- 1 - EVOSHAKE 500 v2

TABLE OF CONTENTS

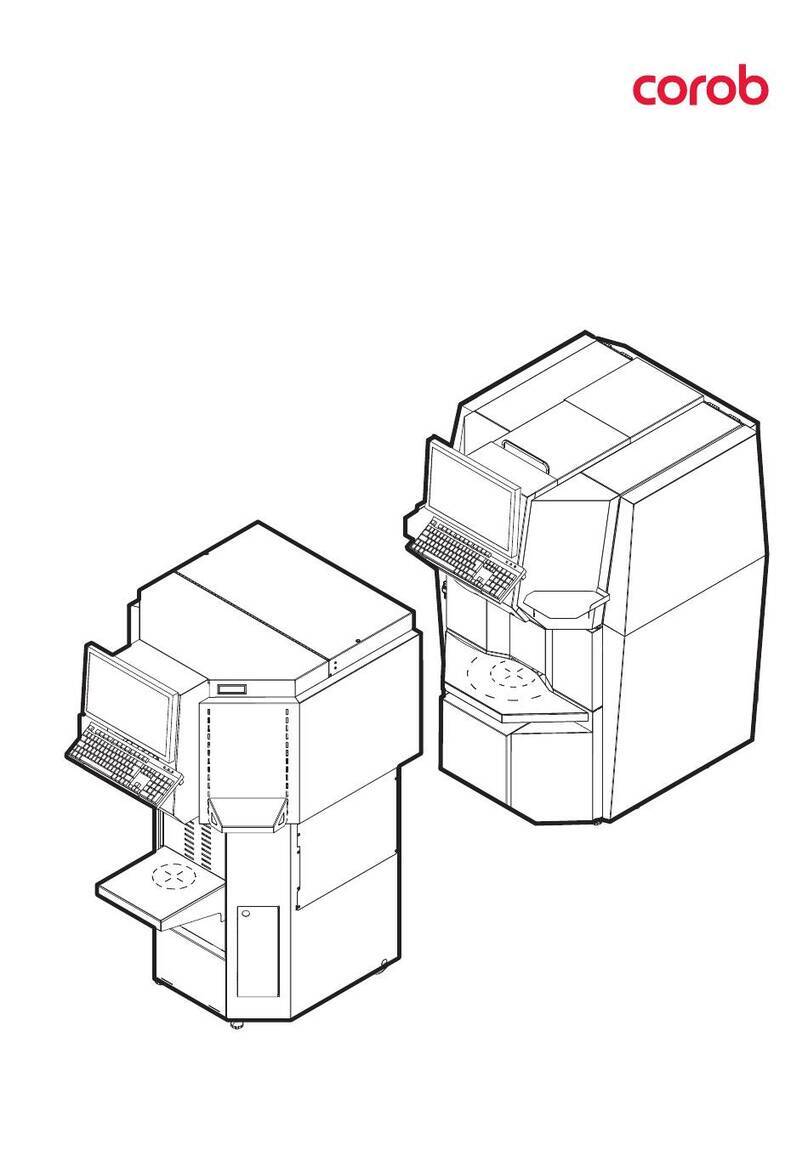

1 GENERAL INFORMATION ..............................................................................................................................................2

1.1 Purpose and use of this manual..........................................................................................................................................................2

1.2 Definitions ..................................................................................................................................................................................................2

2 FEATURES.......................................................................................................................................................................3

2.1 Description of the machine ..................................................................................................................................................................3

2.2 EVOshake 500 v2’s parts ........................................................................................................................................................................3

2.3 Usable cans ............................................................................................................................................................................................4

2.4 Identifying information..........................................................................................................................................................................4

3 SAFETY INSTRUCTIONS ..............................................................................................................................................5

3.1 Connecting and disconnecting the machine to the mains .....................................................................................................5

3.2 Emergency stop .......................................................................................................................................................................................5

3.3 Danger caused by the shaking mechanism ...................................................................................................................................6

3.4 Danger caused by chemicals ...............................................................................................................................................................6

3.5 Explosion safety ........................................................................................................................................................................................7

3.6 Residual risks..............................................................................................................................................................................................7

3.7 Position of labels ......................................................................................................................................................................................8

4 TRANSPORTATION, STORAGE AND DISPOSAL ...........................................................................................................9

4.1 Contents of the basic package ............................................................................................................................................................9

4.2 Handling......................................................................................................................................................................................................9

4.3 Product disposal and recycling ...........................................................................................................................................................9

5 MACHINE INSTALLATION............................................................................................................................................10

5.1 General warnings ................................................................................................................................................................................. 10

5.2 Installation site requirements ........................................................................................................................................................... 10

5.3 Unpacking and placement ........................................................................................................................................................... 10

5.4 Electrical connection and start up ................................................................................................................................................ 13

6 INSTRUCTIONS FOR USE .............................................................................................................................................14

6.1 General warnings ................................................................................................................................................................................ 14

6.2 Control devices and connections.................................................................................................................................................... 14

6.3 The display............................................................................................................................................................................................... 15

6.4 Opening the door.................................................................................................................................................................................. 15

6.5 Loading of cans ..................................................................................................................................................................................... 16

6.6 Handle holder......................................................................................................................................................................................... 16

6.7 Shaking ..................................................................................................................................................................................................... 16

6.8 Changing the language and the preferred height.................................................................................................................... 17

6.9 Special functions ................................................................................................................................................................................... 17

6.10 Troubleshooting ................................................................................................................................................................................ 17

7 ORDINARY MAINTENANCE .........................................................................................................................................18

7.1 General warnings ................................................................................................................................................................................. 18

7.2 External cleaning ................................................................................................................................................................................... 18

7.3 Cleaning the threaded axels ........................................................................................................................................................... 18

8 TECHNICAL SPECIFICATIONS......................................................................................................................................19

8.1 Technical information ......................................................................................................................................................................... 19

8.2 Dimensions ............................................................................................................................................................................................. 19

8.3 Declaration of conformity.................................................................................................................................................................. 20

8.4 Warranty ................................................................................................................................................................................................... 20

APPENDIX: EC DECLARATION ........................................................................................................................................22