6

PREPARING A PROPER FOUNDATION

Just like the spa, the Covana requires a solid foundation. The area that the Covana sits on

must be able to support at least 600 lb (272 kg) and must be leveled. All components of the

Covana must be supported by the foundation.

Note: Damage caused by inadequate or improper foundation support is not covered by

the Covana warranty. It is the responsibility of the owner to provide proper foundation.

Foundation recommendation:

1.

Engineered wood deck OR concrete pad - 4" (10 cm) thick.

2.

Each of the 4 posts on the Covana must be properly anchored to the foundation using at

least one of the pre-drilled holes located at the foot of each post. Use a 1/4” (0.6 cm)

concrete anchor for concrete pads or a 1/4” (0.6 cm) lag bolt for wood foundations of a

minimum of 1-1/4” (3 cm) long.

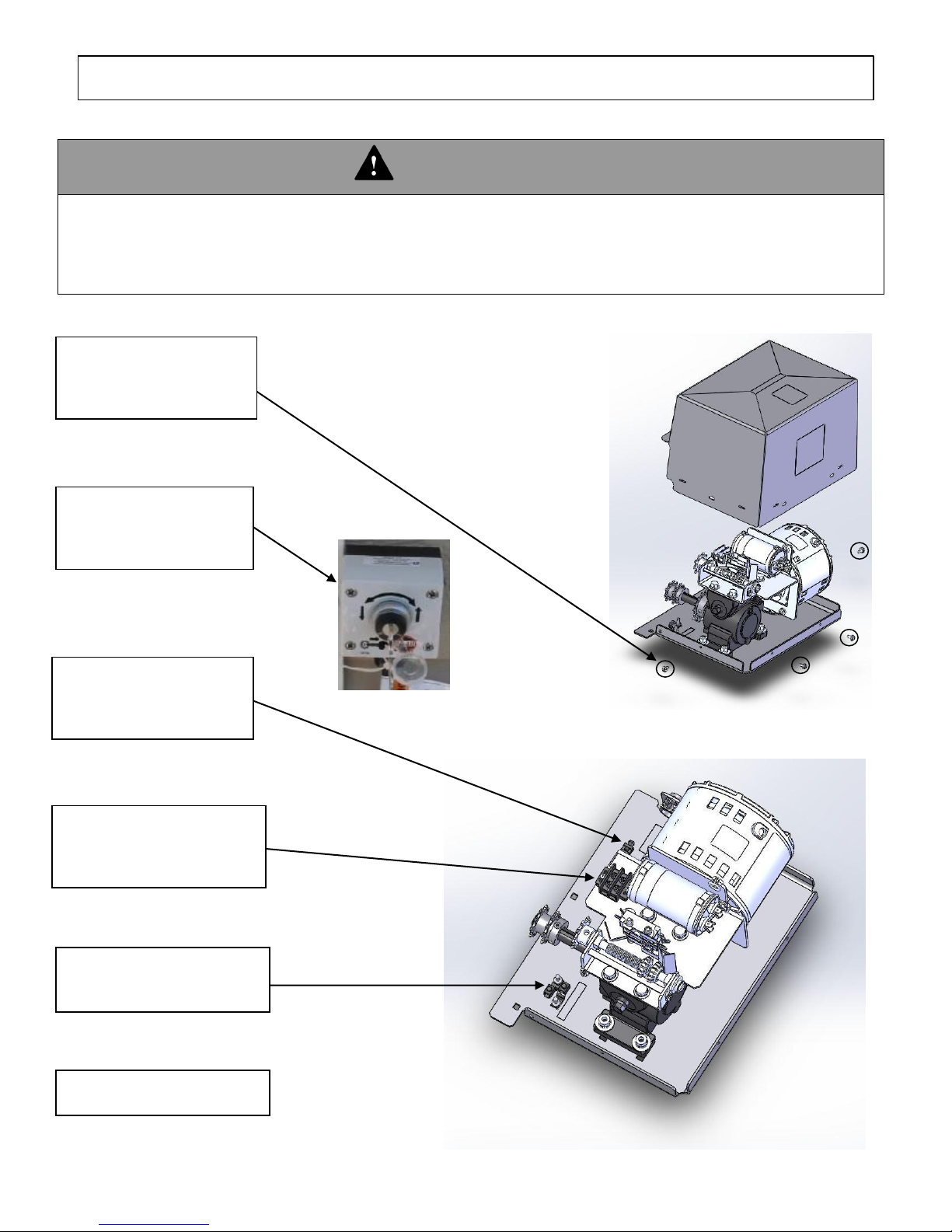

COVANA ELECTRICAL REQUIREMENTS

1.

The Covana requires a dedicated 115V (North America) or 230V (Europe) permanently

connected (hard wired) power supply.

2.

The Covana motor has a dedicated connection for 115V (North America) or 230V

(Europe), please see enclosed connection diagram.

3.

The Covana must be installed in accordance to and comply with all applicable local codes

and regulations. All wiring should be installed by a qualified electrician.

4.

Wire and conduit should be sized as per local codes and regulations.

The electrical circuit for the Covana must include a suitable ground fault interrupter (GFCI) as

required to comply with codes and regulations.

115V (North America) 230V (Europe) (1 hot, 1 neutral, 1 ground)

15A (North America) 10A (Europe) single-pole GFCI breaker, not included

12 (North America) 6 (Europe) Amps

KEY OPERATING INSTRUCTIONS

Turn the key to the right —clockwise to raise the roof.

Turn the key to the left —counterclockwise to lower the roof.

The key will automatically return to center, off position, when released.