7) Installation and repair should be done by a qualified service person. The heater should be inspected before use

and at least annually by a professional service person. More frequent cleaning may be required due to excessive

lint from carpeting, bedding, material, etc. It is imperative that control compartments, burners, and circulating air

passageways of the heater be kept clean.

8) “WARNING: Any changes to this heater or its controls can be dangerous”.

9) Do not use this heater if any part has been under water. Immediately call a qualified service person to inspect the

heater and to replace any part of the control system and any gas control which has been under water.

10) Due to high surface and radiated temperatures, keep children, clothing, and furniture away.

11) Do not install this heater in a recreational vehicle.

12) Never use a match, candle, flame or other source of ignition to check for gas leaks. Use only soapy water or

liquid detergent.

13) Before cleaning or servicing, turn off the gas and allow heater to cool.

14) Do not put objects around the heater that will obstruct the flow of combustion and ventilation air.

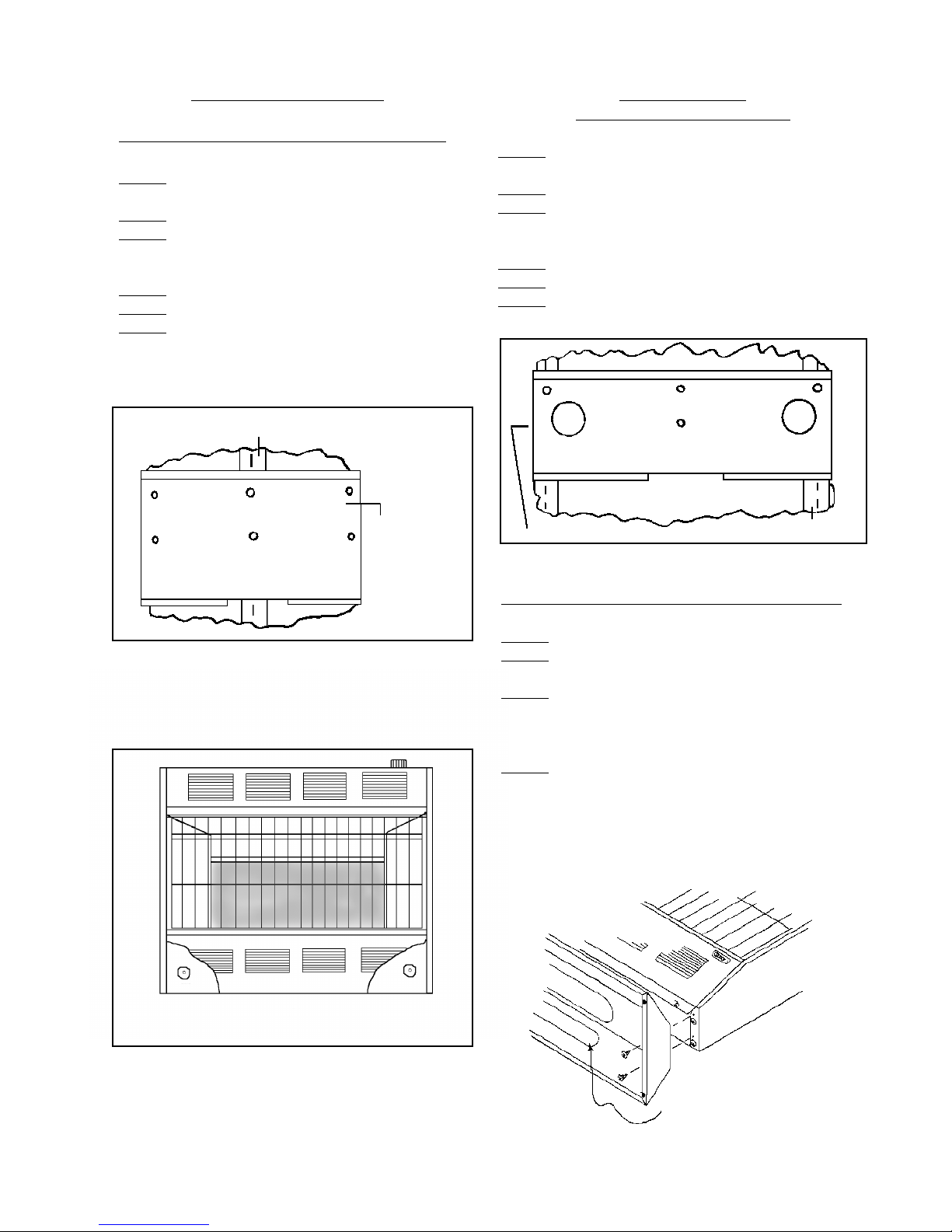

15) When installing the heater allow adequate accessibility clearances for servicing and proper operation.

16) Keep appliance area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

17) Donotinstallin a residential or commercialgarage.

18) WARNING: Do not use a blower or other accessory not approved for use with this heater.

