3 4

Main Technical Parameters

Initial test force: 10kg

Test force: 30, 100, 150kg

Maximum magnetic force: 350kg

Force applying method: by screw

Indenter: 120°diamond cone, Ø1.588mm carbide balls

Testing Items: HRC, HRB, HRA

Resolution: 0.1HR

Accuracy: Meets the requirements of ISO6508/6506

Application: All metals, including steel, forged steel, cast iron, copper,

copper alloy, aluminum, aluminum alloy and carbides etc.

Flat workpiece requirement: length>190mm, width>60mm, thickness>5mm

Cyl i n d er or t ub e wo r k p ie c e re q u ir e m e nt: le n g t h>2 0 0 m m,

diameter>Ø50mm, wall thickness>8mm

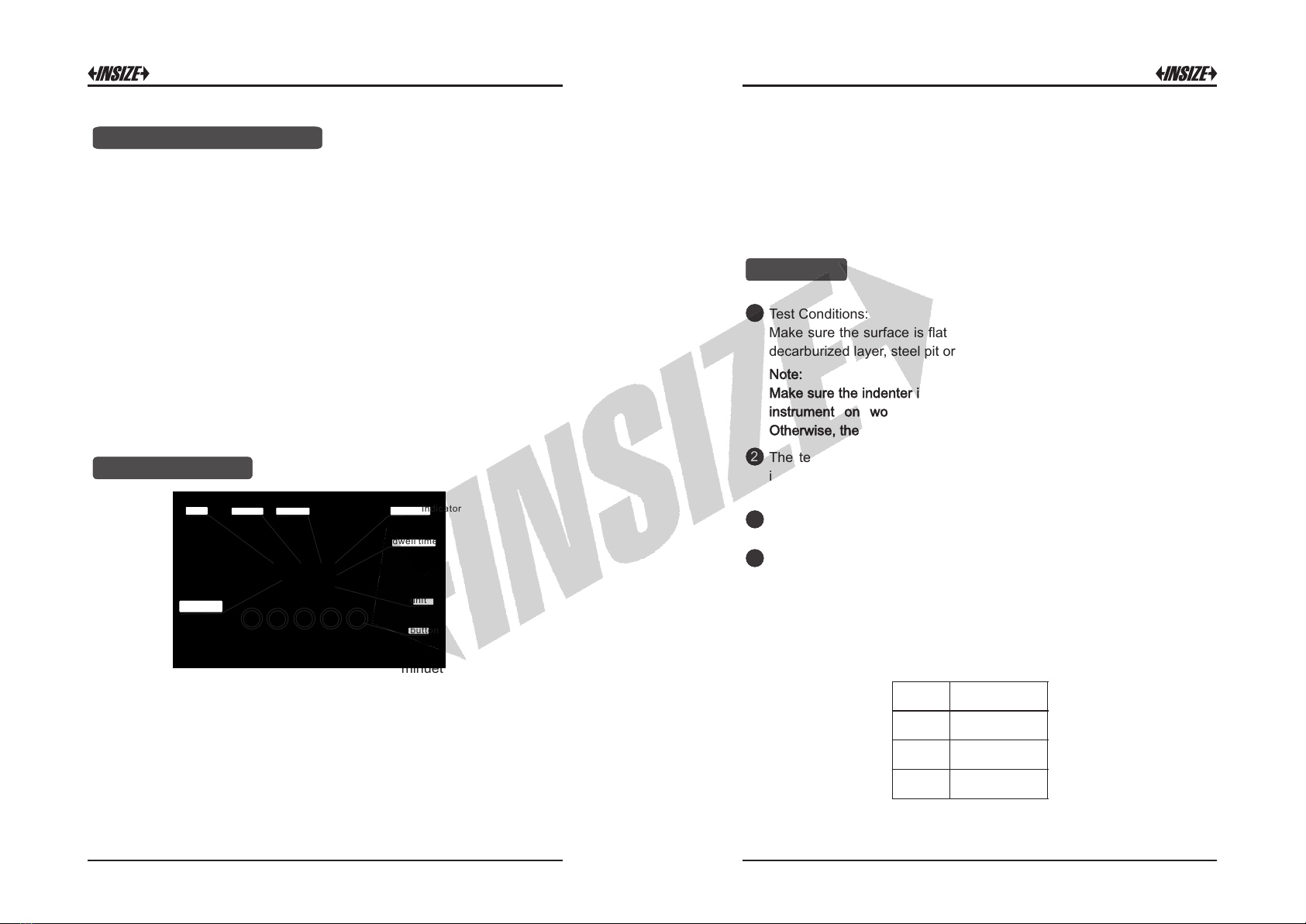

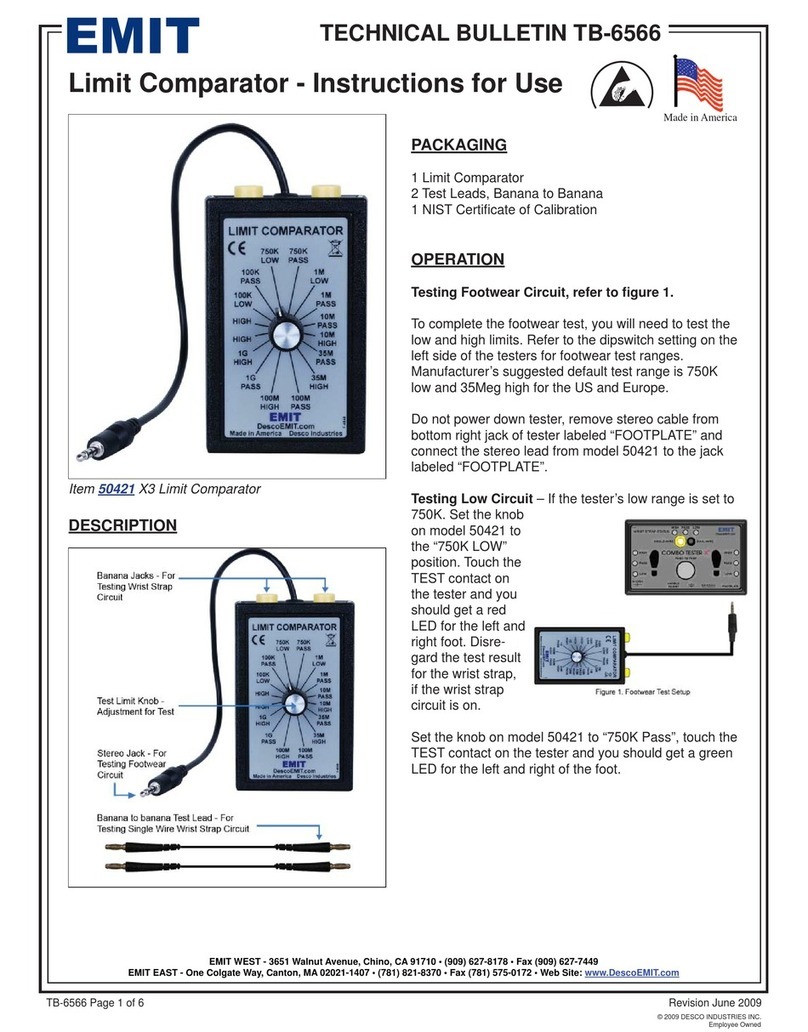

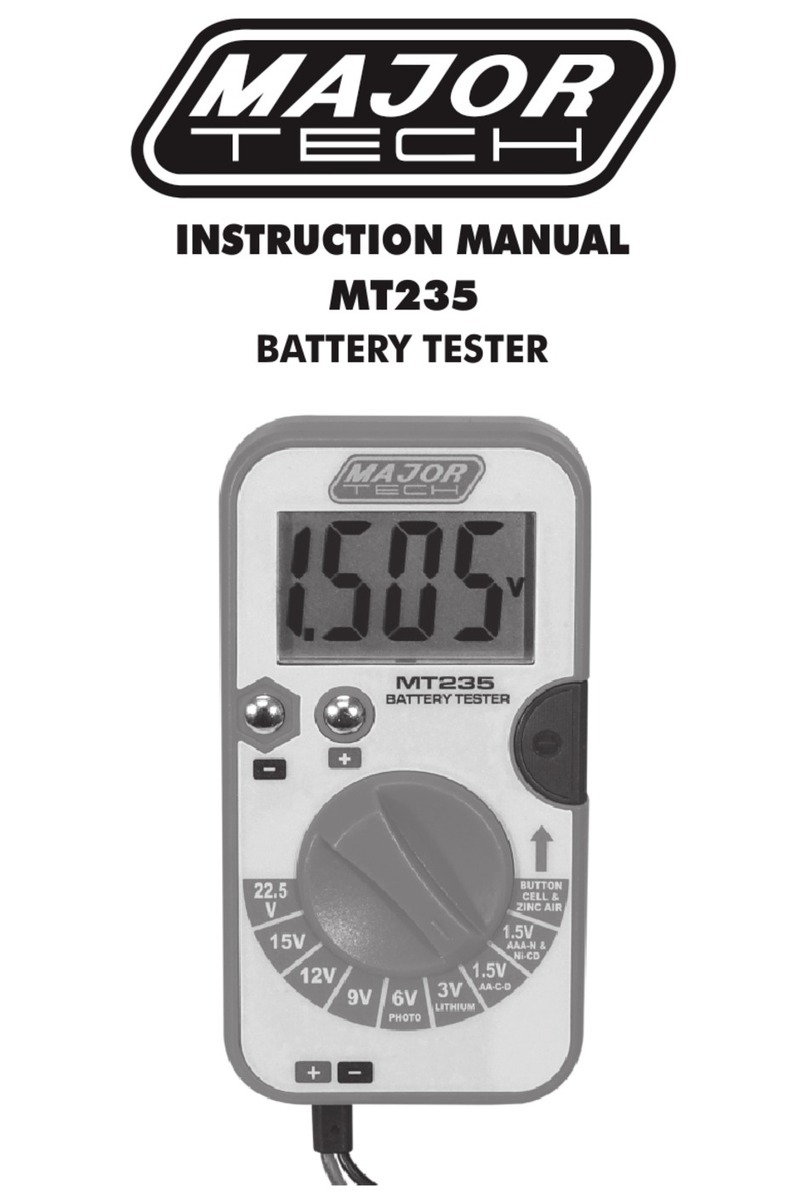

