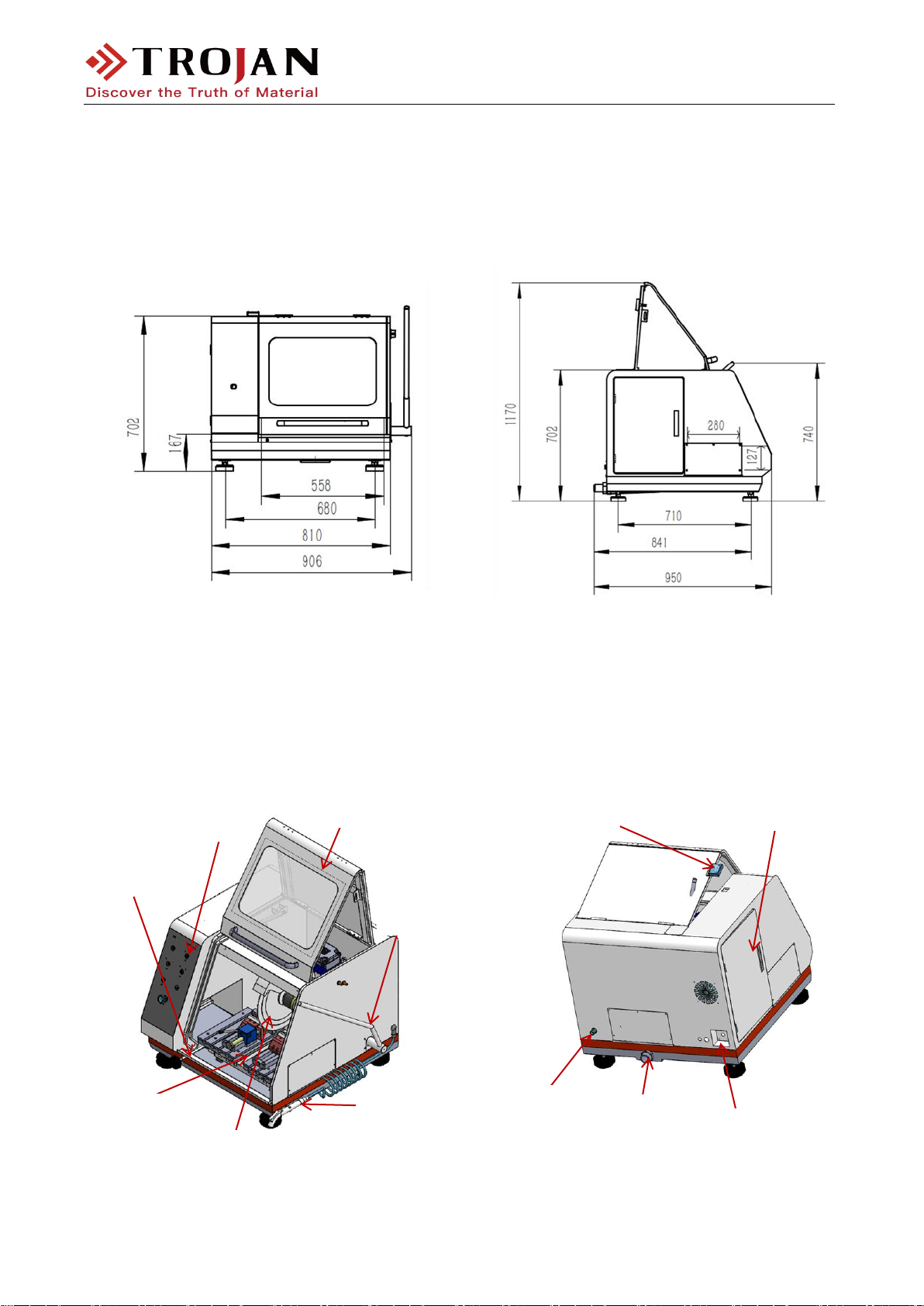

1. Dimension ................................................................................................................................... 5

2. Electrical requirements ...............................................................................................................5

Composition ...........................................................................................................................................5

Equipment Operation ............................................................................................................................ 6

1.Introduction to the functions of the control panel .................................................................6

2.Replacement of cutting blade .................................................................................................6

3.Structure diagram of cutting flange ........................................................................................7

4.Structure diagram of main drive .............................................................................................7

5.Mechanical drawing of X-table ............................................................................................... 8

Wiring diagram .......................................................................................................................................8

Maintenance and Care ...........................................................................................................................9

1. List of consumable parts ............................................................................................................. 9

2. Common faults and solutions ..................................................................................................... 9

3. Maintenance requirements ...................................................................................................... 10

Packing list ........................................................................................................................................... 11

1. Standard accessories: ............................................................................................................... 11

2. Optional accessories: ................................................................................................................ 12

3. Optional before leaving the factory: .........................................................................................12

Product certificate ............................................................................................................................... 13

Product Warranty Card ........................................................................................................................ 14

The Warranty Rules ..............................................................................................................................15