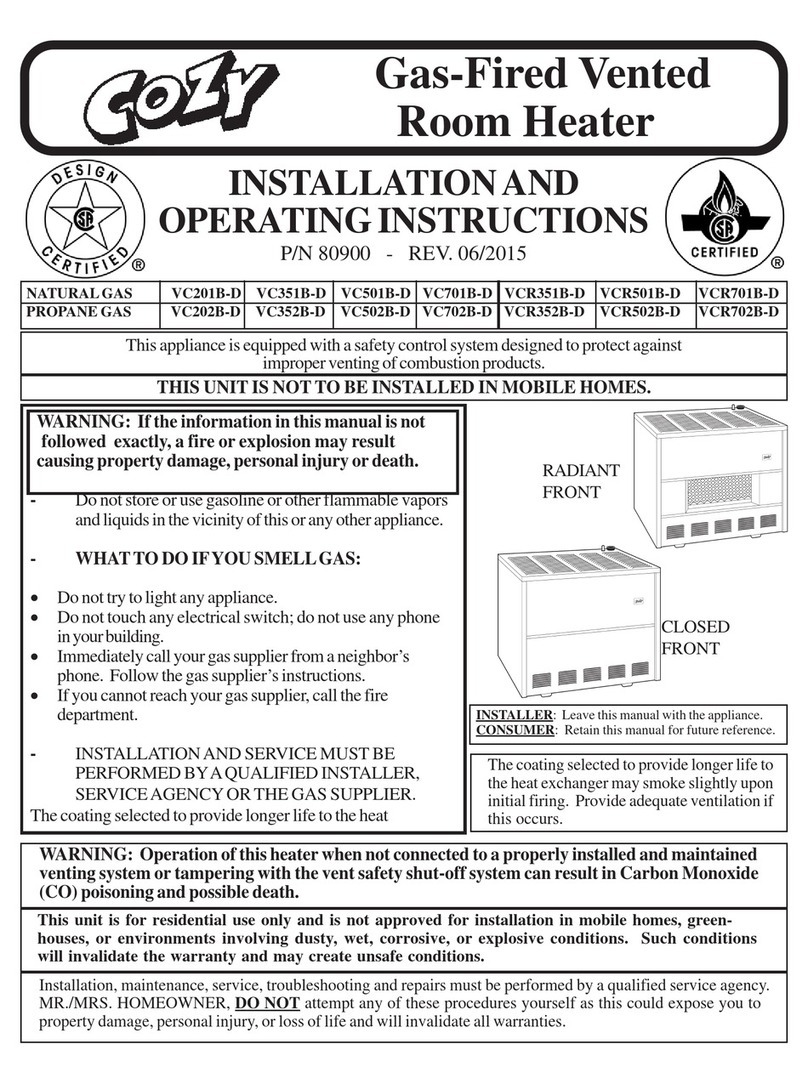

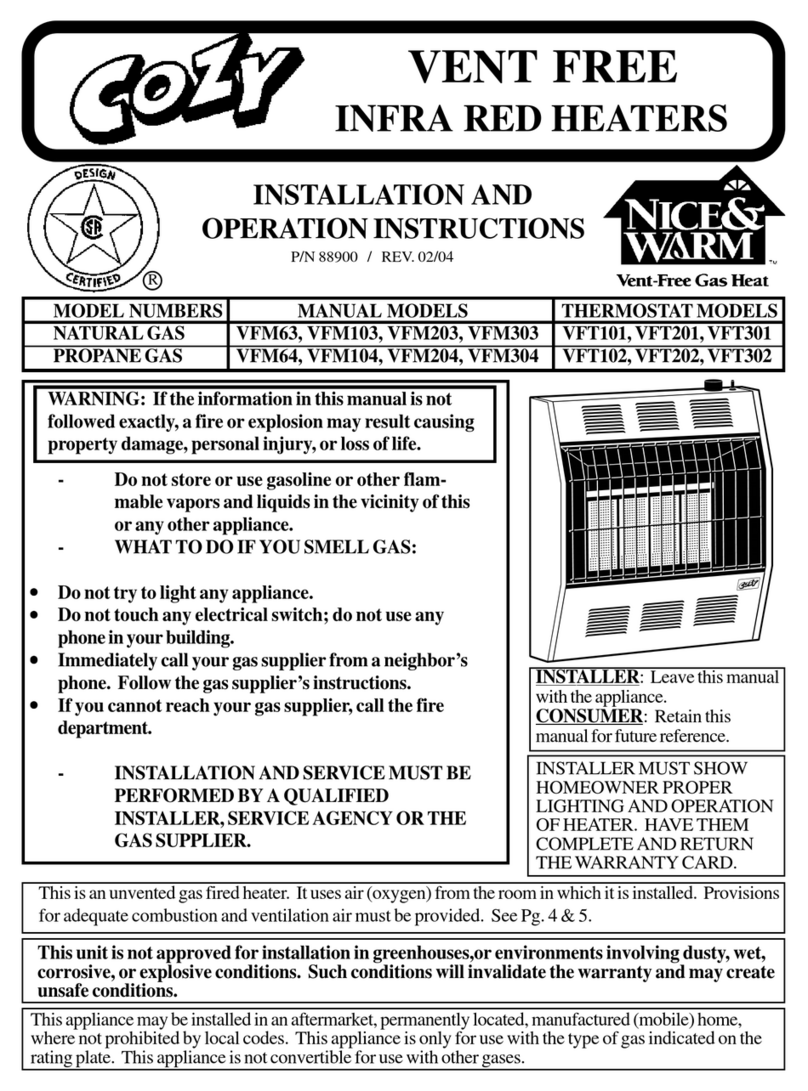

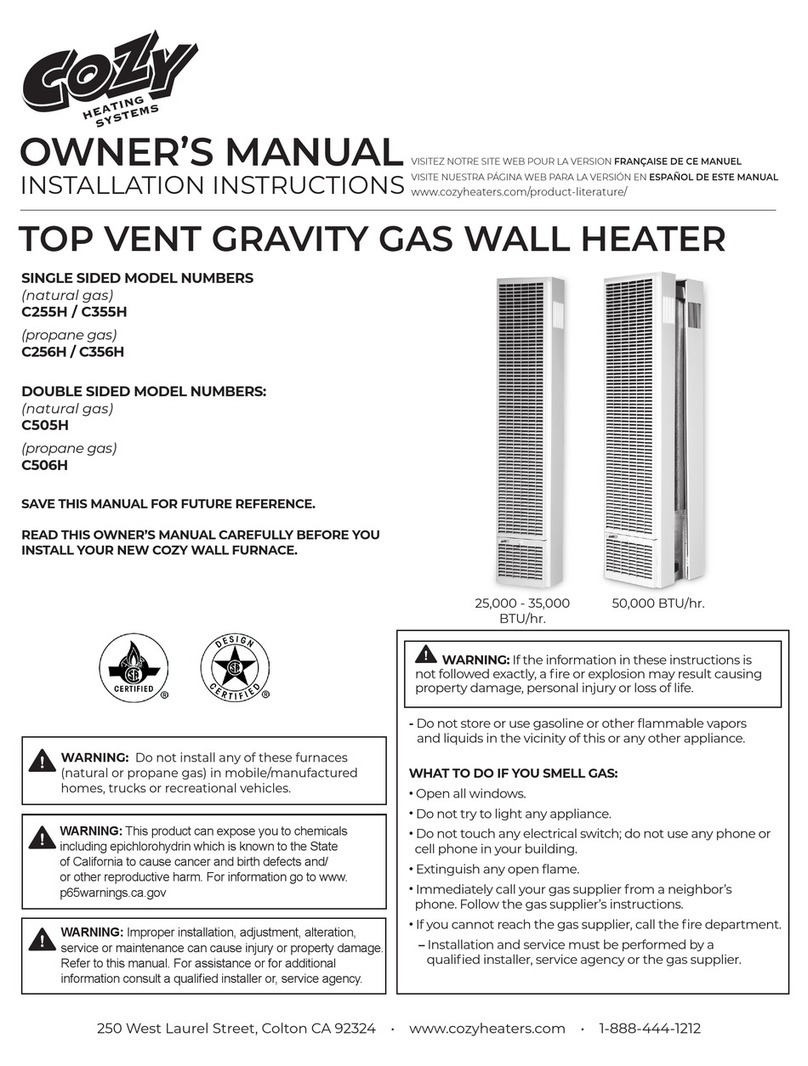

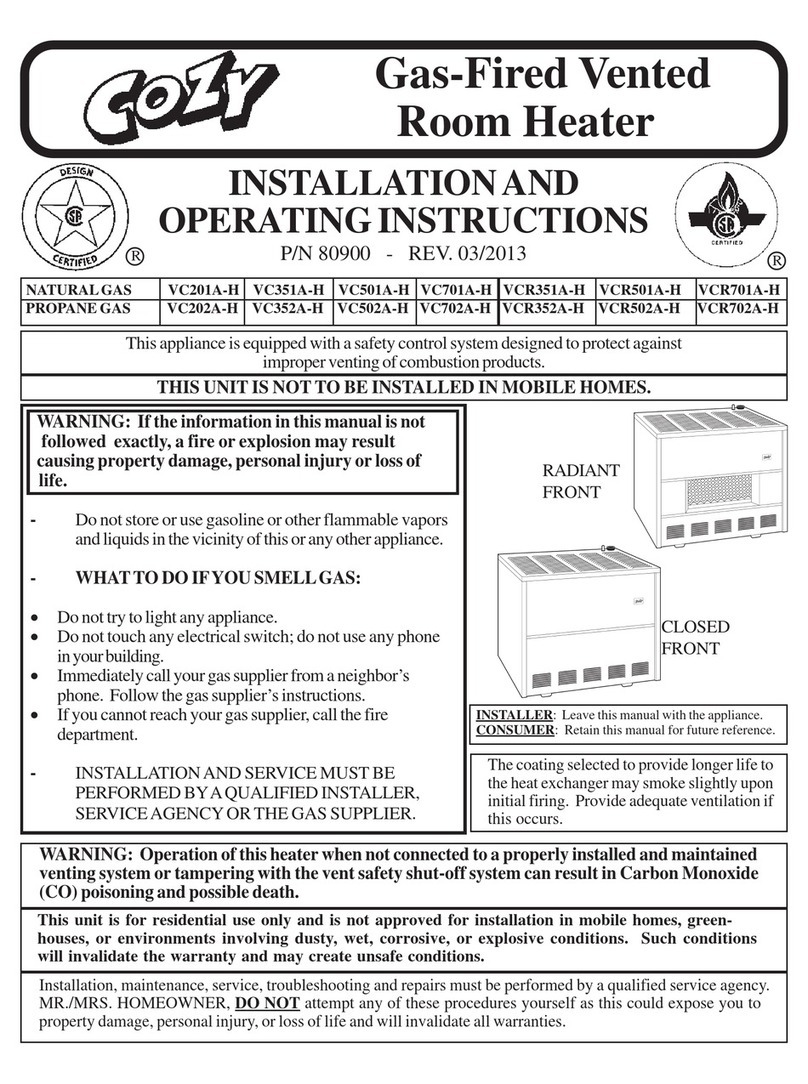

GAS-FIRED VENTED

ROOM HEATER

Installation and Operating Instructions

ENGLISH

Click here for the full manual or

click on the links below to quickly

locate what you’re looking for:

ESPAÑOL

Haga clic aquí para ver el manual

completo o haga clic en los

siguientes enlaces para localizar

rápidamente lo que está buscando:

FRANÇAIS

Cliquez ici pour le manuel complet

ou cliquez sur les liens ci-dessous

pour localiser rapidement ce que

vous recherchez:

Rev. 05/02/17

Specications ...................................... 2

Introduction ......................................... 3

Venting ............................................ 3 - 4

Gas Supply........................................... 5

Location &

Special Precautions ............................. 5

Combustion

& Ventilation Air ................................... 6

Clearances .......................................... 7

Draft Diverter ....................................... 7

Pilot Adjustment ................................... 8

Burner Orice & Orice Chart .............. 9