19) “WARNING: Failure to keep the primary air opening(s) of the burner(s) clean may result in sooting and property

damage.”

20) “WARNING: Do not allow fans to blow directly into the appliance. Avoid any drafts that alter burner flame

patterns.”

21) This appliance is intended for supplemental heating.

SAFETYINSTRUCTIONS-CONTINUED

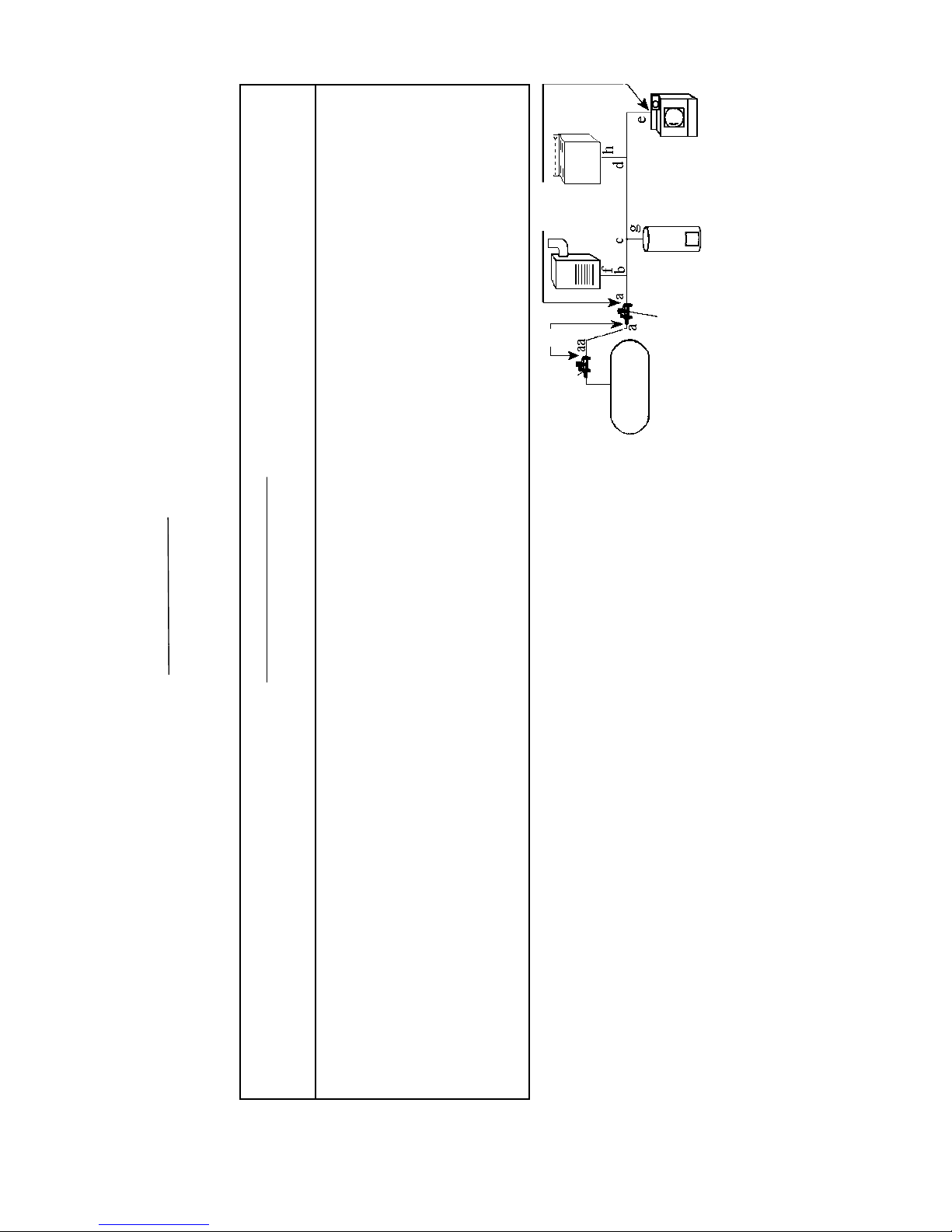

FRESHAIRFOR COMBUSTION,VENTILATION AND HEATDISTRIBUTION

With todays energy efficient homes, it is possible to make your home so air tight that it can result in stale air, dry rot, mold

development and host of other related problems. Gas burning appliances need fresh air for combustion as well as for

good distribution of heated air throughout the home. The following guide provides good general rules for classifying and

properly ventilating most homes.

“The National Fuel Gas Code ANSI Z223.1/NFPA54 defines a confined space as a space whose volume is less than 50

cubic feet per 1,000 Btu per hour (4.8m³ per Kw) of the aggregate input rating of all appliances installed in that space and

an unconfined space as a space whose volume is equal to or greater than 50 cubic feet per 1,000 Btu per hour (4.8m³ per

Kw) of the aggregate input rating of all appliances installed in that space. Rooms communicating directly with the space

in which the appliance is installed, through openings not furnished with doors, are considered a part of the unconfined

space.”