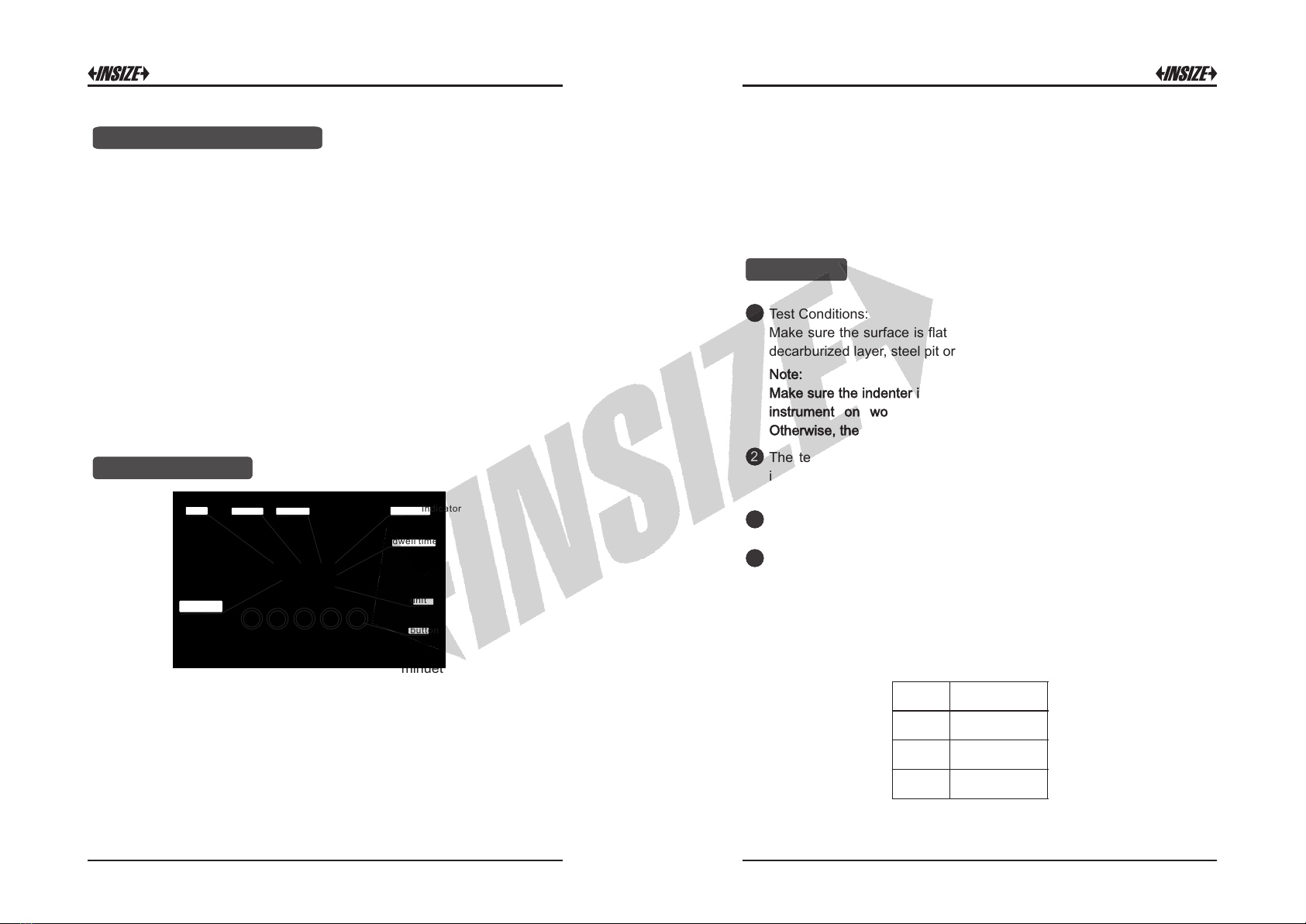

Panel And Screen

Operation

Test Conditions:

Make sure the surface is flat and smooth. It is forbidden to have scale,

decarburized layer, steel pit or dust on the surface of the part.

1

“ ”: Turn on and off the power. After 3 minuets the instruments

without using, the power will be off automatically.

ON

“ ”: After pressing it, the instrument is on status setting and the

menu displaying, then press "Manu" again, it would be on next level

menu.

MENU

“ ”: It’s a multi-functional button. On status of test, press it realizing

the function of counting; on menu setting, it could move the arrow

upward; on the status of calibration, it could increase values.

STAT

“ ”: It’s a multi-functional button. On status of test, press it to see

the conversion value; on menu setting, it could move the arrow down

ward; on the status of calibration, it could decrease values.

CONV

“ ”: It’s a double functional button. On status of test, it could delete

current values; on status menu setting, it could confirm the selection

and back to previous menu.

DEL

Note:

Make sure the indenter is higher than the bottom surface before put the

instrument on workpiece, the indenter can’t touch the test part.

Otherwise, the indenter maybe crash to damaged.

The tester should be attached to test part flatly and steadily with the

indenter erected to the surface of test part. Turn the magnetic switch to

"On", keeping the tester fixed onto the test part.

2

Power on the instrument, set the dwell time and select the test scale

HRA, HRB or HRC. The scale will display on the screen.

3

Rotate the hand wheel to load test force steadily, observe the screen,

stop or add test force extremely slowly when test force is close to the

specified force. Try to keep the test force, now the time counting down

displays on screen. When the time counting down finished, spin hand

wheel reversely to release test force steadily until hardness values

display. Then one full operation is accomplished.

4

Test force

60kg

100kg

150kg

Scale

HRA

HRB

HRC

scale indication calibration battery indicator

test force

dwell time

unit

button