Proper Burner Flame ........................... 9

Maintenance ...................................... 10

Lighting Instructions ........................... 11

Trouble Shooting Chart .............. 12 - 13

Blower Instructions ............................ 14

TSK Wall Stat Kit ............................... 15

Parts List

and Diagrams ............................. 16 - 18

Warranty ............................................ 19

Especicaciones .................................. 2

Introducción ......................................... 3

Ventilación ...................................... 3 - 4

Suministro de gas ................................ 5

Ubicación y

Precauciones Especiales .................... 5

Combustión

y Ventilación Aire ................................. 6

Liquidaciones ....................................... 7

Desviador de borrador ......................... 7

Ajuste del piloto ................................... 8

Oricio del quemador y oricio Gráco 9

Llama apropiada del quemador ........... 9

Mantenimiento ................................... 10

Instrucciones de iluminación ............. 11

Tabla de problemas .................... 12 - 13

Instrucciones para el ventilador ......... 14

TSK Wall Stat Kit ............................... 15

Lista de piezas y

diagramas ................................... 16 - 18

Garantía ............................................. 19

Spécications ...................................... 2

Introduction .......................................... 3

Ventilation ....................................... 3 - 4

Alimentation En Gaz ............................ 5

Emplacement Et

Précautions Spéciales ......................... 5

Air De Combustion Et

De Ventilation ...................................... 6

Dégagements ...................................... 7

Hotte De Tirage ................................... 7

Réglage De La Veilleuse ..................... 8

Orice Du Brûleur Et Tablea U Orice . 9

Flamme Appropriée Du Brûleur ........... 9

Entretien ............................................ 10

Instructions D’ Allumage .................... 11

Tableau De Dépannage .............. 12 - 13

Instructions Sur Le Soufeur ............. 14

Kit De Thermostat Mural Tsk ............. 15

Liste des Pièces

et Diagrammes ........................... 16 - 18

Garantie ............................................. 19