“This heater shall not be installed in a confined space or unusually tight construction unless provisions for adequate

combustion and ventilation air are made. Use the following example to determine if the heater is being installed in a

confined or unconfined space.”

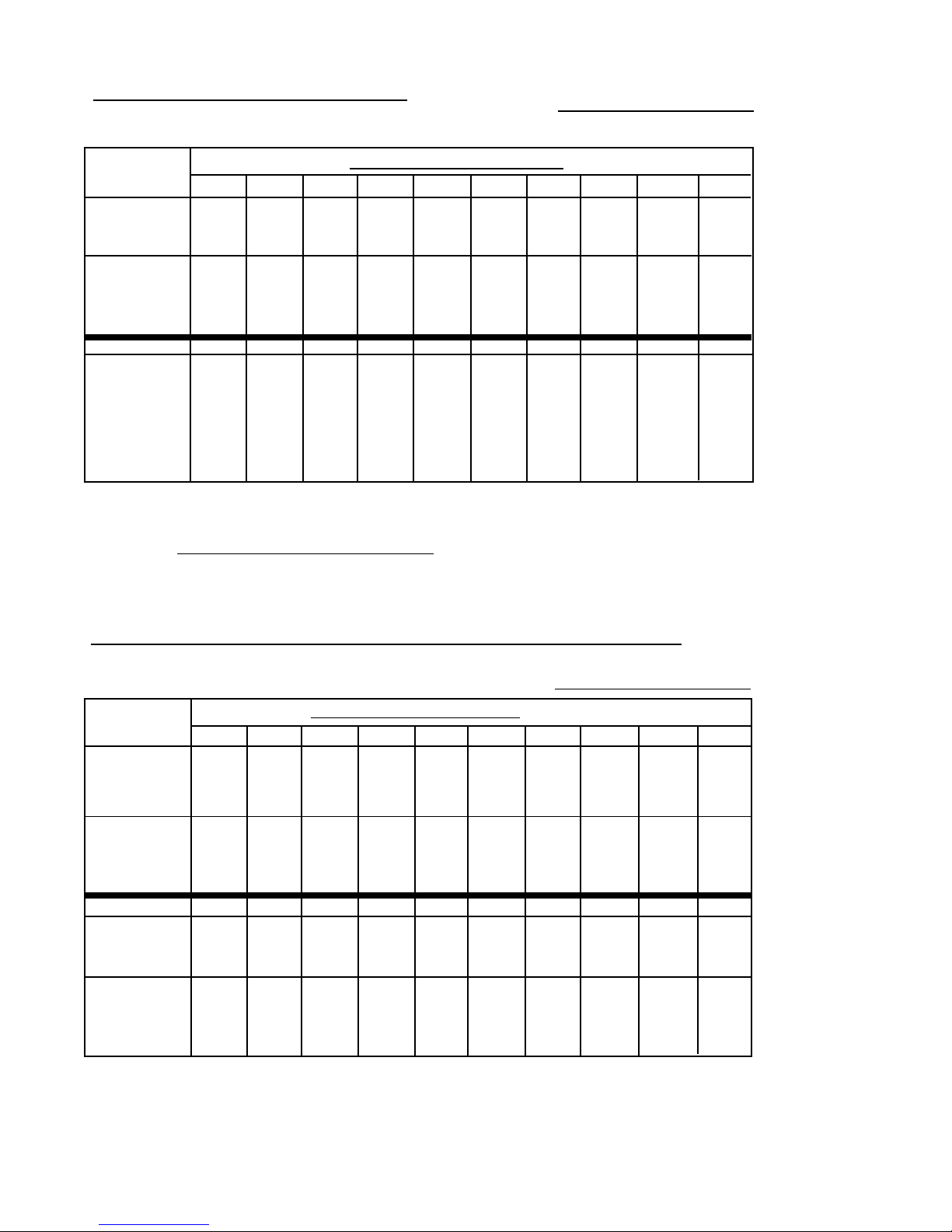

STEP1. First find the cubic feet of area to be heated length x width x height. NOTE: Include any adjoining rooms that

cannot be separated by closing a door or that have a air exchange grille that cannot be closed between rooms.

EXAMPLE: Areasize25ft.x 15 ft. x 7-1/2 ft. =2,812.5cubicfeet.

STEP2. Divide area cubic feet by 50. EXAMPLE: 2,812.5 50 = 56.25. Multiply this number by 1,000 for total Btu input

roomcansupport.E XAMPLE: 56.25 x 1,000 = 56,250Btu.

STEP3. List all gas burning appliances in this area and total the combined Btu input. EXAMPLE:

Cozyvent freeheater…………………….. 20,000Btu

Gaswaterheater………………………….. 58,000 Btu

Gas range (all burners & oven on)……….. 28,000Btu

106,000Btu

Page 4