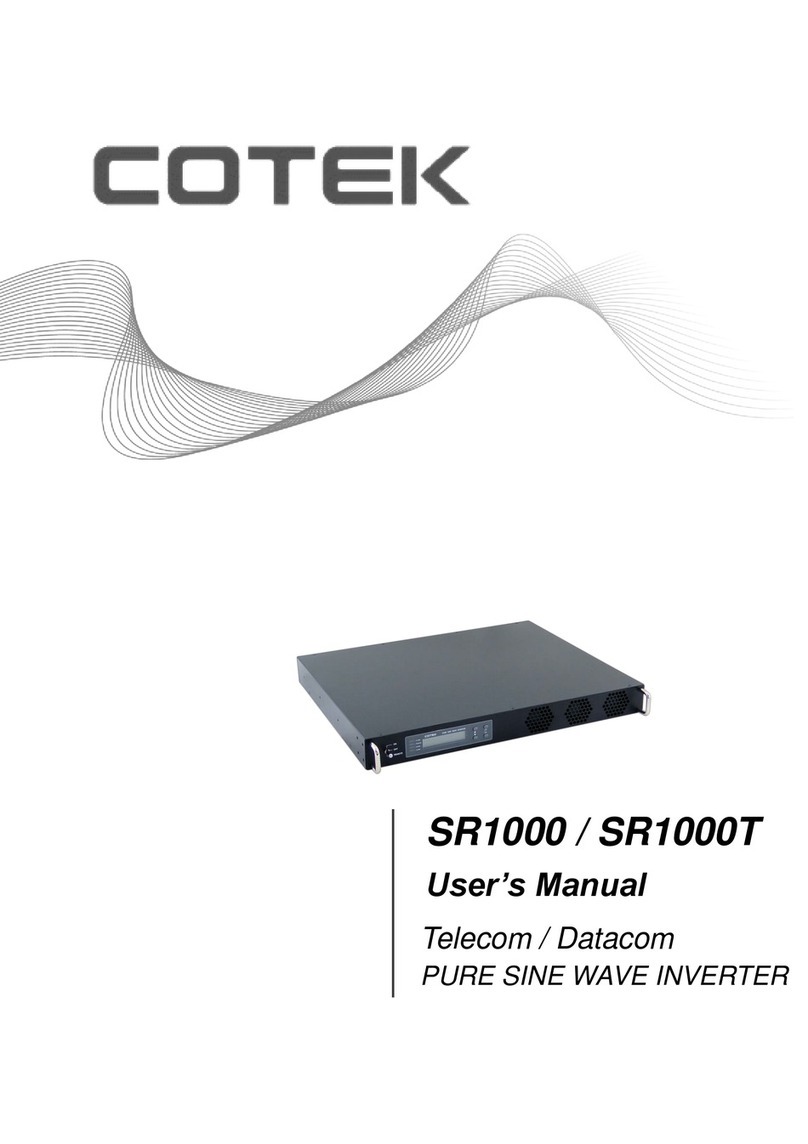

Cotek S Series User manual

Other Cotek Inverter manuals

Cotek

Cotek SK700-112 User manual

Cotek

Cotek SK700-112 User manual

Cotek

Cotek SP Series Reference manual

Cotek

Cotek S1500-112 User manual

Cotek

Cotek S600R Series User manual

Cotek

Cotek SP Series User manual

Cotek

Cotek ST Series User manual

Cotek

Cotek SD2500-112 User manual

Cotek

Cotek S150 Series User manual

Cotek

Cotek S600 Series User manual

Cotek

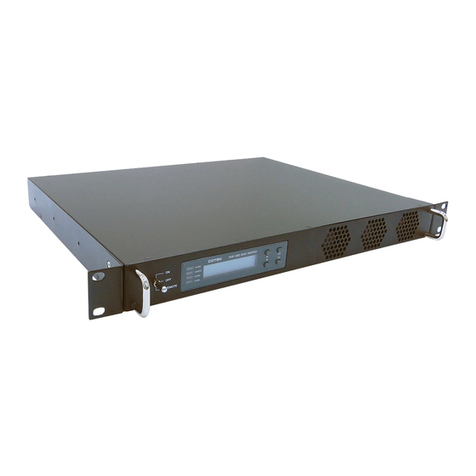

Cotek SR1000 User manual

Cotek

Cotek S1500-112 User manual

Cotek

Cotek SD Series User manual

Cotek

Cotek S150 Series User manual

Cotek

Cotek SE350 series User manual

Cotek

Cotek SK Series User manual

Cotek

Cotek SR-1600 Plus-124 User manual

Cotek

Cotek SK120 Series User manual

Cotek

Cotek S600 Series User manual

Cotek

Cotek SE200-124 User manual

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual